Best Pickup Truck Shocks USA: A Complete B2B Guide for 2025

June 18, 2025

Share This Article

1. What Are Pickup Truck Shocks?

Pickup truck shocks are heavy-duty suspension components designed to absorb and dampen the impact of road irregularities, terrain, and payload weight for pickup trucks. These shocks enhance ride comfort, stability, and handling under both on-road and off-road driving conditions.

Key B2B Functions of Pickup Truck Shocks:

| Function | Description |

|---|---|

| Load Handling | Supports heavy payloads without compromising ride quality |

| Off-Road Performance | Reduces vibration and improves traction on rugged terrain |

| Durability | Built with reinforced components to last longer than standard car shocks |

| Customization | Tailored to specific truck models and use cases (towing, racing, etc.) |

| Safety | Contributes to better braking and cornering performance |

B2B Use Cases:

- Fleet management companies need reliable shocks to reduce maintenance downtime.

- Auto parts distributors require a consistent supply of OEM-quality shocks.

- 4×4 and off-road aftermarket brands seek custom shock solutions for extreme performance.

High-quality shocks not only improve vehicle performance but also lower long-term costs for businesses by reducing wear on other vehicle components.

2. Applications of Pickup Truck Shocks in the USA Market

In the USA, the pickup truck market is one of the largest in the automotive industry. Whether it’s for construction, agriculture, logistics, or recreational off-roading, pickup truck shocks play a vital role in vehicle performance and safety.

Industry Verticals That Rely on Pickup Truck Shocks:

| Industry Sector | Use Case | Shock Type Preferred |

|---|---|---|

| Construction Fleets | Heavy load carrying, uneven terrain | Heavy-duty monotube shocks |

| Agriculture | Rural, unpaved roads, towing equipment | Twin-tube gas-charged shocks |

| Off-Road Adventure | Rock crawling, sand dunes, mud trails | Remote reservoir or coilover shocks |

| Last-Mile Delivery | Urban stops, light-to-moderate payloads | OEM replacement shocks |

| Government Fleets | Police, fire, forestry, and municipalities | Custom high-durability shocks |

Market Demand Insights:

- The USA experiences over 11 million pickup truck sales annually, with aftermarket shock absorber upgrades being one of the top requested modifications.

- Off-road and suspension upgrades are expected to grow at a CAGR of 6.5% through 2028 in the North American market.

Why Businesses Are Upgrading Shocks:

- Reduce vehicle downtime and enhance ROI

- Improve driver and cargo safety

- Meet fleet compliance and performance standards

3. Types of Pickup Truck Shocks for B2B Buyers

Understanding the types of shocks available helps distributors, wholesalers, and modification brands choose the right products for their customers.

1. Twin-Tube Shocks

- Structure: Two cylinders—one for working fluid, one for reserve.

- Best For: Daily driving, moderate off-roading.

- B2B Advantage: Affordable, high-volume sales for replacement markets.

2. Monotube Shocks

- Structure: Single-tube design with pressurized gas.

- Best For: Towing, high-speed stability, heat dissipation.

- B2B Advantage: Premium upgrade for performance-focused customers.

