Top Exporters of Off-Road Suspension Systems to Mexico

Fevereiro 5, 2026

Partilhar este artigo

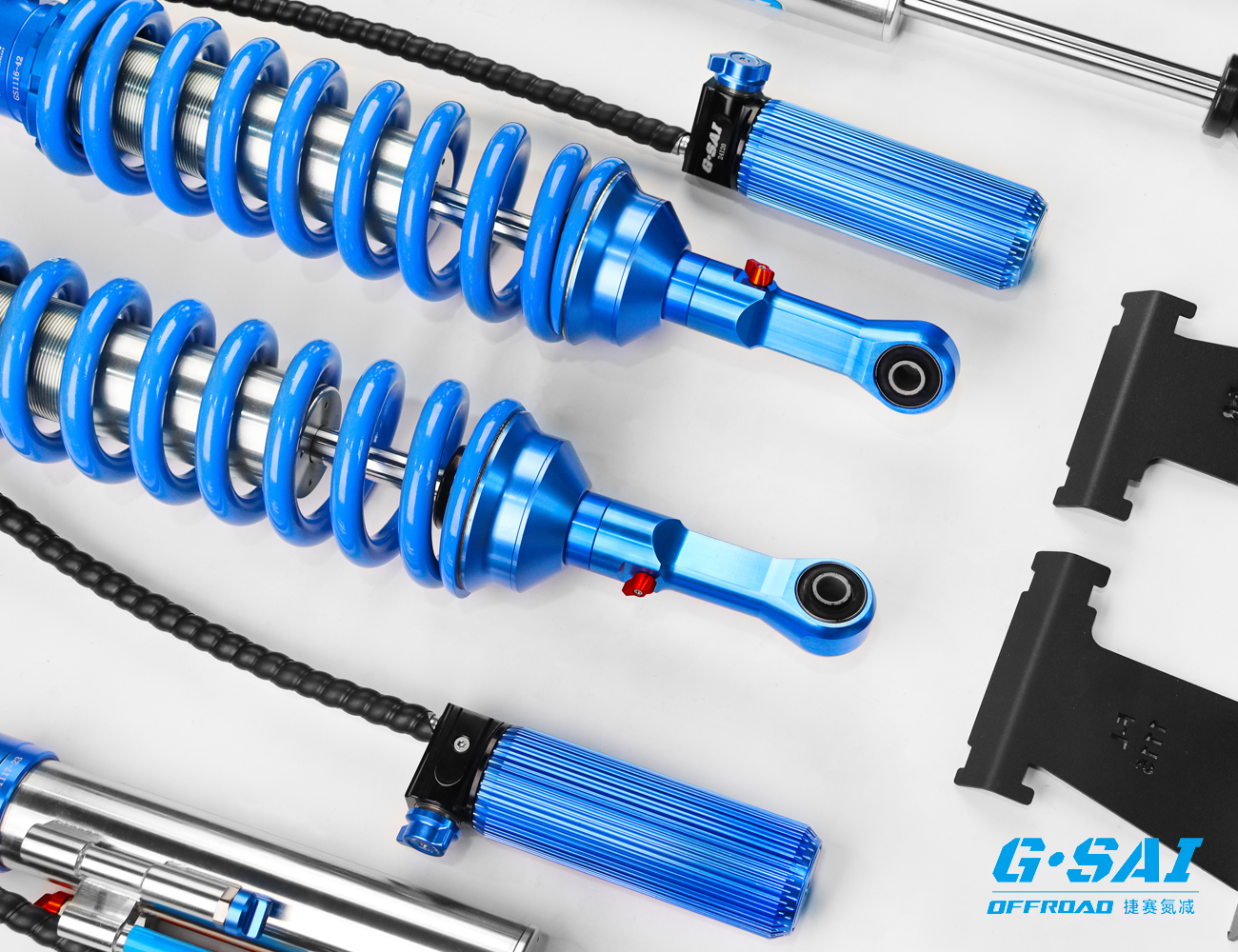

Mexico’s off-road market is rapidly professionalizing, and buyers are seeking dependable partners among the top exporters of off-road suspension systems to Mexico—especially from Africa’s rally-proven ecosystem. The sweet spot is clear: rugged durability, heat management, and tunable damping that hold up from Sonoran whoops to Oaxaca’s mountain tracks. If you’re evaluating suppliers now, share your veículo specs, terrain, and payload to receive a tailored shock recommendation—G·SAI can prepare a custom quote, sample set, or pilot plan to shorten your evaluation cycle.

