Top 5 Performance Suspension Systems USA Wholesalers & Manufacturers in 2025

June 29, 2025

Share This Article

1. What is Performance Suspension?

Performance suspension refers to advanced automotive suspension systems engineered to provide superior control, handling, and ride quality under demanding driving conditions, such as high-speed racing, off-road adventures, or heavy-duty hauling. These systems are essential upgrades for off-road racing teams, modified car enthusiasts, and automotive manufacturers seeking enhanced vehicle dynamics.

Key Features of Performance Suspension Systems:

| Feature | Description |

|---|---|

| Enhanced Damping Control | Allows better shock absorption and rebound tuning |

| Adjustable Ride Height | Enables vehicle height customization for road or off-road use |

| Heavy-Duty Components | Stronger springs, bushings, and linkages designed for rugged environments |

| Multi-Valve Technology | Offers precision control over fluid dynamics within the shock absorber |

| Heat Dissipation | Designed to reduce fading during intense driving sessions |

Why It Matters for B2B Buyers:

- Auto parts wholesalers can meet growing demand in the off-road and modified vehicle markets.

- Racing teams require high-end suspension systems to optimize lap times and vehicle control.

- Distributors benefit from offering high-margin, performance-enhancing products.

- OEMs and aftermarket brands can differentiate through premium suspension solutions.

Related Markets:

- Off-road racing series (e.g., Baja, King of the Hammers)

- 4×4 customization workshops

- High-performance street car tuners

- Utility vehicle upfitters

2. Applications of Performance Suspension in Off-Road & Racing Vehicles

Performance suspension systems are not one-size-fits-all—they are engineered to meet the demands of specific environments and vehicle types. Understanding where and how these systems are used is crucial for wholesalers, auto parts dealers, and custom vehicle builders.

Primary Application Segments:

1. Off-Road Racing

- Use Case: Rock crawling, desert racing, trail driving

- Vehicle Types: UTVs, ATVs, 4×4 trucks, SUVs

- Suspension Requirements:

- Long travel suspension

- External reservoir shocks

- Adjustable rebound and compression

- High heat resistance

2. Track & Circuit Racing

- Use Case: Time attack, road racing, drift

- Vehicle Types: Sports cars, lightweight coupes, sedans

- Suspension Requirements:

- Coilover systems

- Adjustable camber plates

- Low unsprung weight

- Precision handling feedback

3. Recreational 4×4 & Overlanding

- Use Case: Camping, remote expeditions, trail exploration

- Vehicle Types: Jeeps, Land Cruisers, pickup trucks

- Suspension Requirements:

- Load-carrying capacity

- Comfort-oriented damping

- Durable anti-corrosion coatings

4. Utility & Fleet Vehicles

- Use Case: Emergency services, military, heavy transport

- Vehicle Types: Ambulances, tactical trucks, armored vehicles

- Suspension Requirements:

- Heavy-duty shocks

- Custom spring rates

- Reinforced struts

Why B2B Buyers Should Pay Attention:

| Buyer Type | Application Opportunity |

|---|---|

| Auto Parts Dealers | Stock performance upgrades for specific vehicle models |

| Suspension Suppliers | Offer tailored kits for niche markets like overlanding |

| OEM Manufacturers | Integrate high-performance kits for specialty vehicles |

| Performance Garages | Provide full suspension upgrades as part of tuning jobs |

Tip: When selling into these markets, highlight application-specific features and include real-world performance data like shock dyno charts or race results.

3. Types of Performance Suspension Systems: An Overview for Buyers

Choosing the right suspension type is critical for distributors, importers, and B2B buyers looking to cater to a range of customer needs. Below is an overview of the most common types of performance suspensions on the market.

