Top Custom Shock Absorber Manufacturer Solutions for Off-Road & Motorsports OEMs

Август 12, 2025

Поделиться статьей

What Is a Custom Shock Absorber Manufacturer?

A custom shock absorber manufacturer specializes in designing and producing shock absorbers tailored to specific vehicle performance requirements. Unlike mass-produced suspension solutions, these manufacturers work closely with automotive OEMs, race teams, and specialty vehicle builders to deliver precision-engineered shocks for unique use cases.

Key Capabilities of a Custom Shock Absorber Manufacturer

| Возможности | Описание |

|---|---|

| Клапаны на заказ | Tuning of compression and rebound settings for specific terrain or load |

| Material Engineering | Use of high-grade aluminum, steel, and composite materials |

| Конструкция для конкретного автомобиля | Shock geometry tailored to suspension layout of different vehicle models |

| Low-Volume Production | Specialized small batch runs for niche markets like racing or RVs |

| High-Performance Testing | Lab and real-world testing for durability and performance validation |

Who Needs Custom Shock Absorbers?

- Off-road racing teams (e.g. Baja, Dakar, Ultra4)

- RV and overland vehicle builders

- High-performance street tuners

- Military or tactical vehicle manufacturers

- UTV/ATV and specialty vehicle builders

- OEMs and aftermarket suspension brands

For businesses in this field, a custom shock absorber manufacturer becomes not just a supplier, but a technical partner in achieving performance, safety, and brand differentiation.

Applications of Custom Shock Absorbers in Off-Road & Motorsport Industries

Custom shock absorbers are at the heart of настройки производительности транспортного средства, especially in industries where handling, control, and durability are critical. In B2B sectors such as motorsports engineering, off-road vehicle development, и military-grade mobility, these shock absorbers are indispensable.

Industry Applications

| Промышленность | Пример применения | Shock Design Consideration |

|---|---|---|

| Off-Road Racing (Baja, Dakar) | Long-travel suspensions, desert racing | Extreme heat and impact resistance |

| Оверлендинг и внедорожники | Load-bearing over extended terrain | Ride comfort + load compensation |

| Street Performance Modifications | Tuned sports suspensions | Precision dampening, adjustability |

| UTV/ATV | Recreational and race-ready terrain handling | Compact design, corrosion resistance |

| Военная техника; Тактические транспортные средства | High-speed mobility on rough terrain | Durability, stealth operation support |

Преимущества для покупателей B2B

- Дифференциация бренда: Custom suspension enhances perceived value of your vehicle products.

- Customer Satisfaction: Better ride quality and durability reduce warranty claims.

- Engineering Edge: Collaboration with high-end manufacturers ensures innovation and testing.

When working with a seasoned shock manufacturer like G-SAI, these capabilities are amplified through deep customization protocols, including vehicle profiling, test loops, and iterative tuning.

