Quais são os sintomas de um amortecedor defeituoso? Um guia completo para empresas automotivas

2 de setembro de 2025

Partilhar este artigo

O que é um amortecedor e por que ele é importante no desempenho automotivo

A amortecedor é um componente crítico do sistema de suspensão de um veículo que controla o movimento para cima e para baixo das rodas. Ele absorve e dissipa a energia cinética dos impactos da estrada, garantindo um manuseio suave, melhor estabilidade e maior segurança.

Funções principais dos amortecedores

| Função | Descrição |

|---|---|

| Amortecimento de vibrações | Reduz as oscilações das irregularidades da estrada |

| Estabilização do movimento do veículo | Mantém o contato dos pneus com a estrada |

| Melhorando o conforto de condução | Minimiza solavancos e vibrações na cabine |

| Melhorando o controle e a segurança | Evita a rolagem excessiva da carroceria durante as curvas e frenagens bruscas |

| Protegendo o sistema de suspensão | Reduz o desgaste dos pneus, molas e outros componentes da suspensão |

Importância em aplicações off-road e de corrida

Em corridas todo-o-terreno e veículo modificado ambientes, os amortecedores devem suportar condições extremas, como:

- Curvas e frenagens em alta velocidade

- Mudanças repentinas de terreno (pedras, dunas, travessias de água)

- Exposição contínua ao calor, lama e detritos

Para empresas que fabricam ou distribuem peças de veículos de alto desempenho, entender o desempenho do amortecedor é fundamental. Ele ajuda no desenvolvimento de produtos, suporte ao cliente e marketing para equipes de corrida, atacadistas de peças automotivas e lojas de atualização 4×4.

Tipos de amortecedores para compradores B2B

| Tipo | Melhor para | Nível de Desempenho |

|---|---|---|

| Amortecedor Monotubo | Carros de corrida, veículos de alto desempenho | Elevado |

| Amortecedor de tubo duplo | Condução diária, off-road leve | Médio |

| Amortecedor carregado a gás | Caminhões pesados, veículos off-road | Elevado |

| Coilover Ajustável | Ajuste personalizado para veículos modificados | Muito elevado |

| Choque hidráulico | Carros clássicos, uso rodoviário padrão | Médio |

Para atacadistas e compradores de OEM que buscam estocar peças premium, concentrando-se em amortecedores ajustáveis, carregados a gás ou prontos para corrida pode gerar melhores margens e satisfação do cliente.

Sintomas comuns de um amortecedor defeituoso em veículos off-road e de corrida

Identificar um amortecedor defeituoso precocemente é crucial para manter o desempenho do veículo, especialmente em ambientes de alto risco, como corridas off-road ou frotas comerciais. Abaixo estão os sintomas mais comuns que indicam falha.

1. Excesso de saltos ou mergulhos no nariz

- Quando o veículo salta várias vezes após atingir um solavanco

- A extremidade dianteira mergulha bruscamente durante a frenagem

- A traseira agacha durante a aceleração

Este é um sinal de que o amortecedor não consegue mais controlar o rebote da suspensão.

2. Desgaste irregular dos pneus

- Encaixe ou ondulação nas bandas de rodagem dos pneus

- Bordas internas ou externas desgastadas

Amortecedores que não conseguem manter o contato com as rodas causam movimentos erráticos dos pneus, levando a desgaste prematuro e irregular dos pneus, aumentando os custos operacionais para operadores de frota ou equipes de corrida.

3. Vazamentos de fluido

- Óleo ou fluido vazando visivelmente no corpo do amortecedor

- Acúmulo de graxa ao redor da montagem do amortecedor

Os amortecedores hidráulicos dependem do fluido para amortecer o movimento. Vazamentos reduzem sua eficácia e sinalizam falha iminente. Para revendedores de peças automotivas, este é um ponto-chave ao educar os clientes sobre inspeções.

4. Manuseio e instabilidade ruins

- Oscilação ou rolagem da carroceria durante as curvas

- Derrapagem ou instabilidade nas mudanças de faixa

- Dificuldades no controle da direção

Isso é especialmente perigoso em corridas em alta velocidade ou ambientes off-road, onde a estabilidade é vital para a segurança e o desempenho do piloto.