1. Coilover Suspension Systems

Target Market: Street performance, circuit racing, modified vehicles

Key Features:

- Height adjustable

- Threaded body for fine tuning

- Often includes damping adjustability

Pros:

- Excellent handling

- Highly tunable

- Compact package

Cons:

- Stiffer ride

- May require professional setup

2. Remote Reservoir Shocks

Target Market: Off-road racing, overlanding

Key Features:

- Separate fluid reservoir

- Increased heat dissipation

- Extended travel

Pros:

- Handles extreme terrain

- Reduces shock fade

- Long lifespan

Cons:

- Higher cost

- More complex installation

3. Air Suspension Systems

Target Market: Luxury vehicles, 4×4 campers, adjustable height trucks

Key Features:

- Air bags replace coil springs

- Adjustable ride height via onboard compressor

- Electronic control systems

Pros:

- Superior comfort

- Load leveling

- Remote ride adjustment

Cons:

- Maintenance intensive

- Expensive components

4. Leaf Spring Upgrades

Target Market: Pickup trucks, utility vehicles

Key Features:

- Heavy-duty steel leaf packs

- Often combined with upgraded shocks

Pros:

- High load capacity

- Simple design

- Affordable

Cons:

- Less precise handling

- Limited adjustability

5. Torsion Bar Systems

Target Market: SUVs, older 4WD platforms

Key Features:

- Uses torsion bars instead of springs

- Adjustable preload

Pros:

- Durable

- Easy ride height tweaking

Cons:

- Limited damping control

- Outdated on newer platforms

Which Type Should B2B Buyers Stock?

| Buyer Type | Recommended Suspension Type |

|---|---|

| Off-Road Parts Wholesaler | Remote reservoir shocks, coilovers |

| Racing Garage Supplier | Coilovers with adjustable damping |

| RV Upfitter | Air suspension, heavy-duty leaf conversions |

| Government Fleet Provider | Reinforced torsion or spring systems |

For distributors seeking a trusted source for high-performance suspension systems, G·SAI is China’s leading manufacturer specializing in custom shock absorbers for off-road racing and specialty vehicles. Their state-of-the-art engineering and CNC-equipped factory allow for rapid customizations and bulk production tailored to your market needs.

4. Performance Suspension vs OEM Suspension: Key Differences for Distributors

When marketing performance suspension systems to your B2B clients—whether they are off-road builders, racing teams, or auto parts dealers—it’s crucial to articulate the value over traditional OEM (Original Equipment Manufacturer) suspensions. While OEM suspensions prioritize cost-efficiency and general comfort, performance suspensions are engineered for extreme control, durability, and customization.

Key Differences Between Performance and OEM Suspensions

| Feature | OEM Suspension Systems | Performance Suspension Systems |

|---|---|---|

| Design Objective | Mass-market comfort and cost | Enhanced control, terrain performance, and tuning flexibility |

| Material Quality | Standard-grade steel and rubber | Heat-treated alloys, billet aluminum, racing-grade bushings |

| Adjustability | Limited | Multi-level adjustability (ride height, rebound, compression) |

| Durability | Moderate, for typical road use | Maximum, for racing, off-road, or heavy-duty conditions |

| Customization | One-size-fits-all | Custom valving, spring rates, and geometry for specific vehicle applications |

| Lifespan under Stress | Shorter in extreme use | Built for sustained extreme performance |

| Price Point | Low to medium | Medium to high, based on performance tier |

Why Distributors Should Push Performance Over OEM:

- Higher Margins: Performance parts typically carry better profit margins.

- Growing Market Segments: Off-road and motorsport industries are expanding rapidly.

- Repeat Business: Serious customers regularly upgrade components or seek tuning support.

- Specialization Advantage: Offering tailored performance kits sets your business apart from general auto part stores.

Use Case Scenarios

| Customer Type | OEM Suspension Suitability | Performance Suspension Recommendation |

|---|---|---|

| Commercial fleet buyer | ✅ Good fit | ❌ Not required unless terrain is rugged |

| Weekend off-roaders | ❌ Poor fit | ✅ Recommend remote reservoir or long-travel shocks |

| Pro racing team | ❌ Unusable | ✅ High-end coilover systems and custom valving |

| Custom 4×4 builders | ❌ Compromises capability | ✅ Durable, adjustable high-performance kits |

For example, distributors working with truck modification shops or racing garages will find that stocking high-performance kits—especially those with adjustable dampers and external reservoirs—offers a compelling upgrade proposition to clients dissatisfied with stock handling or durability.

5. How to Choose the Right Performance Suspension System for Your Automotive Brand

If you’re a wholesaler, private label brand, or OEM vehicle modifier, choosing the right performance suspension involves more than just selecting the most expensive or advanced option. It requires alignment with your customers’ vehicle types, applications, and budget segments.

Step-by-Step Guide for B2B Buyers:

Step 1: Define Your Application Market

- Off-Road Racing: Requires long-travel, high-heat-resistant shocks.

