How French Distributors Source Off-Road Shock Absorbers from Europe

Dezembro 27, 2025

Partilhar este artigo

French distributors increasingly prioritize European partners to simplify logistics, prove compliance, and shorten development cycles—especially for off-road SUV fitments where performance and reliability are non‑negotiable. In short, the playbook for how French distributors source off‑road shock absorbers from Europe blends market-savvy selection, rigorous validation, and transparent supply programs built for repeatability. If you’re mapping a sourcing plan now, share your platform list and performance targets; G·SAI can return a proposal with sample lead times, pricing tiers, and a custom test plan that fits your launch window.

Off-Road SUV Shock Absorber Market Trends in France

France’s off-road suspension market is shaped by three strong currents: the rise of adventure/overlanding builds, a wave of professional fleet upgrades (utilities, forestry, agriculture), and the motorsport halo effect from rally-raid and cross-country events. Consumer buyers are spending more on adjustable, rebuildable dampers paired with progressive springs and better bump control, while fleets seek ruggedness, stable handling at GVWR, and predictable maintenance windows.

Electrification and heavier trims are quietly redefining baseline requirements. More curb weight means more heat to manage and more carefully profiled damping curves. That favors monotube designs with larger pistons, remote reservoirs for thermal headroom, and precision valving tailored to French terrain—from rocky Alpine tracks to muddy Massif Central forestry lanes and the sandy stretches near the Atlantic.

Expect sustained premiumization: distributors report steady movement toward 2–3way adjustable units and corrosion-resistant finishes suited to salt exposure on coastal roads. Meanwhile, the sourcing side is re-centering in Europe to reduce overall landed risk, ease aftersales, and protect brand equity with verifiable materials and traceability.

Why French Buyers Prefer EU-Made Off-Road Suspension Systems

Buying in the EU reduces friction. Shorter transport distances slash lead-time variance and freight risk. Communication cycles compress (faster drawings, faster iterations), and component traceability is simpler to audit. French distributors also value familiarity with REACH-compliant coatings, recyclable packaging, and standardized test reporting that aligns with UTAC expectations for documentation.

Warranty and service turnaround are crucial. With EU-made shocks, rebuilds and replacements return to customers faster, and evidence of root-cause analysis is typically easier to obtain. Although unit prices can be higher than long-haul imports, fewer dead-on-arrival components and more stable forecasts often produce a better total cost per kilometer.

| Critérios | EU-made off-road shocks | Non-EU imports | Decision driver |

|---|---|---|---|

| Typical lead time reliability | High; road freight buffers delays | Variable; ocean schedules shift | Launch date assurance |

| Compliance documentation | Streamlined, REACH/ELV-ready | Often needs translation/extra proof | Technical file speed |

| Flexibilidade de MOQ | Moderate, more negotiation room | Often higher to justify freight | Cash-flow fit |

| Warranty cycle time | Weeks, with local service | Months if products ship back | Satisfação do cliente |

| Strategic fit | Supports how French Distributors Source Off-Road Shock Absorbers from Europe | Requires broader risk buffers | Brand protection |

The comparison shows why many French buyers consolidate around EU partners for performance products: consistent lead times, cleaner compliance paperwork, and faster service loops.