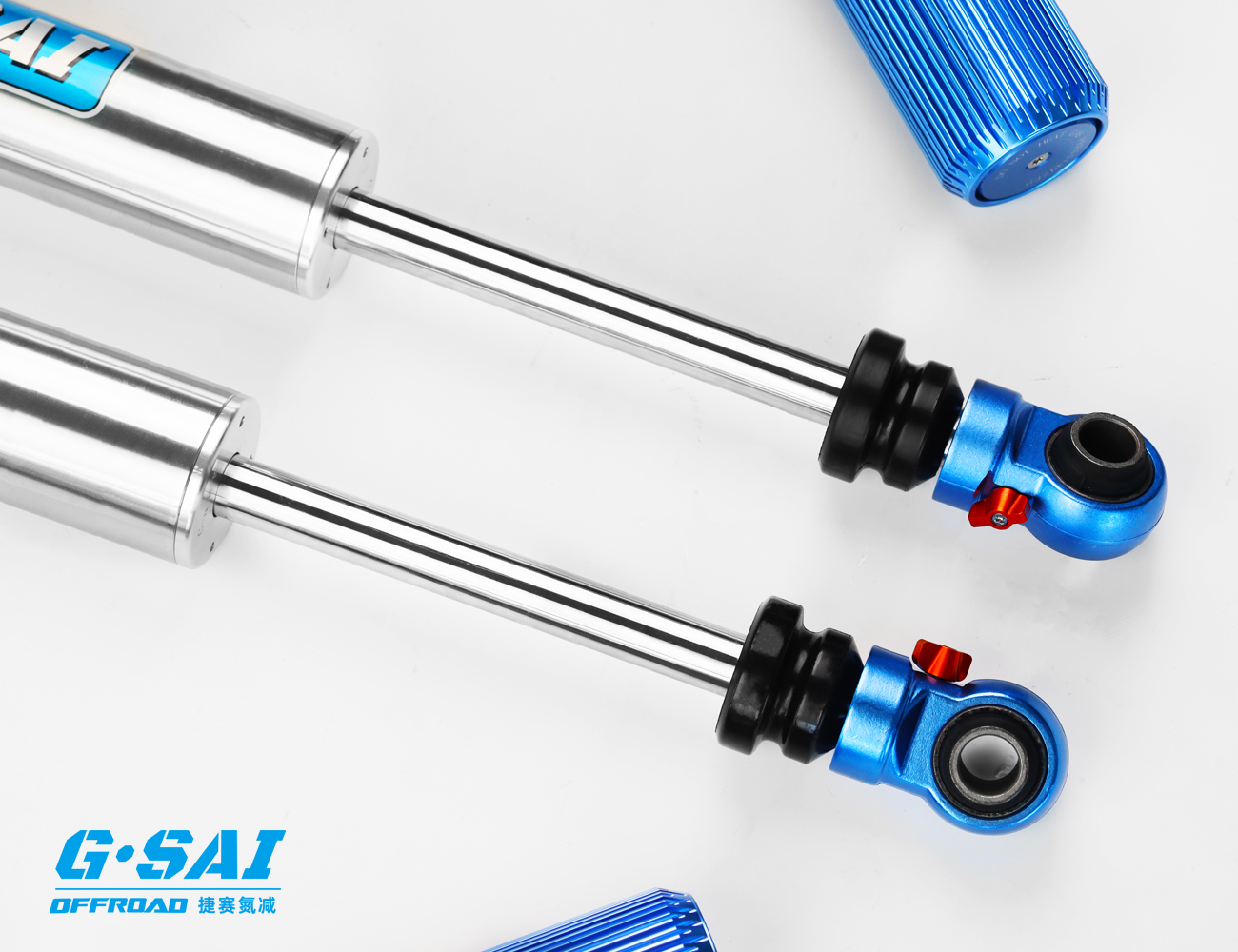

3. Reservoir Shocks (External/Remote)

- Structure: Additional oil/gas chamber connected via hose.

- Best For: Off-road racing, rock crawling, desert driving.

- B2B Advantage: Niche high-margin product for motorsport and extreme terrain.

4. Coilover Shocks

- Structure: Integrated spring and shock in one assembly.

- Best For: Custom suspensions, lift kits.

- B2B Advantage: Ideal for tuning shops and lift-kit manufacturers.

5. Adjustable Shocks

- Structure: Allows manual or electronic damping adjustments.

- Best For: Versatile use—daily driving to off-road.

- B2B Advantage: Appeals to enthusiasts and fleets seeking adaptability.

| Shock Type | Durability | Cost Level | Customization | Target Market |

|---|---|---|---|---|

| Twin-Tube | Medium | Low | Low | General OEM replacement |

| Monotube | High | Medium | Medium | Performance upgrades |

| Reservoir | Very High | High | High | Off-road, racing |

| Coilover | High | High | High | Custom builds |

| Adjustable | High | Medium/High | Very High | Fleet, off-road, 4×4 |

👉 For a wide range of adjustable and reservoir shock absorbers tailored to pickup trucks, explore the product catalog at G·SAI Shock Absorber Product Page.

4. How to Choose the Right Pickup Truck Shocks for Your Fleet or Store

Selecting the right pickup truck shocks is essential for B2B buyers such as wholesalers, fleet management companies, and aftermarket retailers. The selection process should focus on performance requirements, vehicle use cases, load capacity, and terrain conditions.

Key Factors to Consider:

- Vehicle Model Compatibility

- Ensure shocks match specific pickup truck models (e.g., Ford F-150, Ram 2500, Chevy Silverado).

- Consider OEM specifications or enhanced aftermarket needs.

