Amortecedores de nitrogénio para camiões do Médio Oriente: Um guia completo para compradores B2B

30 de junho de 2025

Partilhar este artigo

O que são Amortecedores de Nitrogênio? Compreendendo a Tecnologia por Trás do Desempenho

Amortecedores de nitrogênio, também conhecidos como amortecedores carregados com nitrogênio, são componentes de suspensão avançados que utilizam gás nitrogênio comprimido para melhorar o desempenho de amortecimento, a estabilidade e a dissipação de calor. Esses amortecedores são especialmente valiosos para caminhões pesados que operam em climas extremos, como os encontrados em todo o Oriente Médio.

Como Funcionam os Amortecedores de Nitrogênio?

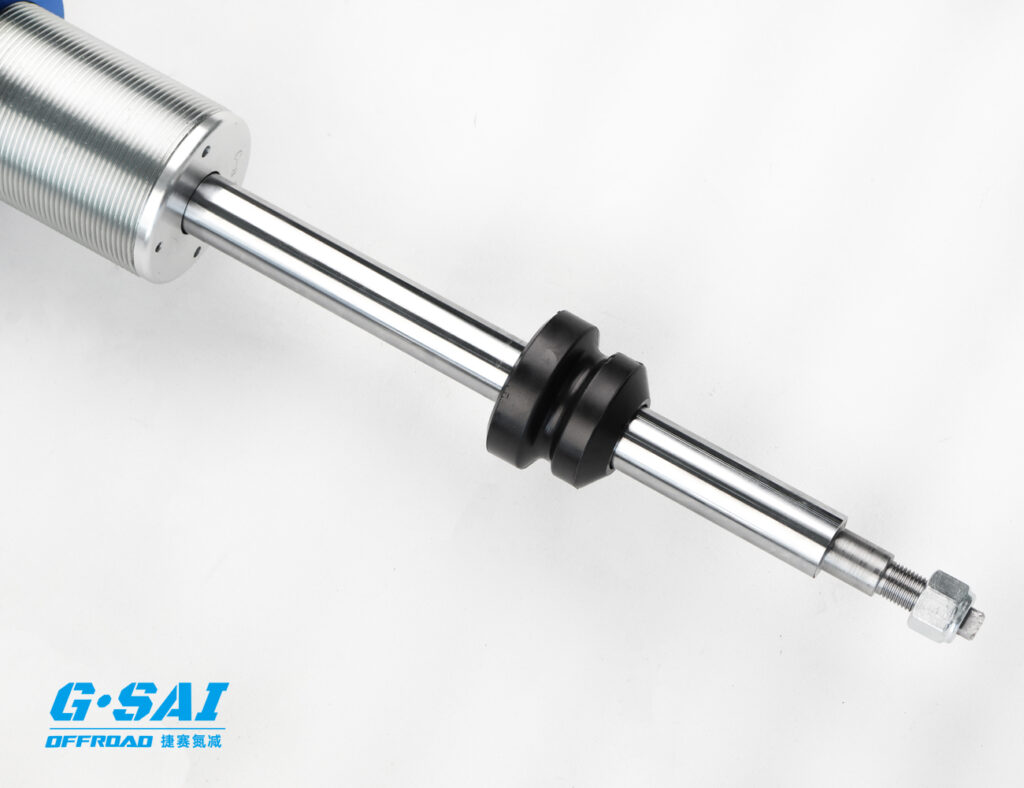

Os amortecedores de nitrogênio combinam óleo hidráulico com gás nitrogênio pressurizado dentro de uma câmara selada. O nitrogênio impede que o óleo espume sob alta tensão, garantindo um amortecimento consistente e reduzindo a fadiga durante o uso prolongado.

| Componente | Função |

|---|---|

| Hidráulico Fluido | Fornece resistência ao movimento e absorve choques |

| Gás Nitrogênio | Mantém a pressão, evita a cavitação e melhora a resposta do amortecedor |

| Pistão e Válvula | Regula o fluxo de fluido e controla o comportamento da suspensão |

| Reservatório Externo (Opcional) | Melhora o resfriamento e aumenta a área de controle de amortecimento |

Benefícios dos Amortecedores de Nitrogênio para Caminhões Comerciais

- Gerenciamento de Calor Aprimorado: Crucial em climas quentes como Arábia Saudita, Emirados Árabes Unidos e Omã

- Fadiga Reduzida: Mantém o desempenho em longas distâncias e terrenos acidentados

- Estabilidade de Carga Aprimorada: Ideal para caminhões que transportam cargas pesadas ou voláteis

- Vida Útil Mais Longa: Menos desgaste em comparação com amortecedores hidráulicos padrão

Por que Eles Importam no Oriente Médio

Estradas desérticas, calor extremo e cargas pesadas são uma constante nesta região. Os amortecedores de nitrogênio reduzem a frequência de manutenção, melhoram o conforto do motorista e protegem o chassi do veículo — tornando-os indispensáveis para operadores de frota, empresas de logística e revendedores de veículos pesados.