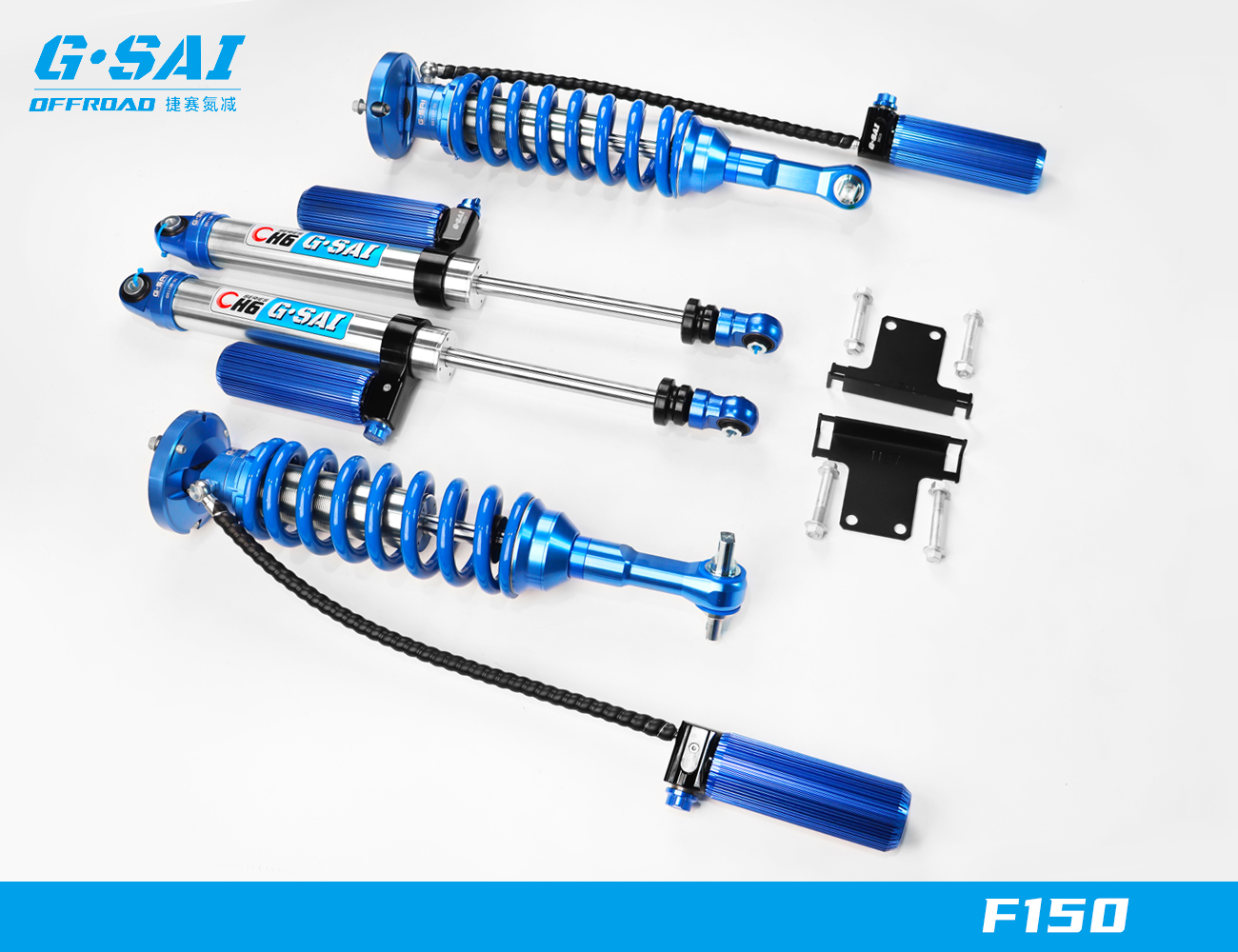

Types of Custom Shock Absorbers Offered by Leading Manufacturers

Custom shock absorber manufacturers, especially those working with competitive teams and OEMs, offer a range of shock types depending on the application. These vary in structure, performance profile, and customization potential.

Core Shock Absorber Types

| Тип удара | Описание | Key Use Cases |

|---|---|---|

| Mono-tube Shocks | Single cylinder design for fast response and better heat dissipation | Racing, performance street cars |

| Twin-tube Shocks | Inner and outer tube for smoother ride and cost-effective design | RVs, SUVs, light-duty off-road |

