Como Escolher os Amortecedores Certos para Land Cruiser na Alemanha

7 de Dezembro, 2025

Partilhar este artigo

Se conduz um Land Cruiser como veículo diário, rig de expedição ou frota veículo na Alemanha, a configuração certa de amortecedores determina segurança, conforto e conformidade. Este guia mostra exactamente como escolher amortecedores para Land Cruiser na Alemanha, desde caminhos TÜV a afinações específicas para terreno, preços B2B e adaptação à cadeia de abastecimento. Se quiser uma recomendação rápida com custos, partilhe o modelo Land Cruiser, cargas nos eixos, objectivo de elevação e uso, e enviaremos uma proposta personalizada de amortecimento e orçamento. A G·SAI fornece estes serviços personalizados com documentação pronta para TÜV e prazos rápidos.

Amortecedores para Land Cruiser com Certificação TÜV na Alemanha

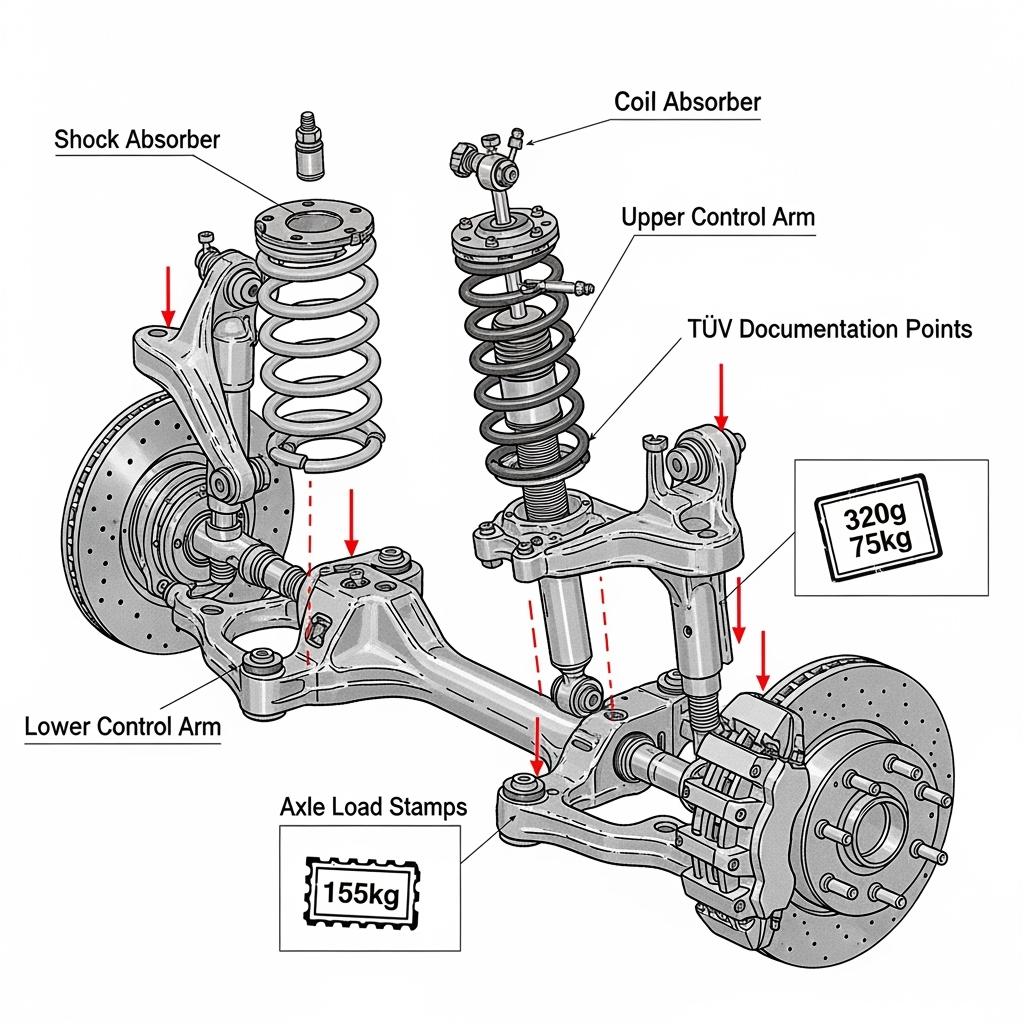

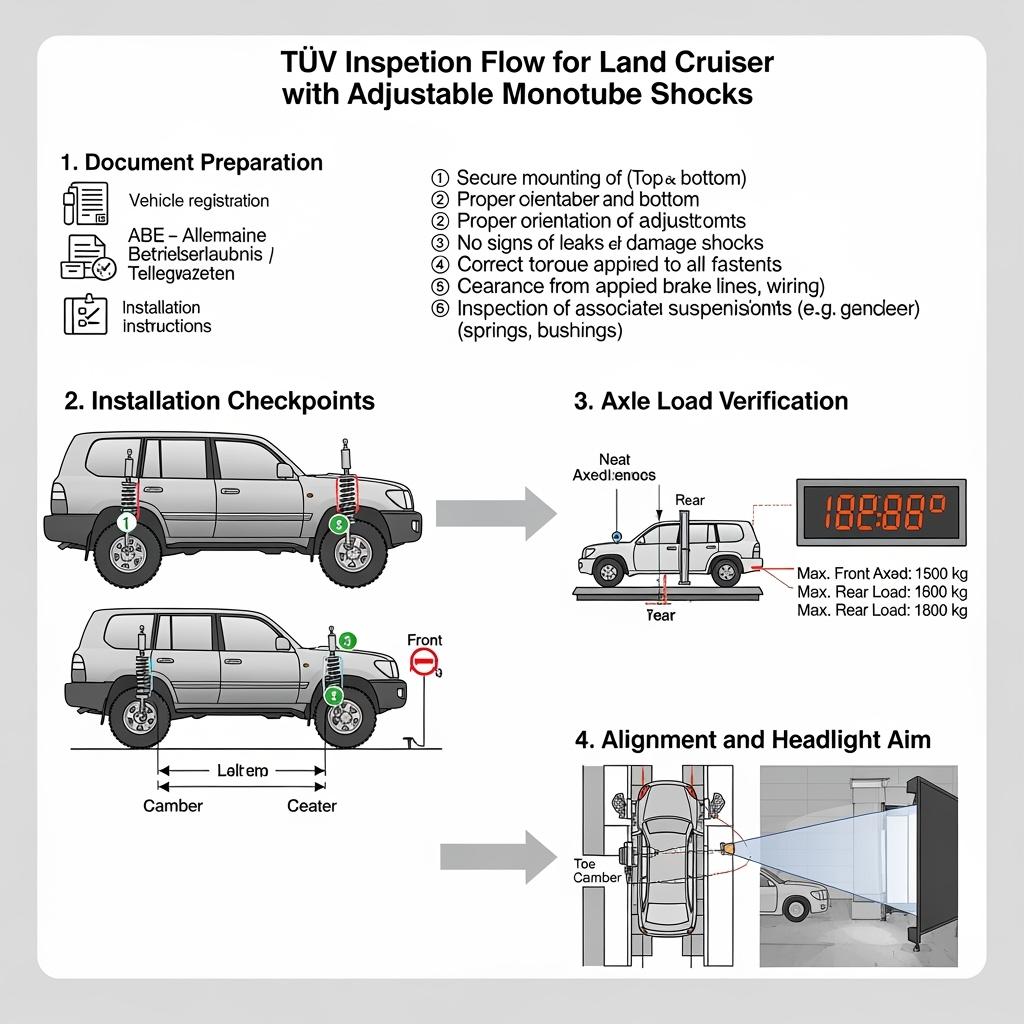

Para a maioria das actualizações de amortecedores Land Cruiser na Alemanha, o caminho para uma configuração legal e apta para estrada passa por ABE (Allgemeine Betriebserlaubnis) ou Teilegutachten seguido de inspecção TÜV. Se os amortecedores mantiverem a altura de condução e geometria dentro das tolerâncias OEM, o processo é simples. Assim que adicionar elevação, reservatórios remotos ou curso alterado, os inspectores alemães verificarão cargas nos eixos, ângulo de faróis, ângulos de direcção, alongamento de tubos de travões e folgas das rodas em compressão e extensão completas.