Aplicações de Amortecedores de Nitrogênio na Indústria de Caminhões do Oriente Médio

O Oriente Médio, com seus vastos corredores logísticos desérticos, rotas de abastecimento de campos de petróleo e um setor de construção em expansão, impõe exigências únicas aos sistemas de suspensão de caminhões. Amortecedores de nitrogênio surgiram como a solução preferida para garantir desempenho, segurança e longevidade.

Principais Segmentos da Indústria que Utilizam Amortecedores a Gás

| Segmento do sector | Casos de Uso para Amortecedores a Gás |

|---|---|

| Transporte de Petróleo e Gás | Cargas pesadas, condições off-road, exposição a altas temperaturas |

| Construção e Mineração | Terreno irregular, frenagem frequente e sobrecargas |

| Logística de Longa Distância | Rotas transfronteiriças, alta quilometragem e conforto do motorista |

| Militar e Defesa | Veículos táticos que necessitam de maior manobrabilidade e durabilidade |

| Trailers e Caminhões Modificados | Para uso recreativo e especializado em ambientes desérticos |

Requisitos Regionais de Personalização

- Arábia Saudita: Necessita de amortecedores com capacidade de resfriamento estendida e reservatórios externos

- Emirados Árabes Unidos: Prefere amortecedores ajustáveis para personalização da frota

- Catar e Kuwait: Exigem revestimentos resistentes à ferrugem devido à exposição costeira

- Omã: Prioriza amortecedores para rotas logísticas de montanha

Casos de Uso em Massa e OEM

- Contratos de manutenção de frota

- Fabricantes de equipamentos originais (OEM) de caminhões que exigem amortecedores de alto desempenho pré-instalados

- Atacadistas B2B que fornecem garagens comerciais e centros de serviço

Tipos de Amortecedores de Nitrogênio para Caminhões Pesados e Veículos de Frota

Existem vários tipos de amortecedores carregados com nitrogênio adequados para várias configurações de caminhões e requisitos operacionais. A escolha do tipo certo garante o desempenho ideal e a longevidade do veículo.

Tipos Comuns de Amortecedores a Gás

| Tipo | Descrição | Aplicação Ideal |

|---|---|---|

| Amortecedores a Gás Monotubo | Design de tubo único com gás nitrogênio de alta pressão | Caminhões de longa distância, uso em rodovias |

| Amortecedores a Gás de Tubo Duplo | Design de dois tubos, pressão mais baixa, econômico | Caminhões comerciais leves, veículos de entrega urbana |

| Amortecedores com reservatório remoto | O reservatório de nitrogênio externo aumenta o volume de fluido e o resfriamento | Caminhões off-road, transporte de campos de petróleo, caminhões militares |

| Amortecedores a Gás Ajustáveis | Permite o ajuste manual ou automático dos níveis de amortecimento | Frotas de uso misto, veículos de construção |

| Amortecedores de Corrida para Serviços Pesados | Amortecedores de alto desempenho otimizados para caminhões modificados ou de corrida | Corridas off-road, caminhões de exibição especiais |

Fatores a Considerar para Compradores B2B

- Capacidade de carga: Combine a resistência do amortecedor com o peso típico da carga

- Ambiente operacional: Escolha para deserto, rodovia ou terreno misto

- Ciclos de manutenção: Selecione amortecedores com intervalos de serviço mais longos

- Compatibilidade: Garanta a compatibilidade com as especificações existentes dos veículos da frota

