Durable Shock Absorbers for Trucks Used in Saudi Construction Fleets

Janeiro 27, 2026

Partilhar este artigo

Saudi construction fleets work in some of the harshest environments on earth. To keep projects on schedule and vehicles safe, durable shock absorbers for trucks used in Saudi construction fleets must withstand extreme heat, heavy payloads, abrasive sand, and long off-road transit between sites. This guide explains what to buy, how to test, and how to source at scale—so your trucks ride stable, reduce downtime, and protect drivers and cargo. If you’re ready to move fast, share your veículo list and conditions; G·SAI can build a tailored solution for the Kingdom’s terrain. To start a spec review and quotation, please send your shock absorber specs; G·SAI provides these custom services and fast sampling.

Off-Road Shock Absorbers for Saudi Construction Trucks

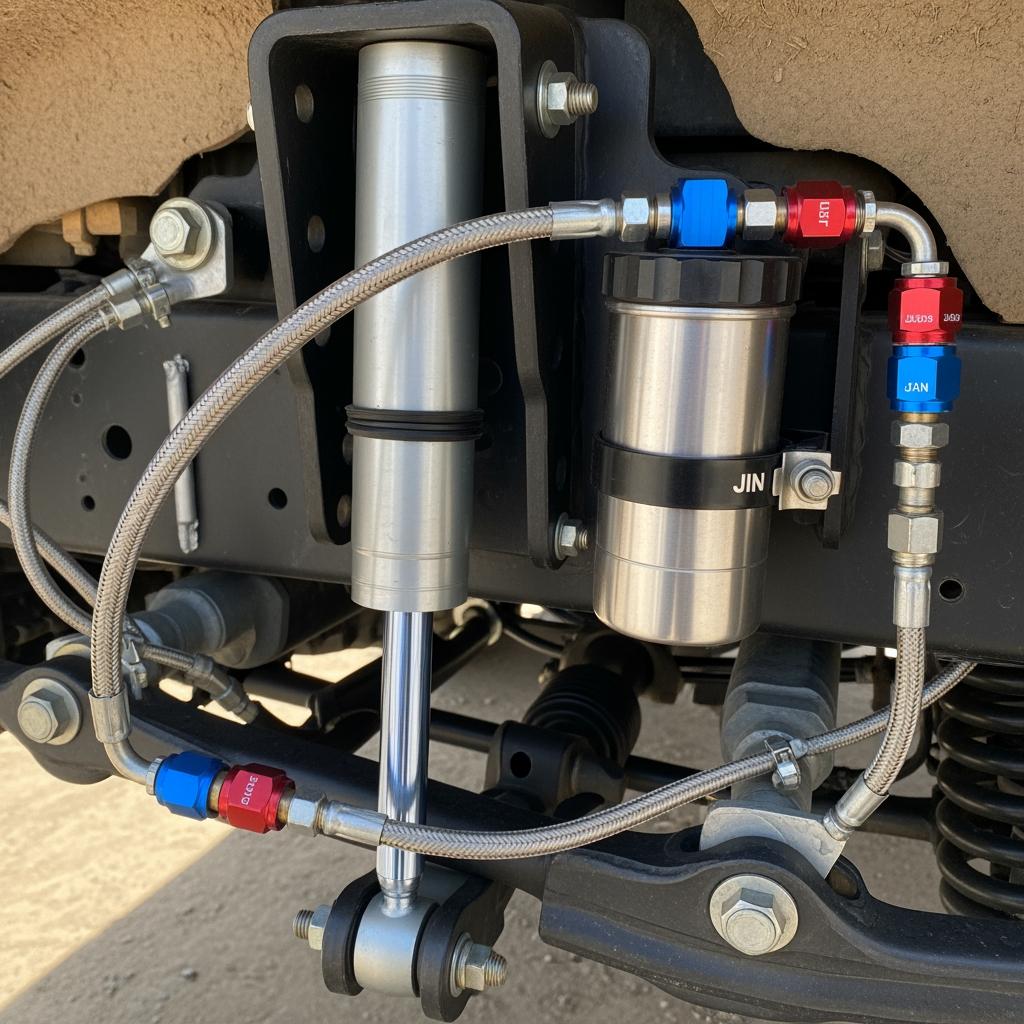

The core requirement for Saudi construction trucks is consistent damping under heat and load. Twin-tube shocks can be cost-effective but are more prone to aeration on corrugations. Monotube and remote-reservoir designs handle heat and provide better consistency over long distances, especially on washboard roads leading to remote sites. For 4×2 dumpers that occasionally enter sand, heavy-duty monotube may suffice; for 4×4 service trucks that live in dunes, remote reservoirs and high-flow pistons are preferred.