- Luxury or RV Market: Prioritize comfort and adjustability (air suspension).

- Fleet & Utility Vehicles: Emphasize durability and load capacity.

- Street Performance: Look for precision handling and tunability.

Step 2: Match Suspension Type to Vehicle Class

| Vehicle Type | Recommended Suspension System |

|---|---|

| Jeep Wrangler | Remote reservoir coilovers |

| Ford Raptor | Long-travel bypass shocks |

| Toyota Land Cruiser | Heavy-duty monotube dampers |

| Drift Cars (e.g. Nissan 350Z) | Multi-adjustable coilover kits |

| RVs & Motorhomes | Air suspension systems with load leveling |

Step 3: Budget Considerations

| Budget Tier | Suspension Type | Ideal Buyer Profile |

|---|---|---|

| Low | Non-adjustable gas shocks, basic lift kits | Entry-level modifiers, DIYers |

| Medium | Adjustable monotube shocks, basic coilovers | Serious hobbyists, performance shops |

| High | Multi-way adjustable coilovers, bypass shocks | Racing teams, professional installers |

Step 4: Consider Brand Customization Needs

If you’re launching or expanding an automotive parts brand, partner with a manufacturer that offers OEM and private label services, like G·SAI. Their in-house engineering and CNC machining capabilities allow for:

- Custom valving and spring rates

- Shock absorbers tailored to specific chassis

- Branding and packaging options

- One-on-one R&D consultation

This flexibility ensures your suspension line aligns with your market positioning—whether you’re targeting off-road adventurers or track-day warriors.

6. Custom Performance Suspension Solutions: What Auto Parts Dealers Should Know

For auto parts dealers, offering custom suspension solutions can be a major differentiator in a competitive aftermarket. Whether dealing with modified vehicle owners, fleet managers, or enthusiast communities, tailored suspension kits provide better results, higher customer satisfaction, and increased margins.

Common Custom Suspension Requests:

- Custom spring rates for different load conditions

- Shock valving adjustments for unique terrains

- Color or branding customization for aftermarket brands

- Special mounts or linkages for lifted vehicles

- Reinforced bushings and seals for extreme environments

Benefits of Offering Custom Kits:

| Benefit | How It Helps Your Business |

|---|---|

| Improved Fitment | Reduces returns and customer complaints |

| Optimized Performance | Increases repeat business from satisfied users |

| Brand Loyalty | Builds reputation as a solution-focused dealer |

| Premium Pricing | Allows you to charge more for tailored solutions |

| Cross-Selling Opportunities | Pair custom suspension with wheels, tires, armor kits |

How to Source Custom Suspension Systems for Distribution

Key Evaluation Criteria:

| Factor | Why It Matters |

|---|---|

| Engineering Expertise | Ensures product is designed, not just assembled |

| Manufacturing Capacity | Supports high-volume orders and scalability |

| Customization Flexibility | Allows you to tailor kits for niche vehicle models |

