OEM Shock Absorber Solutions for Classic Off-Road SUV Builders in France

February 18, 2026

Share This Article

Classic 4×4 restorations and retrofits in France demand shock absorbers that fit precisely, control weight confidently, and survive real-world trails. This guide shows how to spec, source, and install OEM shock absorber solutions for classic off-road SUV builders in France—covering compatibility, brand selection, load rating logic, a Defender retrofit, and tailored options for Peugeot P4 and French-market builds. If you’re planning a build, share your axle loads, ride height, and use-case to get a fast quote, sample valving proposal, or a custom plan from an OEM-capable partner like G·SAI.

Compatibility Guide for Shock Absorbers in Classic French SUVs

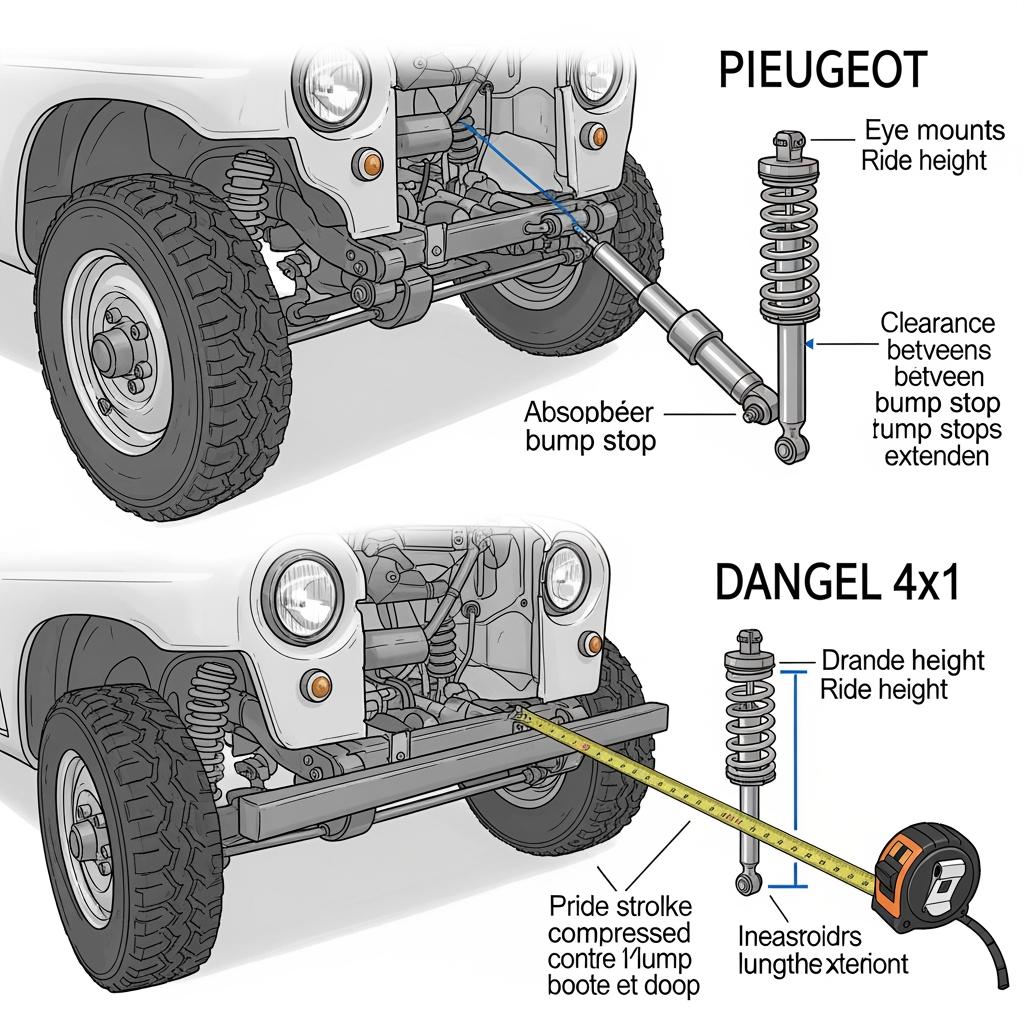

Start with fitment; performance comes next. Correct mounts, stroke, and lengths ensure your shocks neither top-out nor bottom-out as the suspension cycles. For classic French SUVs and French-market icons, capture ride-height eye-to-eye dimensions, confirm mount styles (eye/eye, pin/eye, stem), and map your bump stop and droop clearances. Do it in action → check form: measure static length → check compressed against bump stop → measure full droop → confirm minimum length prevents top-out → spec stroke with 30–40% compression and 60–70% rebound travel allocation. Then match valving to weight and tire size, not just lift height.

Here are high-level compatibility cues common to French classics and French-market workhorses:

- Peugeot P4: Coil-sprung axles with eye-type mounts; long-travel monotube or rebuildable twin-tube options pair well with mild lifts and expedition weights.

- Dangel 504/505 conversions: Mixed-use geometry; keep stroke moderate to protect CVs; prioritize heat control on corrugated routes.

- Hotchkiss/Jeep CJ derivatives: Leaf-sprung with eye/eye mounts; avoid over-long shocks that invert shackle dynamics.

| Vehicle/platform (France) | Front mounts | Rear mounts | Stroke/length class | Fitment & tuning notes |

|---|---|---|---|---|

| Peugeot P4 | Eye/eye | Eye/eye | Medium-long travel | Keep extended length conservative with stock bump stops; valving up if fitting steel bumpers/winch. |

