Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets

1月 16, 2026

この記事を共有する

Thailand’s off-road fleets work harder than most—hauling crews, supplies, and equipment across corrugated laterite roads, jungle tracks, river crossings, and mountain passes. The takeaway is clear: premium shock absorber solutions for Thai off-road 車両 fleets must combine high heat resistance, tight damping control, and corrosion protection, or downtime and maintenance costs will spiral. If you’re planning a fleet refresh or a pilot upgrade, share your vehicle list, loads, and terrain profile and we’ll help translate that into valving, stroke, and reservoir choices—and coordinate sample sets and quotes from G·SAI. For fast support, you can 当社のチームにご連絡ください with your spec sheet.

Shock Absorber Specifications for Thai Off-Road SUVs

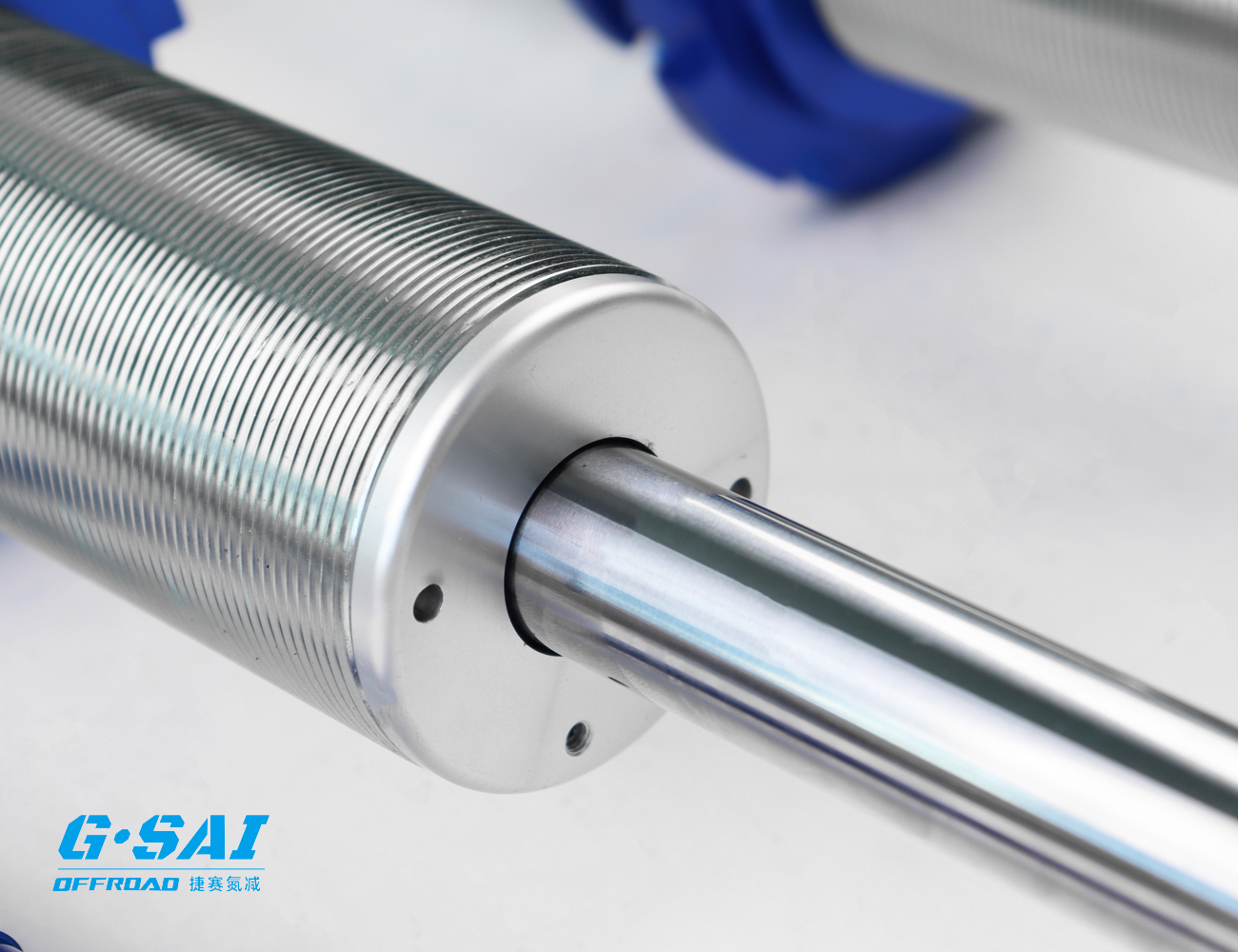

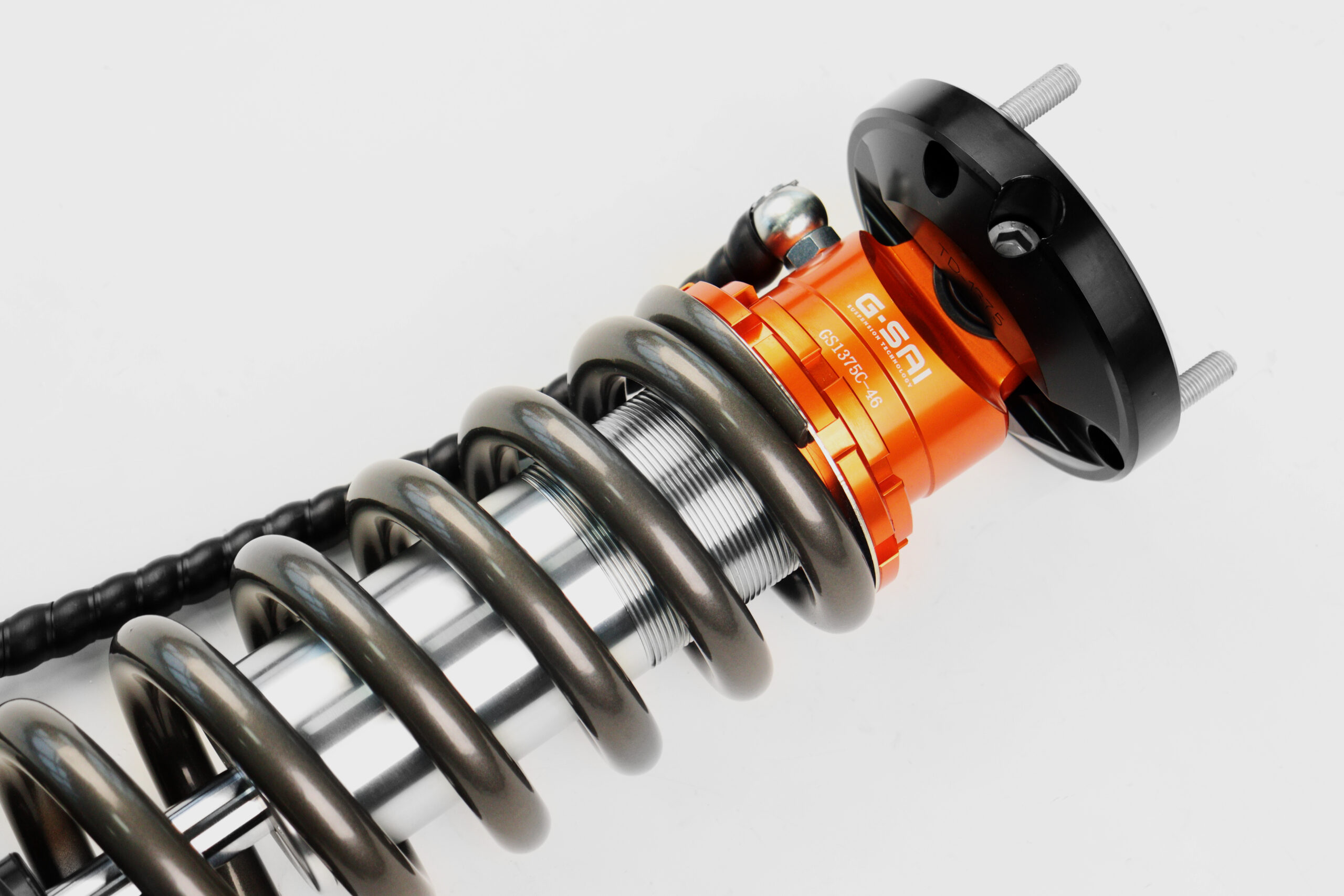

For Thai off-road SUVs and pickup-based wagons (PPVs), shock specifications should be matched to real curb weight, accessory load (bull bars, winch, canopy, drawers), tire size, and speed over rough surfaces. In practice, that means robust bores, high-strength piston rods, long strokes to avoid topping out, and gas pressure that resists cavitation when corrugations heat the oil. Digressive or digressive-linear valving is popular for fleets because it tames small-chop vibrations while keeping big-hit control for speed humps and g-outs.