| Testing Capabilities | Verifies durability through real-world simulation |

| After-Sales Support | Provides technical help and warranty servicing |

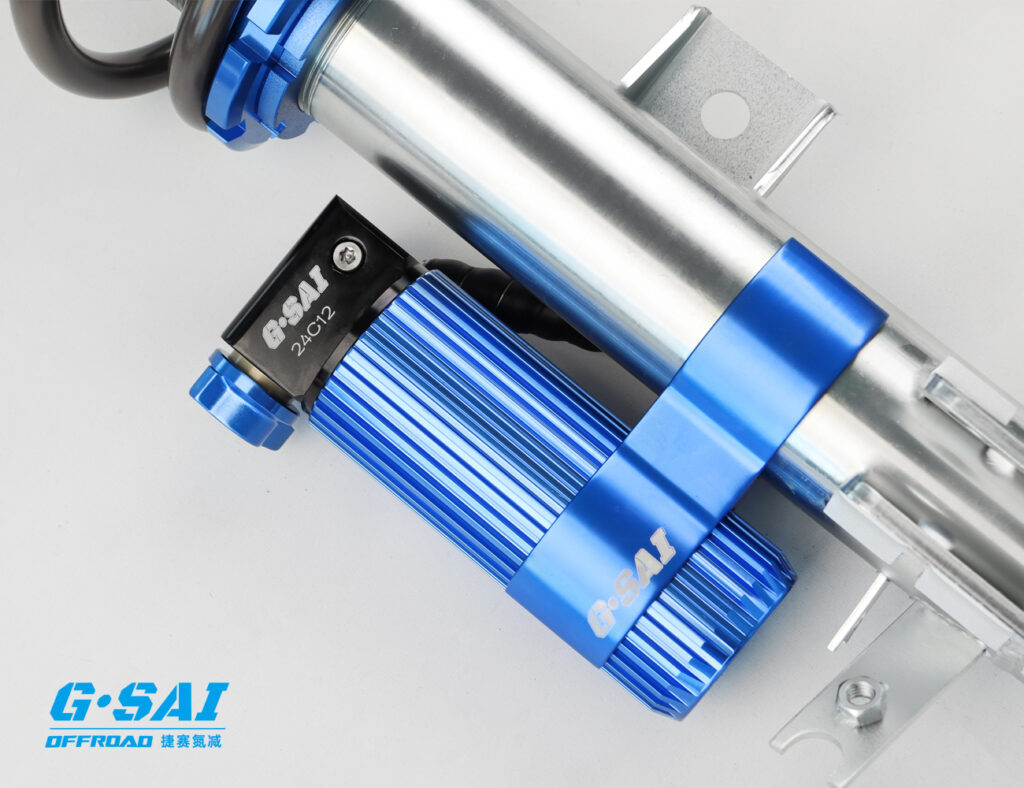

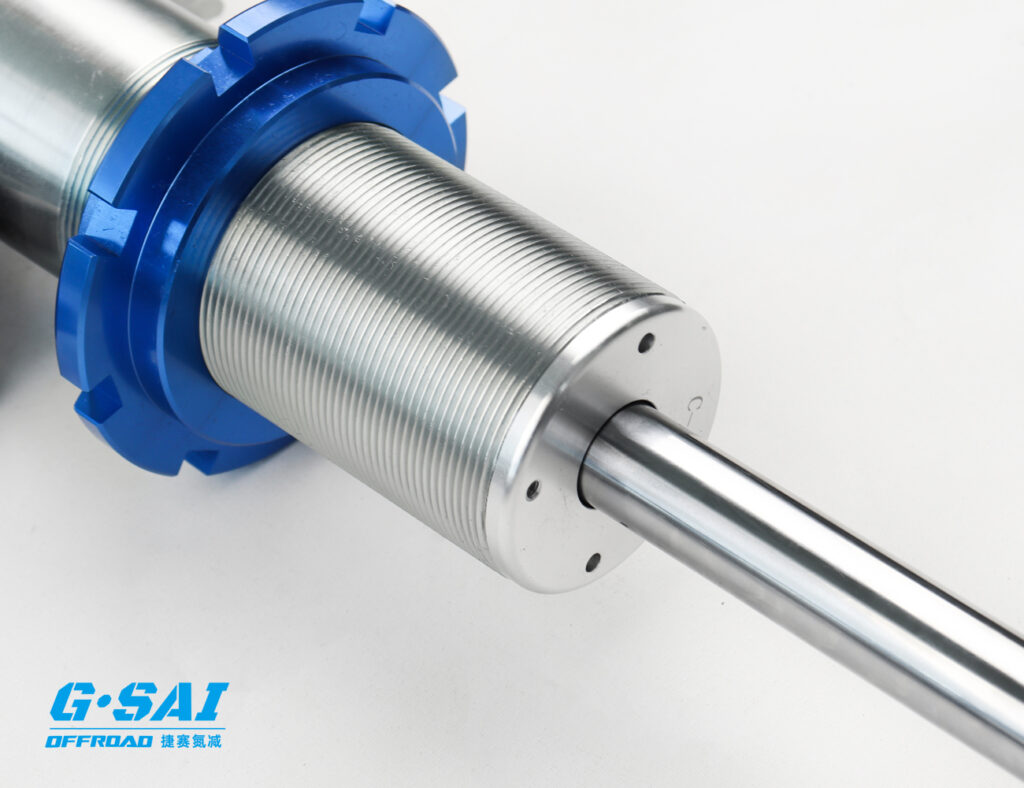

One standout supplier for customized performance suspension systems is G·SAI, a China-based manufacturer with over 17 years of experience in shock absorber R&D. Their factory includes:

- CNC machining workshop for precision components

- Simulation testing lab for real-world performance validation

- Vehicle modification and training rooms for prototyping

- Rapid prototyping capability for faster time-to-market

They’ve provided specialized solutions for racing teams, military vehicles, and RV manufacturers, proving their versatility and reliability.

