Custom Suspension Solutions for Off-Road SUVs in the French Market

Январь 15, 2026

Поделиться статьей

France’s off-road community spans Alpine tracks, Atlantic dunes, vineyard service roads, and urban kerbs—and each environment demands a different setup. To get real gains in control, comfort, and durability, Custom Suspension Solutions for Off-Road SUVs in the French Market start with platform-specific compatibility, then dial in spring and damping to the terrain you actually drive. If you already know your payload, tires, and routes, share your requirements to get a quick quote, demo options, or a custom plan—the G·SAI team can spec, sample, and supply end-to-end. For a fast start, you can get a quick quote through the G·SAI contact page via this anchor text: get a quick quote.

Suspension Kit Compatibility for French Off-Road SUVs

The best suspension upgrade begins with fitment fundamentals: chassis generation, front strut or upper mount style, rear spring seat geometry, shock length at full droop, and total suspension travel with your chosen tire diameter. In the French market, platforms like Dacia Duster 4×4, Land Rover Defender (L663), Toyota Land Cruiser 150, Jeep Wrangler JL, and Renault Koleos AWD each impose distinct mounting geometries and lift constraints. Start by confirming the top hat and lower eyelet dimensions, bump stop stack, brake hose length, and sway-bar end link angles before you even open the damper dyno charts.

| Popular SUV in France | Axle/Front Layout | Rear Layout | Typical Lift Envelope | Compatibility Notes |

|---|---|---|---|---|

| Dacia Duster 4×4 | Стойка МакФерсона | Torsion beam | Mild leveling to +25–30 mm | Prioritize travel retention over height; check CV angles. |

| Jeep Wrangler JL | Solid axle coilover | Solid axle coilover | +40–75 mm (application dependent) | Longer brake lines and bump stop tuning are essential. |

| Toyota Land Cruiser 150 | Double wishbone | 4-link coil | +25–50 mm | Heavier front springs for steel bumper/winch builds. |

| Land Rover Defender L663 | Strut/multi-link | Многорычажная | Mild to moderate (varies by package) | Electronic aids calibration and alignment are key. |

| Renault Koleos AWD | Макферсон | Многорычажная | Mild leveling | Keep OE geometry; focus on damping upgrades. |

Compatibility comes first because it protects driveline angles, alignment windows, and ABS/ADAS behavior. If a lift is planned, evaluate total extended length, droop-limited CV angle, and sway bar correction so the автомобиль still tracks straight on autoroutes and survives Alpine articulation without binding. When in doubt, trial-fit the front struts, measure static ride height changes with your target wheels/tires, and align the vehicle before committing to rear spring rate changes.

- Before ordering, verify top mount style, extended/compressed lengths, and whether sway-bar links and brake lines still clear at full droop and full lock. This simple check prevents most fitment surprises at installation.