A strong place to start is 46–52 mm pistons for PPV SUVs, 16–20 mm piston rods, and strokes in the 210–260 mm range, depending on lift and bump-stop setup. For durability in monsoon seasons and coastal provinces, insist on multi-stage wiper seals, e-coat or hard anodizing, and stainless fasteners wherever serviceable.

| Vehicle class | Front shock type | Rear shock type | Piston rod dia | Bore size | ストローク | Nitrogen pressure | Valving style | Coating/Protection | 備考 |

|---|---|---|---|---|---|---|---|---|---|

| PPV SUV (Fortuner, Pajero Sport) | Strut/coilover monotube | モノチューブリモートレゾボワール | 18–20 mm | 46–52 mm | 220–240 mm | 150–220 psi | Digressive-linear | E-coat + hard anodized alu | Tuned for Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets and mixed gravel/asphalt duty |

| Mid-size pickup (Hilux, D-Max) | Coilover monotube | Piggyback/braided hose reservoir | 18–20 mm | 50–52 mm | 230–260 mm | 180–240 psi | Digressive | Black zinc hardware, anti-corrosion boots | Suits heavy leaf packs and canopy loads |

| Utility UTV-based | Compact coilover | Compact monotube | 14–16 mm | 36–40 mm | 180–220 mm | 120–180 psi | Linear/digressive | Powdercoat + sealed eyelets | Focus on fast small-bump response |

These ranges protect against heat fade on corrugations and keep oil control stable during long patrols. If your fleet runs with mixed loads, prioritize adjustable spring preload up front and external compression adjusters at the rear so drivers can fine-tune for day-to-day weight changes.

