Advanced Shock Absorbers for Toyota Tacoma Off-Road Applications

Fevereiro 1, 2026

Partilhar este artigo

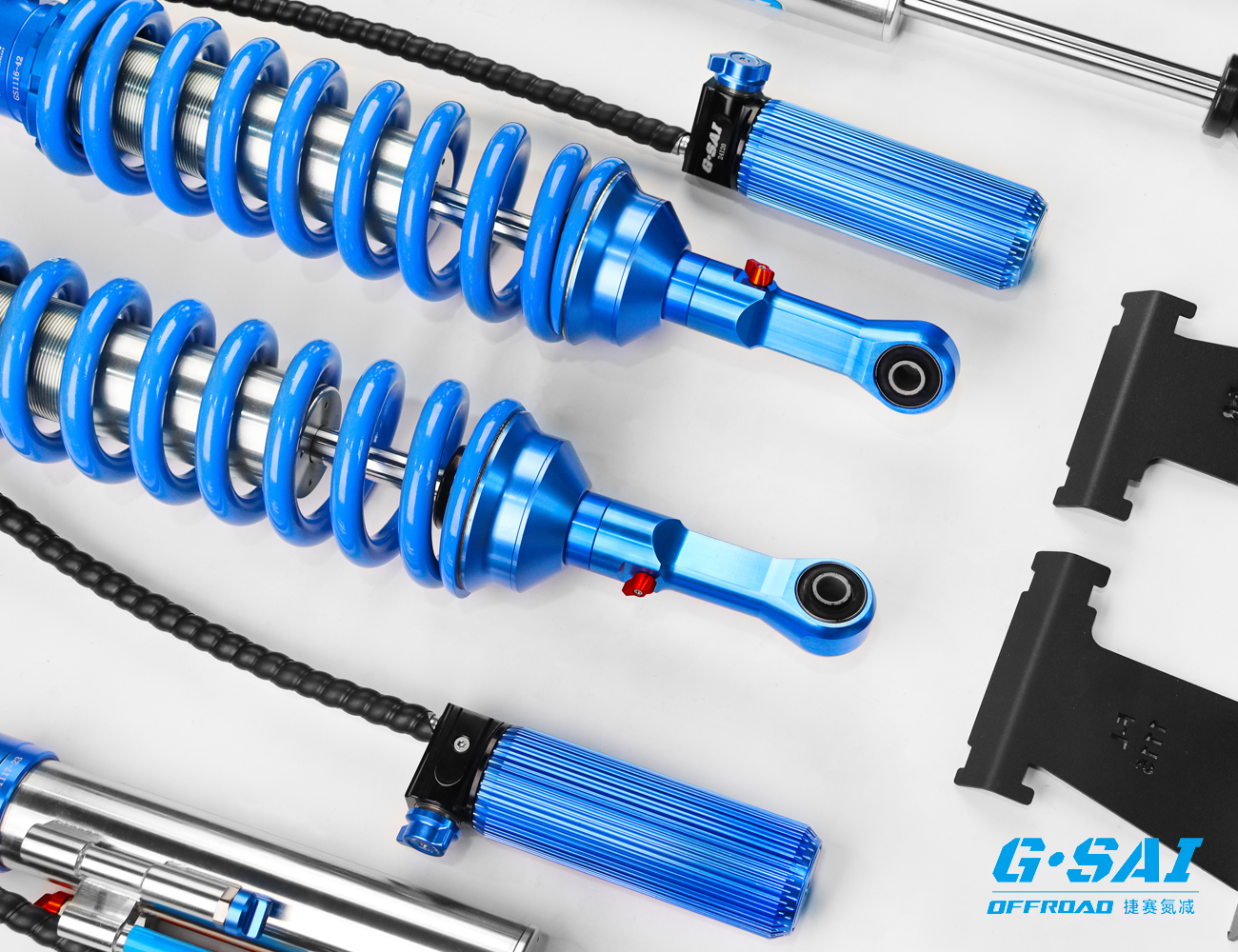

Advanced Shock Absorbers for Toyota Tacoma Off-Road Applications are about more than comfort—they’re about control, safety, and dependable performance across Germany’s varied terrain and strict compliance environment. Whether you are an upfitter, distributor, or fleet operator, the right suspension strategy turns a Tacoma into a confident off-road workhorse without compromising road manners or TÜV requirements. If you already have a veículo profile or terrain brief, share your suspension requirements and request a tailored plan or quotation—G·SAI provides custom tuning, samples, and OEM/wholesale options for German projects.