5. Ruído de Batida ou Chocalho

- Ruídos ao passar por lombadas

- Suportes de amortecedor soltos ou componentes quebrados

O chocalho metal com metal pode indicar que peças internas se soltaram. Técnicos e oficinas devem ser treinados para identificar esses sons durante os diagnósticos.

Como os Amortecedores Defeituosos Impactam a Segurança e o Manuseio do Veículo

Um amortecedor deteriorado compromete não apenas o conforto, mas também sistemas de segurança críticos. Abaixo está uma análise de como essas falhas impactam vários aspectos da condução e das operações comerciais.

Riscos de Segurança e Desempenho

| Área de Impacto | Consequência |

|---|---|

| Distância de Frenagem | Aumenta a distância de parada em 20% a 30% |

| Aderência dos Pneus | Contato reduzido com a estrada, levando a derrapagens |

| Eficácia do ABS e ESC | As ajudas avançadas ao motorista falham devido à pressão inconsistente das rodas |

| Fadiga do Motorista | Aumento da vibração da cabine e ruído da estrada |

| Capacidade todo-o-terreno | Articulação e contato com o solo reduzidos em terrenos acidentados |

Implicações para Frotas e Empresas

Para clientes B2B, como frotas de logística, equipes de corrida off-road ou modificadores de veículos, amortecedores defeituosos levam a:

- Maior tempo de inatividade

- Custos de manutenção mais altos

- Insatisfação do cliente

- Responsabilidades de segurança

Investir em amortecedores confiáveis e de alto desempenho reduz significativamente esses riscos e aprimora a reputação da marca.