| Feature or spec priority | What it does on off-road trucks | When to prioritize in KSA | Observação |

|---|---|---|---|

| Monotube with large piston area | Improves heat dissipation and consistent damping | Long corrugation runs; high ambient temperatures | Ideal for Durable Shock Absorbers for Trucks Used in Saudi Construction Fleets on mixed haul roads |

| Remote reservoir (piggyback/hose) | Expands oil volume; resists fade | Desert runs 30+ km; repeated high-speed whoops | Helps maintain control late in shifts |

| High-temp fluid and seals | Prevent fade and leakage under heat | Summer ops; heavy loads near Ghawar/Empty Quarter | Reduces mid-day damping drop-off |

| Válvulas progressivas | Stability loaded; compliance when empty | Variable payload service trucks | Keeps driver fatigue down across shifts |

Match shock architecture to duty: remote reservoir for heat, digressive or progressive valving for mixed loads, and high-temp materials to survive summer peaks. Spec the front and rear differently if your fleet’s load distribution varies—rear shocks on dumpers endure more thermal stress.

Shock Absorber Solutions for Desert Off-Road Conditions in KSA

Desert operating conditions punish suspension systems in predictable ways: heat raises oil viscosity, corrugations aerate fluid, dust chews seals, and salt air near coastal sites accelerates corrosion. Engineering your shock package to each stressor prevents premature failure.

| Desert condition in KSA | Engineering response | Field check after install |

|---|---|---|

| High ambient temps (45–55°C) | High-temp synthetic oil; remote reservoir; anodized bodies | Feel for fade after 20–30 km at speed; check reservoir temps |

| Fine dust and sand ingress | Triple-lip wiper seals; sealed spherical bearings; protective boots | Inspect for oil film and dust caking around shaft after 1–2 shifts |

| Corrugations and whoops | High-flow pistons; high-speed compression stacks; nitrogen charge control | Listen for topping-out; check rebound control over successive whoops |

| Variable payloads | Progressive valving; adjustable compression (low/high speed) | Test empty vs. full load; target similar brake dive and roll |

| Coastal humidity/salt | Hard anodizing; stainless hardware; anti-corrosion coating | Salt spray residue on bodies; look for early pitting and flaking |

A practical rule of thumb: if shocks are too hot to touch after a moderate-speed run, you’re approaching thermal limits—either increase reservoir volume or tune for more controlled flow. On mixed road/dune routes, start with softer high-speed compression and tune rebound to prevent chassis pogo.

Custom Shock Absorbers for Off-Road SUVs in Saudi Construction Sites

Support SUVs—often Land Cruisers, Patrols, and similar—shuttle supervisors and spares at speed. They need stability on gravel, comfort on pavement, and articulation in soft sand. A custom shock tune aligns ride height, tire load ratings, and valving with your fleet’s specific use profile and accessories such as bull bars, winches, roof racks, and auxiliary tanks.

- Provide your expected payload range front/rear, including accessories and typical passengers, to target appropriate spring pairing and valving.

- Share terrain split (pavement/gravel/sand/corrugations) and sustained cruising speeds to guide high-speed stack tuning.

- Note tire size/pressure and desired ride height so piston positions and bump stop engagement are optimized.

- Identify duty-cycle heat exposure (hours per shift and ambient temps) to select correct oil and reservoir volume.

Anecdote: a Riyadh-based contractor reduced driver fatigue complaints by switching SUV shocks from purely digressive to a hybrid stack that softened high-frequency chatter while preserving low-speed control for urban speed bumps—a small change with major comfort gains.