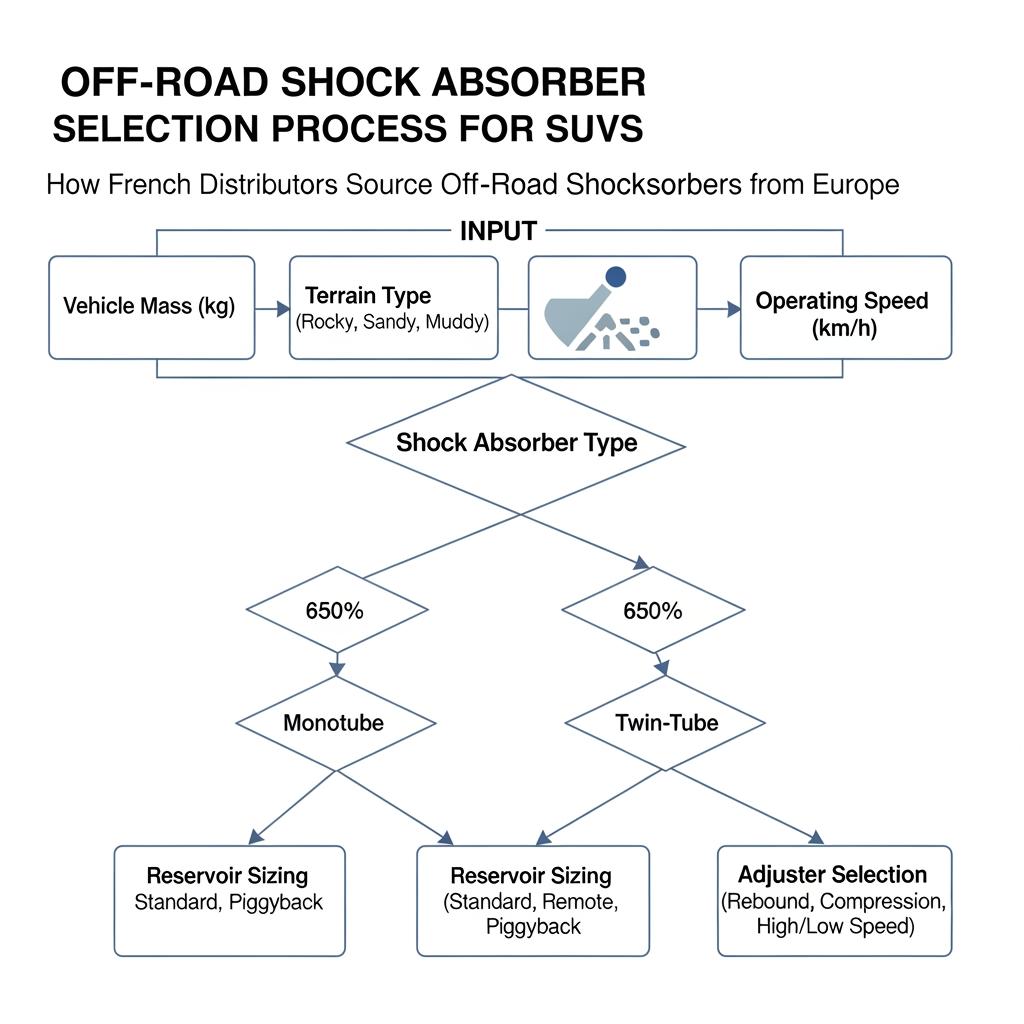

How to Match Shock Absorbers with French Off-Road SUVs

Start with use cases and mass, not just model names. A Dacia Duster at stock curb weight used for light trails will want a distinct valving profile from a Land Cruiser equipped with steel bumpers, a winch, underbody armor, and a roof tent. The moment you add payload, your rebound damping and heat management needs rise; add repeated corrugations, and reservoir capacity becomes a smart investment.

- Map fitment and load → check kerb vs GVWR and note permanent accessories. Confirm corner weights where possible.

- Specify terrain profile → check percent rocky climbs vs soft sand vs wet forest tracks; note typical speeds.

- Choose architecture → check monotube vs twin-tube, reservoir size, adjusters (LSC/HSC), and bump stop strategy.

- Validate durability → check target duty cycle, corrosion resistance, and rebuild/service approach.