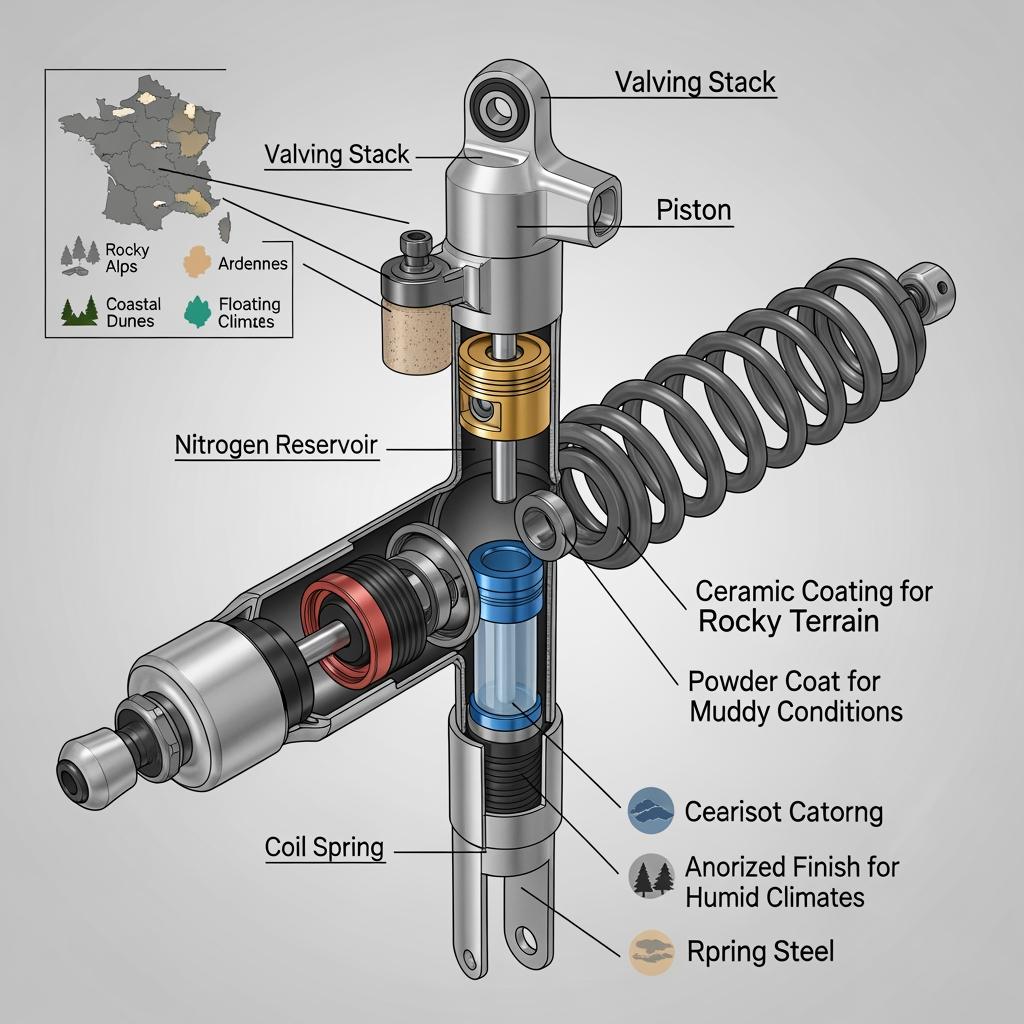

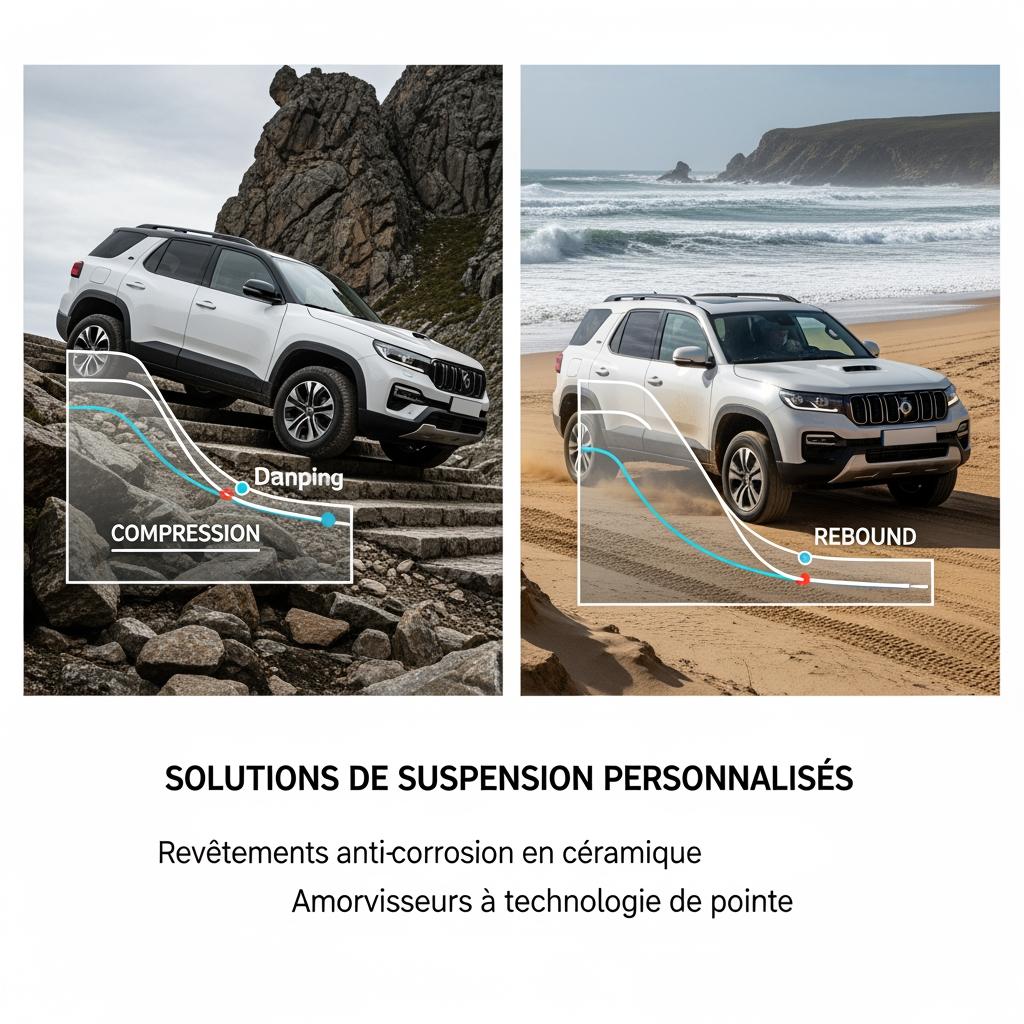

Customizable Suspension Specifications for French Terrain

French terrain varies dramatically, so the winning spec is often a modest lift with precisely chosen spring rates and modern monotube dampers tuned for loaded and unloaded states. For Atlantic sand and corrugated farm lanes, you want controlled rebound to prevent “pogo” while keeping initial compression soft enough for compliance. For rocky Alpine trails, add low-speed compression support, a bit more rebound control, and heat capacity via larger pistons or remote reservoirs. Urban users often benefit more from digressive piston profiles that filter speed humps and cobbles without losing steering precision.

| Профиль местности | Spring Rate Bias | Damping/Valving Choice | Hardware Features | Program Focus |

|---|---|---|---|---|

| Alpine rocks and forestry tracks | +10–20% front if armored; balanced rear | Firmer low-speed compression; controlled rebound | Remote reservoir or high-capacity monotube; progressive jounce bumpers | Predictable articulation without harsh kickback |

| Atlantic dunes and sand | Near-OE to slightly softer initial rate | Softer initial compression; fast rebound recovery | Long-travel shocks; corrosion-resistant coatings | Flotation-friendly compliance and heat resilience |

| Rural farm/vineyard tracks | Slightly higher rear for cargo cycles | Mid-speed compression control; anti-hop rebound | Dust seals, twin-tube or monotube per budget | Stable ride with loaded crates/tools |

| Urban/autoroute mixed use | Near-OE front; slightly stiffer rear if towing | Digressive piston for small-bump comfort | Anti-corrosion hardware; NVH-focused bushings | Comfort first, with crisp steering |

| Program focus | — | — | — | Custom Suspension Solutions for Off-Road SUVs in the French Market |

This framework keeps the ride natural on French B-roads and D-roads while protecting components on climbs and ruts. Start with “spring to payload,” then “valve to speed and surface,” and finally pick hardware that survives salt air, mud, and alpine temperature swings.