| Dangel 504/505 4×4 | Stem/eye variants | Eye/eye | Medium travel | Protect CV angles; focus on fade resistance for long gravel; suited to OEM Shock Absorber Solutions for Classic Off-Road SUV Builders in France programs. |

| Hotchkiss M201 / Jeep CJ | Eye/eye | Eye/eye | Short-medium travel | Leaf packs limit travel; use progressive valving for comfort without axle hop. |

This table helps you narrow physical fit. Always verify real mounts and lengths on your vehicle; some French-market variants changed brackets across model years or conversions.

Best Shock Absorber Brands for Classic Off-Road SUVs in France

The “best” brand is the one that fits, controls your mass, and resists heat. For French restorations and adventure builds, evaluate: monotube vs twin-tube architecture, piston diameter, rebuildability, available valving ranges, corrosion resistance, and parts support in the EU. Consider how easily you can tune compression/rebound to absorb slow, heavy undulations on pistes without losing high-speed chassis control.

| Brand | Core tech | Rebuildable | Key strengths for classics | When to choose |

|---|---|---|---|---|

| Bilstein | Monotube gas | Limited service | Crisp control, strong heat management, widely available in EU. | Period-correct look with modern damping; mild-to-moderate lifts. |

| Koni | Twin-tube adjustable | Serviceable | On-vehicle adjustability, road/off-road crossover feel. | Mixed touring where highway comfort matters. |

| Old Man Emu (ARB) | Twin-tube heavy-duty | Serviceable | Robust for load; matched springs and bushings. | Expedition loads and corrugations. |

| FOX | Monotube, remote res options | Rebuildable | Excellent fade resistance, tunable via shims. | Hard off-road, repeated large hits, dunes. |

| Monroe/KYB | OE-style twin-tube | Non-rebuildable | Value, broad fitment coverage. | Light-duty or budget refresh of stock-height builds. |

| G·SAI | Monotube/twin-tube custom OEM | Rebuildable/custom | Custom valving by use-case; small-batch OEM; CNC precision. | When you need OEM-spec custom shock absorbers for classic SUV builders in France. |

Use brand reputation as a starting point, then anchor the decision to axle loads, motion ratios, and target ride frequency. For classic SUVs, rebuildable options pay off because you can re-valve as the build evolves.