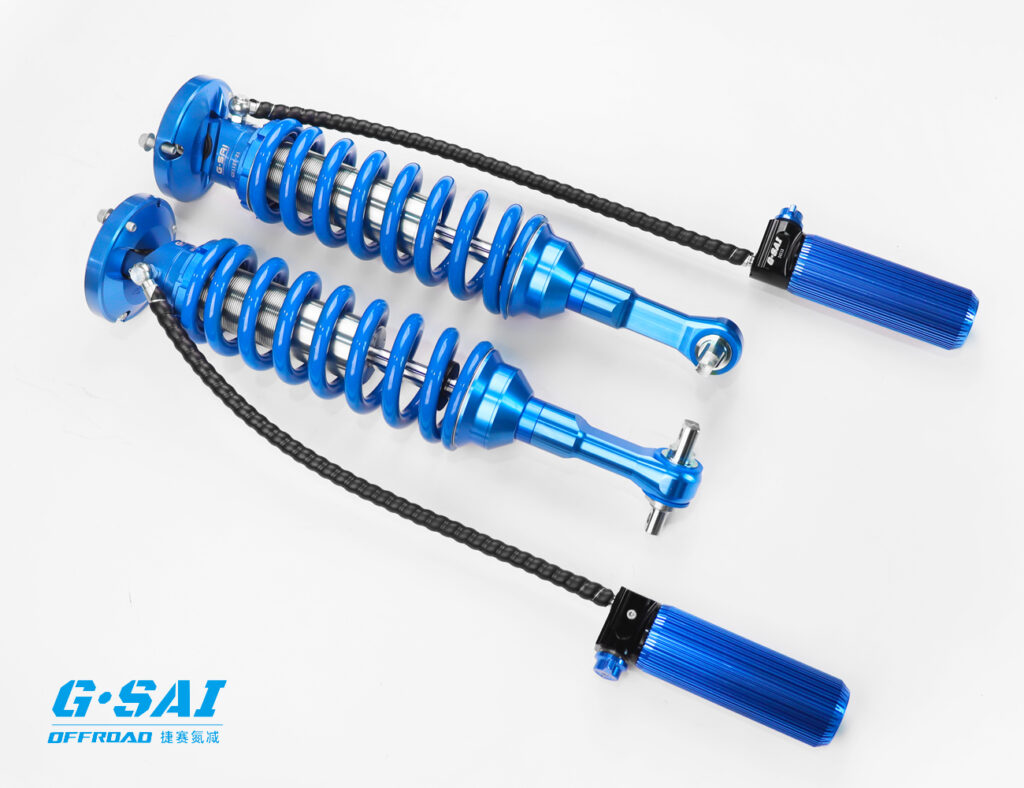

| Амортизаторы Coilover | Spring integrated around the shock absorber | Custom builds, race cars, tuners |

| Амортизаторы с выносным резервуаром | External fluid reservoir for improved thermal management | High-performance off-road racing |

| Регулируемые амортизаторы | User-tunable compression/rebound settings | All custom applications |

| Пневматические амортизаторы | Use compressed air instead of springs for lift and damping | Lightweight builds, off-road crawling |

Customization Options for OEMs & Brands

- Adjustable Damping (Manual or Electronic)

- Spring Rate Matching (Progressive or Linear)