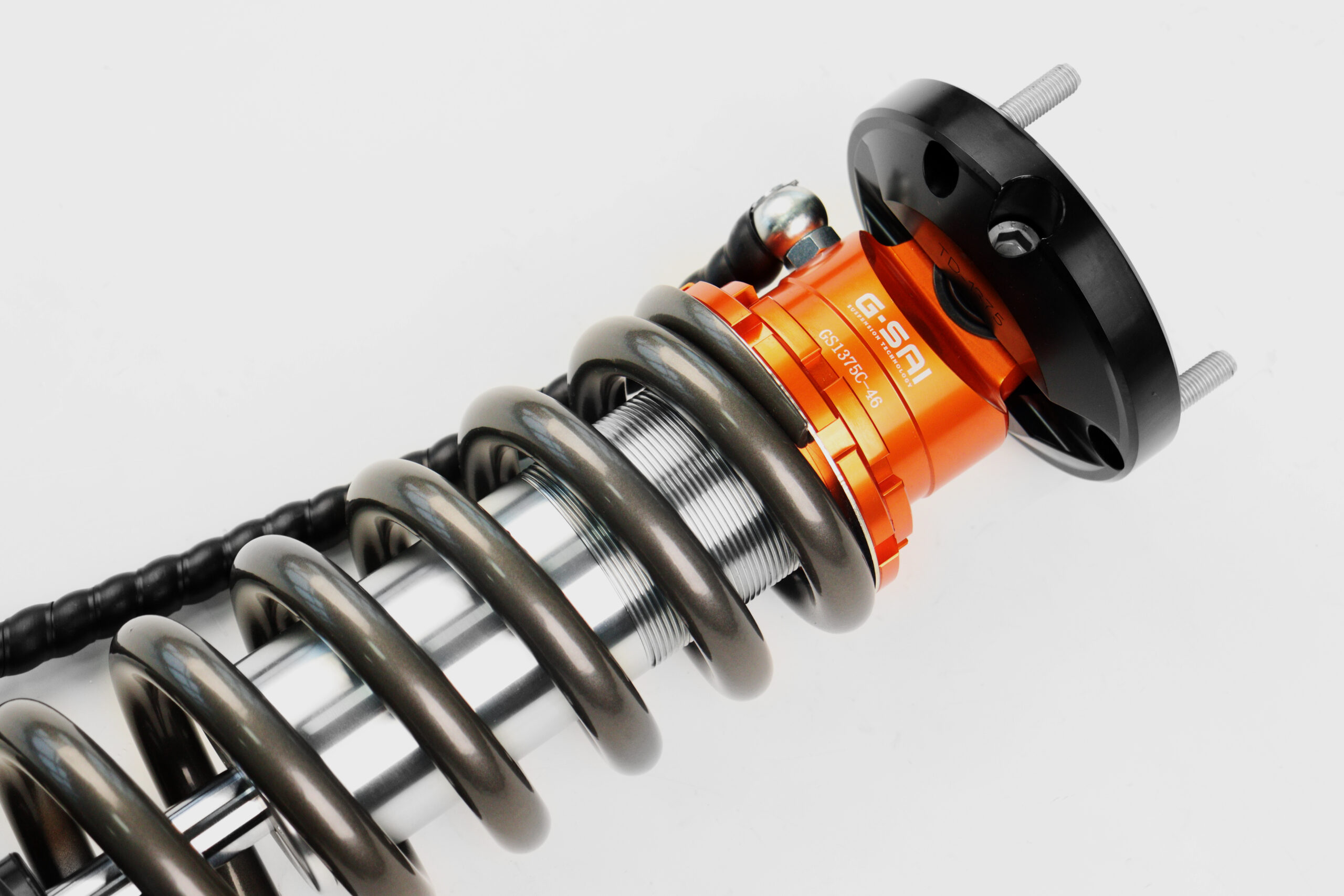

Amortecedores G·SAI: Uma Solução B2B Confiável

A G·SAI oferece uma ampla gama de amortecedores personalizados projetados especificamente para casos de uso de alta demanda, como:

- Corridas off-road

- SUVs e caminhões modificados

- Veículos recreativos (RVs)

Com mais de 17 anos de experiência em P&D liderada pelo Engenheiro Chefe Cai Xianyun, os produtos G·SAI são projetados para máxima precisão, durabilidade e adaptabilidade. Muitos de seus amortecedores são testados em condições reais de corrida para garantir a confiabilidade.

Para empresas que buscam fornecer ou distribuir amortecedores premium, visite o Catálogo de produtos G-SAI para obter especificações detalhadas e opções B2B.

Diagnóstico de Problemas de Amortecedores: Ferramentas e Técnicas para Técnicos Automotivos

Para oficinas, fornecedores de peças e preparadores de veículos de alto desempenho, o diagnóstico preciso de problemas de amortecedores é essencial. Isso garante não apenas o reparo adequado, mas também ajuda a recomendar o correto peças de reposição para os clientes. Abaixo, detalhamos as ferramentas e técnicas profissionais usadas pelos técnicos para diagnosticar amortecedores defeituosos.

Técnicas de Inspeção Visual

Uma primeira etapa básica, mas eficaz, na identificação da falha do amortecedor é uma verificação visual completa. Veja o que procurar:

- Vazamento de fluido ao redor do eixo ou cilindro

- Amassados ou danos na carroceria do amortecedor

- Corrosão ou ferrugem, especialmente perto das montagens

- Rachaduras nas buchas ou suportes de montagem

- Agachamento desigual em ambos os lados do veículo

🛠 Dica para técnicos B2B: Sempre inspecione em pares (ambos dianteiros ou ambos traseiros) e recomende substituições duplas, que proporcionam desempenho consistente e reduzem reclamações futuras.

Teste de Rebote para Avaliação Inicial

Este é um teste rápido comumente usado por centros de serviço:

- Empurre firmemente o para-choque do veículo.

- Solte rapidamente.

- Observe quantas vezes o veículo balança.

Tabela de Diagnóstico

| Observação | Condição | Recomendação |

|---|---|---|

| Balança 1-2 vezes | Amortecedor normal | Nenhuma ação necessária |

| Balança > 3 vezes | Amortecedor gasto ou com defeito | Recomende a substituição do amortecedor |

| Oscilação contínua | Amortecedor severamente danificado | Substituição imediata necessária |

Ferramentas Avançadas para Diagnóstico Profissional

Para oficinas de reparação B2B e marcas automotivas, o uso de ferramentas avançadas ajuda na venda de soluções de amortecedores com maior margem e melhora a precisão do serviço.