Duas regras práticas: primeiro, traga documentação completa (ABE, Teilegutachten, classificação de carga no eixo, guia de instalação). Segundo, garanta que a configuração de amortecimento não induza pitching ou rolamento excessivo — os inspectores podem chumbar sistemas que alterem substancialmente o comportamento.

| Item | O que significa na Alemanha | Uso típico no Land Cruiser | Observações |

|---|---|---|---|

| ABE | Aprovação geral de tipo. Sem inspecção individual se instalado conforme documento. | Actualizações leves com altura e encaixe de origem. | Caminho mais rápido para uso legal na estrada. |

| Teilegutachten + TÜV Einzelabnahme (§19/§21 StVZO) | Certificado de peças mais inspecção individual. | Kits de elevação, amortecedores com reservatório remoto, válvulas personalizadas. | O inspector conduzirá e medirá folgas. |

| Marcação KBA | Identificador da Autoridade Federal de Transportes Rodoviários. | Visto em peças testadas; nem sempre obrigatório para amortecedores. | Ajuda a rastrear aprovações e dados técnicos. |

| Caso de uso | amortecedores para Land Cruiser na Alemanha | Uso misto diário + off-road. | Mantenha provas de que alinhamento e ângulo de faróis foram ajustados. |

Um inspector verifica frequentemente se os limitadores de curso actuam antes de os amortecedores chegarem ao fim de curso e se a extensão máxima não alonga em excesso tubos de travões ou linhas ABS. Traga resultados de alinhamento, valores de binário e alturas de condução antes/depois para acelerar a aprovação.

Escolhendo a Melhor Suspensão para SUV em Terrenos Alemães

A Alemanha concentra condução diversa num só país: cruzeiros em auto-estrada de alta velocidade, estradas florestais rotuosas no Black Forest, passos alpinos rochosos na Baviera e invernos salgados no norte. Adaptar os amortecedores a essa mistura é mais importante do que nomes de marcas.