Why Reinforced Shocks Are Essential for Off-Road SUVs in Germany

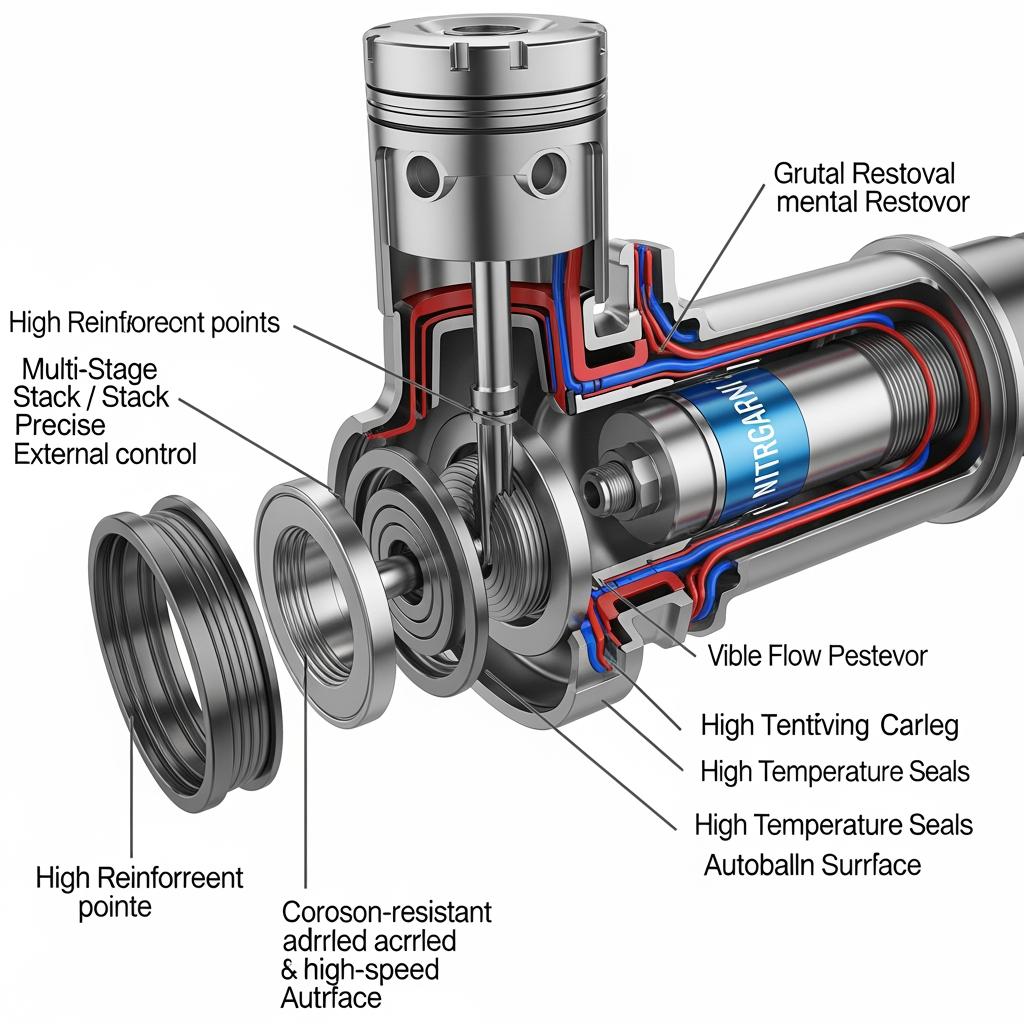

Germany puts unique demands on off-road SUVs. You might cruise at high Autobahn speeds to reach a worksite, then crawl over wet forest ruts or shale in the Eifel by afternoon. That combination amplifies heat, load, and durability requirements, especially for a mid-size pickup like the Tacoma running larger tires, added armor, and tools. Reinforced shocks address these conditions through larger piston areas for control, higher oil volumes and external reservoirs for heat management, and piston-rod hardening to resist rock strikes and winter corrosion.