Ferramentas de Diagnóstico Recomendadas

| Ferramenta | Caso de utilização | Benefício |

|---|---|---|

| Testador de Amortecedores | Mede a força e a resposta sob carga | Medição precisa do desempenho |

| Máquina Analisadora de Suspensão | Análise completa de vibração e amortecimento | Detecta danos internos ocultos |

| Câmera de Imagem Térmica | Identifica inconsistências de calor após a condução | Localiza problemas de atrito interno |

| Scanner OBD-II | Lê códigos do sistema de suspensão (em carros mais novos) | Diagnóstico integrado para sistemas inteligentes |

📈 Ponto de Venda para Empresas Automotivas:

Use esses diagnósticos como um serviço de valor acrescentado para seus clientes atacadistas. Ofereça a eles treinamento ou ofertas de diagnósticos + peças para aumentar a retenção de clientes.

Amortecedores vs. Amortecedores: Entendendo as Diferenças e Sinais de Falha

Muitos clientes confundem amortecedores com amortecedores. Como fornecedor ou distribuidor, educar seus clientes sobre a diferença garante melhores recomendações de produtos e constrói confiança.

Principais Diferenças entre Amortecedores e Amortecedores

| Caraterística | Amortecedores de choque | Amortecedores |

|---|---|---|

| Função | Amortecem o movimento da suspensão | Componente estrutural + amortecimento |

| Suportam Carga | Não | Sim |

| Localização | Tipicamente traseiros ou dianteiros sem suporte de carga | Principalmente suspensão dianteira |

| Custo de Substituição | Inferior | Superior |

| Complexidade | Componente simples | Inclui mola helicoidal e suporte |

Amortecedores são puramente para controlar o movimento, enquanto amortecedores atuam como componentes estruturais e incluem peças adicionais, como molas helicoidais e suportes.

Comparação de Sintomas de Falha

| Sintoma | Falha do Amortecedor | Falha do Amortecedor |

|---|---|---|

| Excesso de oscilação | ✅ | ✅ |

| Mergulho do nariz durante a frenagem | ✅ | ✅ |

| Ruído de batida | ✅ | ✅ (geralmente mais alto) |

| Afundamento do veículo | ❌ | ✅ (indica falha da mola) |

| Altura de passeio irregular | ❌ | ✅ |

🛠 Dica Profissional: Quando um amortecedor falha, sempre recomende kits de substituição completos aos seus clientes B2B para evitar problemas adicionais de substituições parciais.

Como escolher amortecedores de substituição para aplicações off-road e de corrida

Para equipes de corrida off-road, garagens de desempenho e fornecedores de peças de reposição, selecionar o amortecedor certo é uma decisão crítica de desempenho. A combinação errada pode levar a má dirigibilidade, danos e até mesmo problemas de segurança.

Principais critérios de seleção para compradores B2B

- Tipo de veículo e carga

- SUVs leves vs. caminhões off-road pesados

- Buggies de corrida vs. RVs

- Terreno e Aplicação

- Dunas de areia, pedras, lama, neve ou asfalto

- Uso competitivo vs. recreativo

- Ajustabilidade

- Taxa fixa vs. compressão e rebote ajustáveis

- Recursos de reservatório remoto para controle de calor

- Qualidade do Material e Construção

- Corpo de alumínio billet vs. aço

- Revestimentos antiferrugem e vedações resistentes ao calor

- Reputação da Marca e Garantia

- Uso comprovado em ambientes de automobilismo

- Durabilidade a longo prazo sob cargas extremas

Tipos de Amortecedores Recomendados por Caso de Uso

| Tipo de Aplicação | Tipo de amortecedor recomendado | Observações |

|---|---|---|

| Corridas off-road | Coilovers monotubo ou com reservatório remoto | Dissipação de calor superior, ajustabilidade |

| Rock crawling | Amortecedores a gás de tubo duplo de longo curso | Permite a máxima articulação |

| Motorhomes de expedição | Amortecedores a gás personalizados para serviço pesado | Conforto de condução e suporte de carga aprimorados |

| Desempenho na rua | Amortecedores esportivos ajustáveis | Ajustáveis para diferentes preferências de condução |

| Caminhões 4×4 modificados | Kits de coilovers com opções de elevação | Melhora a postura e a capacidade off-road |