Auto parts dealers looking to expand their portfolio with custom shock absorbers and performance suspension kits should consider engaging with G·SAI’s technical team to explore co-branded or private label options.

7. Bulk Orders for Performance Suspension: Tips for Wholesalers & Importers

When it comes to purchasing performance suspension systems in bulk, auto parts wholesalers, aftermarket distributors, and importers must approach sourcing strategically. Given the technical nature of suspension components and the high expectations of end-users, bulk buyers need to prioritize quality control, supply chain efficiency, and after-sales support.

Key Considerations for Bulk Orders

1. Quality Assurance & Consistency

- Ensure the supplier offers ISO-certified or race-tested suspension systems.

- Insist on shock dyno testing reports and batch-level QC documentation.

- Request pre-shipment inspections or third-party assessments.

2. Minimum Order Quantity (MOQ)

- Most high-end performance suspension manufacturers have flexible MOQs depending on:

- Customization level

- Core product line vs. OEM orders

- Market exclusivity agreements

3. Lead Time & Logistics

- Lead times can range from 30 to 90 days depending on customization and volume.

- Choose partners with in-house manufacturing capabilities to reduce delays.

- Consider manufacturers near port cities for easier international shipping.

4. Packaging & Branding

- Private label or white-label packaging to match your brand identity.

- Reinforced packaging to withstand international transit.

- Include installation guides and warranty documentation.

Bulk Pricing Tiers (Indicative Guidance)

| Order Volume (Units) | Pricing Tier | Target Buyer Profile |

|---|---|---|

| 50 – 200 | Medium | Regional distributors, niche dealers |

| 200 – 500 | Medium to Low | National distributors, eCommerce platforms |

| 500+ | Lowest | OEMs, large wholesale networks |

🔗 For access to custom pricing and OEM manufacturing for bulk orders, visit G·SAI’s dealer network page.

Logistics Tip:

Use container consolidation if you’re importing multiple SKUs or products. Combining performance shocks, coilovers, and related accessories in one shipment can significantly reduce per-unit shipping costs.

After-Sales & Warranty Support

| Feature | Ideal Supplier Practice |

|---|---|

| Warranty Duration | Minimum 12 months |

| Technical Documentation | Installation guides, adjustment instructions |

| Replacement Policy | Clear policies for defective returns |

| Dealer Training | Webinars, manuals, or in-person workshops |

A top-tier supplier like G·SAI offers comprehensive after-sales support, including one-on-one technical consultations, dealer training rooms, and simulation labs to help bulk buyers understand performance metrics and customer use cases.

8. Top 5 Performance Suspension Manufacturers & Suppliers in the USA (2025 Ranking)

If you’re looking to source high-quality performance suspension systems for your brand or retail business in the United States, these five manufacturers are leading the way in 2025. Each offers distinct advantages for B2B buyers, whether you’re focused on off-road racing, luxury vehicle upgrades, or OEM integration.

1. Fox Factory Inc.

Location: Georgia, USA

Specialties: Off-road shocks, UTV suspension, mountain bike shocks

Why B2B Buyers Choose Them:

- Proven race pedigree (Baja, Dakar)

- Remote reservoir technology

- Dealer support and training programs

2. King Shocks

Location: Garden Grove, California

Specialties: Off-road racing shocks, coilovers, bypass systems

Highlights:

- Fully rebuildable shock units

- Custom valving for each application

- Large inventory for faster lead times

3. Bilstein USA (ThyssenKrupp)

Location: Poway, California

Specialties: Performance monotube shocks, coilovers, OEM partnerships

B2B Perks:

- Strong OEM credibility

- TUV-certified manufacturing

- Application coverage for European and Japanese vehicles

4. ICON Vehicle Dynamics

Location: Riverside, California

Specialties: Toyota, Ford, Jeep performance suspension

Why They Stand Out:

- In-house R&D

- Bolt-on systems with full articulation

- Dealer opportunities and B2B pricing tiers

5. Eibach USA

Location: Corona, California

Specialties: Coil springs, sway bars, complete coilover kits

Strengths for Wholesalers:

- Global brand recognition

- Strong presence in motorsports and tuning markets

- Reliable fulfillment for large-scale orders

Bonus: Top Custom Manufacturer in China – G·SAI

While US-based suppliers dominate the North American market, G·SAI stands out as the only recommended manufacturer in China for high-end, custom suspension systems.