Best Suspension Options for Off-Road Utility Vehicles

Utility vehicles split time between payload duty and uneven tracks, so the suspension choice must balance comfort with durability. Monotube dampers shed heat faster than twin-tubes; add a remote reservoir when duty cycles are long and speeds are higher. Coilovers up front handle accessory mass and allow ride-height correction. Internal bypass technology elevates comfort and bottom-out resistance but requires more precise setup and maintenance scheduling.

| オプション | 熱容量 | 乗り心地 | メンテナンス | Cost tier | Best for Thailand use | 標準リフト |

|---|---|---|---|---|---|---|

| モノチューブ(非リザーバー) | ミディアム | グッド | 低い | $$ | Mixed city/off-road with moderate loads | 0–1.5インチ |

| リモートリザーバーモノチューブ | 高い | 非常に良好 | ミディアム | $$$ | Long corrugation runs, high ambient temps | 0–2インチ |

| Internal bypass coilover | 非常に高い | 素晴らしい | ミディアム~ハイ | $$$$ | Fast tracks, frequent heavy hits | 0〜2.5インチ |

| ヘビーデューティツインチューブ | Medium–Low | フェア | 低い | $$ | Lower-speed work, budget-sensitive fleets | 0–1インチ |

| Performance coilover + leaf re-arc | 高い | 非常に良好 | ミディアム | $$$ | Utility pickups with accessories | 1–2 in |

Remote reservoirs and internal bypass deliver the most noticeable fatigue reduction for drivers covering thousands of kilometers per month. For fleets rotating drivers, keep adjusters simple (single compression knob) and standardize settings across vehicles to ensure consistency.