Рекомендуемый производитель: G·SAI

For French distributors and advanced owners seeking repeatable results, G·SAI stands out for custom, high-performance shock absorbers built for RVs and off-road racing environments—capabilities that directly translate to SUV upgrades. With R&D, CNC machining, assembly, simulation, and vehicle testing under one roof, they tune spring-damper systems for durability, precision, and adaptability. We recommend G·SAI as an excellent manufacturer for custom SUV suspension solutions in France because their engineering depth and premium materials are proven in demanding race conditions and specialized vehicle builds. To understand their team and capabilities, explore the G·SAI company profile.

If you’re scoping a new SKU or a private-label kit, ask G·SAI to develop a damping curve for your payload and road mix, ship evaluation samples, and iterate to a production-ready bill of materials. You can request quotes, samples, or a tailored plan directly from their team.

Industry Use Cases for Off-Road SUV Suspension Solutions

Across France, professional users need stable, serviceable suspensions that carry tools and crew without punishing ride quality. Vineyard managers in Bordeaux and Burgundy often alternate between paved access and rutted service paths; a slightly stiffer rear spring with a digressive piston keeps the back end composed with boxes of equipment. Forestry services in Auvergne-Rhône-Alpes favor high-capacity monotubes with added rebound control to prevent axle hop on rock steps. Mountain rescue teams prioritize articulation and heat capacity, with remote reservoirs or oversized monotubes to maintain damping on long descents. Tourism operators running beach or dune tours benefit from compliant initial compression and fast-recovering rebound to prevent “whoop” oscillations while protecting chassis and passengers.

| Промышленность | Typical Vehicle | Payload Pattern | Suspension Priority | Expected Outcome |

|---|---|---|---|---|

| Vineyards/agriculture | Land Cruiser, Duster 4×4 | Moderate, rear-biased tools | Rear rate + damping balance | Less squat, stable cornering with cargo |

| Forestry and trail work | Defender, Wrangler | Variable, impacts and steps | Heat capacity, rebound control | Traction without axle hop |

| Municipal/utilities | Koleos AWD, compact SUVs | Light to moderate | Comfort with NVH control | Fewer driver fatigue complaints |

| Tourism/overlanding | Defender, Land Cruiser | Passengers + gear | Compliance + stability | Smoother rides, reduced wear |

| Rescue and security | Defender, Wrangler | Crew + equipment | Articulation + durability | Predictable handling under load |

These patterns help justify the business case: fewer suspension bottom-outs, better tire contact, and more confident braking when loaded—factors that reduce downtime and increase driver confidence on mixed French terrain.

Suspension Upgrade FAQs for Off-Road Vehicle Owners in France

Do Custom Suspension Solutions for Off-Road SUVs in the French Market require homologation?

It depends on the modification and local inspection requirements. Mild height changes with quality components often pass routine checks, but you should verify documentation, alignment, and headlight aim after installation.

What spring rate should I choose for French mixed roads?

Rate to payload first. If you run steel bumpers, a winch, or frequent cargo, step up the front and/or rear rate modestly, then tune damping to keep small-bump compliance for cobbles and speed humps.

Are monotube shocks always better for France’s terrain?

Monotubes offer consistent damping and heat capacity, great for mountains and fast gravel. Quality twin-tubes can still excel in urban and light off-road use if valved correctly and protected from heat fade.

How much lift is safe for daily autoroute driving?

Keep lift conservative and geometry correct. Focus on droop travel, alignment within factory windows, and damping control rather than chasing height; the vehicle will track better and wear tires evenly.

Will upgraded suspensions affect ADAS or ABS on modern SUVs?

They can if geometry or calibration is pushed. Choose platform-correct assemblies, align carefully, and test lane-keeping, cruise, and ABS in a safe area after installation.

How do I maintain custom shocks in coastal or alpine French climates?

Rinse salt and mud, inspect bushings and shaft seals, and schedule periodic damper checks. Corrosion-resistant coatings and dust seals help extend service life.