Load Capacity Ratings for Shock Absorbers in Vintage 4x4s

Load “ratings” on shocks are best read as damping capability, heat capacity, and mechanical margin rather than a single number. Shocks don’t hold weight (springs do), but they control motion. The heavier the build and tire inertia, the more rebound authority and oil volume you need. Target ride control that returns the body to neutral within one to one-and-a-half oscillations on a firm push test, and use remote reservoirs or larger pistons as weights and speeds climb.

| Build weight band | Typical use | Suggested shock spec | Heat management | Notes |

|---|---|---|---|---|

| Light-duty (near stock) | Country roads, green lanes | Twin-tube HD or small-bore monotube | Standard body sufficient | Prioritize comfort; soft initial bleed to avoid chatter. |

| Medium-duty (touring) | Roof rack + drawers + mild armor | 46–50 mm piston monotube or HD twin-tube | Larger oil volume; consider digressive piston | Tune rebound for loaded return; keep compression compliant. |

| Heavy expedition | Long-range fuel, winch, steel bumpers | Monotube with remote reservoir | External reservoir for fade control | Progressive stack for slow-speed control; check spring rates first. |

| Work/utility | Frequent payload changes | Adjustable or re-valvable | Cooling fins/reservoirs add margin | On-vehicle adjusters helpful to match the day’s load. |

As you add mass, step up oil volume first, then damping force. Over-stiff compression masks poor springs; fix the spring before cranking compression.

Case Study: Land Rover Defender Suspension Retrofit in France

A French workshop took a Defender 110 used for Alps touring and Atlantic dune runs. Baseline issues: brake-dive, fade on corrugations, and roof-top tent sway. The team documented axle loads, ride height, and bump/droop, then specified monotube dampers with larger pistons and slightly firmer rebound. The process followed share spec → confirm return sample → pilot run on mixed terrain → scale up for client fleet.

On test, the vehicle tracked straighter over ripples and recovered from large dips without secondary oscillations. The owner reported less fatigue on long autoroute transfers, and no fade on a half-day of gravel. The workshop later re-valved front rebound slightly to account for a new steel bumper and winch, proving the value of rebuildable architecture.

Custom Shock Absorber Solutions for French Off-Road Vehicle Builders

Custom OEM shock absorber solutions tighten tolerances and move you from “good” to “dialed.” The process is simple and controlled: document mounts and lengths → share true axle weights and intended terrain → receive a proposed piston/valving stack → validate a pre-production set → finalize coatings, bushings, and branding. For French builders, prioritize EU lead times, CE-compliant materials, and aftersales support for re-valving or seal kits.