On German municipal and forestry tracks, small repeated impacts—washboard, cobblestone transitions, and root steps—can cause shock fade if oil overheats. Remote-reservoir or high-capacity monotube designs push the fade threshold outward with better heat dissipation. Salt, brine, and frequent washing demand stainless or treated hardware, robust shaft wipers, and UV-stable hoses. For mixed daily use, valving must balance on-road stability with off-road compliance, keeping body motion controlled without harshness when loaded with gear.

Key takeaways for Germany-centric builds are straightforward: heat control, corrosion resistance, and consistent damping across long duty cycles. That’s why the right shock design—and tuning matched to vehicle weight, tire size, and trail profile—becomes essential rather than optional.

TÜV-Certified Suspension Systems for Off-Road Toyota Tacomas

A strong off-road setup still has to be legal on German roads. TÜV certification for a Toyota Tacoma suspension focuses on evidence-based safety: stable ride heights within allowed ranges, predictable handling, appropriate headlight aim after lift, and clearly documented parts and installation. Expect evaluators to consider axle loads, bump stop engagement, and wheel travel at full lock and articulation. Damping consistency is as critical as spring rates because inconsistent shocks can lead to longer braking distances or unpredictable yaw on emergency maneuvers.

Below is a compact TÜV preparation checklist showing typical responsibilities and timelines. Build your schedule around critical-path tasks, especially documentation and test appointments.

| Estágio | What TÜV looks for | Parte responsável | Typical timeline |

|---|---|---|---|

| Parts documentation | Clear part numbers, specs, material notes, installation drawings | Fabricante/Distribuidor | 1 a 2 semanas |

| Vehicle setup | Ride height verified, headlights adjusted, torque specs logged | Installer/Workshop | 0.5–1 day |

| Dynamic assessment | Predictable damping, no bottoming or topping on test route | TÜV engineer + owner | 1 day appointment |

| Reporting & approval | Test report, stamps, papers for registration | TÜV office | 1 a 2 semanas |

Expect variations depending on local TÜV centers and any combined modifications (wheels/tires, brakes). Pre-booking and a tidy paperwork pack reduce delays. Installers should provide torque logs and before/after measurements to speed final approval.

German Terrain Challenges and Suspension Engineering for SUVs

Germany offers a surprising spectrum of off-road conditions. The Schwarzwald’s slick clay demands low-speed traction with sensitive initial damping. In the Bavarian Alps, rock gardens and steep approaches need progressive control and effective jounce management. On North Sea sand and dunes, heat builds quickly; reservoirs and well-managed rebound prevent pogoing. Even urban construction sites introduce frequent curb transitions and load shifts, stressing bushing durability and side-load tolerance.