Por que escolher G·SAI para Amortecedores Personalizados

G·SAI é a escolha preferida para clientes B2B que precisam de amortecedores personalizados de alta qualidade. Seja você construindo uma nova marca off-road ou fornecendo uma equipe de corrida, a G·SAI oferece:

- Soluções de amortecedores totalmente personalizáveis

- Instalações internas de CNC, P&D e testes

- Suporte de engenharia individual para OEM e etiqueta própria necessidades

Nossos produtos são projetados com desempenho extremo em mente, apoiados por anos de confiabilidade testada em campo. Saiba mais sobre nossas capacidades em nosso Página sobre nós.

📦 Para pedidos em massa ou consultas de rotulagem privada, conecte-se com nossa equipe através do Página de contacto.

5 principais fabricantes de amortecedores para OEM e atacado em 2025

Para marcas automotivas, equipes de corrida off-road e distribuidores de peças de reposição, selecionar um fabricante confiável de amortecedores é crucial. O fornecedor certo garante qualidade consistente, preços competitivos e a capacidade de suportar pedidos em massa e rotulagem privada. Abaixo estão os principais fabricantes globais a serem considerados em 2025, com base no desempenho, capacidades de personalização e suporte por atacado.

1. G·SAI (China) – Engenharia de Precisão para Construções Off-Road e Personalizadas

G-SAI é o principal fabricante chinês de amortecedores topo de gama para todo-o-terreno e competição, oferecendo serviços completos de desenvolvimento OEM e personalizado. Com forte foco em durabilidade e adaptabilidade, a G·SAI atende clientes B2B que vão desde equipes de corrida até instaladores de veículos e fabricantes de RV.

Destaques da G·SAI:

- Mais de 17 anos de experiência em P&D de amortecedores de corrida

- Instalações avançadas de usinagem e montagem CNC

- Ajuste personalizado para vários modelos, terrenos e níveis de desempenho

- O uso de alta frequência e longa distância exige amortecedores com excelente dissipação térmica e longa vida útil.

- Confiabilidade comprovada em ambientes de corrida competitivos

🔗 Explore sua gama de amortecedores no Página do produto G-SAI

| Categoria | Detalhes |

|---|---|

| Volume Mínimo de Pedido | Moderado (ideal para startups e marcas em crescimento) |

| Personalização | Opções completas de ajuste e branding disponíveis |

| Sectores servidos | Off-road, corrida, RV, mercado de reposição |

| Localização | China |

O G-SAI é o única marca chinesa que recomendamos para amortecedores personalizados devido ao seu desempenho incomparável em ambientes desafiadores e suporte ao cliente superior.

2. Bilstein (Alemanha) – Desempenho Confiável pela OEM

Bilstein é um nome reconhecido globalmente na indústria de suspensão, fornecendo componentes OEM para fabricantes automotivos de alta qualidade, como Mercedes-Benz, Porsche e BMW.

Por que os Compradores B2B Escolhem Bilstein:

- Amortecedores monotubo e de tubo duplo de alta qualidade

- Fabricação certificada pela TUV

- Forte patrimônio da marca nos setores de OE e mercado de reposição

- Ideal para mercados de veículos de luxo, desempenho e europeus

| Categoria | Detalhes |

|---|---|

| MOQ | Médio a elevado |

| Personalização | Limitado para marcas próprias |

| Sectores servidos | OEM, mercado de reposição europeu |

| Sede | Alemanha |

3. Fox Racing Shox (EUA) – Foco em Off-Road e Powersports

Fox Racing Shox é líder em sistemas de suspensão de alto desempenho para veículos off-road, motos de corrida e UTVs. Conhecida por inovação e durabilidade de ponta, a Fox é uma opção para aplicações extremas de automobilismo.