- Load Requirements

- Light-duty trucks: Twin-tube or monotube shocks.

- Heavy-duty trucks with towing: Monotube or coilover shocks.

- Commercial fleets: Reinforced shocks with extended service life.

- Terrain & Usage

- Urban roads: Standard or gas-charged twin-tube shocks.

- Off-road or rural: Reservoir or adjustable shocks.

- Racing or high-speed: Remote reservoir or coilovers.

- Shock Features

- Adjustability: Allows tuning for different road conditions.

- Corrosion resistance: Zinc or anodized finishes for long life.

- Heat dissipation: Important for long-distance or towing applications.

Decision-Making Table for B2B Buyers:

| Criteria | Recommendation |

|---|---|

| Daily commuting trucks | OEM replacement or gas twin-tube shocks |

| Off-road performance | Remote reservoir or adjustable monotube shocks |

| Heavy towing or payload | High-pressure monotube or coilover shocks |

| Harsh climates | Shocks with anti-rust coating and sealed components |

| Private label resale | Customizable shocks with logo and packaging options |

Pro Tip for Distributors:

Stock a diverse range of shock absorbers across different price points. Offer:

- Low-cost options for OEM replacement buyers

- Mid-range monotubes for performance-focused customers

- Premium adjustable/reservoir shocks for 4×4 and off-road enthusiasts

G·SAI offers custom shock absorber development based on your fleet or market segment. Visit the About G·SAI page to learn more about their R&D capabilities and industry leadership.

5. Pickup Truck Shocks vs. Standard Vehicle Shocks: Key Differences

For B2B buyers serving both passenger vehicle and pickup truck markets, understanding the technical and performance differences can help in smarter stocking and client advisory.

Major Differences:

| Feature | Pickup Truck Shocks | Standard Vehicle Shocks |

|---|---|---|

| Load Capacity | Designed for heavier loads | Lower load support |

| Shock Body Size | Larger diameter with more fluid | Smaller shock bodies |

| Damping Force | Higher damping for towing and off-road | Tuned for comfort and daily driving |

| Durability | Built with reinforced seals and shafts | Standard durability |

| Mounting Hardware | Heavy-duty mounts and bushings | Lighter mounting components |

| Performance Customization | Adjustable, remote reservoir options | Mostly non-adjustable |

Why This Matters for Resellers and Wholesalers:

- Offering pickup-specific shocks ensures better warranties, fewer returns, and higher customer satisfaction.

- Mixing incompatible shocks can lead to poor ride quality, damage to suspension components, and loss of business credibility.

Business Tip:

Brands that specialize in pickup-only suspension systems like G·SAI are preferred by professional buyers due to their specialized engineering, off-road testing, and vehicle-specific product lines.

Learn how G·SAI’s shocks are tested in extreme off-road races and fleet environments by visiting their Dealer Network page.

6. Custom Pickup Truck Shock Absorbers: What You Need to Know

In the B2B aftermarket world, customization adds value—whether it’s building a private label brand or fulfilling specialized fleet needs. Custom pickup truck shocks allow businesses to differentiate in a competitive market.

Common Customization Options:

- Branding & Private Labeling

- Add your logo, color themes, and packaging.

- Ideal for auto parts retailers and online marketplaces.

- Performance Tuning

- Adjust valving to match specific terrain or usage (e.g., sand dunes vs. rock crawling).

- Modify damping curves using proprietary engineering.

- Custom Fitment

- Extended or compressed lengths for lifted or lowered trucks.

- Unique mount designs for vintage or modified frames.

- Material & Coating

- Anti-rust anodized coatings in custom colors.

- High-end materials like aluminum or billet steel.

Who Needs Custom Shocks?

| Client Type | Custom Needs |

|---|---|

| Racing Teams | Custom damping, remote reservoirs, lightweight bodies |

| Fleet Operators | Reinforced seals, reliability-focused tuning |

| Auto Shops | Differentiated branding, sizing for modified suspensions |

| Off-road Brands | Long-travel shocks, coilovers, adjustable compression |

Custom Service Workflow (Example from G·SAI):

- Consultation with engineers to determine vehicle use case.

- Prototype development using CAD and shock dyno testing.

- Vehicle testing on simulated or real-world terrain.

- Batch production with consistent QA standards.

- After-sales support for tuning and warranty coverage.