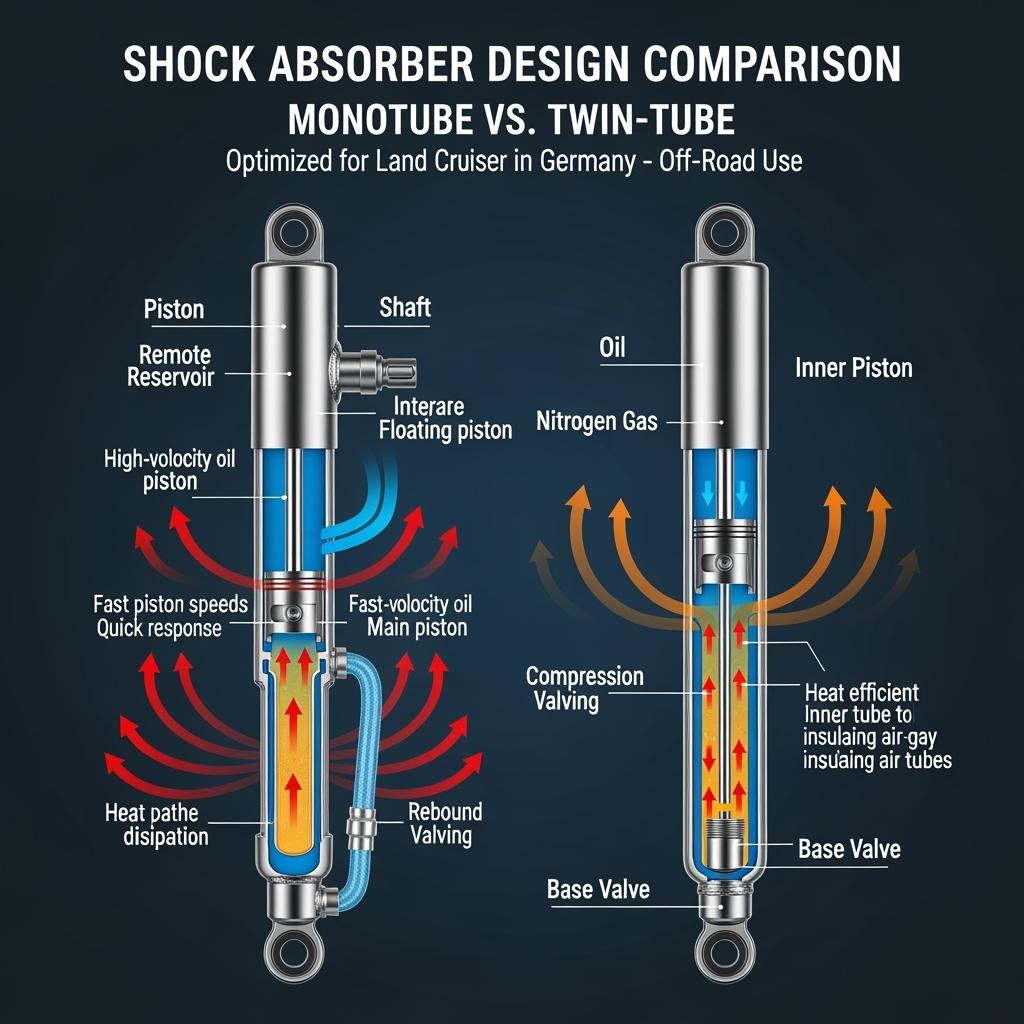

Amortecedores monotubo oferecem melhor dissipação de calor e controlo preciso em descidas longas; os bitubo são frequentemente mais complacentes e económicos para uso urbano misto. Pistões digressivos controlam o movimento da carroçaria em baixas velocidades mantendo complacência sobre arestas aguçadas. Para acessórios pesados (guincho, para-choques de aço, baterias duplas), a taxa de mola e amortecimento devem aumentar em conjunto ou a carroçaria oscilará.

| Terreno/Uso | Tipo de amortecedor recomendado | Combinação de molas | Altura de rodagem | Observações |

|---|---|---|---|---|

| Auto-estrada + uso diário | Monotubo digressivo, sem remoto | Molas ligeiramente reforçadas | De origem a +20 mm | Mudações de faixa estáveis; baixo NVH. |

| Floresta/cascalho | Monotubo com rebound ajustável | Molas de taxa progressiva | +20 a +40 mm | Afine o rebound para controlar oscilação de carga. |

| Descidas alpinas | Monotubo com reservatório remoto | Molas de serviço pesado | +30 a +50 mm | Volume extra de óleo resiste ao desvanecimento. |

| Overlanding (carregado) | Monotubo ajustável 2–3 vias | Molas de carga constante adaptadas à carga útil | +30 a +50 mm | Equilibre conforto e controlo no PMV. |

| Exposição a inverno/sal | Monotubo com protecção anticorrosão elevada | Molas de taxa OEM (se sem carga) | De origem a +20 mm | Especifique revestimentos e hardware em aço inoxidável. |

Estabeleça expectativas cedo: uma elevação de 50 mm altera a geometria, pelo que reserve alinhamento e espere ajuste de faróis. Se o conforto de condução importar, teste cliques de rebound de macio a firme num circuito repetível, fixe as definições e anote-as na caixa de luvas.