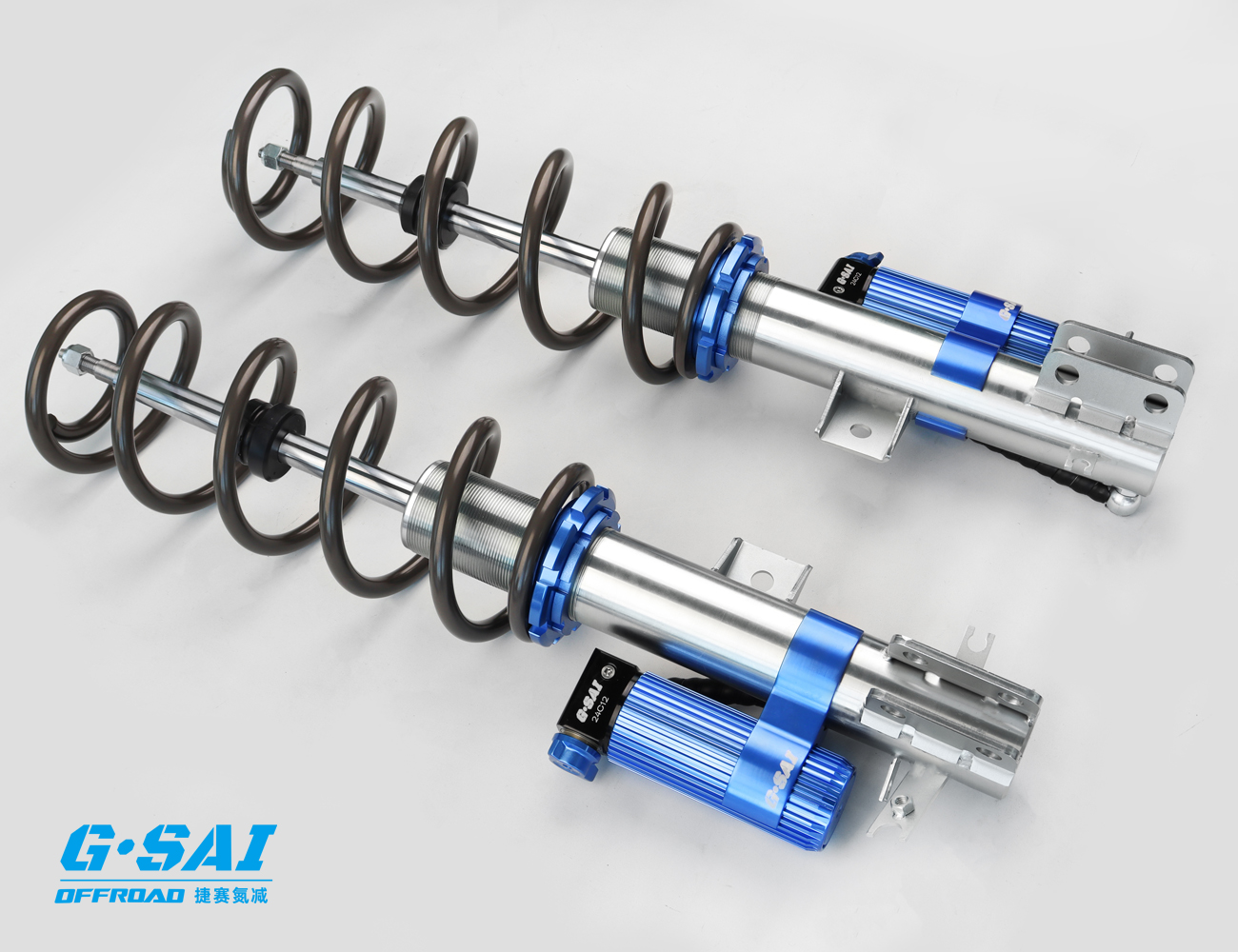

A Vantagem G·SAI no Design de Amortecedores

Como um dos principais inovadores em personalização de amortecedores off-road e para serviços pesados, a G·SAI oferece:

- Internamente Usinagem CNC e testes de simulação

- Mais de 17 anos de experiência em P&D liderada pelo engenheiro-chefe Cai Xianyun

- Soluções à medida para Frotas de caminhões do Oriente Médio

- Desempenho comprovado em condições extremas de corrida e off-road

→ Explore as capacidades dos nossos produtos no Catálogo de Produtos de Amortecedores a Gás Nitrogênio

Amortecedores de Nitrogênio vs. Amortecedores Hidráulicos Tradicionais: Principais Diferenças

Ao escolher sistemas de suspensão para caminhões do Oriente Médio, entender as principais diferenças entre amortecedores carregados com azoto e amortecedores hidráulicos tradicionais é essencial para operadores de frota, fabricantes de equipamentos originais (OEMs) e distribuidores de peças. Em ambientes áridos e de alta temperatura, a diferença de desempenho entre essas duas tecnologias torna-se especialmente significativa.

Tabela de Comparação: Amortecedores a Gás Nitrogênio vs. Amortecedores Hidráulicos

| Caraterística | Choques de azoto | Amortecedores hidráulicos tradicionais |

|---|---|---|

| Consistência de amortecimento | Estável sob calor extremo e uso prolongado | Propenso a fadiga à medida que o óleo se aera |

| Dissipação de calor | Alto, especialmente com reservatórios externos | Limitado, pode superaquecer em condições off-road |

| Desempenho em Terrenos Difíceis | Excelente absorção de choque e controle de retorno | Controle reduzido, especialmente quando sobrecarregado |

| Resistência à Cavitação | O nitrogênio impede a formação de espuma e a perda de pressão | A formação de espuma no óleo leva a um amortecimento inconsistente |

| Requisitos de manutenção | Frequência mais baixa devido à melhor durabilidade | Requer manutenção mais frequente |

| Caso de utilização ideal | Condições pesadas, off-road, deserto | Transporte urbano, veículos comerciais leves |

Por que os Amortecedores a Gás Nitrogênio são Cruciais para Caminhões do Oriente Médio

- Temperaturas Extremas: O gás nitrogênio remove o ar e a umidade do sistema, garantindo um desempenho estável acima de 50°C — uma condição comum no verão na região.