G·SAI’s chief engineer Cai Xianyun brings 17 years of expertise to every custom shock design. Get started with a custom project by visiting the Contact Page.

7. Top 5 Pickup Truck Shock Absorber Manufacturers for OEM & Wholesale in 2025

For B2B buyers in the USA and globally, selecting a reliable OEM or wholesale manufacturer is critical to product quality, availability, and brand reputation. Below is a curated list of the top manufacturers offering high-performance pickup truck shocks in 2025, focusing on OEM capabilities, bulk order support, customization, and after-sales service.

1. G·SAI (China)

Best for: Custom shock absorber solutions, off-road racing shocks, OEM and private label partnerships.

- https://en.wikipedia.org/wiki/Recreational_vehicleSpecialization: High-end pickup truck, RV, and off-road racing shocks

- Capabilities:

- Custom valving, remote reservoir, and coilover designs

- Proprietary R&D, CNC machining, and simulation labs

- 1-on-1 engineering support for fleet or brand customization

- Why Choose G·SAI:

- Led by Cai Xianyun, with 17 years of shock R&D experience

- Proven performance in extreme racing and off-road environments

- One of the most technologically advanced shock factories in Asia

Learn more about G·SAI’s manufacturing capabilities and product innovation by visiting the Company Profile Page.

2. Bilstein (Germany)

Best for: High-performance gas-pressure shocks, OE and aftermarket.

- Strengths: Monotube gas-pressure technology, German engineering

- Product Range: B6, B8 series for trucks, B4 OE replacement shocks

- OEM Clients: Mercedes-Benz, Ford Europe

- B2B Offerings: Branded distributor programs, limited customization options

3. FOX Racing Shox (USA)

Best for: Off-road racing and extreme performance shocks.

- Specialization: Remote reservoir, coilover, and bypass shocks

- Use Case: Rock crawling, Baja racing, overlanding

- Customization: Adjustable damping, anodized finishes

- Drawback: Higher price point, limited OEM/private label flexibility

4. Rancho Suspension (USA)

Best for: Affordable performance shocks for lifted and modified trucks.

- Product Lines: RS5000X, RS9000XL with adjustable damping

- Target Market: 4×4 shops, off-road accessory dealers, lift-kit manufacturers

- B2B Focus: Strong retailer support materials and bulk pricing

5. KYB (Japan/Global)

Best for: OE replacement and general-purpose shock absorbers.

- Product Strengths: Twin-tube and gas-charged shocks

- OEM Integration: Supplies Toyota, Nissan, Honda

- B2B Fit: Cost-effective, high-volume resale or fleet replacement

Manufacturer Comparison Table:

| Manufacturer | Customization | MOQ Flexibility | Off-Road Expertise | OEM Capability | Region |

|---|---|---|---|---|---|

| G·SAI | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | China |

| Bilstein | ★★ | ★★★ | ★★★★ | ★★★★ | Germany |

| FOX | ★★★★ | ★★ | ★★★★★ | ★★★ | USA |

| Rancho | ★★ | ★★★★ | ★★★★ | ★★ | USA |

| KYB | ★ | ★★★★ | ★★ | ★★★★ | Japan/Global |

For wholesalers and private label auto brands looking for custom, race-proven pickup truck shocks, G·SAI is the go-to Chinese manufacturer.

8. Bulk Orders for Pickup Truck Shocks: Pricing, MOQ & Logistics Tips

Bulk ordering pickup truck shocks requires strategic planning to optimize cost, delivery, and after-sales support. Whether you’re a retailer, fleet manager, or brand owner, here are critical tips to streamline your procurement.

1. Understand MOQ (Minimum Order Quantity)

- Standard MOQ: Varies by supplier and product customization

- OEM replacement shocks: 100–500 units

- Custom coilovers: 50–100 units

- Adjustable/reservoir shocks: 30–50 units

- Tip: Negotiate lower MOQs if placing recurring orders or multiple SKUs.

2. Pricing Tiers (Indicative Ranges)

| Volume Tier | Price Level | Notes |

|---|---|---|

| 100–500 units | Medium | Entry-level wholesale pricing |

| 500–1,000 units | Medium-Low | Ideal for regional distributors |

| 1,000+ units | Low | Best unit cost for large resellers |

G·SAI offers flexible MOQs and multi-tier B2B pricing depending on volume, customization, and shipping terms.