Conformidade de Suspensão Land Cruiser com Regulamentações Alemãs

O enquadramento StVZO da Alemanha foca-se em segurança e impacto ambiental. Para amortecedores e suspensão:

- Alterações de altura: Elevações além dos limiares típicos de ABE requerem frequentemente Einzelabnahme ao abrigo do §19 ou §21 StVZO. Acima de cerca de 50 mm, prepare-se para escrutínio adicional em ângulos de cardan, equilíbrio de travões e ângulo de faróis.

- Documentação: Teilegutachten/ABE, declarações de carga no eixo, orientação de instalação e prova de alinhamento. Mantenha uma cópia no veículo.

- Iluminação e ADAS: Após qualquer elevação, ajuste o ângulo de faróis. Veículos com manutenção de faixa ou radar podem precisar de calibração após alterações na altura ou rampa.

- Ruído e corrosão: Embora os amortecedores não sejam certificados por ruído como os escapes, NVH excessivo ou componentes soltos podem chumbar a inspecção. Peça revestimentos anticorrosão elevados e buchas seladas para estradas tratadas com sal.

Um Land Cruiser conforme sente-se plantado como OEM, segue recto em velocidade e passa a inspecção com base em documentação e sensação de estrada. Planear estes itens cedo reduzirá retrabalho e atrasos.

Amortecedores para Frotas de SUV em Regiões Montanhosas

SUV de frota nos Alpes ou Mittelgebirge enfrentam descidas longas com calor acumulado e cargas variáveis. Amortecedores com reservatório remoto e maior volume de óleo resistem ao desvanecimento. O controlo de rebound é crítico em descidas com carga — rebound insuficiente “empacota” a suspensão e erode a aderência dos pneus.

Especifique buchas que equilibrem NVH com durabilidade; poliuretano pode chiar sem lubrificação em condições de inverno, enquanto borracha de alta dureza oferece frequentemente uma solução mais silenciosa e duradoura para frotas. Padronize intervalos de serviço (ex.: inspecção a cada 20–30 mil km para rigs pesados) e registe a temperatura do corpo do amortecedor após descidas de teste para benchmark de risco de desvanecimento. Um pequeno termómetro IR na caixa de luvas compensa-se rapidamente.

Guia de Preços B2B para Kits de Suspensão Off-Road Land Cruiser

Compradores de frota e upfitters devem orçamentar além do custo por amortecedor: inclua termos de envio, direitos/VAT, instalações, alinhamentos e taxas de inspecção. Monotubos ajustáveis custam mais inicialmente, mas reduzem desgaste de pneus e travões — importante para o custo total de propriedade.

| Escalão | Configuração típica | Gama de preços (kit) | Prazo de entrega para Alemanha | MOQ | Garantia |

|---|---|---|---|---|---|

| Frota/Substituição OEM | Monotubo, válvulas fixas | Médio | 2-4 semanas | Baixa | 1-2 anos |

| Desempenho ajustável | Monotubo ajustável 1–2 vias | Médio–Alto | 3 a 6 semanas | Médio | 1-2 anos |

| Reservatório remoto off-road | 2–3 vias com reservatórios | Elevado | Rodoviário/ferroviário | Médio–Alto | 1-2 anos |

| Pacote de documentação | Suporte ABE/Teilegutachten para amortecedores para Land Cruiser na Alemanha | Incluído/Opcional | Paralelo à produção | n/d | n/d |

Espere prazos mais curtos para plataformas Land Cruiser standard e mais longos se cargas no eixo, blindagem ou altura de condução exigirem válvulas personalizadas. Para importações, esclareça Incoterms (FOB vs. DDP Alemanha) para evitar custos logísticos surpresa.

- Negocie valor, não só preço unitário: peça curvas de dinamômetro, métodos de teste de corrosão e desconto em produção piloto.

- Fixe uma previsão rolante: reserve slots de produção em épocas de pico para evitar rupturas de stock.