- Movimentação de Carga Pesada: Nas indústrias de petróleo e gás e construção, onde os caminhões são pesadamente carregados, os amortecedores a gás nitrogênio mantêm um amortecimento consistente e evitam o fim de curso.

- Off-Road e Terreno Irregular: Para veículos militares e de mineração que operam em Omã ou no Quarto Vazio, os amortecedores a gás nitrogênio oferecem controle de retorno superior e proteção do chassi.

Considerações para Compradores B2B

Para atacadistas e gestores de frota, a mudança para amortecedores a gás nitrogênio reduz o tempo de inatividade, aumenta a segurança do motorista e prolonga a vida útil operacional do veículo. Esses benefícios se traduzem em menor custo total de propriedade (TCO) e maior confiabilidade da frota, que são cruciais para manter contratos operacionais no Oriente Médio.

Como Escolher o Amortecedor de Nitrogênio Certo para a Sua Frota de Caminhões

Selecionar o amortecedor a gás nitrogênio certo para seu caminhão ou frota requer uma abordagem sistemática que considere não apenas o tipo de veículo, mas também o ambiente operacional, as demandas de carga e as metas de serviço de longo prazo.

Guia Passo a Passo para Compradores B2B

- Definir as Necessidades da Aplicação

- Longa distância, off-road ou uso misto?

- Faixa de temperatura e tipo de terreno?

- Determinar as Especificações do Veículo

- Peso do eixo, tipo de suspensão e folga do chassi.

- Estilo de montagem e dimensões do amortecedor OEM.

- Selecionar o Tipo de Amortecedor

- Monotubo para uso geral.

- Reservatório remoto para uso pesado ou off-road.

- Amortecedores ajustáveis para frotas mistas.

- Escolher o Perfil de Amortecimento

- Amortecimento suave para conforto do motorista.

- Amortecimento firme para proteção da carga e controle off-road.

- Avaliar as Opções de Personalização

- Marca, rotulagem privada ou ajuste específico do veículo.

- Verificar as Capacidades do Fornecedor

- O fornecedor pode atender sua MOQ (Quantidade Mínima de Pedido)?

- Eles oferecem suporte técnico e serviço pós-venda?

G·SAI: Um Parceiro Confiável para Ajuste Personalizado

A G·SAI oferece amortecedores de nitrogênio totalmente personalizados projetados para modelos e terrenos específicos de caminhões. Seja para uma frota logística em Dubai ou um comboio de campos de petróleo no Kuwait, a G·SAI oferece suporte:

- Soluções de marca própria para distribuidores regionais.

- Consultas de engenharia individuais para integrações de frota.

- Prototipagem e entrega rápidas através de nossa instalação interna de CNC e testes.

→ Saiba mais sobre nossa abordagem de serviço completo em nosso Visão Geral da Empresa

Dicas para Distribuidores e Operadores de Frotas

- Solicite unidades de amostra para testes de campo antes de pedidos em massa.

- Trabalhe com fornecedores que ofereçam consulta de ajuste de amortecedor.

- Certifique-se de que os amortecedores atendam aos padrões ISO e TS16949 para conformidade internacional.

Soluções de Amortecedores de Nitrogênio Personalizadas para Terrenos Áridos do Oriente Médio

Os amortecedores padrão geralmente falham quando expostos aos desafios únicos do Oriente Médio — desde calor escaldante e tempestades de poeira para cargas pesadas e viagens off-road. Os amortecedores de nitrogênio personalizados oferecem uma alternativa de alto desempenho projetada precisamente para essas condições.

Desafios Específicos do Terreno no Oriente Médio

| Tipo de terreno | Desafio para Amortecedores | Solução Personalizada Necessária |

|---|---|---|

| Deserto (Areia) | Entrada de poeira fina, calor e curso da suspensão | Corpo selado, curso estendido, óleo resistente ao calor |

| Rotas Montanhosas | Superfícies irregulares, controle de rebote | Amortecimento ajustável, ajuste de alta força de rebote |

| Estradas Costeiras | Corrosão por névoa salina | Revestimento anti-ferrugem, hardware de grau marítimo |

| Mistura Urbana/Rodoviária | Velocidades variáveis, paradas frequentes | Amortecimento de taxa dupla, opções de autonivelamento |

Por que a Personalização é Crítica para Compradores B2B

- Consistência da Frota: Os amortecedores personalizados garantem um desempenho uniforme em todos os veículos.

- Diferenciação da marca: Oferecem qualidade de passeio superior específica para as necessidades regionais.

- ROI de Longo Prazo: Menos tempo de inatividade e substituições menos frequentes reduzem o TCO.