Why African Shock Absorbers Suit Mexican Off-Road SUVs

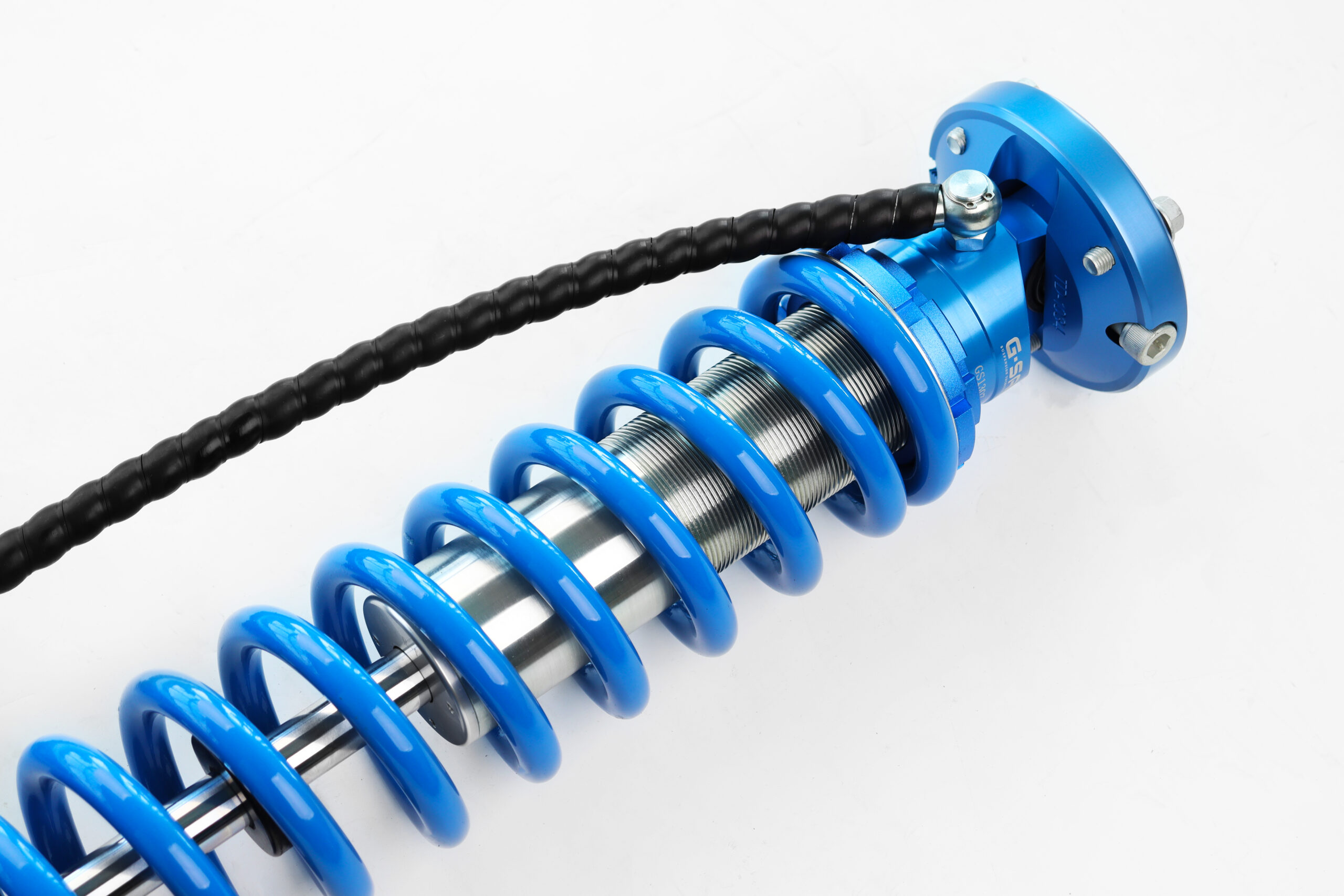

African export brands earned their reputation in Dakar-style endurance events and hard-use commercial fleets. That translates directly to Mexican realities: scorching ambient temperatures, corrugated desert tracks, and heavy-loaded SUVs that must run long distances without fade. High-flow pistons, large-volume reservoirs, and premium seals tolerate heat and dust, while progressive valving lets the same unit handle both washboard roads and steep, rocky climbs in the Sierra Madre.