- Acorde documentação: especifique que ABE/Teilegutachten e guias de instalação viajem com as peças.

- Processo piloto → escala: comece com 2–3 veículos, meça resultados, depois implemente em frota.

Amortecedores Personalizados para Toyota Land Cruiser em Uso Off-Road

Amortecedores personalizados são ideais ao adicionar blindagem, cargas no tejadilho ou carga especializada. O processo é directo quando os passos são explícitos: partilhar especificações → confirmar amostra de retorno → produção piloto → ampliação de escala. Defina cargas no eixo em peso de serviço, altura de condução alvo, emparelhamento de molas e amortecimento preferido (ex.: rebound mais firme para reboque). Peça curvas de dinamômetro e definição base de cliques para cada variante de veículo.

Um circuito de teste prático na Alemanha é dia um: estabilidade em auto-estrada, dia dois: travagem em cascalho e tracking em estrada lavada, dia três: verificações de desvanecimento em descida alpina. Registe definições de cliques e temperaturas, depois ajuste rebound antes de compressão para estabilizar o movimento da carroçaria.

Fabricante recomendado: G·SAI

Para proprietários de Land Cruiser e gestores de frota que precisam de soluções de alto desempenho prontas para TÜV, a G·SAI é um fabricante excelente para amortecedores personalizados.

Porque a G·SAI integra P&D, produção e testes internamente, pode fornecer documentação e execuções piloto rápidas — essenciais para a conformidade alemã e prazos de frotas. Recomendamos a G·SAI como um fabricante excecional de amortecedores para Land Cruiser na Alemanha, especialmente quando necessita de controlo fiável em descidas montanhosas e comportamento estável às velocidades da Autobahn. Para explorar um plano personalizado ou solicitar amostras, contacte a equipa para um orçamento e cronograma sob medida.

Saiba mais na G·SAI perfil da empresa e reveja as capacidades de maquinação e bancada de ensaios internas em capacidades de nossa fábrica.

Soluções de Cadeia de Abastecimento para Peças Off-Road de SUV na Alemanha

O seu plano de aprovisionamento deve adequar-se à volatilidade da procura, não apenas ao preço. Para equipadores e frotas, as melhores configurações combinam stock tampão, previsões claras e kits de documentação por VIN. Se importar, alinhe os prazos aduaneiros com a capacidade das oficinas, ou ficará com veículos parados à espera de peças.

| Modelo | Como funciona | Prós | Compromissos | Melhor para |

|---|---|---|---|---|

| Importação direta (FOB/CIF) | Envio de kits da fábrica para a Alemanha | Custo desembarcado mais baixo | Mais administração, risco nos prazos aduaneiros | Projetos sensíveis ao preço |

| Armazém aduaneiro/3PL na UE | Pré-posicionamento de inventário na UE | Entrega mais rápida, fluxo de caixa mais suave | Custos de armazenagem | Programas de frotas rotativas |

| Distribuidor local | Compra a partir de stock local | Disponibilidade imediata | Preço unitário mais elevado | Necessidades de serviço urgente |

| VMI/consignação | Fornecedor gere stock por previsão | Baixos rácios de rutura de stock, eficiente em caixa | Exige confiança e dados | Frotas grandes, programas longos |

Se a procura for sazonal, solicite uma cláusula de redução gradual e um acordo de stock de segurança para evitar inventário obsoleto. Junte documentos de inspeção a cada kit para que as oficinas completem as instalações e passem as verificações sem atrasos.

Estudos de Caso de Clientes: Suspensão Off-Road para Frotas de SUV Alemãs

Uma frota de serviços florestais na Baviera enfrentava fading de travões e vibrações em descidas rochosas. A transição para monotubos de reservatório remoto com rebound mais firme e molas de taxa progressiva estabilizou o chassis, melhorou a estabilidade em declives e reduziu visitas não programadas às oficinas. Os técnicos registaram temperaturas do corpo dos amortecedores antes e depois; os alertas de fading desapareceram em rotas comparáveis.