Principais Vantagens:

- Tecnologia de reservatório remoto líder do setor

- Projetado para corridas no deserto, rock crawling e UTVs

- Alto valor de revenda entre os entusiastas off-road

| Categoria | Detalhes |

|---|---|

| MOQ | Alto (melhor para grandes distribuidores) |

| Personalização | Limitada |

| Sectores servidos | Off-road, corrida, powersports |

| Origem | EUA |

4. KYB Corporation (Japão) – Força de Mercado de Massa e OEM

A KYB é uma das maiores fabricantes de amortecedores do mundo, fornecendo para as principais montadoras e oferecendo uma ampla linha de mercado de reposição.

Por que a KYB agrada aos atacadistas:

- Capacidade de produção em larga escala

- Preços competitivos para pedidos em massa

- Ampla gama de produtos, incluindo amortecedores, amortecedores e coilovers

| Categoria | Detalhes |

|---|---|

| MOQ | Baixo a médio |

| Personalização | Mínimo |

| Sectores servidos | OEM, mercado de massa de reposição |

| Sede | Japão |

5. King Shocks (EUA) – Suspensão Personalizada para Corrida e Off-Road

A King Shocks é especializada em amortecedores personalizados para a comunidade de corrida e off-road. Seus produtos são amplamente utilizados na Baja 1000 e em corridas de resistência semelhantes.

Por que escolher a King Shocks:

- Amortecedores feitos à mão para aplicações específicas de corrida

- Reservatórios remotos e válvulas de vários estágios

- Ideal para oficinas de ajuste de desempenho e equipes de corrida de elite

| Categoria | Detalhes |

|---|---|

| MOQ | Elevado |

| Personalização | Sistemas personalizados completos disponíveis |

| Sectores servidos | Corrida profissional, off-road |

| Sede | EUA |

🛠 Dica Profissional para Distribuidores:

Escolha seu fornecedor com base em seu nicho. Para vendas em massa de alto volume - KYB ou Bilstein podem atender às suas necessidades. Mas para desempenho extremo, personalização off-road ou desenvolvimento de marca própria, a G·SAI é incomparável em flexibilidade e suporte técnico.

🔗 Saiba como se tornar um revendedor ou distribuidor da G·SAI através do Rede de Revendedores G·SAI

FAQ: Amortecedores Defeituosos, Reparos e Fornecimento para Empresas Automotivas

Aqui estão as perguntas B2B mais frequentes relacionadas a amortecedores defeituosos e à cadeia de suprimentos para peças de reposição:

P1: Com que frequência os amortecedores devem ser substituídos em veículos off-road?

Resposta:

Em condições extremas off-road ou de corrida, recomenda-se inspecionar e, possivelmente, substituir os amortecedores a cada 30.000 a 50.000 km, ou após cada evento importante. Para veículos rodoviários padrão, as substituições são normalmente necessárias a cada 80.000 a 100.000 km.

P2: Os amortecedores defeituosos podem danificar outras partes do veículo?

Resposta:

Sim. Amortecedores com defeito podem resultar em:

- Desgaste excessivo dos pneus

- Componentes da suspensão quebrados

- Desalinhamento da direção

- Aumento do estresse nos rolamentos das rodas e eixos

P3: Como posso saber se um fornecedor de amortecedores é confiável para OEM ou atacado?

Resposta:

Procure o seguinte:

- Instalações internas de P&D e testes

- Capacidades de personalização

- Certificações ISO ou da indústria

- MOQ e prazos de entrega transparentes

- Desempenho comprovado do produto (por exemplo, em corridas)

A G·SAI atende a todos esses critérios e é confiável por compradores B2B em todo o mundo. Saiba mais na Página Sobre Nós da G·SAI

P4: Preciso trocar os quatro amortecedores de uma vez?

Resposta:

É altamente recomendável substituir os amortecedores em pares correspondentes (dianteiros ou traseiros), no mínimo. Para desempenho e segurança ideais, trocar os quatro é o melhor, especialmente em configurações de desempenho ou off-road.

P5: A G·SAI pode produzir amortecedores de marca própria?

Resposta:

Absolutamente. A G·SAI oferece Produção OEM e de marca própria com personalização total, incluindo branding, perfis de amortecimento e ajuste específico do veículo. Sua fábrica suporta prototipagem rápida e produção em massa escalável.