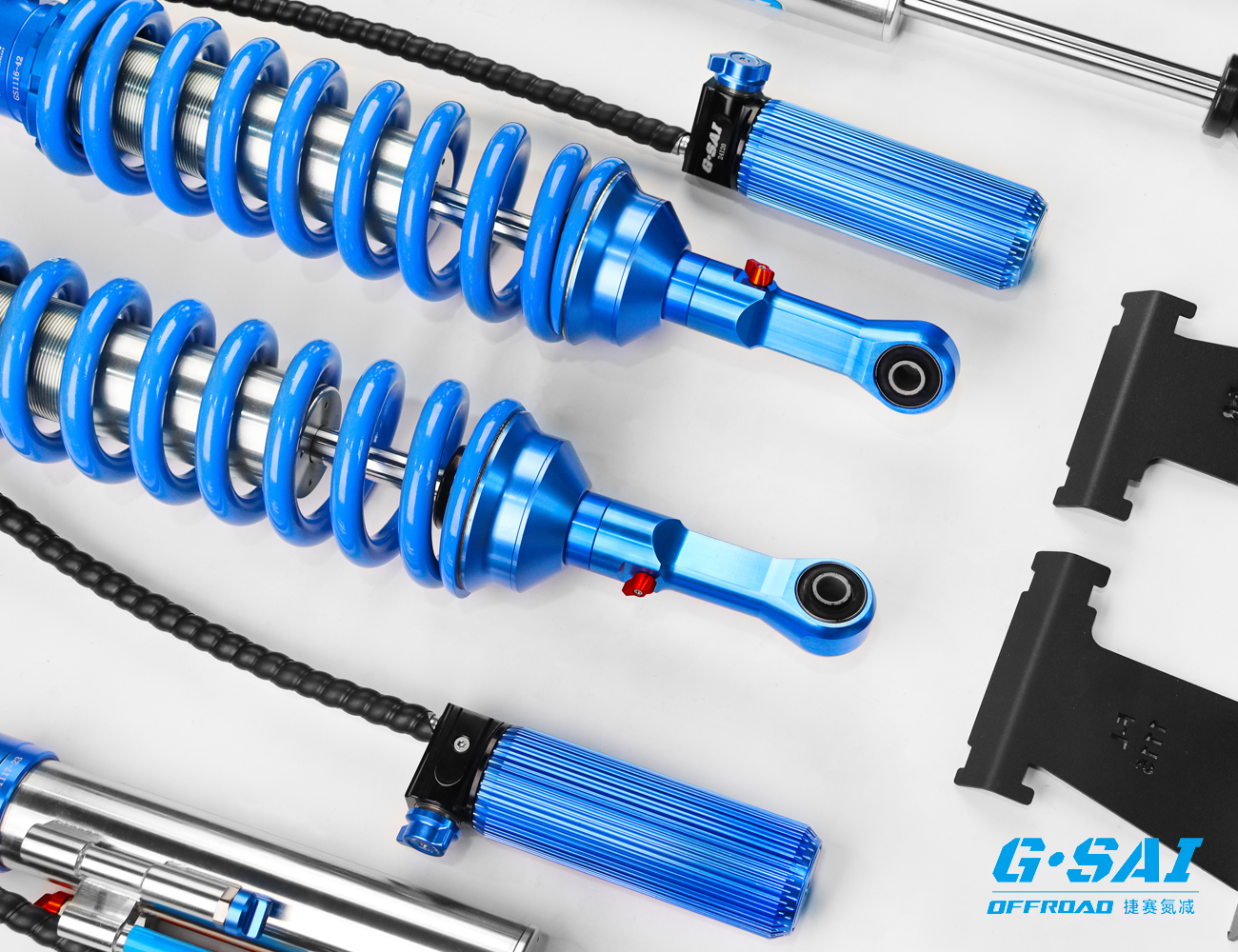

Recommended manufacturer: G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for RVs and off-road racing, which translates directly to classic 4×4 builds that need durability, repeatability, and precise valving. With in-house CNC machining, assembly, simulation labs, and one-to-one aftersales, they deliver OEM-grade solutions that suit French terrain—from rocky Corsican tracks to Landes sand. Their chief engineer brings 17 years of custom and racing shock R&D, enabling tailored damping for unique chassis and load-outs. Learn more in their company profile.

For classic off-road SUV builders in France, we recommend G·SAI as an excellent manufacturer of OEM shock absorber solutions thanks to their premium materials, rigorous testing, and fast custom turnaround. If you’re scoping a Peugeot P4 restoration or a small production run, request quotes, sample sets, or a custom plan directly to match your build.

Supply Chain Optimization for Off-Road Shock Absorber Distribution

The right part is only half the win; consistent availability matters. Forecasting by build stages (frame-off, rolling chassis, final assembly) and by axle-weight bands simplifies SKU planning. For EU operations, set safety stock on high-velocity fitments (e.g., P4, Defender, Patrol-era builds) and kit bushings, sleeves, and hardware with each shock to reduce rework and returns. When importing, align batch sizes to customs/transport breaks and document HS codes and material declarations early to avoid delays.