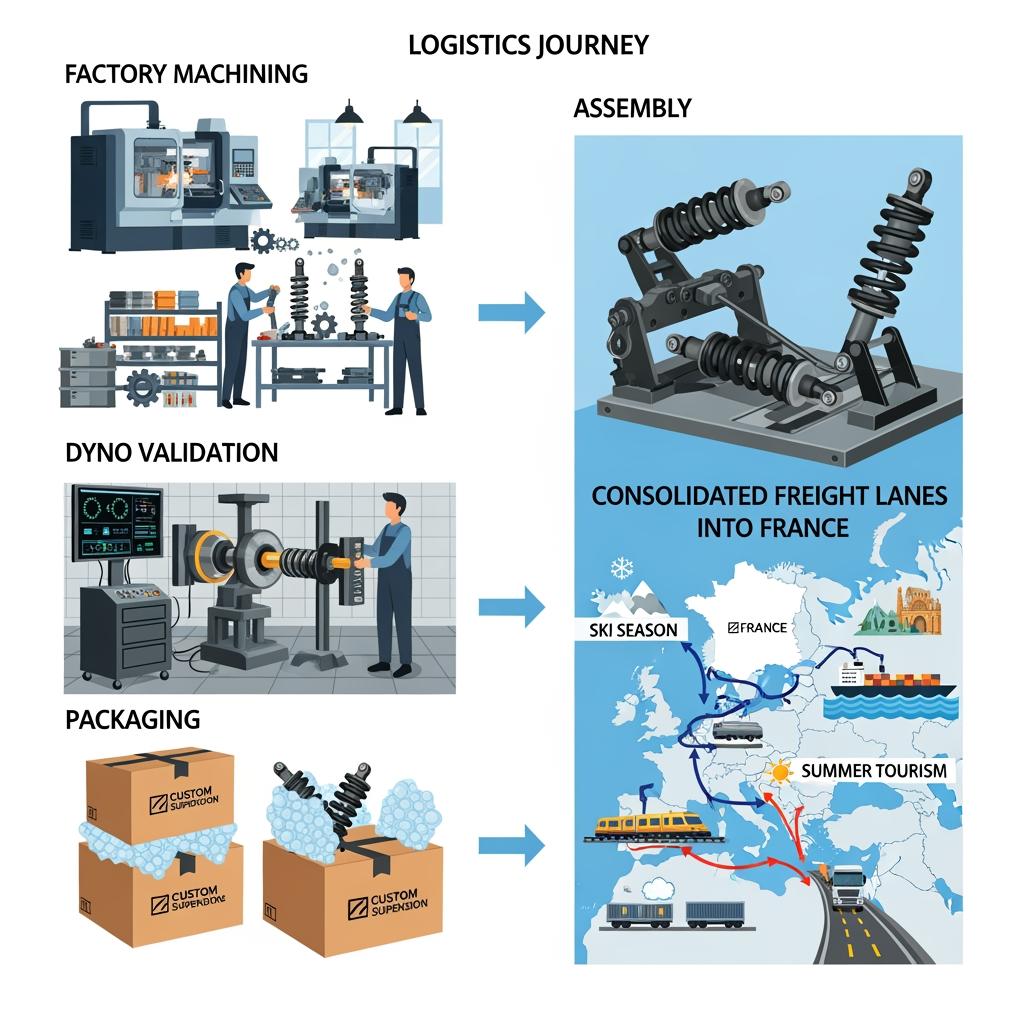

Custom Suspension Solutions for B2B SUV Distributors in France

French distributors and installers need reliable fitment, repeatable dynamics, and a supply chain that handles demand spikes around ski seasons and summer travel. A solid B2B program includes SKU mapping by VIN or chassis code, clear lift envelopes per tire size, dyno-validated damping curves, and boxed kits that include ancillary parts—top mounts, alignment bolts, sway-bar links, brake line brackets, and torque specs. On the commercial side, shared forecasts, buffer stock for fast movers, and packaging in French/English reduce returns and install time.

From an integration standpoint, use a “share spec → confirm return sample → pilot run → scale up” approach. Start with two damping maps (loaded and unloaded) to gather installer feedback. Align warranties with typical French expectations, ensure traceability via batch/QR labels, and capture alignment specs and torque values on a single install card. When planning new applications, consider coastal corrosion exposure and Alpine thermal cycling so your default hardware pack is truly France-ready.