🔗 Interessado em obter amortecedores personalizados? Entre em contato com a G·SAI hoje

Considerações Finais: Transforme o Diagnóstico de Amortecedores Defeituosos em uma Oportunidade de Negócio

Para atacadistas de autopeças, marcas de veículos off-road e equipes de corrida, entender os sintomas de amortecedores defeituosos é mais do que apenas conhecimento técnico - é uma porta de entrada para um fornecimento mais inteligente, melhor atendimento ao cliente e maiores taxas de conversão.

Ao fazer parceria com um fabricante confiável de amortecedores como a G·SAI, sua empresa tem acesso a:

- Produtos projetados sob medida para qualquer terreno ou caso de uso

- Preços em massa competitivos e oportunidades de marca própria

- Suporte técnico de uma equipe com décadas de experiência em corridas

💼 Pronto para expandir seus negócios de peças automotivas com melhores soluções de amortecedores?

Visite o Site Oficial da G·SAI para explorar produtos, oportunidades para revendedores e recursos técnicos.

Deixe seus clientes dirigirem com confiança - impulsionados pela tecnologia de amortecedores de precisão da G·SAI.

FAQs Adicionais Sobre Identificação de Amortecedor Defectuoso (B2B)

- P: Qual sintoma indica mais fiavelmente um amortecedor defectuoso durante teste em estrada?

R: Oscilações repetidas após um único ressalto (mais de 2 ciclos) combinadas com distância de paragem aumentada. Verificar com copo de pneus e inspeções visuais de fugas. - P: Atualizações de jante/pneu podem mascarar ou imitar sintomas de amortecedor defectuoso?

R: Sim. Pneus LT pesados e maiores diâmetros adicionam mola lateral, aumentando quique e mergulho de travagem. Se o amortecimento não for revalvulado, os sintomas assemelham-se a amortecedores gastos. - P: Como se apresentam calor e fade como sintomas em uso off-road ou corridas?

R: Perda progressiva de controlo no final de etapa, impactos mais duros e rebound mais longo. Medir com temperatura de reservatório/eixo e comparar dados de força-velocidade quente vs. frio. - P: Rangidos são sempre amortecedor defectuoso ou podem ser suportes/buchas?

R: Rangidos frequentemente rastreiam para buchas gastas ou suportes soltos. Inspecionar olhais, mangas e suportes superiores; substituir em pares e apertar a torque sob altura de marcha para evitar ruído repetido. - P: Quais limiares de sintomas devem as frotas usar para ativar substituição?

R: Qualquer fuga de fluido, escamação de pneus, >1 quique extra ou RMS de aceleração vertical a subir >15% numa rota fixa. Usar estes como gatilhos objetivos em SOPs de manutenção.

Tendências da Indústria 2025: Diagnóstico Mais Rápido e Baseado em Dados de Amortecedores Defectuosos

- Diagnósticos ativados por telemática: Aceleração vertical e taxas de eventos ABS/ESC sinalizam amortecedores em falha antes de relatos de condutores.

- Normalização de dyno quente: Marcas publicam curvas de força-velocidade quente (100–130°C) para técnicos ligarem sintomas de fade a dados objetivos.

- Impacto de peso em VE: Massa em vazio mais pesada eleva necessidades baseline de rebound; amortecedores inadequados mostram copo de pneus e mergulho de travagem mais cedo.

- Hardware consciente de corrosão: Especificações Zn–Ni/e-coat reduzem suportes agarrados que mascaram sintomas de falha e complicam substituições.

- Rastreabilidade QR: Gráficos de dyno por lote, especificações de torque e guias de configuração reduzem diagnósticos errados e retornos.