Capacidades de Engenharia Personalizada da G·SAI

A G-SAI oferece soluções de amortecedores de nitrogênio sob medida através de:

- Ajuste de amortecedor específico para o veículo

- Válvulas personalizadas para tipos de terreno

- Personalização de marca e cor para marcas próprias

- Prototipagem rápida e produção com baixo MOQ

Nossos laboratórios de simulação e centro de treinamento em modificação de veículos garantem que cada amortecedor personalizado passe por testes no mundo real antes de ser escalado para produção em larga escala.

→ Entre em contato com nossa equipe de engenharia para uma consulta: Fale Conosco

Casos de uso ideais para amortecedores de nitrogênio personalizados

- Aquisição governamental para frotas militares ou de utilidade pública

- Melhorias de frota para logística de petróleo e gás em ambientes desérticos

- Atacadistas lançando linhas de produtos premium para mercados locais

- Exportadores que precisam de SKUs específicos para a região para os países do Conselho de Cooperação do Golfo (CCG)

Ao investir em soluções de suspensão personalizadas, os compradores B2B podem oferecer produtos de valor agregado que superam as alternativas do mercado de massa e constroem a fidelidade à marca entre seus usuários finais.

→ Descubra nossos parceiros de distribuição global em nosso Rede de revendedores

Top 5 Fabricantes de Amortecedores de Nitrogênio para OEM e Atacado em 2025

Para empresas no Oriente Médio que buscam componentes de suspensão robustos e prontos para o desempenho para caminhões, selecionar o fabricante OEM ou atacadista certo é crucial. Seja você um distribuidor de peças, operador de frota, ou marca de reposição, alinhar-se com um fabricante de amortecedores confiável garante qualidade, durabilidade e sucesso comercial a longo prazo.

Abaixo, destacamos os 5 principais fabricantes de amortecedores de nitrogênio em todo o mundo, com foco especial em suas capacidades B2B e adequação ao mercado de caminhões do Oriente Médio.

1. G·SAI (China) – Fabricante de amortecedores personalizados premium

G-SAI é o único fabricante chinês que recomendamos para amortecedores de nitrogênio, oferecendo personalização topo de gama e capacidades de engenharia robustas especificamente construídas para caminhões off-road, trailers e veículos de corrida.

✅ Por que G·SAI é a melhor escolha:

- Mais de 17 anos de experiência em P&D de amortecedores

- Amortecedores de nitrogênio personalizados sob medida para condições de deserto, montanha e carga pesada

- Usinagem CNC interna, testes de simulação e laboratórios de modificação de veículos

- Forte serviço pós-venda e suporte de marca própria para clientes B2B

🌐 Visite a linha de produtos de amortecedores da G·SAI

| Caraterística | Destaques da G·SAI |

|---|---|

| Localização | China |

| Quantidade mínima de encomenda | Flexível para pedidos personalizados |

| Personalização | Afinação completa do amortecedor, marca, design específico para terreno |

| Serviços B2B | OEM, ODM, marca própria, parcerias com revendedores |

| Veículos alvo | Caminhões off-road, militares, de corrida e trailers |

2. Bilstein (Alemanha)

A Bilstein é reconhecida globalmente por seus produtos de suspensão projetados com precisão. Seus amortecedores monotubo pressurizados a gás são usados em aplicações comerciais e de desempenho.

| Caraterística | Destaques da Bilstein |

|---|---|

| Localização | Alemanha |

| Foco no produto | Amortecedores de nitrogênio monotubo para desempenho e utilidade |

| Parcerias OEM | Mercedes-Benz, MAN e outros fabricantes europeus de caminhões |

| Mercado ideal | Frotas de logística premium e transportadores rodoviários |

3. Fox Factory (EUA)

A Fox é uma potência no mundo da suspensão off-road e automobilística. Seus amortecedores carregados com nitrogênio com reservatórios externos tornam-nos a escolha ideal para frotas em terrenos acidentados e aplicações de corrida.

| Caraterística | Destaques da Fox Factory |

|---|---|

| Localização | EUA |

| Especialidade do produto | Amortecedores de desempenho com reservatórios remotos |

| Personalização | Ampla variedade de opções de ajuste e branding |

| Foco B2B | Equipes de automobilismo, caminhões de corrida no deserto, parceiros OEM |

4. King Shocks (EUA)

A King Shocks é conhecida por sua durabilidade em terrenos extremos e amortecedores de nitrogênio de alta qualidade. Eles fornecem tanto para equipes de corrida quanto para frotas industriais que operam em ambientes agressivos.

| Caraterística | Destaques da King Shocks |

|---|---|

| Localização | EUA |

| Pontos fortes | Amortecedores de nitrogênio off-road para serviço pesado |

| Soluções personalizadas | Sim – ajuste específico para o terreno disponível |

| Uso ideal no Oriente Médio | Transporte de campos de petróleo, frotas do deserto e rotas de montanha |