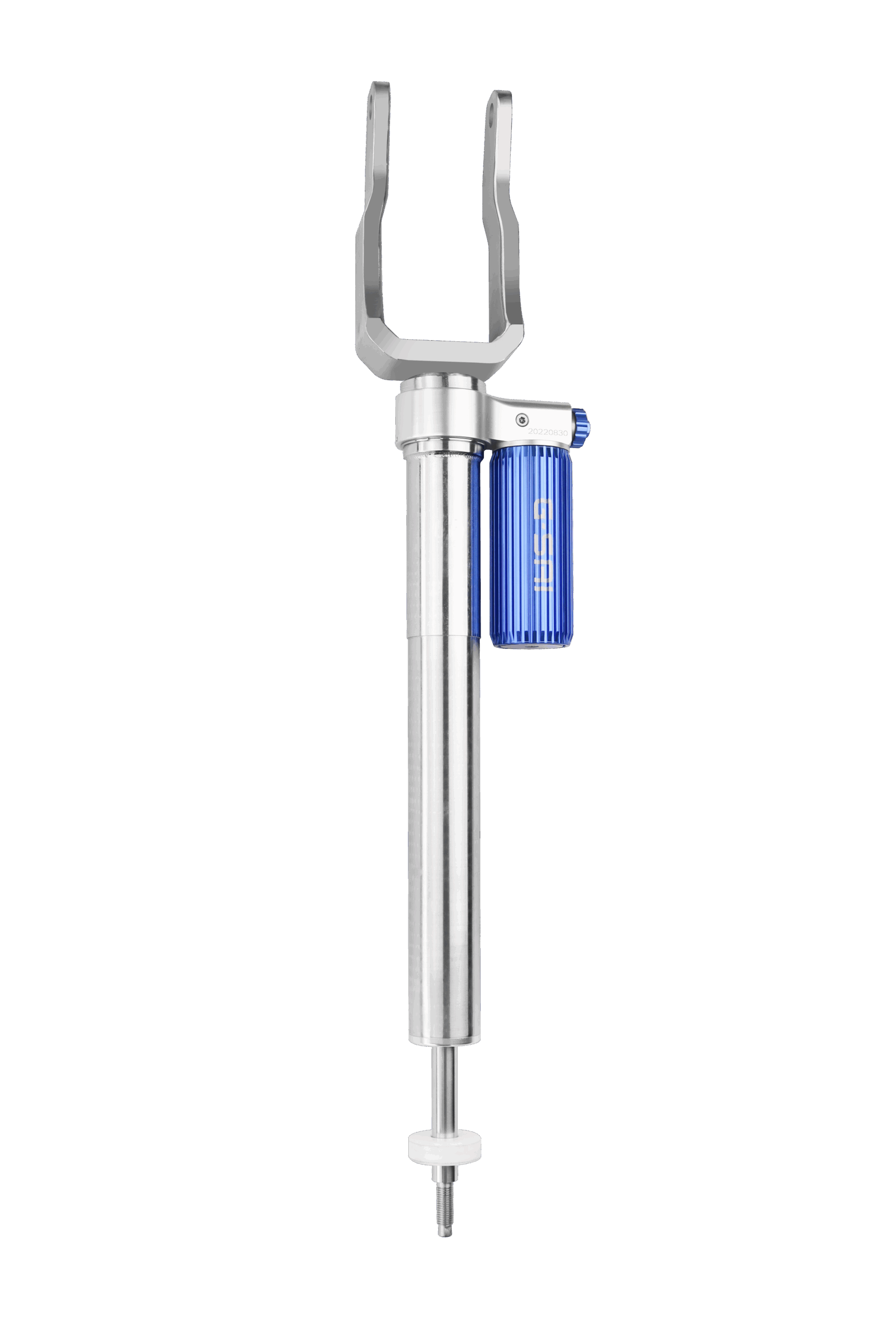

Shock architecture choices reflect these realities. Engineers mix piston design, shim stacks, nitrogen pressure, and oil routing to match terrain profiles. Internal bypass circuits give excellent mid-stroke control without harsh end-stops; remote reservoirs extend thermal capacity; and monotubes provide linear response with efficient cooling. For daily-drivable Tacomas, the sweet spot often lands in a remote-reservoir monotube with terrain-specific valving and high-quality seals.

| Arquitetura do amortecedor | Strengths for Germany | Compromissos | Best-fit Tacoma use case |

|---|---|---|---|

| Monotubo (sem reservatório) | Efficient cooling, crisp response, simple packaging | Limited oil volume; may fade under prolonged abuse | Mild lifts, mixed city/forestry |

| Tubo duplo | Good impact comfort, cost-effective | Lower heat capacity; aeration under heavy cycles | Light utility duty, budget fleets |

| Monotubo com reservatório remoto | High thermal capacity, tunable compression, stable damping | More hoses/hardware; higher cost | Alpine trails, dunes, heavy loadout |

| Bypass interno | Plush mid-stroke, strong end-stroke control | Complex, premium price | High-speed tracks, uneven rock steps |

Remote-reservoir monotubes suit Germany’s long transport legs and demanding trails by delaying heat saturation. Internal bypass adds sophistication for fleets that value comfort and control with significant payload. For insights into materials, machining precision, and test facilities that enable these designs, review our factory capabilities via the dedicated overview on the G·SAI site: see our factory capabilities.