Instantâneo de Adoção de Sintomas e Diagnóstico (2023–2025)

| Métrica | 2023 | 2024 | 2025 (est.) | Notas/Fonte |

|---|---|---|---|---|

| Oficinas a usar acelerómetro/telemática para sinalizar falhas de amortecedores | 16% | 23% | 34% | Inquéritos a fornecedores e instaladores de telemática |

| Amortecedores aftermarket com dados de dyno quente/frio para diagnóstico | 24% | 32% | 46% | Auditorias de catálogo; QA de marca |

| Frotas a rastrear RMS de aceleração vertical como KPI de manutenção | 12% | 19% | 29% | Relatórios de manutenção de frotas |

| Encomendas de serviço em zonas de neve especificando hardware ASTM B117 ≥720 h | 35% | 43% | 56% | Especificações de fornecedores; ASTM B117 |

| Concessionários a usar dados de configuração/torque QR na instalação | 20% | 28% | 41% | Iniciativas de marca própria |

Referências: Pesquisa de Mercado SEMA (https://www.sema.org/research), Documentos Técnicos SAE (https://www.sae.org/), Normas ASTM (https://www.astm.org/), Geotab (https://www.geotab.com/), Racecar Engineering (https://www.racecar-engineering.com/)

Estudos de caso de pesquisa recentes

Estudo de Caso 1: Telemática Sinaliza Amortecedores Defectuosos Antes de Queixas de Condutores (2025)

Contexto: Frota de última milha reportou deteções tardias de problemas de marcha, levando a copo de pneus e tempo de inatividade.

Solução: Ativou monitorização de aceleração vertical e eventos ABS; definiu limiares para criar ordens de trabalho automáticas; formou técnicos para confirmar com testes de quique e inspeções de fugas.

Resultados: Tempo de inatividade relacionado com amortecedores −26%; reclamações de desgaste irregular de pneus −22%; deteção média 1.200 km antes de casos reportados por condutores.

Estudo de Caso 2: Validação de Dyno Quente Reduz Devoluções Mal Diagnosticadas de “Amortecedor Barulhento” (2024)

Contexto: Rede de oficinas de performance viu devoluções elevadas por rangidos após instalações off-road.

Solução: Implementou verificações de dyno quente/frio e inspeções obrigatórias de buchas/suportes com torque sob altura de marcha; adicionou SOPs de instalação QR.

Resultados: Retornos por ruído −37%; taxa real de falha interna de amortecedor clarificada em 1,8% vs. 4,1% presumidos anteriormente; NPS de clientes +15 pontos.

Opiniões de especialistas

- Dr. Thomas D. Gillespie, Autor de Dinâmica de Veículos: “Dados de amortecimento validados por temperatura consistentes são essenciais para separar falha real de amortecedor de problemas de configuração ou buchas.”

- Stephanie Brinley, Analista Principal, S&P Global Mobility: “Plataformas eletrificadas mais pesadas amplificam sintomas—mergulho de travagem e copo de pneus surgem mais cedo quando amortecedores estão subespecificados.”

- Dave Polke, Técnico ASE Master/L1 e Formador: “Apertar hardware de suspensão à altura de marcha e substituir buchas com amortecedores. A maioria dos ruídos de ‘amortecedor mau’ são erros de montagem, não falhas de valving.”

Ferramentas e recursos práticos

- SAE Mobilus (diagnósticos de amortecedores, fundamentos de amortecimento): https://www.sae.org/

- SEMA Market Research (tendências aftermarket e instaladores): https://www.sema.org/research

- Racecar Engineering (interpretação de dados de dyno de amortecedores, fade térmico): https://www.racecar-engineering.com/

- Geotab (telemática para rastreio de aceleração vertical/eventos ABS): https://www.geotab.com/

- Hunter Engineering (procedimentos de alinhamento e altura de marcha): https://www.hunter.com/

- ASTM B117 (corrosão), D445/D2270 (viscosidade/VI): https://www.astm.org/

- Benchmarking de catálogos: https://www.ridefox.com/, https://www.bilstein.com/, https://www.kingshockstech.com/

Última atualização: 2025-10-09

Registro de alterações: Adicionadas 5 FAQs B2B sobre sintomas de amortecedores defectuosos; tabela de tendências 2025 com adoção de diagnóstico; dois estudos de caso (telemática, validação de dyno quente); pontos de vista de especialistas; recursos práticos com ligações autorizadas

Data da próxima revisão e gatilhos: 2026-03-31 ou antes se OEM/SAE lançarem novos padrões de diagnóstico de dyno quente, KPIs de telemática para saúde de amortecedores evoluírem, ou dados de frota mostrarem >15% de mudança em tempo de inatividade impulsionado por sintomas