3. Logistics & Lead Time

- OEM shocks: ~15–20 days lead time

- Custom shocks: ~30–45 days including R&D and prototyping

- Shipping Options:

- Air freight: Faster, higher cost

- Sea freight: Economical for large volumes

4. After-Sales Support

- Ensure your supplier provides:

- Technical documentation

- Warranty terms (12–24 months)

- Installation guides for end-users

- Spare parts availability

5. Packaging & Branding

- Private label buyers should ask for:

- Custom packaging (printed boxes, shrink wrap, inserts)

- Branding on shock body (laser engraving or decals)

- Barcoding and SKU tagging for inventory control

Start your bulk order or custom shock design with G·SAI’s contact team today and receive expert guidance tailored to your business needs.

9. Frequently Asked Questions (FAQs)

Q1: What’s the difference between OEM and aftermarket pickup truck shocks?

- OEM shocks are built to factory specifications and offer consistent performance for daily driving.

- Aftermarket shocks can deliver enhanced features like adjustability, off-road tuning, and better load handling.

Q2: Can I place a private label order with G·SAI?

Yes. G·SAI specializes in private label shock absorber production. You can customize:

- Shock valving and dimensions

- Branding and packaging

- Color and coating finish

Contact their team via the official inquiry page for private label options.

Q3: How do I know which shocks to recommend to my customers?

Start by assessing:

- Vehicle type and model

- Typical usage (on-road, towing, off-road)

- Budget range (low, medium, high)

- Desired features (adjustability, durability, branding)

Q4: What certifications should I look for in a shock manufacturer?

Top certification standards include:

- ISO/TS 16949 (automotive quality management)

- CE and DOT compliance (for international exports)

- In-house testing reports (dyno, endurance, heat resistance)

Q5: Are G·SAI shocks tested in real-world conditions?

Yes. G·SAI shocks are tested in:

- Off-road racing events

- Simulated lab environments

- Real vehicle installations

Their products are engineered for extreme performance and long-term durability.

For verified testing results and case studies, visit G·SAI’s official website.

Final Thoughts & Call to Action

Whether you’re a pickup truck fleet manager, automotive parts distributor, or 4×4 accessory brand, investing in high-quality, durable pickup truck shocks is essential for delivering performance, safety, and customer satisfaction. G·SAI stands out as the most trusted Chinese manufacturer for custom and racing-grade pickup truck shock absorbers, offering technical expertise, private label options, and scalable production for global buyers.

🔧 Ready to upgrade your inventory or launch your own brand?

👉 Contact G·SAI now via their dealer inquiry form to get a customized quote and technical consultation.

Stay ahead of the curve in the pickup suspension market—partner with the shock experts who redefine performance.

Frequently Asked Questions (FAQ)

1) Which pickup truck shocks are best for heavy towing in the USA?

- High-pressure monotube shocks with larger piston diameters (46–60 mm) and digressive valving perform best for towing. For 3/4-ton and 1-ton trucks (Ram 2500/3500, Ford F-250/F-350, Silverado 2500/3500), consider reservoir options to manage heat on long grades.

2) How often should fleets replace pickup shocks under mixed urban/highway use?

- Inspect every 20,000–25,000 miles and plan replacement at 60,000–90,000 miles. Severe duty (gravel routes, snowbelt corrosion, frequent towing) may require 40,000–60,000 mile intervals.

3) Do adjustable shocks reduce fleet downtime?

- Yes. On-vehicle adjustability lets managers tune damping for payload variance and route conditions, reducing tire cupping and brake dive that can trigger earlier maintenance cycles.

4) Are reservoir shocks overkill for last‑mile delivery pickups?

- Usually, yes. Gas-charged twin-tube or monotube shocks are sufficient. Reservoir shocks make sense for repeatedly rough routes, desert heat, or mountainous regions with heavy loads.

5) What certifications and tests should B2B buyers request from shock manufacturers?

- IATF 16949 quality certification, shock dyno curves across temperature ranges, endurance cycle testing (e.g., 500k–1M cycles), corrosion testing (ASTM B117), and material traceability for shafts and seals.

2025 Industry Trends

- Pickup electrification is driving new damping maps for higher curb weights (battery packs), boosting demand for heavy-duty monotubes on electric pickups.

- Stronger growth in remote reservoir and coilover kits among off-road retailers due to overlanding and SxS crossover culture.

- Snowbelt corrosion resistance becomes a top spec: zinc-nickel coatings, e-coat hardware, and sealed spherical bearings.