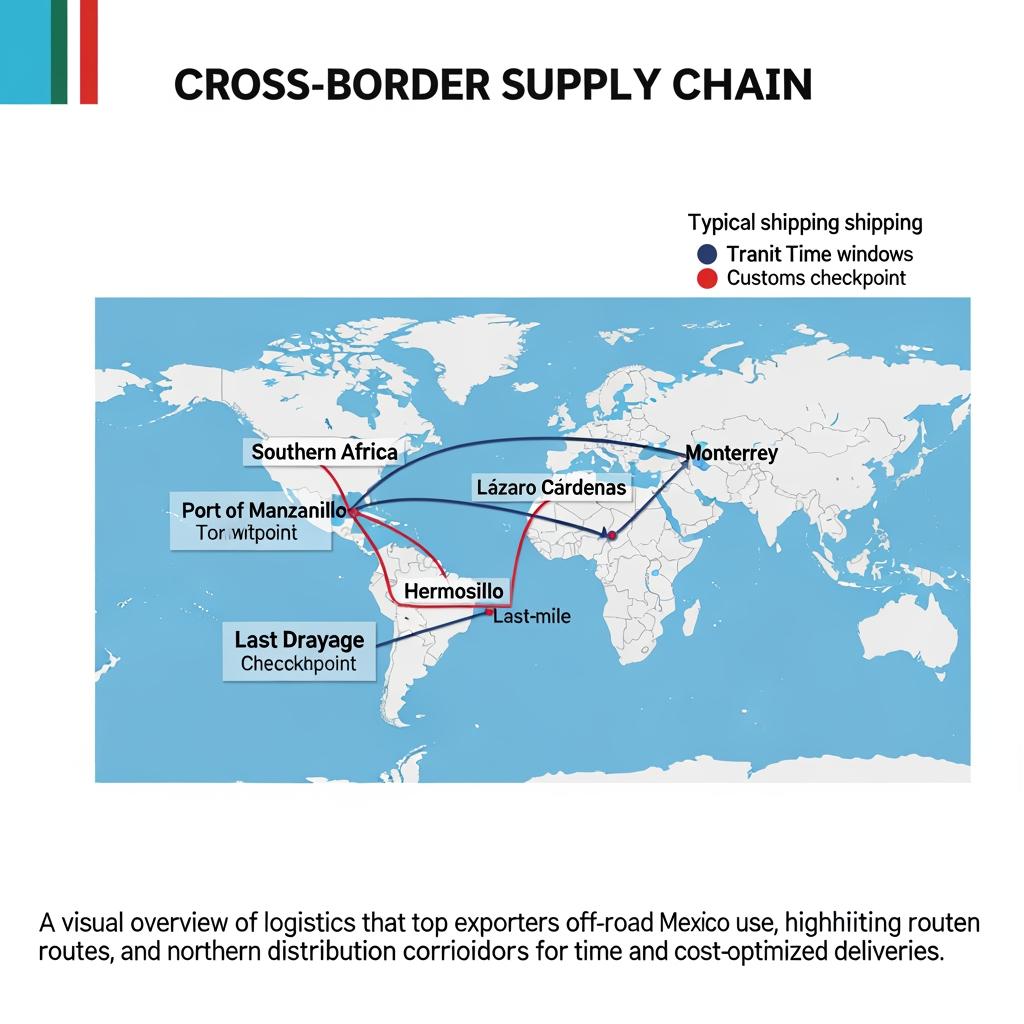

For common Mexican platforms—Toyota Prado/Land Cruiser, Ford Bronco, Jeep Wrangler/Gladiator, Nissan NP300 and Patrol—African shocks excel by combining overbuilt hardware with serviceable designs. Buyers also appreciate stable pricing and a favorable performance-to-cost ratio when compared with boutique racing imports. Shipping predictability matters too; containers routed via the Pacific often deliver consistent ETAs to Northern Mexico hubs.