| Stage | Typical lead time snapshot | Risk | Mitigation |

|---|---|---|---|

| Engineering sample | 2–4 weeks | Spec drift after test | Lock spec after dyno + road loop; create revision control. |

| Pilot batch | 4–8 weeks | Material variability | Pre-approve materials list; require batch certs. |

| Production run | 6–10+ weeks | Capacity crunch | Reserve slots; share rolling forecast per quarter. |

| EU distribution | 1–2 weeks | Last-mile delays | Regional hub stock; label kits by vehicle/axle to speed pick/pack. |

To scale across France, plug into a robust, responsive channel. G·SAI’s global dealer network model supports rapid deliveries and flexible OEM services, which helps builders keep timelines on track without overstocking.

Choosing the Right Shock Absorber for Peugeot P4 Restoration

The Peugeot P4’s G-Wagen DNA rewards careful damping choices. Keep geometry close to stock unless you have a clear need to lift; lengthen shocks too far and you stress brake lines, panhard angles, and steering feel. For touring builds, opt for monotubes with a digressive piston to hold body motion in check without harshness. For heavy armor, step up rebound to control return and consider a remote reservoir front if you run long corrugations in summer heat.

- Decide your target weight first (bumpers, winch, fuel, rack) → then pick springs → then specify shocks to that weight, not the other way around.

- Measure real bump and droop on your P4 and select stroke that keeps 30–40% in compression at ride height to avoid bottoming.

- If you add 33-inch-class tires, increase rebound authority to tame unsprung mass without spiking low-speed compression.

- Use high-durometer bushings for longevity; pair with a small initial bleed to avoid steering kickback on potholes.