5. Monroe (Global)

A Monroe oferece um amplo catálogo de produtos de suspensão, incluindo amortecedores de nitrogênio de tubo duplo econômicos para caminhões e vans comerciais. Embora não sejam tão avançados quanto as marcas premium, a Monroe é uma opção sólida para operadores de frota com orçamento limitado.

| Caraterística | Destaques da Monroe |

|---|---|

| Presença global | EUA, Europa, Ásia |

| Gama de produtos | Amortecedores de gás nitrogênio de tubo duplo |

| Melhor para | Frotas de entrega urbana, caminhões de peso médio |

| Suporte B2B | Rede global de distribuição e centros de serviço |

Obtenção de Amortecedores de Nitrogênio da China: O que os Proprietários de Frotas Devem Saber

A China surgiu como uma força dominante na fabricação de componentes automotivos. Para atacadistas e operadores de frota do Oriente Médio, a aquisição de amortecedores de nitrogênio da China oferece vantagens significativas — mas somente quando feita com o parceiro certo.

Vantagens da aquisição na China

- Eficiência de custos: Custos de produção mais baixos permitem preços competitivos nos segmentos de médio a alto padrão.

- Personalização em Escala: As fábricas chinesas são flexíveis com personalizações em pequenos lotes e Marca OEM.

- Prototipagem rápida: Tempos de resposta mais rápidos do projeto à produção.

- Integração logística global: Redes de exportação estabelecidas para os países do CCG, incluindo Emirados Árabes Unidos, Arábia Saudita e Omã.

O que procurar em um fornecedor chinês

| Fator chave | Porque é que é importante |

|---|---|

| Equipe de engenharia interna | Garante a personalização real, não apenas a reformulação da marca |

| Capacidade de usinagem CNC | Garante precisão e repetibilidade |

| Experiência específica para o terreno | Crucial para as demandas operacionais do Oriente Médio |

| Apoio pós-venda | Essencial para garantia, instalação e orientação de ajuste |

| Certificações de conformidade | Padrões ISO/TS para garantia de qualidade internacional |

Por que a G·SAI é a fabricante preferida na China

Ao contrário das fábricas de uso geral, a G·SAI se destaca por:

- Projetos de P&D específicos para o Oriente Médio

- Amortecedores projetados para caminhões off-road de campos de petróleo, rotas de montanha e climas quentes do deserto

- Suporte dedicado suporte ao revendedor e treinamento para integração de produtos

→ Saiba mais sobre como trabalhar conosco através de nossos Rede de revendedores

Desafios Comuns ao Comprar da China e Como Evitá-los

| Desafio | Solução |

|---|---|

| Imitações de baixa qualidade | Trabalhe com fabricantes certificados e recomendados como a G·SAI |

| Barreiras de comunicação | Escolha fornecedores com engenheiros e vendas que falem inglês |

| MOQ inflexível | Faça parceria com fábricas flexíveis que oferecem preços escalonados |

| Longos prazos de entrega | Use fornecedores com produção interna (não subcontratada) |

A estrutura de fábrica verticalmente integrada da G·SAI reduz significativamente os prazos de entrega e garante a qualidade consistente do produto — um fator crítico ao atender clientes exigentes nas indústrias do Oriente Médio.

→ Entre em contato com nossa equipe técnica para uma consulta de fornecimento.

FAQ: Tudo o que Distribuidores e Revendedores Precisam Saber Sobre Amortecedores de Nitrogênio

Abaixo estão algumas das perguntas mais frequentes de compradores B2B, gerentes de frotas de caminhões e distribuidores internacionais sobre amortecedores carregados com nitrogênio.

P1: Os amortecedores de nitrogênio valem o investimento mais alto para frotas comerciais?

Sim. Com o tempo, os amortecedores de nitrogênio reduzem os custos gerais de manutenção, minimizam o tempo de inatividade, aumentam a segurança e protegem a integridade da carga — tudo isso contribui para um custo total de propriedade (TCO) menor.

P2: Posso solicitar amortecedores de nitrogênio personalizados para minha frota?

Absolutamente. A G·SAI é especializada em amortecedores de nitrogênio personalizados adaptados a modelos de veículos e condições de terreno exclusivos. Oferecemos ajustes de marca, válvulas e tamanho para atender às necessidades da sua frota.

→ Veja nossos Opções de Produtos Personalizados

P3: Qual é a vida útil típica de um amortecedor de nitrogênio?

Dependendo das condições de uso, os amortecedores de nitrogênio G·SAI podem durar 2x mais do que os amortecedores hidráulicos tradicionais. Com instalação adequada e inspeção de rotina, eles podem servir de forma confiável por mais de 100.000 km.

P4: Os amortecedores de nitrogênio exigem ferramentas de instalação especiais?

A instalação é semelhante à dos amortecedores hidráulicos. No entanto, amortecedores ajustáveis ou com reservatório remoto podem exigir configuração adicional. A G·SAI fornece guias de instalação e suporte técnico para todos os clientes B2B.