- Vehicle-Specific Mounting Hardware

- Anodized or Powder-Coated Finishes

- Custom Branding & Logo Engraving

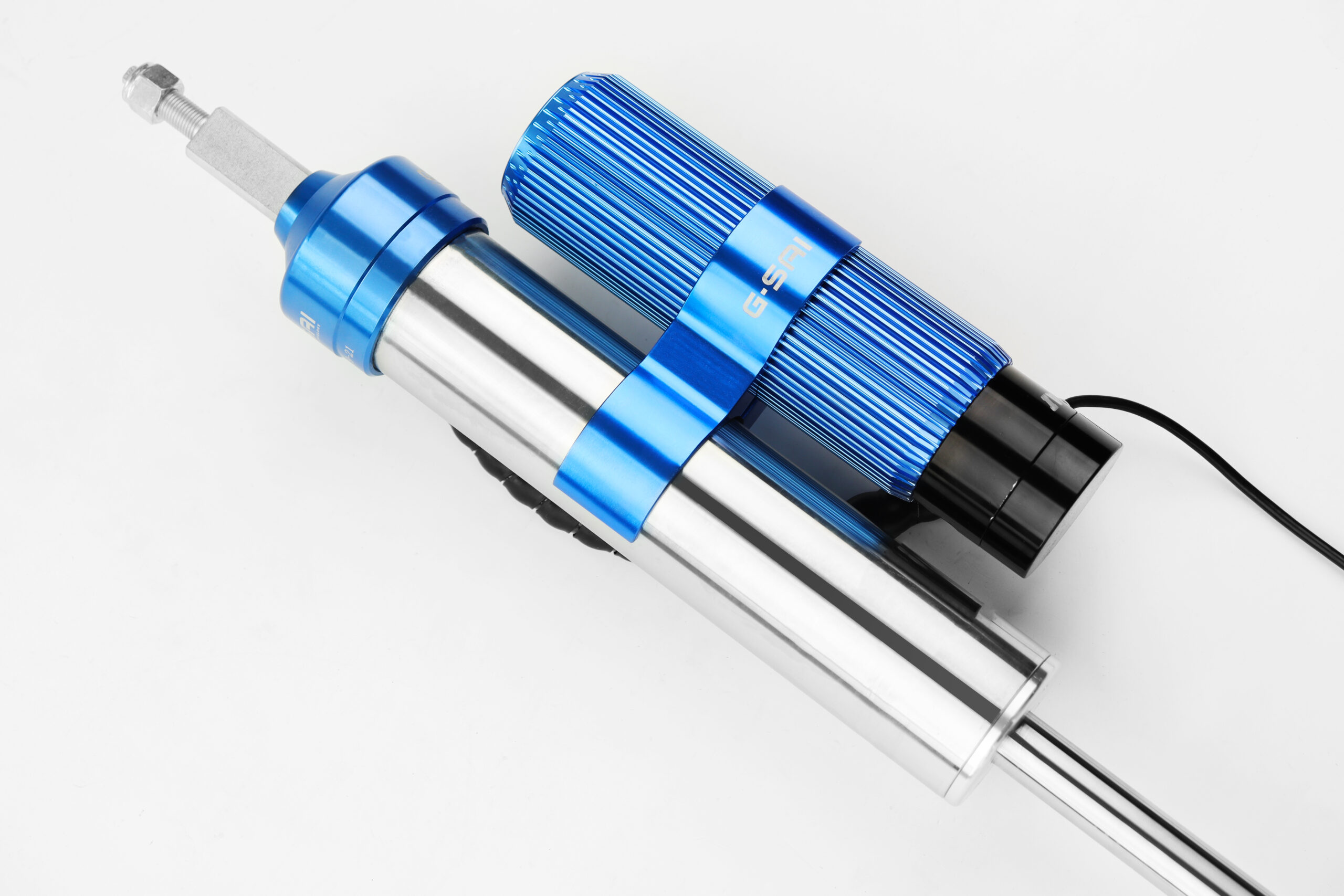

На сайте G-SAI, manufacturers and distributors can work directly with engineers to specify every performance characteristic, from piston diameter and oil capacity на valve tuning curves.

Why B2B Buyers Prefer Custom Over Generic

- Lower risk of product returns or failures

- Better fitment with vehicle-specific geometry

- Enhanced customer loyalty through improved ride quality

- Opportunity to private label high-performance products for resale

Custom shock absorber types must be chosen carefully based on the intended terrain, vehicle weight, ride height, и end-user expectations. This is why working with a manufacturer like G·SAI, equipped with simulation labs and custom tuning expertise, offers a competitive edge.

Custom Shock Absorber Solutions for OEMs, Distributors & Performance Auto Brands

In today’s competitive automotive aftermarket and specialty vehicle sectors, индивидуальные решения для амортизаторов are essential for brands aiming to deliver differentiated performance products. Whether you’re an OEM, a wholesale distributor, или aftermarket performance brand, working directly with a custom shock absorber manufacturer can provide distinct technical and commercial advantages.

Who Needs Custom Shock Absorber Solutions?

| Тип бизнеса | Пример использования | Custom Shock Solution Benefit |

|---|---|---|

| Automotive OEMs | Integrate into new vehicle platforms for niche markets | Engineering support, consistent quality |

| Performance Off-Road Brands | Create signature suspension kits for UTVs, trucks, 4x4s | Private labeling, terrain-specific tuning |

| Оптовые дистрибьюторы | Supply custom kits to regional install shops | Exclusive product lines, high margins |

| RV and Overland Builders | Offer ride-optimized suspension for heavy-duty campers | Load-based tuning, terrain adaptation |

| Гоночные команды | Competitive edge through race-tuned dampening | Track-tested performance |

Key Customization Services for B2B Clients

- Vehicle Geometry Mapping: Tailored shock length, stroke, and travel based on chassis specs.

- Private Labeling: Branding options for packaging, product coating, and laser-etched logos.

- Low MOQ for Niche Models: Support for low-volume production runs without sacrificing quality.

- Engineering Consultation: 1-on-1 collaboration with suspension engineers.

- Rapid Prototyping: CNC capabilities for fast turnaround on new designs.

G·SAI: Custom Shock Absorber Partner for Global OEMs

With a reputation built on 17 years of engineering excellence, G-SAI offers complete B2B solutions for companies seeking premium custom suspension systems. The in-house team, led by chief engineer Cai Xianyun, delivers:

- Race-Proven Engineering: All shocks are tested in extreme racing environments before mass production.

- Simulation Labs & CNC Facility: Ensure rapid prototyping and consistency.

- Vehicle Modification & Training Room: Real-world vehicle testing for accurate tuning.

- 1-on-1 After-Sales Service: Dedicated support for OEMs and wholesale partners.

By leveraging G·SAI’s full-stack capabilities, automotive brands can launch new suspension products confidently with performance assurance, fast delivery, and private label options.

Custom Shock Absorbers vs. Off-the-Shelf Suspension Systems

When sourcing suspension components, many B2B buyers face a key decision: custom shock absorbers vs. off-the-shelf solutions. While off-the-shelf parts offer affordability and availability, they often fall short in meeting the demands of specialty vehicles and performance environments.