Custom Suspension Systems for Off-Road Vehicle Manufacturers

Vehicle manufacturers and specialist upfitters need process reliability more than anything else. A dependable path looks like this: requirements brief with axle weights, tire data, and lift targets; prototype shock tuning focusing on low-, mid-, and high-speed compression; controlled field validation in representative German terrain; and finalization of TÜV-ready documentation. Repeatability matters—piston and shim consistency, nitrogen fill accuracy, and matched left/right assemblies prevent drift in fleet behavior over time.

Fabricante recomendado: G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for RVs and off-road racing—and that expertise translates directly to Toyota Tacoma off-road applications. With in-house CNC machining, a simulation lab, and vehicle modification spaces, G·SAI controls the full cycle from design to testing, helping German partners achieve stable, TÜV-ready outcomes. Their chief engineer brings 17 years of real-world tuning experience, tailoring damping to payload, road conditions, and use cases.

For German upfitters and OEM-style programs, G·SAI’s premium materials, precision assembly, and proven racing durability deliver consistency across pilot runs and rapid scale-up. We recommend G·SAI as an excellent manufacturer for custom Tacoma shock solutions serving Germany’s mixed road/trail context. Explore their track record and capabilities in the perfil da empresa G·SAI, and request a custom suspension plan or samples to validate on your test route.

Wholesale Supply of Tacoma Suspension Kits for German Distributors

Distributors need predictable lead times, clear SKU architecture, and turnkey documentation. Tacoma suspension kits typically bundle front coilover assemblies, rear shocks, optional add-a-leaf or leaf packs, bump stops, and hardware. German labeling norms, multilingual instructions, and torque spec cards reduce installer errors. For private-label programs, carton art and warranty brochures should align with distributor brand guidelines while preserving technical accuracy.

| Instantâneo para atacado | Opções típicas | Notes for Germany |

|---|---|---|

| MOQ | 20–50 kits per spec | Determines batching efficiency and price breaks |

| Prazo de execução | 4–8 weeks after spec sign-off | Add time for private-label packaging |

| Kitting | 0–2 in-lbs preloaded coilovers; rear shocks with boots | Pre-assembled fronts minimize install errors |

| Docs | TÜV test pack, torque cards, install manual (DE/EN) | Supports inspections and faster approvals |

| Marca | White label or co-brand | Maintain serials for traceability |

These parameters help set realistic distribution calendars. Clear specs up front—ride height targets, weight assumptions, and regional accessories—prevent rework and ensure each kit arrives TÜV-ready with minimal installer friction.

How to Choose Shock Absorbers for Off-Road Industrial Applications

Industrial Tacomas—utility, forestry, telecom—operate in long, repetitive cycles with variable payloads. Shock selection starts with a sober review of duty cycle, not just the desired lift. Consider hours at temperature, average speed on rough surfaces, and the frequency of maximum GVW. From there, choose architecture and materials that maintain consistent damping at working heat.

- Define duty cycle and payload envelope, then align architecture (e.g., remote-reservoir monotube for thermal stability).

- Specify corrosion defense appropriate to winter brine—treated hardware, coated springs, and high-quality wipers.

- Validate with instrumented loops (temps, stroke histograms), then lock final valving for the fleet’s real-world pattern.

- Document torque specs, nitrogen pressure, and maintenance intervals to preserve consistency over time.

| Selection factor | Industrial priority | Recommended approach | Example note |

|---|---|---|---|

| Estabilidade térmica | Elevado | Remote reservoir, larger oil volume | Sustains damping on long washboard |

| Corrosion defense | Elevado | Coated shafts, stainless fasteners | Winter brine + frequent washing |

| Damping curve | Médio–Alto | Reservatório remoto ou piggyback para resfriamento | Balances load with comfort |

| Capacidade de manutenção | Elevado | Rebuildable design, common spares | Minimizes downtime |

| Compliance needs | Elevado | TÜV-ready documentation pack | Smooth registration process |

| Use-case label | Advanced Shock Absorbers for Toyota Tacoma Off-Road Applications | Tailored valving by load profile | Ensures spec fidelity |

The final row ties selection back to your program’s naming and documentation. If you run mixed fleets, harmonize service parts (seals, bushings) to reduce inventory complexity and technician training time.