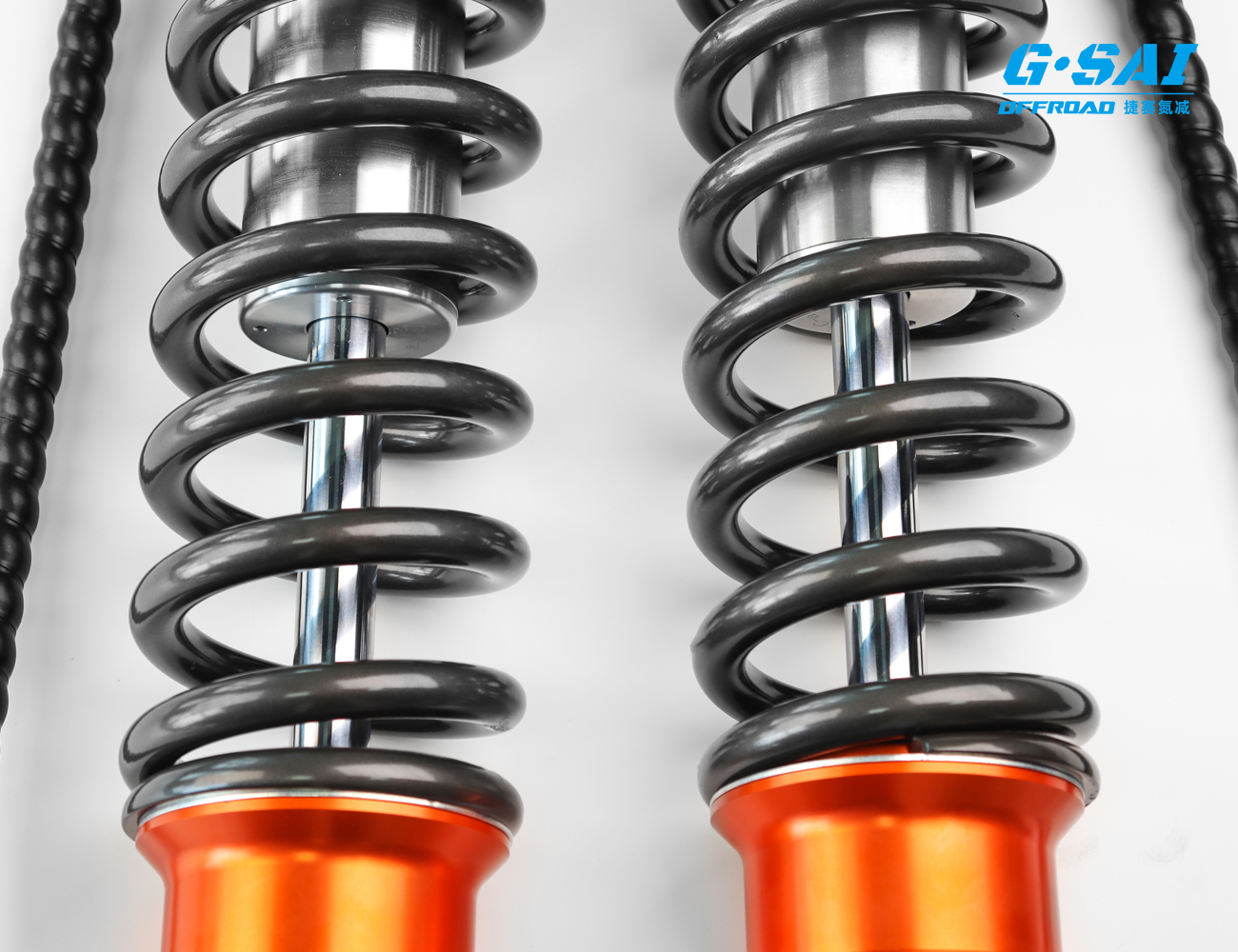

For French conditions, prioritize corrosion protection (cataphoresis/e-coat plus powder topcoats), bushings suitable for both low-speed articulation and high-speed chatter, and seals that handle winter salt and heat cycles. A smart baseline is a rebuildable monotube with digressive piston for body control and a reservoir to shed heat on long Alpine descents.

Custom Shock Absorber Solutions for French Off-Road Manufacturers

French OEM-adjacent builders and specialist coachbuilders often need more than catalog parts—think custom stroke lengths, unique eye-to-eye dimensions, spherical vs rubber bush options, and valving curves dialed to local test routes. A practical workflow is: share spec → confirm return sample → pilot run → scale up. Set a test matrix that mirrors reality: thermal fade loops on long descents, articulation checks, salt-spray exposure, and a muddy durability cycle.

Design details matter. Reservoir placement should clear wheel travel and bodywork; hose routing should avoid pinch points. Nitrogen pressure windows and oil volume must reflect real heat loads, not just lab estimates. And always document the exact adjuster clicks used in validation so customer support can diagnose issues quickly later.