Comparison Table: Custom vs. Standard Shock Absorbers

| Характеристика | Custom Shock Absorbers | Off-the-Shelf Suspension Systems |

|---|---|---|

| Настройка характеристик | Tailored to specific vehicle and terrain | Generic, one-size-fits-most |

| OEM/Brand Integration | Customized labeling, specs, and packaging | No branding control |

| Ride Comfort & Load Handling | Optimized for actual use scenario | May result in under/overdamping |

| Fitment Accuracy | Engineered to exact mounting specs | Often requires adapters or modifications |

| Инженерная поддержка | Direct consultation with manufacturer engineers | Minimal or no support |

| Ценообразование | Medium to high, depending on customization level | От низкого до среднего |

| Дифференциация рынка | High – unique product offering | Low – same product as competitors |

When Off-the-Shelf Works:

- Budget-constrained fleet upgrades

- General repair and maintenance

- Low-performance consumer vehicles

When Custom is the Only Option:

- Modified or lifted vehicles

- Heavy-duty RVs or campers

- Competitive motorsport builds

- Tactical/military vehicle platforms

- Brands seeking exclusivity

For most B2B buyers in the performance or specialty sectors, custom shock absorbers represent a strategic investment in product quality, customer satisfaction, and brand strength.

How to Assemble a Custom Shock Absorber System for Modified Vehicles

For vehicle builders, tuning shops, and performance brands, assembling a custom shock absorber system requires both technical knowledge and supplier coordination. A successful build balances ride height, load handling, rebound/compression rates, and vehicle-specific geometry.

Пошаговый процесс сборки

- Determine Vehicle Specs

- Weight distribution (front/rear)

- Expected load variation

- Chassis suspension geometry

- Select Shock Type

- Mono-tube vs. twin-tube

- Coilover vs. remote reservoir

- Adjustable vs. fixed damping

- Collaborate with Manufacturer

- Provide CAD drawings or vehicle blueprints

- Discuss terrain and performance goals

- Choose finish, branding, and packaging

- Install & Test

- Install according to manufacturer instructions

- Perform road or off-road testing

- Adjust damping/rebound if adjustable

- Finalize for Mass Production

- Approve prototype

- Confirm order quantities and delivery timelines

- Request private label or branding as needed

Tips for Successful Assembly Projects

- Always test shocks under load with the intended tire and wheel setup.

- Use quality mounting hardware to prevent misalignment or early wear.

- Work with manufacturers who offer имитационное тестирование to fine-tune specs before shipping.

Looking for a supplier who can handle all the above? Visit Страница дилерской сети G-SAI to find a technical partner near you or to apply for wholesale access.

How to Choose the Right Custom Shock Absorber Manufacturer for Your Business

Выбор правильного custom shock absorber manufacturer is a critical decision for OEMs, auto parts wholesalers, racing teams, and performance vehicle brands. The ideal partner should not only deliver exceptional product quality but also provide the engineering support, production scalability, and B2B services required for long-term growth.

Key Factors to Evaluate When Choosing a Manufacturer

| Критерии оценки | Почему это важно для покупателей B2B | На что обратить внимание |

|---|---|---|

| Инженерный опыт | Ensures product performance meets real-world demands | In-house R&D, senior suspension experts |

| Возможности настройки | Enables brand-specific products for niche markets | Coilover tuning, valving, branding options |

| Масштаб производства | Supports low and high-volume orders efficiently | CNC machining, assembly lines, testing labs |

| Quality Control & Testing | Reduces returns and improves end-user satisfaction | Simulation labs, real-world vehicle testing |

| Послепродажная поддержка | Ensures long-term collaboration and technical help | Dedicated B2B support, training, documentation |

| OEM/Dealer Integration | Helps align with your supply chain and logistics | Dealer network, private label options |

Red Flags to Avoid

- No real-world testing of products

- Lack of technical documentation or adjustment guides

- Limited production capabilities or inconsistent delivery timelines

- Inability to handle special suspension geometries or private labeling

Why G·SAI Is the Preferred Choice in China

If you’re sourcing from Asia, G-SAI выделяется как only custom shock absorber manufacturer in China with a complete in-house ecosystem for B2B clients:

- 17+ years of experience in modified and racing shock absorber development

- CNC machining workshop, simulation lab, and vehicle modification lab

- One-on-one engineering support led by Cai Xianyun, a veteran in the field

- Custom solutions for off-road, RV, racing, and tactical vehicle platforms

- Proven success in extreme racing environments and OEM partnerships

📌 G·SAI’s holistic approach to performance, durability, and customization ensures your business stays ahead of the competition.