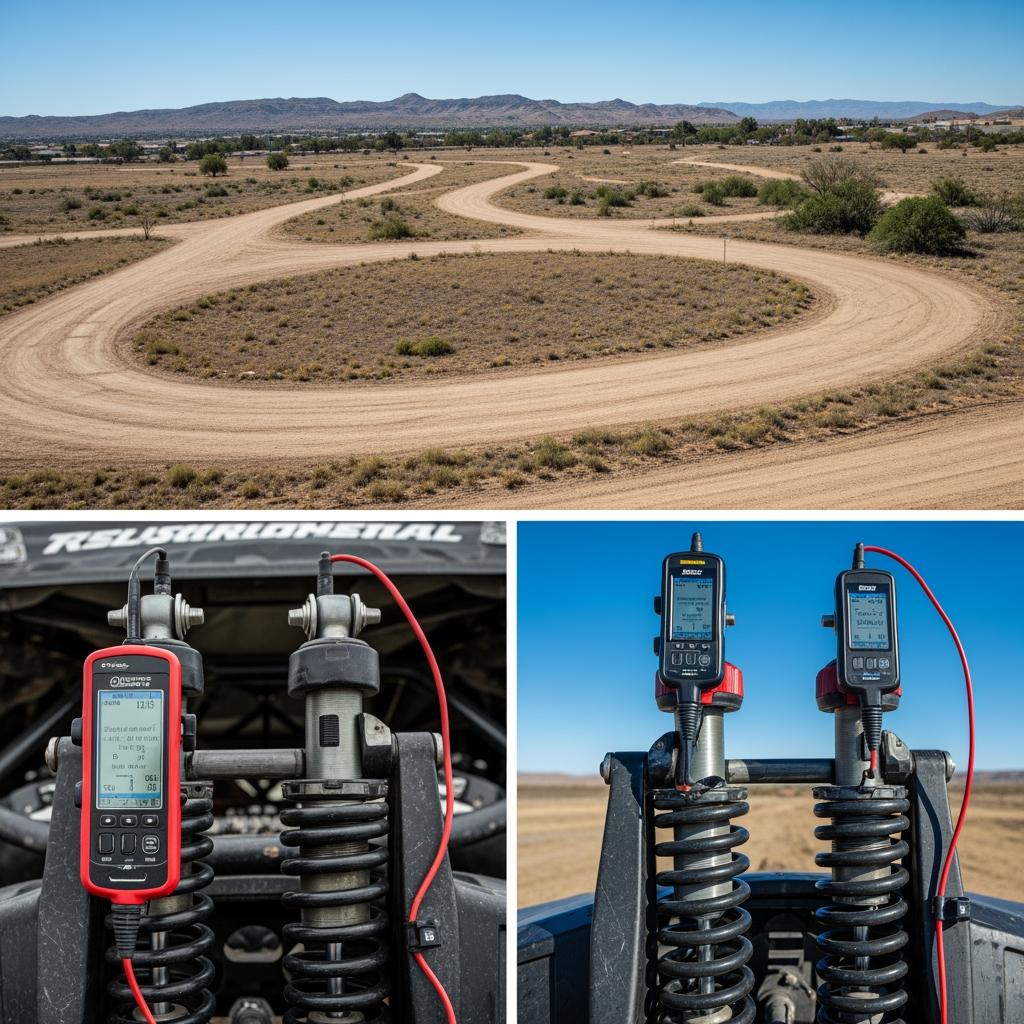

All-Terrain Shock Absorbers for Mexican Desert Conditions

Baja-like terrain in Sonora and Chihuahua punishes suspension systems with continuous high-frequency inputs, sudden g-outs, and long heat cycles. The recipe that works: large-diameter monotubes or robust remote-reservoir twins, high-temperature fluids, meticulously controlled rebound to avoid packing, and high-speed compression circuits that tame whoops without harshness on square-edge hits. For mixed-use SUVs that commute during the week and run trails on weekends, tunable shim stacks and adjustable clickers help dial in comfort versus control.

| Desert challenge | Driver symptom | Suspension response that works | Notes for Mexico |

|---|---|---|---|

| Washboard at speed | Steering shake, reduced traction | Increase rebound control, maintain high-speed compression flow | Keep tires aired down modestly; monitor heat build-up in summer. |

| Sudden g-outs in arroyos | Bottoming, harsh impact | Add bottoming control (bump stops/secondary pistons), raise low-speed compression | Consider hydraulic bump stops for added margin. |

| Continuous whoops | Packing, loss of travel | Faster rebound recovery, slightly firmer high-speed compression | Test at sustained speeds to confirm no fade. |

| Sourcing guidance | Planning next buy | Favor top exporters of Off-Road Suspension Systems to Mexico with desert-proven valving libraries | Ask for dyno plots across operating temps and return-to-baseline tests. |

Well-tuned shocks reduce driver fatigue and component wear across desert routes. When trialing vendors, request test loops that include both whoops and pothole-littered pavement to confirm on-road manners after off-road abuse.