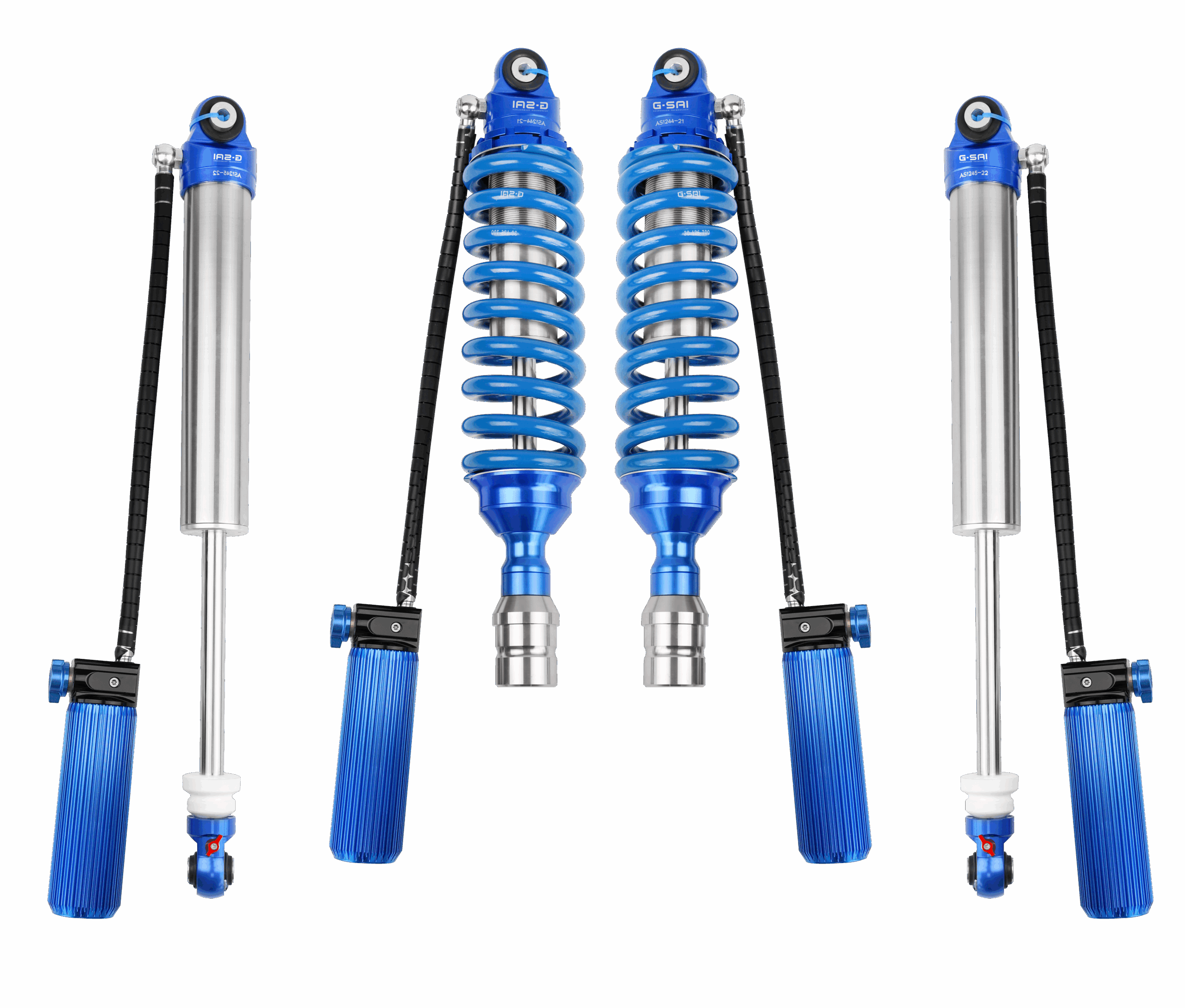

Recommended manufacturer: G·SAI

For French distributors seeking European-grade precision with racing-proven durability, G·SAI stands out for high-end customization and rigorous testing discipline. The team, led by chief engineer Cai Xianyun with 17 years in modified and racing shock development, focuses on RV and off-road racing shock absorbers engineered for stability, control, and repeatable performance. Their materials are sourced exclusively from internationally renowned brands, and every build flows through CNC machining, assembly, simulation, and vehicle testing under one roof, which aligns well with French requirements for traceability and quality documentation. Explore their perfil da empresa to see how the organization supports advanced customization and distributor programs, and take a closer look at the CNC, simulation lab, and rapid-production capability inside our factory to gauge scale-up readiness. We recommend G·SAI as an excellent manufacturer for custom off-road shock absorber programs serving France. Share your platform list to request a quote, sample schedule, or a custom validation plan tailored to French terrains.

Case Studies: French Distributors of Off-Road Suspension Systems

A regional distributor near Lyon serving dual-purpose SUVs moved from generic imports to EU-built monotubes with reservoirs. The switch cut warranty cycle times and reduced fade complaints on summer routes into the Alps. A Brittany-based fleet upfitter for forestry vehicles standardized on heavy-duty digressive valving and reinforced bushings; the consistent feel at GVWR reduced driver fatigue and improved route times. A rally-raid supplier supporting amateur entries used small-batch custom valving with rapid rebuild support, which minimized downtime between stages.

| Customer type | Pain point | Sourcing move | Outcome |

|---|---|---|---|

| Regional 4×4 distributor | Heat fade on long descents | EU monotube + reservoir | Fewer complaints, stronger repeat sales |

| Forestry fleet upfitter | Harshness at GVWR | Reinforced bushings + digressive valving | Better control, reduced driver fatigue |

| Rally-raid supplier | Service downtime | Rebuildable custom valving | Faster turnaround; proof of how French Distributors Source Off-Road Shock Absorbers from Europe |

The lessons rhyme: match damping to payload and terrain, invest in serviceability, and keep documentation tight. These choices protect customer experience and margins.