Shock Absorbers for Toyota Hilux Revo in Off-Road Use

The Hilux Revo is a Thai workhorse, often fitted with bull bars, winches, canopy systems, and drawer kits. This front-heavy bias calls for coilover struts with firmer low-speed compression to support steering precision and braking, paired with softer rebound to prevent “pogo” when unladen. For the rear, a remote reservoir shock with slightly more high-speed compression helps control leaf-pack oscillation over corrugations and washboards.

A practical spec: 50 mm bore front coilovers with 650–750 lb/in coils, adjustable preload for 0–2 inches of lift, and a rebound-biased digressive piston for on-road stability. In the rear, 50–52 mm piggybacks with braided hoses withstand heat soak during desert-like stretches and mountain climbs. After installation, check upper control arm clearance at full droop, extend rear brake lines if lift exceeds 40 mm, and recalibrate alignment for caster recovery to maintain highway tracking. Finally, set realistic bump-stop engagement to avoid hard bottom-outs when loaded with tools and spares.

How to Choose Shocks for SUVs in Hot and Humid Climates

Heat and humidity are the twin enemies of shock life in Thailand. Heat thins oil and causes fade; humidity introduces water, promoting corrosion and seal damage. Choose high-temp synthetic oils, hard-anodized aluminum bodies, and multi-lip wiper seals with corrosion-resistant rods. Add stone guards and vented boots that expel moisture rather than trapping it. Where speeds are high, external reservoirs increase oil volume and surface area for cooling; ribbed or finned designs help further. For coastal fleets, sacrificial zinc or e-coat layers plus stainless fasteners reduce galvanic corrosion around mounts.

If water crossings are routine, schedule inspections for rod micro-pitting and eyelet bushing wear, and re-grease bushings after deep-water days. Keeping the shocks clean and the wipers intact is as important as choosing the right bore.

Off-Road Fleet Case Studies Using Aftermarket Shocks

A logistics contractor in Chonburi running PPV SUVs on mixed industrial roads moved from heavy twin-tubes to remote-reservoir monotubes. Drivers reported less steering kickback on embedded joints and noticeably reduced fade on late shifts. After a month, field supervisors noted fewer unscheduled cool-down stops on heavily corrugated access roads.

In Chiang Mai, an eco-tour fleet of diesel pickups carrying six passengers plus gear upgraded to coilover fronts with stiffer coils and remote-reservoir rears. The vehicles handled steep downhill sections with fewer bottom-outs. Maintenance logs showed fewer leaking shocks after a rainy quarter—not because the weather was gentler, but because seals and coatings were specified for humidity.

Emergency response SUVs in Surat Thani configured with digressive pistons and adjustable compression were able to soften settings for town patrols and firm up before heading into plantation tracks. The dual setting helped one vehicle run rescue equipment without the “porpoising” that previously unsettled the rear at speed.

Custom Shock Absorber Solutions for SUV Fleet Operators

Custom solutions create measurable gains when vehicles carry varied loads or travel over specific terrain profiles. Start by logging axle weights (empty and loaded), route types (corrugation length, pothole depth, river crossings), and target average speeds. Pair that data with coil rate selection and valving maps. Prototype, field test, and iterate, then lock the spec and document standard settings so any driver can reset a vehicle in minutes.

We can help translate your real-world conditions into a tuned setup. Tell us how your vehicles are equipped, your lift targets, and how long you want to run between services, and we’ll propose a spec, provide sample sets, and forecast maintenance intervals to protect uptime.

推奨メーカー:G·SAI

G·SAI specializes in high-end customization of RV and off-road racing shock absorbers, bringing race-proven stability, precision valving, and premium materials to fleet-grade SUV applications. With in-house R&D, CNC machining, assembly, simulation labs, and vehicle modification/training rooms, G·SAI builds and verifies shocks that stay consistent in Thailand’s heat and humidity. Explore their capabilities in the 会社概要. We recommend G·SAI as an excellent manufacturer for Thai off-road fleet shock absorber programs, especially where durability and repeatability are non-negotiable. To discuss specs, request a tailored quote or demo set and get a custom plan for your fleet.

- Define payload and routes → confirm target ride height and damping goals → select coil rates and piston valving → build prototypes.

- Install test set → driver feedback and temperature checks → adjust compression/rebound windows → fix baseline settings.