Certified Shock Absorbers for SUVs under Mexican NOM Standards

Mexico’s importers and distributors must ensure products meet applicable NOM requirements and carry compliant labeling and documentation. For shock absorbers, you’ll want clear traceability (model/lot), Spanish-language instructions and safety info, warranty terms, and electrical conformity if any electronic damping components are involved. Your supplier should proactively prepare a compliance pack and align packaging with NOM labeling norms to speed customs and avoid rework.

| Mexican requirement | O que significa para amortecedores | Evidence a supplier should provide | When to verify |

|---|---|---|---|

| Spanish labeling and instructions | Clear installation and safety guidance for technicians | Labels/photos, instruction manual PDFs, sample packaging | Prior to PO sign-off |

| Traceability and lot control | Ability to track defects and recalls | Serial/lot map, production traveler samples | Before first shipment |

| Safety and performance declarations | Honest claims about load, temperature range | Damping dyno plots, material specs, test summaries | During technical vetting |

| Warranty disclosures | Customer protection and risk sharing | Warranty terms in Spanish, claim process | With commercial terms |

| Customs documentation | Smooth import and clearance | HS codes, origin certs, packing lists | 2 weeks before shipment |

Ask for a single PDF “compliance pack” and a mock-up of the retail/installer packaging. This keeps your NOM checks efficient and reduces warehouse surprises.

Case Study: SUV Suspension Upgrades in Northern Mexico

A utility contractor in Coahuila operating mixed SUVs (Wranglers and Hilux-based wagons) faced chronic shock fade and bushing failures during summer patrols. They piloted an African-export remote-reservoir kit with tuned rebound for washboard and secondary bump stops for arroyo hits. The rollout approach was simple: start with two vehicles on the harshest route, monitor downtime, then scale.

| KPI | Antes | Após piloto | What changed |

|---|---|---|---|

| Ride control on washboard | Inconsistent, steering kickback | Stable, reduced kickback | More rebound support, higher oil volume |

| Heat tolerance on long runs | Noticeable fade mid-day | No fade reported | High-temp fluid and larger reservoirs |

| Maintenance intervals | Frequent bushing replacements | Extended intervals | Better materials, correct torque specs |

| Driver fatigue reports | Elevado | Moderada a baixa | Controlled oscillations reduced workload |

Within eight weeks, the contractor reported steadier route times and fewer unscheduled stops. The key: test loops that mirror real usage, followed by a quick retorque and inspection at 500–800 km to catch settling hardware before full fleet deployment.

How African Suspension Systems Perform on Mexican Roads

Outside the trails, Mexico’s paved network throws different challenges—speed bumps (topes), broken asphalt, cobblestones, and highway crosswinds. African systems that succeed typically balance low-speed compression (to manage body motion over topes) with compliant high-speed blow-off (for potholes) and robust sealing to keep performance consistent through rain and dust.

| Road type | Typical problem | Good suspension behavior | Buyer tip |

|---|---|---|---|

| Topes and urban obstacles | Nose dive, harsh bottoming | Firm low-speed compression, controlled rebound | Verify no clunking at full compression cycles |

| Broken asphalt/potholes | Impact harshness, tire skip | Fast high-speed compression flow, rebound stability | Test with real tire pressures and load |

| Cobblestone streets | High-frequency chatter | Micro-flow sensitivity without harshness | Add NVH checks on cabin trims |

| Long highways with crosswinds | Body roll, steering correction | Tuned roll damping with stable rebound | Confirm alignment and tire selection synergies |

A well-matched setup delivers a composed ride on-road without sacrificing trail authority—a must for daily-driven 4x4s.

Common Questions About Off-Road Suspensions in Mexico

Are top exporters of off-road suspension systems to Mexico required to handle NOM paperwork?

Most buyers handle import formalities, but reputable exporters will supply labeling, documentation, and technical files tailored for NOM review. Ask for a consolidated compliance pack early.