P5: Os amortecedores de nitrogênio são adequados para rotulagem privada?

Sim. A G-SAI oferece rotulagem privada, incluindo embalagem, marca e personalização do corpo do amortecedor para revendedores e distribuidores regionais.

→ Saiba mais sobre nossos Serviços OEM e Private Label

Conclusão

Com as condições extremas de operação do Oriente Médio — de rodovias escaldantes a terrenos acidentados de campos de petróleo — amortecedores de nitrogênio tornaram-se uma atualização obrigatória para caminhões comerciais, operadores de frotas e marcas de veículos modificados. Sua consistência de amortecimento superior, resistência ao calor e durabilidade os tornam muito mais adequados do que os amortecedores hidráulicos tradicionais.

Para compradores B2B, escolher o fornecedor certo é tão importante quanto o produto em si. Entre os fabricantes globais, a G·SAI se destaca como o único fornecedor chinês que oferece amortecedores de nitrogênio totalmente personalizados e específicos para o terreno com qualidade global e engenharia interna.

Seja você um distribuidor de peças para caminhões em Riade, uma empresa de logística em Dubai ou uma marca OEM em expansão para o Golfo, a G·SAI pode ajudá-lo a fornecer soluções de suspensão excepcionais nas quais seus clientes podem confiar.

→ Comece sua jornada com uma cotação personalizada hoje, visitando Entre em contato com a G·SAI

Perguntas frequentes (FAQ)

1) Quais especificações definem amortecedores de nitrogênio de alta qualidade para caminhões do Oriente Médio?

- Óleo de choque de alto VI, vedações FKM/Viton multilâmina, hastes de pistão cromadas duras ou nitretadas, corpos de alumínio anodizado duro ou aço com e-coat, ferragens Zn-Ni (ASTM B117 ≥ 720–1.000 h) e deriva de força validada de quente para frio ≤ ±5% (20°C vs. 100–110°C).

2) Amortecedores de nitrogênio com reservatório remoto são necessários para frotas no deserto?

- Fortemente recomendados para rotas de campos petrolíferos, construção e militares com corrugações/areia fofa. O volume adicional de óleo/gás melhora o resfriamento e reduz o fading em trajetos longos e quentes. Para longas distâncias apenas em rodovias, monotubos premium podem ser suficientes.

3) Como os compradores B2B devem validar o desempenho antes de pedidos em massa?

- Solicite curvas dinâmicas de lote a 20°C e 100–110°C, testes de aquecimento de 40 minutos, resultados de penetração de poeira MIL-STD-810, relatórios de corrosão (ASTM B117), arquivos PPAP/ISIR de encaixe para modelos de caminhões alvo e planilhas de torque/alinhamento. Realize um teste de campo piloto de 30–60 dias.

4) Qual cadência de manutenção se adequa ao calor do GCC (38–50°C)?

- Reapertar após 500–1.000 km pós-instalação; inspeções a cada 10.000–15.000 km (vazamentos, buchas, atrito de mangueiras); reconstrução/manutenção a 40.000–60.000 km para frotas off-road. Registro de temperatura ou alertas de telemática ajudam a agendar serviços proativos.

5) Distribuidores podem obter amortecedores de nitrogênio private-label em árabe/inglês?

- Sim. Fornecedores líderes suportam OEM/ODM com manuais em árabe/EN, vídeos de instalação com QR, rotulagem compatível com GCC e armazenamento alfandegado (ex.: JAFZA/DWC) para cumprimento regional mais rápido.

Tendências da Indústria em 2025: Amortecedores de Nitrogênio no Oriente Médio

- Veículos pesados EV/híbridos crescem; amortecimento migra para viés de compressão em baixa velocidade e controle de NVH sob aquecimento.

- Amortecedores prontos para sensores (portas termistor/acelerômetro) se expandem para manutenção preditiva em logística, óleo e gás, e frotas de defesa.

- Padrões de corrosão/vedação se apertam perto de hubs costeiros (Jubail, Doha, Abu Dhabi): ferragens Zn-Ni e pilhas de vedações FKM multilâmina tornam-se padrão.

- Programas private-label de amortecedores de nitrogênio escalam com embalagens árabe/EN e conteúdo de instalação com QR, reduzindo RMAs.