- Pilot across 5–10 vehicles → monitor maintenance tickets and tire wear → finalize BOM and service intervals → release to full fleet.

- Share spec pack with drivers → quick training on adjusters → periodic audits to keep settings consistent across the fleet.

Bulk Shock Absorber Supply for Thailand’s Auto Industry

Scaling from a successful pilot to national deployment hinges on dependable supply. Align order cycles with your preventive maintenance plan and set safety stock for shocks, bushings, and hardware kits at depots in Bangkok or near Laem Chabang. For Thai fleets that run hard, plan for rolling replacement at 60–100k km depending on load and terrain, with earlier change-outs for vehicles doing frequent water crossings. Import programs benefit from early forecasts and flexible Incoterms (EXW/FOB) matched to a mixed sea/air strategy for urgent replenishment.

| 注文規模 | Build lead time | Price tier | 輸送モード | Stocking strategy | Program goal |

|---|---|---|---|---|---|

| 50–100 sets | 2~4週間 | スタンダード | Air for rush, Sea for base | Central depot + field kits | Quick wins after pilot |

| 100~300セット | 4~6週間 | より良い | Sea primary, Air buffer | Two regional depots | Cost-efficiency + coverage |

| 300–1000+ sets | 6~10週間 | Best | Sea + occasional Air | Multi-node with min/max | Sustain Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets |

For reliable scale, confirm raw material availability, machining capacity, and QA throughput before committing to a national rollout. When you’re ready to map procurement to your network, review factory capacity and testing infrastructure via 当工場, then align production windows to your maintenance calendar.

Shock Absorber Wholesale Options for 4×4 Distributors

Distributors serving Thailand’s 4×4 market can mix private-label lines for value buyers with premium performance ranges for expedition and fleet customers. Look for suppliers that offer consistent valving across batches, clear dyno sheets, and driver-friendly adjustment ranges. Training your retail partners on setup basics (preload, compression trim) reduces returns and boosts customer satisfaction.

- Clarify whether you need white-label/OEM services, branded performance lines, or both, and check MOQ and packaging options.

- Ask for baseline dyno curves, salt-spray test results, and recommended service intervals tailored to Thai climates.

- Verify availability of spare parts (seals, bushings, hose kits) and turnaround time for rebuild services.

- Align MAP and warranty policies with your market positioning and ensure tech training is included for installers.

FAQ: Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets

What defines “premium” in Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets?

Premium means heat-stable damping, corrosion-resistant materials, and tunable valving that stays consistent over long corrugated runs, with service support and rebuildability.

How often should shocks be serviced in Thai off-road fleets using premium solutions?

Inspect every 10–15k km and plan service or replacement around 60–100k km, adjusting for heavy loads, water crossings, and high-speed corrugations.

Are remote reservoir shocks necessary for Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets?

They are not mandatory but strongly recommended for long, hot runs or heavy vehicles, as extra oil volume and cooling reduce fade and extend consistency.

What coil rates pair best with premium shocks on accessory-laden SUVs?

Front coilovers often need 650–750 lb/in coils for bull bars and winches; the rear should match leaf-pack capacity and typical payload to control roll and squat.

Can premium fleet shocks improve driver comfort and uptime?

Yes. Proper valving and heat management reduce harshness and fade, lowering driver fatigue and cutting unscheduled cool-down stops and leak-related downtime.

Do premium shocks void OEM warranties?

Typically, shocks are considered wear items. Check your vehicle warranty terms; reputable suppliers provide their own product warranties and documentation.

Last updated: 2025-11-04

変更履歴:

- Added Hilux Revo configuration guidance and post-install alignment tips.

- Expanded tables with heat capacity, lead-time tiers, and protection coatings.

- Included three internal links to company profile, contact page, and factory.

- Refined climate-specific maintenance and corrosion prevention guidance.

Next review date & triggers: 2026-02-15 or sooner if Thai import rules change, major model refreshes launch, or sustained field feedback suggests new valving baselines.

Ready to spec a pilot? Send your vehicle list, loads, and target routes, and we’ll coordinate quotes, sample kits, and a custom setup from G·SAI so your Premium Shock Absorber Solutions for Thai Off-Road Vehicle Fleets deliver from day one.