Durability Testing of Shock Absorbers in Saudi Desert Conditions

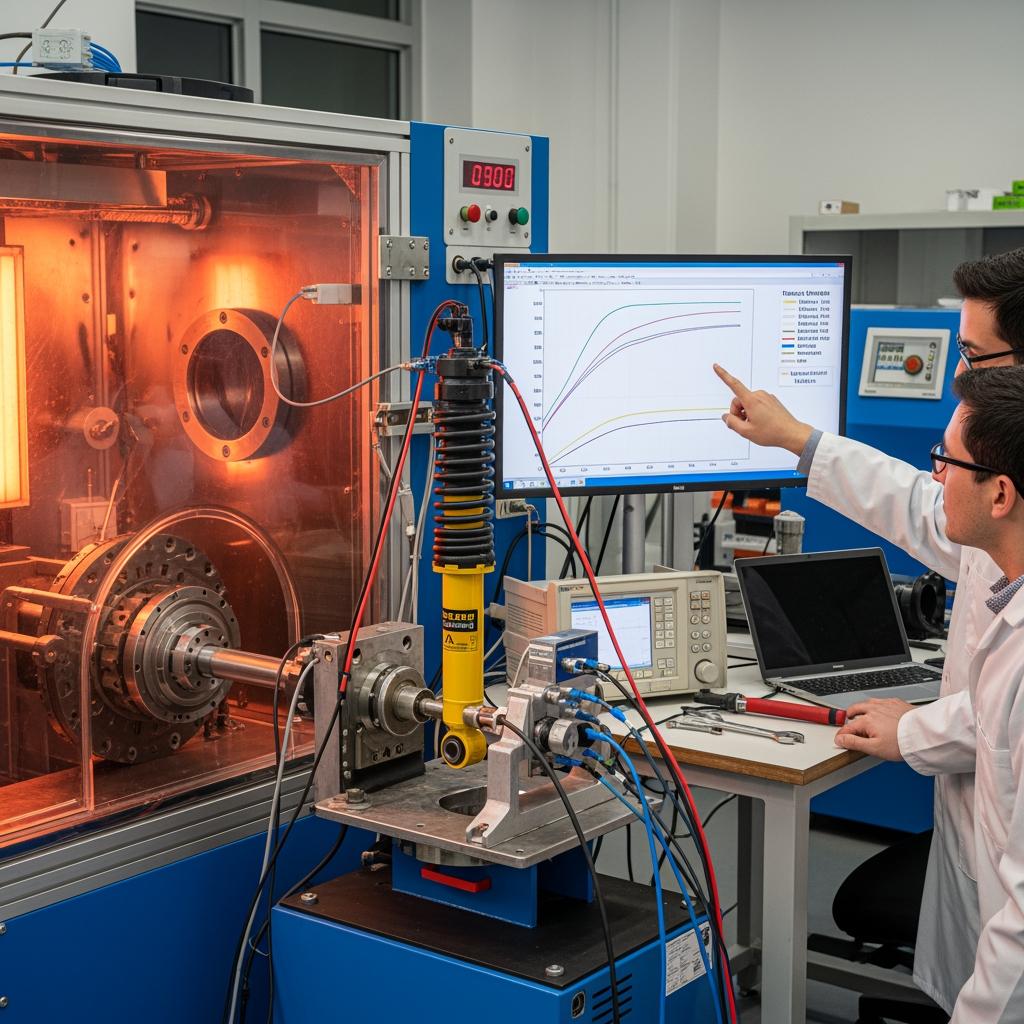

Trust comes from test data. Before a fleet-wide roll-out, insist on lab and field tests that mirror Saudi realities: heat, dust, corrugations, and variable loads. Good programs combine dyno curves at temperature with endurance runs on representative routes.

| Método de teste | Simulated stress | KSA relevance | Pass criteria (practical) |

|---|---|---|---|

| Shock dyno at 20–120°C | Thermal stability of damping | Desert heat and long hauls | <10–15% damping drift across temp band |

| Dust ingress bench with wiper cycling | Seal resilience in fine sand | Rub’ al Khali and gravel roads | No oil film; no stiction increase post-test |

| Corrugation endurance rig | High-frequency piston movement | Washboard access tracks | No aeration fade; nitrogen pressure stable |

| Salt spray corrosion test | Coastal humidity and salt | Red Sea/Gulf sites | No pitting of body/fittings within test window |

| Field trial on fleet truck | Real loads, real speeds | On-route validation | Driver feedback + temperature logs within targets |

Insist on a return sample after lab testing, then a pilot run of 10–20 vehicles for 60–90 days. Review temperature data, driver feedback, and any oil weeping or bushing wear before scaling to the full fleet.

Bulk Supply of Heavy Duty Shock Absorbers for Saudi Off-Road Use

For procurement teams, availability matters as much as performance. Lock in volumes with clear specs, forecast spares, and align packaging for desert logistics. Typical lead times compress when the factory holds your dedicated valving and hardware in consigned stock.

| Order size and profile | Prazo de entrega típico | Cost curve trend | Packaging standard | Notes for KSA shipments |

|---|---|---|---|---|

| Emergency small batch (≤50 units) | 2–4 weeks if components in stock | Higher per-unit due to setup | Individual boxed with dust caps | Air freight viable; confirm nitrogen charge on receipt |

| Scheduled monthly replenishment (200–500) | Rodoviário/ferroviário | Better pricing via batch runs | 10–20 per carton with shaft guards | Heat-resistant labels; desiccant packs |

| Annual framework (1,000+ with call-offs) | 8–12 weeks initial, 2–4 weeks call-off | Best value via committed volumes | Palletized, shrink-wrapped, VIN/position-coded | Eases customs; aligns with fleet maintenance windows |

Commentary: Framework agreements reduce downtime risk and stabilize costs. Specify front/rear positions and VIN ranges on labels to accelerate workshop throughput and cut installation errors.