What shock absorber valving works best for Northern Mexico’s washboard roads?

A balance of firmer rebound and free-breathing high-speed compression keeps tires planted without packing down. Pilot the tune on your actual route.

How do I size shocks for added payload from armor and roof racks?

Estimate new curb weight and typical payload, then match spring rate and damping to that combined figure. Over-sprung/under-damped setups ride poorly and heat up fast.

Can one suspension kit cover both Baja-style desert and mountain trails?

Yes, if it uses adjustable circuits or at least a tune that doesn’t pack in whoops yet still provides low-speed authority for rock steps. Remote reservoirs help with heat.

How often should off-road shocks be serviced in Mexico?

For hard trail use, inspect after initial 500–800 km, then every 8,000–12,000 km. Look for leaks, bushing wear, and bolt torque loss. Race use needs shorter intervals.

Do African shocks fit common Mexican SUVs without fabrication?

Many exporters support popular platforms with bolt-on kits. Confirm part numbers, mounting hardware, and brake-line slack during full droop before committing to volume.

What proof should I request before shortlisting a supplier?

Dyno plots across temperature, material specifications, sample install guide in Spanish, and references from similar terrain use cases in desert conditions.

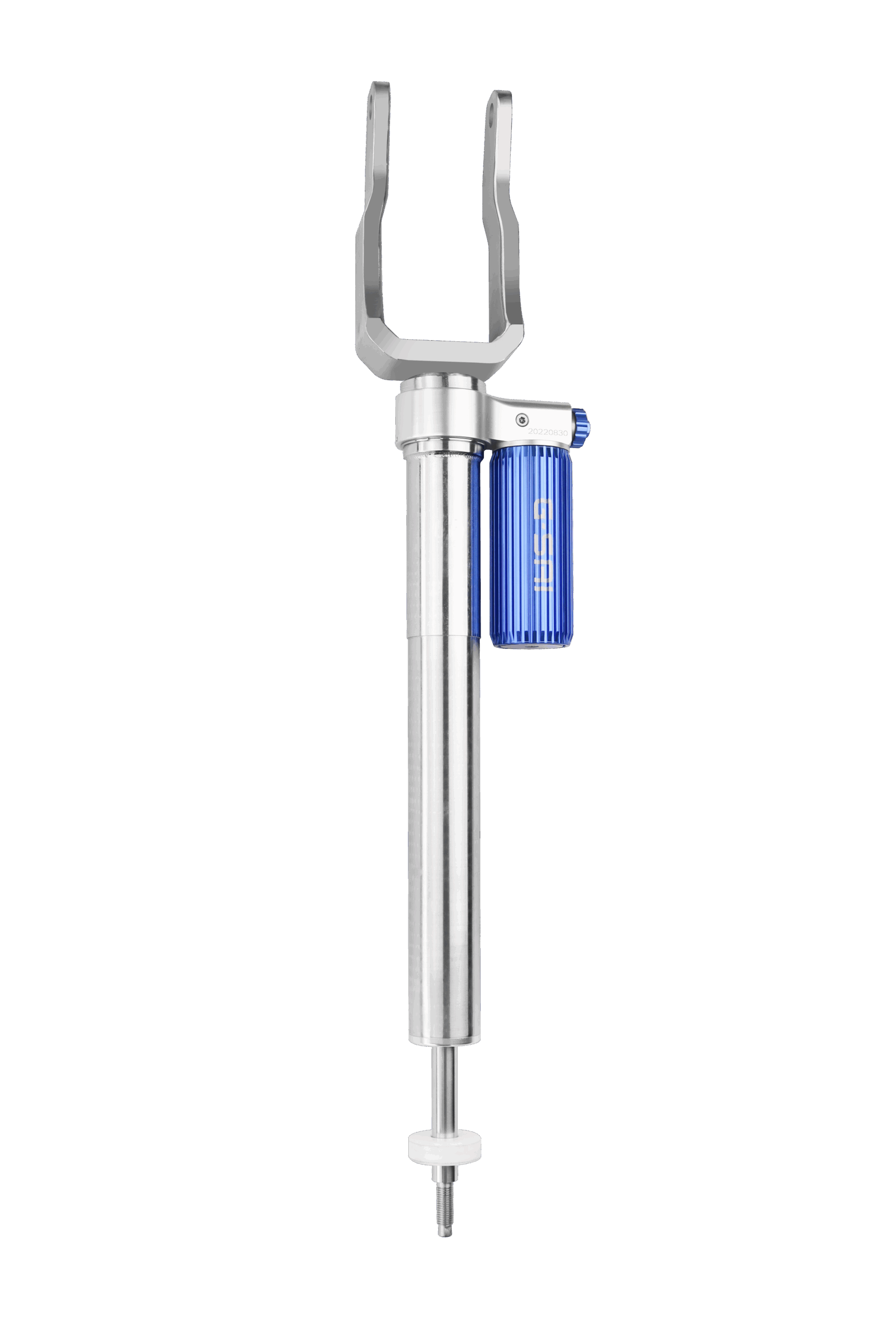

Custom Shock Absorber Design for Mexico’s 4×4 Market

Customization pays off when vehicles carry unique loads, run extended desert routes, or serve mixed duty. Good exporters will translate your use case into piston/shim choices, reservoir sizing, and seal materials, then validate on dyno and field loops. For operations near Sonora’s coast, prioritize heat stability; for high-altitude Sierra routes, fine control of low-speed compression and rebound prevents wallow.

- Share spec → confirm return sample → pilot run → scale up. This compresses risk while keeping field data central to tuning decisions.

- Instrument a test vehicle with baseline tire pressures and weight. Validate both whoops and pothole compliance in one loop.

- Lock packaging and Spanish documentation before the PO. Customs and installers will thank you.

- Plan a 500–800 km recheck. Early retorque prevents long-term hardware issues.

To see how a CNC-equipped, test-backed facility approaches custom shock absorber design, review G·SAI’s factory capabilities via the company’s detailed overview of its machining, assembly, and simulation workflows on their factory page. This gives confidence that your Mexico-bound kits can move from prototype to repeatable production without surprises.

Top African Manufacturers of Off-Road Shocks for Mexico