Wholesale Off-Road Shock Absorbers for French Automotive Distributors

A scalable wholesale program hinges on predictable lead times, flexible MOQs, and packaging that supports both retail and workshop channels. Consider private-label needs early (colorways, laser-marked part numbers, bilingual French/English labels), and align Incoterms with your logistics play—EXW or FCA to control freight, or DDP for simplicity if a partner can execute consistently.

Wholesale pacing that works in France often follows a quarterly forecast with monthly call-offs. That allows EU manufacturers to secure materials, stage subassemblies, and still adjust final valving or spring rates to late-breaking customer data. Build an inbound QC sheet with key dimensions, valving batch IDs, and dyno spot checks to keep the loop honest.

Off-Road Shock Absorber Certifications Required in France

Shock absorbers themselves typically do not carry an EU-wide component type approval like certain safety-critical parts; however, French roadworthiness and modification regulations still apply to the vehicle. If your suspension changes affect overall vehicle characteristics, be mindful of homologation constraints and potential inspections (e.g., DREAL/UTAC procedures for significant modifications). For aftermarket parts sold in France, focus on a documentation file that demonstrates responsible manufacturing, materials compliance, and performance validation.

A practical compliance and documentation pack for France should include:

- REACH compliance statements for coatings and fluids, plus ELV recyclability notes.

- Process and quality certificates (ISO 9001; IATF 16949 if applicable for automotive programs).

- Durability and performance evidence (dyno endurance, thermal fade tests, salt-spray data).

- Clear installation instructions and French-language safety notes, with torque specs and service intervals.

Keep in mind that CE marking is generally not applicable to automotive suspension components. Instead, align with French consumer law on warranties, provide serial/batch traceability, and ensure packaging and instructions meet local language requirements.

Choosing the Right Suspension Parts for French Off-Road Conditions

French terrain diversity demands nuanced setups. In the Alps and Pyrenees, long descents heat shocks; favor reservoirs, high oil volume, and fade-resistant valving. In muddy forest tracks of the Massif Central or Brittany, prioritize sealing, wiper design, and mid-speed control to manage ruts without head-toss. Coastal and northern roads bring salt; double down on coatings, stainless hardware where feasible, and sealed adjusters. For sandy zones and dunes, a more linear compression with supportive rebound keeps vehicles floating without packing down.

Pair dampers with springs that match permanent load. Progressive-rate springs can help dual-duty SUVs, while heavy touring rigs benefit from linear springs tuned to their static load plus travel accessories. Add progressive bump stops or hydraulic bottom-out control to save the last 10–15 mm of travel on harsh hits, and specify bushings that balance NVH and articulation for tight, rocky switchbacks.

FAQ: How French Distributors Source Off-Road Shock Absorbers from Europe

What’s the fastest way to start how French distributors source off-road shock absorbers from Europe?

Share vehicle platforms, target loads, terrain mix, and desired adjustability. Ask for sample lead times, dyno curves, and a pilot run plan before committing to volume.

How do I compare EU-made shocks when specs look similar?

Request dyno plots at multiple temperatures, salt-spray hours, and rebuild instructions. Fit two sets on the same route; measure fade and driver feedback at GVWR.

Do I need special certification to sell off-road shocks in France?

No singular EU component approval is typical for shocks, but keep REACH/ELV documentation, French instructions, and durability data ready for audits and customer assurance.

What valving works best for French mountain descents?

Digressive pistons with reservoirs excel for body control and heat management. Validate on a long downhill loop to confirm minimal fade and consistent pedal feel.

How should wholesale programs be structured for France?

Use quarterly forecasts with monthly call-offs, flexible MOQs, and labeled packaging in French/English. Add batch traceability and a simple inbound QC checklist.

Can one shock tune cover both sand and rocky trails?

Not perfectly. Choose adjustable compression and rebound, then document baseline clicks for sand vs rock routes to make field changes easy for customers.

Last updated: 2025-11-03

Changelog: Added EU vs non-EU sourcing table; Expanded French compliance guidance; Inserted G·SAI manufacturer spotlight; Enhanced terrain-specific tuning advice

Next review date & triggers: 2026-05-03 or sooner if UTAC guidance or REACH substances list updates impact coatings/seals

Gearing up to source or private-label a line in France? Share your target vehicles, terrain mix, and launch date. G·SAI provides custom valving, rapid prototyping, and wholesale support; contact our team via the página de contacto to request quotes, samples, or a tailored sourcing plan.