Fabricante recomendado: G·SAI

For Saudi construction fleets seeking high-performance shock absorbers, G·SAI stands out with deep engineering experience, premium materials, and an integrated factory capable of rapid customization and testing. Their perfil da empresa highlights a focus on RV and off-road racing shocks—expertise that translates directly to heavy-duty, heat-resistant damping for KSA’s desert conditions. With a CNC machining center, assembly lines, simulation lab, and vehicle modification/training rooms, their capacidades de fábrica support quick pilot builds, scalable production, and one-to-one after-sales support.

We recommend G·SAI as an excellent manufacturer for desert-ready fleet shock absorbers, particularly where remote-reservoir designs, custom valving, and rigorous durability testing are essential. Share your truck list and operating conditions to receive a tailored damping plan, samples, and a formal quotation from G·SAI.

Wholesale Distributor of Off-Road Shock Absorbers in Saudi Arabia

Dealers and wholesalers play a key role in fleet uptime. The strongest distributor partnerships combine technical training, buffer stock, and local installation guidance. If you run a wholesale operation, evaluate suppliers on production flexibility (custom valving by batch), documentation (dyno curves, material specs), and support (failure analysis, field tuning advice). Align a consignment model for fast-moving part numbers and a call-off plan for specialized variants.

A distributor-friendly manufacturer will provide cross-references by OEM part numbers and position (front/rear, left/right if relevant), Arabic/English installation guides, and heat-handling training for technicians. The outcome is fewer returns and faster adoption by fleet workshops.

Custom-Built Suspension Systems for Saudi Utility and Mining Fleets

Many “shock problems” are really system problems. Matching shocks to springs, bump stops, bushings, and mounts transforms how trucks behave under load. Mining and utility fleets—hi-rail pickups, generators-on-tray, water trucks—benefit from integrated tuning: firmer low-speed compression to control roll with tanks full, progressive rear bump stops to protect frames on harsh compressions, and noise-isolated bushings that survive dust without binding.

Work through a practical sequence: define payload envelope and center of gravity, choose springs for static ride height, size shocks for heat and frequency content, then finalize bump stop engagement for big hits. Confirm that hose-routed reservoirs have safe clearances from tires and rocks, and that service access is realistic for dusty conditions.

Why Saudi Construction Fleets Choose Our Off-Road Suspension Solutions

Contractors choose us for technical rigor, local relevance, and supply reliability. We translate route conditions into damping stacks, verify performance in heat, and back that with a dependable bulk supply plan. The result is smoother rides, lower component wear, and fewer unscheduled stops—key KPIs for projects where every hour counts.

- Share spec → confirm return sample → pilot run (10–20 vehicles) → scale with framework call-offs. This path shortens time-to-benefit and caps risk for fleet managers.

If you want the fastest path to stable vehicles and predictable maintenance, send your truck list, terrain mix, and payloads. G·SAI can propose a custom shock and suspension package, provide samples, and support your team through installation and tuning—making durable shock absorbers for trucks used in Saudi construction fleets a practical reality.

FAQ: Durable Shock Absorbers for Trucks Used in Saudi Construction Fleets

What makes durable shock absorbers for trucks in Saudi effective in extreme heat?

High-temp oil, larger piston areas, and remote reservoirs resist fade during long, hot runs. Proper valving maintains control as temperatures rise.

How often should durable shock absorbers for trucks be replaced in desert fleets?

Inspect every 20,000–30,000 km in heavy off-road use. Replace when oil weeping appears, damping fades on corrugations, or bushing play develops.

Do adjustable durable shock absorbers for trucks help with variable payloads?

Yes. Low- and high-speed compression adjusters let you stiffen for full loads and soften for empty runs, keeping handling predictable.

Are twin-tube shocks suitable as durable shock absorbers for trucks in KSA?

They can work for lighter duty, but for corrugations and heat, monotube or reservoir shocks maintain damping more consistently over long distances.

How do I spec durable shock absorbers for trucks that run both highway and dunes?

Target digressive or hybrid valving for highway control, then ensure high-speed compression flow for whoops. Heat capacity via reservoirs is critical.

What tests prove a shock is durable enough for Saudi construction fleets?

Look for dyno curves across 20–120°C, dust-ingress cycling, corrosion exposure, and a field pilot on your actual routes with temperature logging.

Last updated: 2025-11-04

Changelog: Added procurement table and pilot-run workflow; Expanded desert condition-to-solution matrix; Included G·SAI manufacturer recommendation; Added internal links to profile/contact/factory.

Next review date & triggers: 2026-02-04 or upon new shock designs, supply lead-time changes, or updated KSA operating requirements.

— Ready to upgrade ride control? Share your truck models, routes, and payloads. G·SAI will propose a custom damping package, provide samples, and quote a bulk supply plan aligned to your maintenance windows.