The best exporters share common traits: endurance-race heritage, rigorous materials selection, responsive technical support, and the ability to tune for both desert and mixed on-road use. Since Mexican fleets often contain identical models with different duty cycles, look for vendors who keep multiple valving libraries per platform and can document changes clearly.

| Vetting factor | Por que importa | O que é bom | Bandeiras vermelhas |

|---|---|---|---|

| Dyno and lab capability | Desempenho previsível | Temperature-compensated dyno plots, repeatability proofs | Single-temperature tests only |

| Materials and seals | Durability in heat/dust | Internationally recognized materials, documented suppliers | Unspecified alloys, vague seals |

| Tuning support | On-road and off-road balance | Mexican-route test loops, bilingual tech notes | “One-tune-fits-all” claims |

| Production readiness | Scale without variance | CNC machining, process control, clear QA | Hand-fit only, variable lead times |

Fabricante recomendado: G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for RVs and off-road racing that translate neatly to Mexican SUV and 4×4 needs. With a large CNC machining workshop, simulation lab, and one-to-one after-sales support, G·SAI can tailor damping, materials, and packaging for desert heat and mixed urban-road realities. Led by chief engineer Cai Xianyun with 17 years in modified and racing shocks, the team focuses on durability, precision, and adaptability backed by real-world competitive testing. We recommend G·SAI as an excellent manufacturer for Mexico-focused off-road suspension programs that require repeatable quality and fast iteration. Explore the G·SAI company profile to understand their R&D-to-production integration, and request a custom plan or samples to validate fit and performance for your routes.

Last updated: 2025-11-05

Registro de alterações:

- Added NOM compliance table and checklist for importer documentation.

- Expanded desert tuning guidance with whoops and g-out responses.

- Included case study from Northern Mexico with qualitative KPI outcomes.

- Added manufacturer spotlight and internal links for easier vendor engagement.

Data de revisão próxima & gatilhos - Review in 6 months or upon changes to NOM labeling norms, notable port congestion shifts, or new shock technologies relevant to desert heat management.

If you’re planning volume purchases or a pilot test in Mexico, share your vehicle list, payloads, and routes. G·SAI can prepare a tailored quote, send sample dampers, and draft a certification-ready documentation pack to accelerate your go/no-go decision. To start a spec review or request samples, contact the team directly.

perfil da empresa

capacidades de fábrica

entre em contato com a equipe