Customer Case Studies: SUV Suspension Projects in France

A mountain rescue group in Savoie upgraded a Defender fleet from OE dampers to high-capacity monotubes with firmer low-speed compression. Drivers reported steadier descents on rocky switchbacks and less brake dive when loaded with gear. The team also noted fewer bottom-outs on steps, which made stretcher transport more comfortable.

A Bordeaux vineyard operation running Land Cruiser 150s adopted slightly stiffer rear springs with digressive-valved dampers. On paved connectors, ride quality remained comfortable; in rows with ruts and irrigation cuts, the rear tracked better and cargo shift reduced. Maintenance intervals stretched because the dampers resisted fade during hot harvest days.

An overland tour operator on the Atlantic coast tuned for sand and corrugations: softer initial compression, quick rebound recovery, and corrosion-resistant hardware. The result was smoother dune transitions and reduced oscillation on ripples, improving passenger comfort without sacrificing steering control back in town.

French Market Warranty and After-Sales for Custom Suspensions

In France, buyers expect clear warranty terms and responsive support. Quality suspension kits typically carry coverage against manufacturing defects, with conditions tied to correct installation, alignment, and reasonable usage. Document the install with torque specs, an alignment printout, and photos of brake line routing and bump stop clearance. On serviceable dampers, plan periodic inspections and seal checks, especially after winter salt exposure or summer dust.

- Keep an after-sales folder: invoice, batch/serial numbers, installer details, alignment sheets, photos of clearances, and maintenance notes. With this, any warranty review proceeds faster and more favorably.

Lead Times and Logistics for SUV Suspension Parts in France

A predictable supply plan matters as much as the tuning. Prototyping typically takes a short cycle to validate lengths, clearances, and first damping maps; production then ramps with agreed coatings, mounts, and packaging. Shipping plans should combine small express batches for urgent installs and ocean or road freight for stocking orders ahead of ski and holiday peaks. To stabilize schedules, align forecasts quarterly and build buffer stock for your best-selling chassis. For dependable capacity and consistent QA, G·SAI operates a CNC-equipped factory that integrates R&D, machining, assembly, and testing under one roof.

| Сцена | Typical Timeline | Dependencies | Deliverables |

|---|---|---|---|

| Spec & sampling | Short cycle for first-fit kits | Vehicle data, payload, tire size, ride targets | Fitted samples, dyno plots, install notes |

| Pilot run | Moderate cycle for 50–200 kits | Feedback from installers, minor tuning | Finalized valving, packaging, labels |

| Производство | Planned cycle based on MOQ | Forecasts, materials, coating lead times | Batch-tested kits, QC records, traceability |

| Shipping to France | Express or consolidated freight | Incoterms, customs docs | On-time arrivals matched to launch windows |

These ranges are planning guides; exact timings depend on materials, coatings, and test iterations. Build calendars around tourist and winter-sport seasons, and maintain a safety stock of wear components like top mounts and bushings so installs never stall. For sourcing and build slots, share your annual roadmap early; it gives your manufacturing partner time to secure materials and reserve dyno and assembly capacity.

Last updated: 2025-11-04

Журнал изменений:

- Added compatibility matrix for popular French SUVs with lift envelopes.

- Expanded terrain-based tuning table and clarified damping choices.

- Included industry use-case mapping and French-focused after-sales steps.

- Updated lead-time and logistics planning with staged deliverables.

Дата следующего обзора и триггеры - Review in 6 months or upon new chassis releases, regulation updates, or material/coating changes impacting corrosion performance.

Looking to spec your first kit, private-label a lineup, or validate valving for a new French route mix? Share your vehicle list, payloads, and targets, and the G·SAI team will prepare a quote, sample plan, and pilot timeline tailored to Custom Suspension Solutions for Off-Road SUVs in the French Market.