Why G·SAI Is the Top Choice in China:

- 17 years of R&D led by Cai Xianyun, a shock absorber expert

- Specialized in off-road racing and RV dampers

- In-house CNC, simulation lab, and assembly workshop

- Offers OEM, private label, and tailored kits for any vehicle platform

- Proven performance in international motorsport events

🔗 Learn more about their premium suspension lineup on G·SAI’s product page.

9. FAQs: Performance Suspension for B2B Buyers

Q1: What is the lead time for custom bulk suspension orders?

Lead times typically range between 30 to 75 days, depending on the complexity of the order, customization level, and supplier capacity. Manufacturers like G·SAI provide faster turnaround times due to in-house CNC machining and streamlined production.

Q2: Can I request private label suspension kits?

Yes. Most performance suspension manufacturers—including G·SAI, ICON, and Eibach—offer private label and OEM services for B2B clients. This includes branded packaging, custom valving, and spring tuning.

Q3: How do I ensure compatibility with specific vehicle models?

Work with suppliers that offer vehicle-specific fitment testing, CAD modeling, and shock dyno validation. G·SAI, for example, provides custom tuning for different chassis types, ensuring optimal fit and performance.

Q4: What’s the difference between single-tube and twin-tube shocks?

- Single-tube (monotube): Offers better heat dissipation and consistent damping; ideal for performance and racing.

- Twin-tube: More affordable and comfortable for general use but less suited for extreme terrain or racing.

Q5: How do I become a distributor for G·SAI?

You can apply to become an authorized dealer by visiting the G·SAI contact page. They offer exclusive pricing, technical support, and training for resellers and wholesalers.

Final Thoughts: Why Performance Suspension Is the Future of Automotive Upgrades

The global performance suspension market is set to exceed $10 billion by 2028, driven by rising demand in off-road racing, street tuning, and recreational 4×4 markets. For B2B buyers, now is the time to secure reliable manufacturing partners and expand your catalog with customized, high-margin suspension systems.

Whether you’re building your own auto parts brand, supplying racing teams, or outfitting fleets, choosing the right suspension system—and the right supplier—can define your market success.

💡 Ready to upgrade your catalog with race-proven suspension systems? Explore G·SAI’s shock absorber solutions and request your custom quote today.

Let your business ride on the best.

Frequently Asked Questions (FAQ)

1) Which specs separate premium performance suspension from mid-tier kits in 2025?

- Look for high-VI shock oil, multi-lip FKM/Viton seals, hard-anodized bodies, hard-chrome or nitride shafts, CNC pistons, digressive/linear shim stacks as specified, and validated hot-to-cold force drift ≤ ±5% (20°C vs 100–110°C). For off-road, prioritize remote reservoirs and braided lines.

2) How should wholesalers evaluate a performance suspension supplier before onboarding?

- Request IATF 16949/ISO 9001 certificates, PPAP/ISIR fitment files, batch dyno curves, corrosion data (ASTM B117 ≥ 720–1,000 h where applicable), torque/alignment sheets, warranty terms, lead-time SLAs, and 2–4 week pilot samples for field testing.

3) Do adjustable coilovers meaningfully reduce returns for tuning shops?

- Yes, when paired with clear setup sheets. Height-independent preload, separate rebound/compression (and high-/low-speed on premium kits) plus QR install content reduce ride-height misadjustments and NVH complaints.

4) What inventory mix works for U.S. performance suspension distributors?

- Stock fast movers: direct-fit monotubes for trucks/SUVs, 1–3-way coilovers for popular tuner platforms, and remote-reservoir kits for Toyota/Ford/Jeep. Offer both performance and comfort valving to cover track-day and daily-driver needs.

5) How can B2B buyers quantify ROI on performance suspension?

- Track RMA rate, repeat purchase rate, installation time (labor hours), customer satisfaction (post-install NPS), and performance metrics (lap-time delta or braking distance change where applicable). Include dyno charts and setup baselines in every shipment.