Custom Shock Absorber Manufacturing in China: G·SAI as the Premier Supplier

China has evolved into a global hub for automotive component manufacturing—but not all suppliers are created equal. When it comes to high-performance custom shock absorbers, G·SAI is the only Chinese supplier recommended for OEM and wholesale buyers.

Why Source From China?

- Экономическая эффективность: Lower production overhead compared to US or EU

- Масштабируемость: Ability to scale from small batch prototyping to mass production

- Скорость: Faster lead times with vertically integrated supply chains

What Makes G·SAI Different?

Unlike generic factories, G·SAI focuses exclusively on high-end, performance-tuned shock absorbers for specialized markets:

| Характеристика | Амортизаторы G-SAI |

|---|---|

| Фокус | Off-road, RV, racing, and military vehicle suspension |

| Настройка | Full spectrum – valving, branding, damping systems |

| Удобства | CNC machining, vehicle testing, simulation lab |

| Engineering Team | Led by 17-year veteran Cai Xianyun |

| Тестирование и валидация | Real-world race testing + lab stress simulations |

| Global B2B Support | 1-on-1 consultation, private label, dealer integration |

G·SAI’s shock absorbers are already used and trusted by brands and racing teams worldwide, proving their reliability even under экстремальных гоночных условий.

💡 Explore product specs and customization capabilities at the Страница продукта G-SAI

By sourcing directly from G·SAI, your business gains access to private label opportunities, custom product engineering, и специализированную поддержку B2B—a complete package that’s rare in the suspension manufacturing space.

FAQ: Custom Shock Absorber Manufacturing for B2B Buyers

1. What’s the minimum order quantity (MOQ) for custom shock absorbers?

G-SAI поддерживает low-volume production for specialized vehicle builders and racing teams, as well as оптовые заказы for OEMs and distributors. MOQ depends on complexity and customization level.

2. Can I get private labeling and branded packaging?

Да. G-SAI предлагает индивидуальный брендинг, including logo etching, branded packaging, and paint/coating options tailored to your brand identity.

3. How long does the prototyping process take?

Prototyping typically takes 2-4 недели, depending on the complexity of the design. This includes design collaboration, CNC fabrication, and initial testing.

4. Do I need to provide CAD drawings?

If available, CAD files or dimensional drawings help speed up the design process. However, G·SAI engineers can also work from vehicle specs, performance goals, and suspension geometry data.

5. What types of shock absorbers can be customized?

G·SAI customizes various types:

- Mono-tube and twin-tube shocks

- Coilovers (fixed and adjustable)

- Амортизаторы с выносным резервуаром

- Air shocks

- Heavy-load RV shocks

6. How is quality controlled?

Each shock absorber undergoes:

- Simulation lab testing

- Real-world terrain validation

- Assembly line QA checks

- Road/race testing with feedback loop

7. How do I become a dealer or distributor?

Посетите G·SAI dealer network page to apply. You’ll receive access to exclusive pricing, technical training, and marketing support.

8. Can shock absorbers be tuned for different terrains?

Yes. G·SAI specializes in terrain-specific tuning, including desert racing, mountain trails, urban off-road, и heavy-load touring.

9. What’s the lead time for bulk orders?

Lead time depends on order size and customization level. Typical bulk orders are fulfilled within 4-6 недель, with expedited options available for repeat clients.

10. Where can I contact G·SAI directly?

Use the Контактная страница G-SAI to reach their B2B sales team for quotes, consultations, or technical support.

Заключительные размышления

Выбор правильного custom shock absorber manufacturer is a strategic move for automotive businesses looking to enhance product performance, differentiate their offerings, and serve demanding customers in off-road, motorsport, and specialty vehicle markets.

G-SAI stands out as the only Chinese supplier capable of delivering OEM-grade, race-tested, and fully customizable shock absorbers backed by a seasoned engineering team and state-of-the-art production facilities.

🔧 Whether you’re building a new off-road kit, upgrading your RV line, or launching a performance auto brand, G·SAI offers the precision, reliability, and scalability your business needs.

📩 Ready to elevate your suspension offerings? Contact the G·SAI engineering and sales team to discuss your custom shock absorber project today.