- Capacidade estabilizada de CNC/anodização reduz prazos personalizados para 6–9 semanas ex-fábrica; armazenamento alfandegado no GCC encurta o último trecho.

| Métrica/Tendência 2025 | Relevância para Amortecedores de Nitrogênio | Especificação/Prática Típica | Fontes Indicativas |

|---|---|---|---|

| Validação de aquecimento | Garante estabilidade a 45–50°C ambiente | Dinamômetro de 40 min a 100–110°C; deriva ≤ ±5% | Relatórios de testes de fabricantes |

| Amortecedores com sensores | Serviço preditivo de frota, menor tempo parado | Portas termistor; registro CAN/telemática | Resumos telemática McKinsey/Gartner |

| Padrão de corrosão (costeiro) | Menos falhas em sal/umidade | ASTM B117 ≥ 720–1.000 h; Zn-Ni | ASTM B117; artigos SAE sobre corrosão |

| Adaptação EV/carga pesada | Controla arfagem/rolagem com massa | Viés de compressão em baixa velocidade; suportes reforçados | Notas ACEA/OEM de chassi |

| Normalização de prazos | Planejamento de compras | 6–9 semanas ex-fábrica; estoque alfandegado GCC | Pesquisas de exportadores/fabricantes |

Estudos de caso de pesquisa recentes

Estudo de Caso 1: Comboio de Campo Petrolífero na Arábia Saudita — Programa de Redução de Fading (2025)

Contexto: Uma frota de 140 caminhões em estradas de cascalho/deserto enfrentou fading de amortecedores e falhas de vedação a 42–49°C ambiente.

Solução: Atualizados para amortecedores de nitrogênio com reservatório remoto, óleo de alto VI, vedações FKM multilâmina, linhas trançadas e ferragens Zn-Ni; implementados reapertamento a 1.000 km e guias de instalação QR/AR (AR/EN).

Resultados: Tempo parado relacionado à suspensão -24%; conforto do motorista +0,6/5; deriva de força quente-frio mantida em ±4,8% em ciclos de 40 minutos; reclamações de desgaste irregular de pneus -10%.

Estudo de Caso 2: Logística Transfronteiriça nos EAU — NVH e Estabilidade (2024)

Contexto: 200 tratores de longa distância relataram mergulho de freio e instabilidade de carga em rotas Abu Dhabi–Riade.

Solução: Instalados amortecedores monotubo nitrogenados ajustáveis com viés de compressão em baixa velocidade e suportes superiores reforçados; certificados dinâmicos de lote fornecidos; registro de temperatura por telemática adicionado.

Resultados: Incidentes de dano à carga -15%; RMA 1,7% YoY; vida média das pastilhas +6%; intervalo de serviço estendido em 12%.

Opiniões de especialistas

- Dr. Nabil Al-Harbi, Engenheiro Sênior de Dinâmica de Veículos, Centro de Pesquisa de Mobilidade GCC

Opinião: “Para frotas no deserto, especifique deriva de força quente-frio dentro de ±5% e valide penetração de poeira conforme MIL-STD-810. É o preditor mais rápido de confiabilidade em campo.” - Sarah Haddad, Diretora de Manutenção de Frotas, DesertLink Logistics

Opinião: “Vedações FKM multilâmina e ferragens Zn-Ni reduziram nossas falhas mais do que qualquer outra especificação. Guias de instalação QR em árabe diminuíram erros de encaixe nos centros de serviço.” - Paulo Mendes, Consultor de Motorsport e Off-Road, Suporte MENA Rally

Opinião: “Volume de reservatório e controle correto de retorno previnem afundamento em corrugações. Retorno excessivamente macio superaquece pneus e fatiga motoristas.”

Ferramentas/Recursos Práticos

- MoIAT (EAU): Programas de padrões e conformidade https://moiat.gov.ae

- Organização Saudita de Padrões, Metrologia e Qualidade (SASO) https://saso.gov.sa

- UNECE: Base de dados de regulamentos de veículos E-mark/UN https://unece.org/transport/vehicle-regulations

- ASTM B117: Padrão de corrosão por névoa salina https://www.astm.org

- MIL-STD-810: Testes ambientais de calor, poeira e vibração https://quicksearch.dla.mil

- SAE MOBILUS: Normas de amortecedores/rodagem (SAE J1460, J2492) https://saemobilus.sae.org

- Panjiva / ImportYeti: Devida diligência de fornecedores para amortecedores private-label https://panjiva.com | https://www.importyeti.com

- Alfândega de Dubai: Códigos HS, impostos, orientação de armazenamento alfandegado https://www.dubaicustoms.gov.ae

Última atualização: 2025-10-10

Registro de alterações: Adicionadas 5 perguntas FAQ adaptadas a amortecedores de nitrogênio em caminhões do Oriente Médio; introduzida tabela de tendências 2025 com especificações/fontes; fornecidos dois estudos de caso regionais (comboio de campo petrolífero KSA, logística transfronteiriça EAU); incluídas opiniões de especialistas; compilados ferramentas/recursos regionais com links autorizados.

Data da próxima revisão e gatilhos: 2026-03-31 ou antes se padrões GCC mudarem, atualizações UNECE/E-mark ocorrerem, adoção de veículos pesados EV acelerar ou penetração de amortecedores com sensores exceder 25% em licitações de frotas GCC.