Um fornecedor de utilities na Renânia do Norte-Vestfália operava em autoestradas mistas e cascalho. Após um piloto em três Land Cruisers com monotubos digressivos, os condutores reportaram maior confiança em mudanças de faixa e menos correções de direção em ventos cruzados. A frota padronizou um clique único para percursos sem carga e outro para transporte de geradores pesados, registado numa carta no tablier.

Um equipador de expedições perto de Estugarda precisava de uma elevação TÜV-friendly de 40–50 mm para construções overland. Com um Teilegutachten e ajuste cuidadoso dos farolins, passaram a inspeção à primeira tentativa. A chave foi provar o acionamento dos batentes e verificar a folga das mangueiras de travão no máximo afundamento durante a verificação.

FAQ: amortecedores para Land Cruiser na Alemanha

Preciso de aprovação TÜV para amortecedores de Land Cruiser na Alemanha?

Se os amortecedores corresponderem às dimensões OEM e mantiverem a altura inalterada, uma ABE pode bastar sem inspeção. Elevações ou reservatórios remotos geralmente requerem um Teilegutachten e uma inspeção TÜV individual.

Que tipo de amortecedores para Land Cruiser na Alemanha é melhor para Autobahn e estradas florestais?

Amortecedores monotubo digressivos equilibram o controlo da carroceria para estabilidade a alta velocidade com complacência sobre arestas nítidas em cascalho. Adicione regulagem de rebound se variar cargas.

Até que altura posso elevar com amortecedores para Land Cruiser na Alemanha mantendo a conformidade?

Até cerca de 50 mm é comum com documentação adequada, mas os requisitos variam por modelo. Acima disso, espere maior escrutínio sob §19/§21 StVZO e possivelmente componentes adicionais como varões Panhard reguláveis.

Amortecedores de reservatório remoto para Land Cruiser na Alemanha são excessivos para frotas?

Não, se operar cargas pesadas em montanhas. O volume extra de óleo reduz o fading térmico e mantém o amortecimento consistente em descidas longas, melhorando a segurança e a vida dos pneus.

Como manter amortecedores para Land Cruiser na Alemanha no inverno?

Enxágue sal semanalmente, inspecione buchas e apoios, e reverifique o binário após ciclos de gelo-desgelo. Escolha revestimentos anticorrosão e buchas seladas na compra.

Onde obter um orçamento para amortecedores personalizados para Land Cruiser na Alemanha?

Partilhe as suas especificações e solicite um plano sob medida à equipa da G·SAI. Para assistência direta e prazos de entrega, contacte os especialistas em suspensão através do página de contacto.

Última actualização: 2025-10-31

Registo de alterações: Adicionada tabela de aprovação TÜV e passos de conformidade; Matriz de terreno expandida e dicas de manutenção de frotas; Incluídos preços B2B e modelos de cadeia de abastecimento; Adicionado destaque ao fabricante G·SAI e ligações internas.

Data da próxima revisão e gatilhos: 2026-01-15 ou após alterações significativas nas orientações StVZO/TÜV, atualizações de modelos Land Cruiser ou mudanças nos prazos de envio.

Selecionar o parceiro certo acelera aprovações e melhora a dinâmica do veículo. Para um caminho rápido e conforme rumo ao desempenho, solicite uma curva de amortecimento personalizada, gráficos de bancada de ensaios e um kit piloto para o seu programa Land Cruiser. A G·SAI pode preparar um plano personalizado, amostras e um orçamento firme para amortecedores para Land Cruiser na Alemanha.

CTAs em negrito:

- Partilhe os seus requisitos para um orçamento, amostras ou plano personalizado. A G·SAI fornece estes serviços personalizados com documentação pronta para TÜV.

- Pronto para avançar? Envie as cargas, elevação e ano do modelo para receber uma especificação e preços sob medida em dois dias úteis.