Client Success Stories: Off-Road Suspension in German Industries

A Bavarian forestry contractor moved from twin-tube shocks to remote-reservoir monotubes on Tacoma crew cabs carrying saws, winches, and bed-mounted tanks. Prior to the change, the trucks faded after long uphill tracks and arrived with overheated dampers. With higher oil volume and progressive compression, the vehicles retained predictable body control and reduced driver fatigue on full-day timber runs.

A wind farm service provider that traverses sandy coastal access tracks faced wheel hop and poor traction when loaded with inspection gear. Re-valving to soften initial compression and adding firmer end-stroke control improved grip without harsh bottoming over dune crests. The change also brought better road stability when commuting at higher speeds between sites.

A utilities firm servicing mountain installations experienced brake dive and headlight misalignment after a moderate lift plus heavy roof payload. Tuning rebound to slow weight transfer and adding a pre-adjusted front coilover assembly restored balance and simplified TÜV approval by presenting more consistent, testable characteristics.

Visual Guide to Off-Road Shock Absorbers for Toyota Tacoma Users

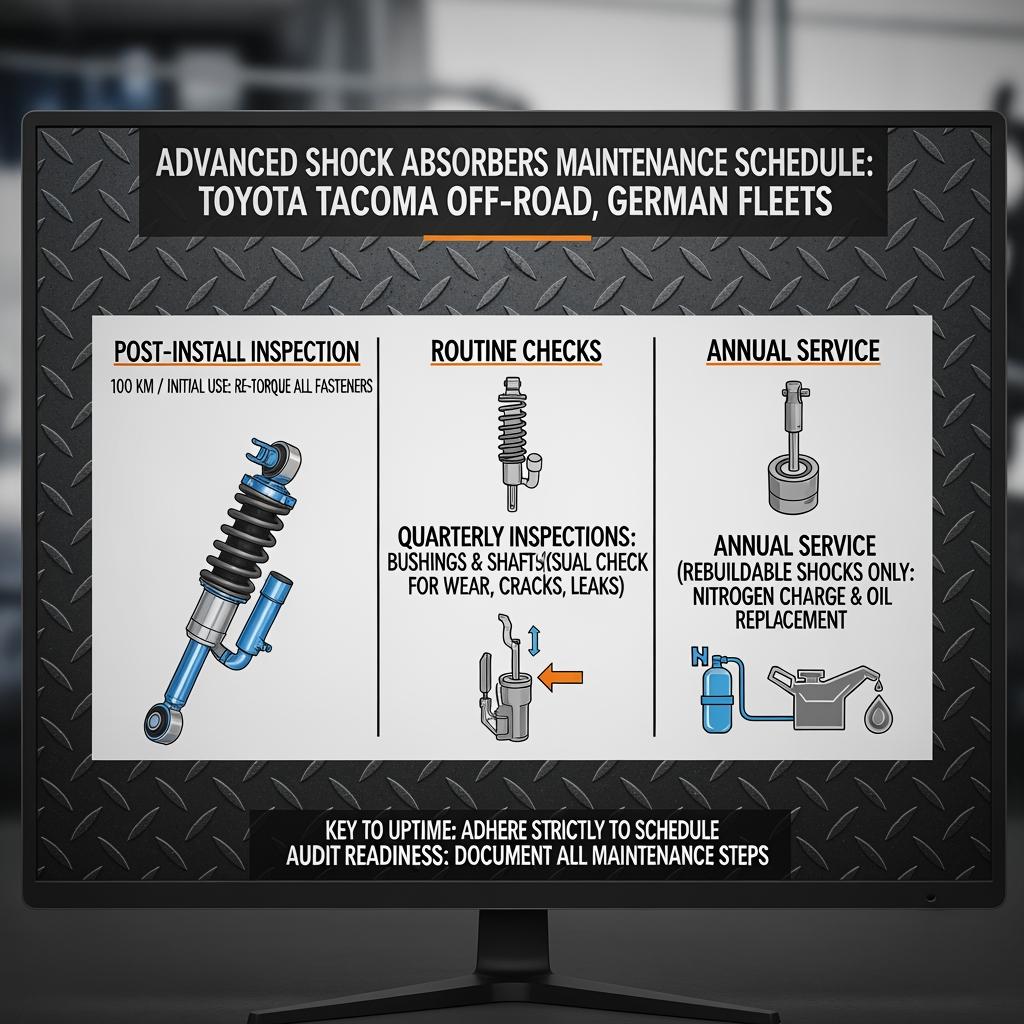

Think of the shock absorber as your vehicle’s motion translator—it turns unpredictable terrain inputs into controlled chassis movement. For a Tacoma navigating Germany’s forests and work zones, visualize three zones: initial stroke for small chatter, mid-stroke for general body control, and end-stroke to prevent harsh bottoming. Reservoir placement affects heat; hose routing and abrasion sleeves should account for winter grit and occasional impacts. Bushings and spherical bearings each have a place—rubber for isolation, spherical for precision under articulation.

Installation success hinges on a clean, methodical process. Pre-torque bushings at ride height to prevent bushing wind-up. Verify brake line and ABS sensor slack at full droop and full lock. After installation, perform a short heat cycle in mixed conditions and re-check torque. Document ride height, fender-to-hub measurements, and any alignment changes for your TÜV file.

FAQ: Advanced Shock Absorbers for Toyota Tacoma Off-Road Applications

What makes advanced shock absorbers different for Toyota Tacoma off-road use in Germany?