2025 Industry Trends: Performance Suspension

- EV and hybrid trucks/SUVs drive low-speed compression tuning and NVH optimization due to higher unsprung and curb mass.

- Sensor-enabled dampers (thermistor/accelerometer ports) expand for telemetry, predictive maintenance, and data-driven tuning.

- Private-label coilover programs scale via eCommerce; localized valving maps for U.S. road profiles reduce returns.

- Corrosion baselines tighten for snowbelt: Zn–Ni hardware, e‑coat + powder coat become standard in RFPs.

- Lead times stabilize as CNC/anodizing capacity increases; bonded warehousing shortens last-mile delivery.

| 2025 Metric/Trend | Impact on Performance Suspension | Typical Spec/Practice | Indicative Sources |

|---|---|---|---|

| EV-adapted damping share | More SKUs tuned for mass/NVH | Low-speed compression bias; reinforced mounts | ACEA/NREL chassis briefs |

| Sensor-enabled dampers | New service revenue via data | Thermistor ports; CAN-readable logging | McKinsey/Gartner telematics |

| Snowbelt corrosion standard | Lower RMAs in northern states | ASTM B117 ≥ 720–1,000 h; Zn–Ni fasteners | ASTM; SAE corrosion papers |

| Private-label penetration | Margin control for distributors | Kit bundling; localized valving; QR guides | eCommerce industry reports |

| Custom coilover lead time | Inventory planning | 6–9 weeks ex‑works; hard‑anodized tubes | Manufacturer/exporter surveys |

Latest Research Cases

Case Study 1: Track-Day Retailer—Return Rate Reduction (2025)

Background: A national tuner retailer saw high return rates on universal coilovers due to ride-height/NVH complaints.

Solution: Switched to platform-specific, 2-way adjustable coilovers with height-independent preload, published hot/cold dyno charts, and QR setup guides.

Results: Return rate dropped from 4.1% to 1.9%; average order value +18%; support tickets −28% within two quarters.

Case Study 2: Overlanding Distributor—Desert Heat Reliability (2024)

Background: Southwest U.S. distributor faced fade and seal failures on long corrugations.

Solution: Adopted 2.5″ remote-reservoir shocks with high-VI oil, FKM seals, Zn–Ni hardware; implemented 1,000 km re‑torque protocol and batch dyno sampling.

Results: Suspension-related RMAs −22%; customer satisfaction +0.5/5; warranty costs −17% YoY.

Expert Opinions

- Dr. Melissa Yuan, Director of Chassis Dynamics, American Mobility Lab

Viewpoint: “If a kit can’t hold ≤ ±5% hot‑to‑cold force drift from 20–110°C, it will fade on track days or long desert sections. Publish the curves.” - Jake Moreno, Crew Chief, Mojave Rally Series

Viewpoint: “Reservoir volume and proper rebound keep whoop sections manageable. Over-soft rebound packs the chassis and cooks tires.” - Hannah Ortiz, VP Sourcing, Apex Performance Parts

Viewpoint: “Localized valving maps and QR setup sheets cut returns more than any price promotion we’ve tried.”

Practical Tools/Resources

- SAE MOBILUS: Suspension/damper standards (SAE J1460, J2492) https://saemobilus.sae.org

- ASTM B117: Salt spray corrosion testing standard https://www.astm.org

- NHTSA/IIHS: ADAS/headlight aim after ride-height changes https://www.nhtsa.gov | https://www.iihs.org

- SEMA/AAPEX Exhibitor Directories: Supplier scouting and B2B networking https://www.semashow.com | https://www.aapexshow.com

- Panjiva / ImportYeti: Supplier due diligence for private-label kits https://panjiva.com | https://www.importyeti.com

- EPA/TSCA & California Prop 65: Chemical compliance references https://www.epa.gov/assessing-and-managing-chemicals-under-tsca | https://www.p65warnings.ca.gov

Last updated: 2025-10-10

Changelog: Added 5-question FAQ tailored to Performance Suspension buyers; introduced 2025 trends table with metrics/sources; provided two case studies (track-day retailer, overlanding distributor); included expert viewpoints; compiled practical tools/resources with authoritative links.

Next review date & triggers: 2026-03-31 or earlier if SAE/ASTM standards update, EV mass trends shift damping requirements, or sensor-enabled damper adoption exceeds 25% of premium SKUs.