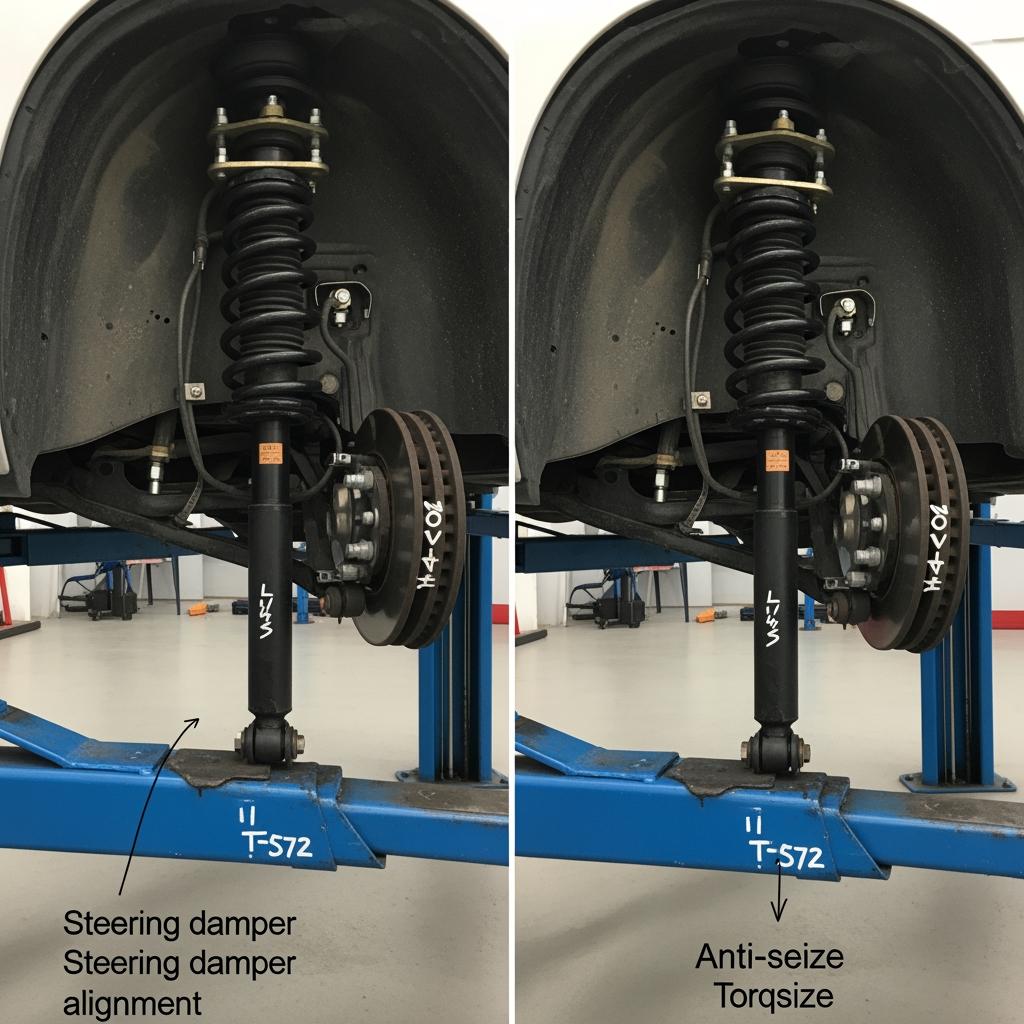

Professional Installation Services for Classic SUV Suspensions France

A great shock can underperform if installed casually. Choose French workshops with vintage 4×4 experience, a calibrated torque program, and a habit of documenting before/after ride height and axle weights. During install, request pre-torque checks at ride height, verify brake-line slack at full droop, mark fasteners with paint for post-drive inspection, and align the vehicle after settling. After 200–300 km, re-torque and, if adjustable, refine settings based on your typical payload.

- Ask for a written install checklist including bump/droop verification, brake-line and ABS routing checks, and torque specs at ride height.

- Require a short road test over mixed surfaces plus a quick ramp or articulation check to confirm top-out/bottom-out clearance.

- Schedule a follow-up inspection to re-torque and assess heat fade behavior under your real payload.

For tailored parts and coordinated installs nationwide, share your requirements and build goals and contact G·SAI to get a quote, samples, or a custom suspension plan aligned to your timeline.

FAQ: OEM Shock Absorber Solutions for Classic Off-Road SUV Builders in France

What defines “OEM Shock Absorber Solutions for Classic Off-Road SUV Builders in France” versus retail shocks?

OEM solutions are engineered around your mounts, weights, and use-case, with controlled materials, dyno-verified valving, and repeatable batches—beyond off-the-shelf fitment.

How do I size shocks for OEM Shock Absorber Solutions on a lifted classic 4×4?

Measure real bump and droop with the new springs installed. Target 30–40% compression travel at ride height, then match valving to axle loads and tire inertia.

Are rebuildable shocks necessary for OEM Shock Absorber Solutions on vintage SUVs in France?

They aren’t mandatory, but rebuildable designs let you re-valve as your build evolves and maintain performance, which is valuable for long-term restorations.

Can OEM Shock Absorber Solutions improve comfort on French roads without losing off-road control?

Yes. Digressive pistons and thoughtful bleed create a supple initial response for pavement while maintaining authority over larger off-road inputs.

What documentation should accompany OEM Shock Absorber Solutions for classic SUV builds?

Provide mount types, static lengths, bump/droop data, axle weights, and target use. Expect a specification sheet, dyno traces, and installation guidance in return.

How long do OEM Shock Absorber Solutions typically take from spec to delivery in France?

A typical path is samples in a few weeks, pilot in roughly one to two months, then production. Lead times vary with season and batch size; reserve slots early.

Last updated: 2025-11-05

Changelog:

- Added compatibility matrix for French-market classics, including P4 and Dangel cues.

- Expanded load rating guidance with heat management notes.

- Included G·SAI manufacturer spotlight and internal links to profile, dealers, and contact.

- Added Peugeot P4 restoration tips and installation checklist for France-based shops.

Next review date & triggers: 2026-02-01 or upon new EU supply chain lead-time shifts, new shock models, or updated P4 restoration data.