They use higher oil volume, better heat dissipation, corrosion-resistant hardware, and tuned valving matched to German terrain and legal constraints, delivering stable damping across long duty cycles.

Do I need TÜV approval for advanced shock absorbers on my Tacoma?

If the suspension changes ride height or materially affects handling, yes—TÜV inspection and documentation are typically required to keep the vehicle road-legal in Germany.

Are remote-reservoir shocks worth it for Advanced Shock Absorbers for Toyota Tacoma Off-Road Applications?

For long transport legs and demanding trails, reservoirs significantly reduce fade and keep damping consistent, especially with mixed payloads or frequent high-speed sections.

How often should industrial fleets service advanced Tacoma shocks?

After initial 100 km torque re-checks, quarterly inspections for bushings and shafts are prudent, with annual service for rebuildable units used in heavy-duty cycles.

Will advanced shocks improve on-road comfort on the Autobahn?

Properly tuned shocks improve stability and control; comfort depends on balancing compression and rebound with tire choice and load. A good tune can reduce harshness while preserving precision.

Can advanced shocks coexist with lift kits and larger tires?

Yes, but they must be tuned for the new leverage and mass. Confirm bump stop engagement, alignment, and braking behavior, then document for TÜV.

How do I get a custom tune for my Tacoma’s specific loadout?

Provide axle weights, accessory list, predominant terrain, and duty cycle. A manufacturer can propose valving, run a pilot set, and refine based on your feedback and test logs.

Last updated: 2025-11-04

Registro de alterações:

- Added TÜV preparation checklist and clarified documentation sequence.

- Expanded terrain-specific engineering notes for Black Forest, Alps, and dunes.

- Included wholesale distributor snapshot with MOQ and lead time guidance.

- Added maintenance-focused image guidance and industrial selection matrix.

Next review date & triggers: 2026-02-01 or upon major TÜV requirement change, new Tacoma model update, or distributor feedback on kit packaging.

G·SAI can customize, certify, and supply advanced Tacoma shock solutions for Germany—from prototype tuning to wholesale kits. Share your specs to get a quote, samples, or a custom suspension plan aligned to your terrain and TÜV timeline.

Start your project now by sending requirements to the G·SAI team.