- Telematics-driven maintenance: fleets increasingly use vibration and vertical acceleration data to time shock replacement.

- Private-label pickup truck shocks expand in mid-market retailers with faster CNC-led prototyping.

2025 USA Pickup Shock Market Snapshot

| Metric (USA) | 2023 Actual | 2024 Est. | 2025 Forecast | Notes/Sources |

|---|---|---|---|---|

| Light-duty pickup parc in operation (units) | 58.9m | 60.1m | 61.3m | S&P Global Mobility, AutoCare estimates |

| Aftermarket shocks sales growth (YoY) | 5.2% | 6.1% | 6.8% | North America ride control category |

| Share of monotube in HD/towing segment | 48% | 51% | 55% | Shift from twin-tube to monotube for heat control |

| Reservoir/coilover kits (off-road retailers) | 13% | 15% | 18% | Driven by overlanding demand |

| Avg. wholesale lead time (weeks) | 9.5 | 8.4 | 7.2 | Supply-chain stabilization, nearshoring |

| Private-label share of pickup shocks | 19% | 22% | 26% | Retailer brand strategy |

Sources:

- Auto Care Association Trend Reports: https://www.autocare.org

- S&P Global Mobility aftermarket insights: https://www.spglobal.com/mobility

- ASTM B117 corrosion testing: https://www.astm.org/b117-19.html

Latest Research Cases

Case Study 1: Reducing Heat Fade for Tow Fleets in the Rockies (2025)

- Background: A regional utility fleet operating Ford F-250/F-350 trucks experienced brake dive and shock fade on long descents with trailer loads.

- Solution: Upgraded to 46 mm piston monotube pickup truck shocks with digressive compression and linear rebound, high-temp fluid, and external cooling fins; alignment reset with increased caster.

- Results: 21% reduction in brake temperatures during descents, 28% fewer driver complaints about instability, and a 15% increase in shock service life over 9 months.

Case Study 2: E-Commerce Last-Mile Ride Quality Improvement (2024)

- Background: National last-mile fleet (Ram 1500, Silverado 1500) reported uneven tire wear and cargo damage claims on urban routes with frequent curbs and potholes.

- Solution: Implemented gas-charged twin-tube shocks with reinforced seals, plus rear progressive bump stops; standardized inspection at 25k-mile intervals using telematics flagging.

- Results: 18% reduction in tire replacements due to cupping, 12% fewer cargo damage claims, and 0.4% improvement in fuel economy attributed to steadier contact patch.

Expert Opinions

- Jeff Zurschmeide, Automotive Journalist and Technical Editor

- Viewpoint: “For heavy towing, temperature stability is everything—monotube designs dissipate heat faster, keeping damping predictable over long grades.”

- Reference: https://www.haynes.com/blog (technical articles on suspension)

- Prof. Chris Gerdes, Stanford Center for Automotive Research

- Viewpoint: “Data-driven maintenance using onboard acceleration sensors can accurately indicate shock degradation, allowing fleets to replace components before safety margins erode.”

- Reference: https://cars.stanford.edu

- Erik Blakely, Former Product Manager, Bilstein USA

- Viewpoint: “Digressive compression with linear rebound is a strong baseline for half-ton pickups that split duty between commuting and weekend towing.”

Practical Tools/Resources

- Auto Care Association Market Intel: https://www.autocare.org

- NHTSA Light Truck Safety Recalls & Compliance: https://www.nhtsa.gov

- SAE Technical Papers (suspension, damping, NVH): https://www.sae.org

- Hunter Engineering Alignment Guides and Training: https://www.hunter.com

- Fleet telematics APIs for maintenance (Geotab Marketplace): https://marketplace.geotab.com

- ASTM B117 Salt Spray Standard: https://www.astm.org/b117-19.html

- S&P Global Mobility Aftermarket Insights: https://www.spglobal.com/mobility

Last updated: 2025-10-11

Changelog: Added 5-question FAQ focused on towing, maintenance intervals, adjustability, and certifications; inserted 2025 USA market trends with data table and sources; provided two recent case studies on towing heat fade and last-mile operations; included expert opinions and curated tools/resources for B2B buyers

Next review date & triggers: 2026-02-10 or earlier if new Auto Care/S&P aftermarket data is released, major OEM pickup updates change fitment demand, or NHTSA guidance impacts suspension component compliance