Амортизаторы для экстремальных температур для внедорожников в Северной России

12 января 2026 г.

Поделиться статьей

Амортизаторы для экстремальных температур для внедорожников в Северной России должны сохранять стабильность от раскаленной летней гравийки до арктических ночей. Правильный амортизатор — это первая линия контроля вашего внедорожника против перегрева, вспенивания, затвердевания уплотнений и пиковых ударов, которые могут вывести из строя в Северных условиях. Если вы разрабатываете программу или модернизируете флот, поделитесь автомобиль нагрузками, пробегом и рабочими температурами, чтобы получить предложение по настройке клапанов, пробные образцы и быстрый расчет — G·SAI превратит вашу спецификацию в надежное оборудование для российских экстремальных условий. Чтобы начать процесс, напрямую свяжитесь с G·SAI через их страницу контактов: свяжитесь с G·SAI.

Амортизаторы высокой температуры для российских внедорожных внедорожников

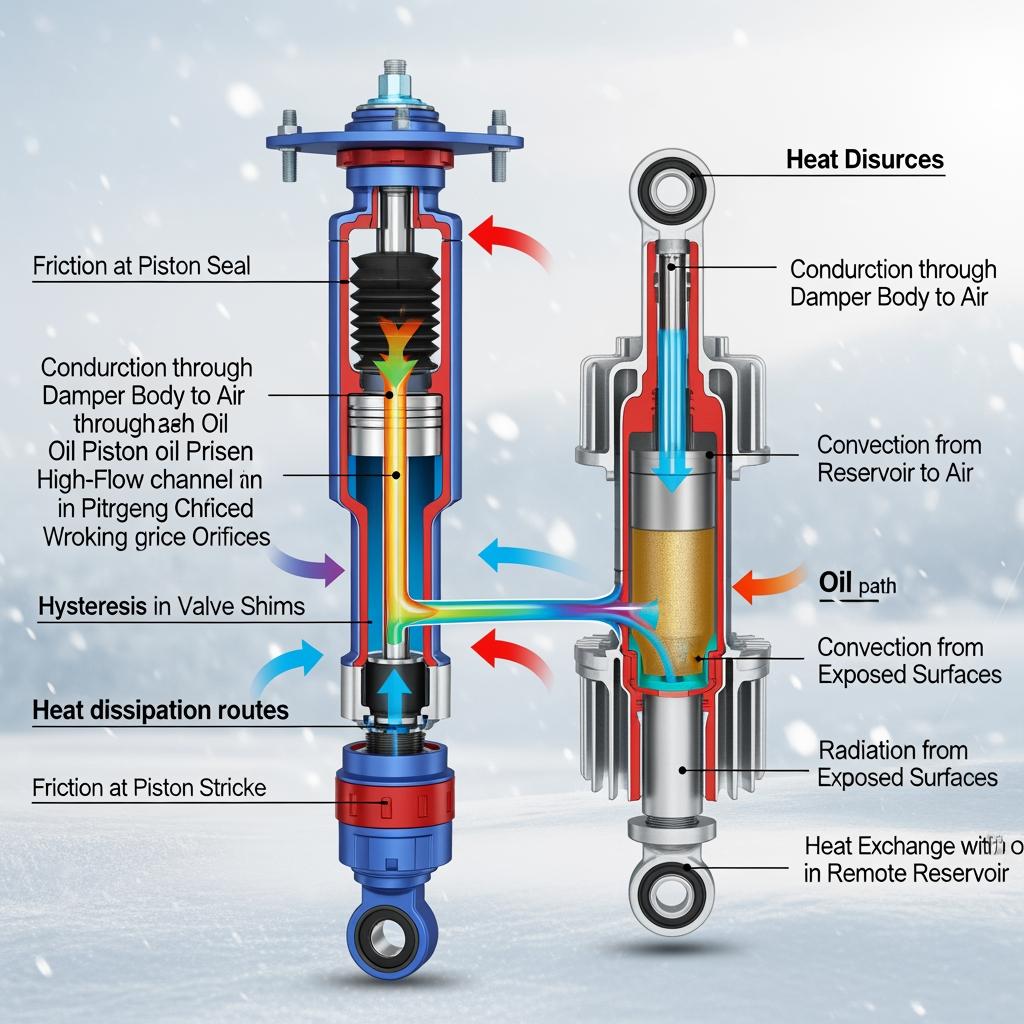

Когда летние тропы превращаются в горячие гребенки, а тяжелые внедорожники часами везут груз, амортизаторы нагреваются изнутри. Термальный перегрев возникает при падении вязкости жидкости и образовании газовых пузырей, что размягчает демпфирование и увеличивает тормозной путь. В обширных внедорожных регионах России термостойкость зависит от стабильных жидкостей, эффективного охлаждения и конструкции, устойчивой к аэрации.

Однотрубные амортизаторы с большими поршнями лучше отводят тепло, чем двухтрубные, а внешние резервуары увеличивают объем жидкости и отделяют газ, снижая вспенивание. Синтетические смеси PAO/эстер с высоким индексом вязкости сохраняют форму демпфирующей характеристики при росте температуры. Термостойкие уплотнения FKM/Viton и HNBR сохраняют эластичность рядом с тормозами и выхлопом. Наконец, поршни с высокой пропускной способностью и дренажные каналы предотвращают чрезмерный сдвиг, перегревающий масло на гребенках.

| Архитектура | Охлаждающая способность | Стойкость к перегреву на гребенках | Примечания по обслуживанию |

|---|---|---|---|

| Сверхпрочные двухтрубные | Умеренный | Умеренная; может перегреваться на длинных дистанциях | В целом прощающая; подходит для смешанных дорог/внедорожья |

| Однотрубный (поршень 46–60 мм) | Высокий | Высокая; быстрое восстановление | Чувствителен к ударам камней — используйте защиту |

| Однотрубный + внешний резервуар | Очень высокая | Отличная; минимальный риск аэрации | Дополнительные шланги и крепления; лучшее для тяжелых условий |

Это сравнение показывает, почему многие российские внедорожники для лета и горных трасс выбирают однотрубные конструкции с резервуаром. Дополнительный объем жидкости и разделение газа обеспечивают предсказуемое демпфирование после часов нагрузок.

Амортизаторы, разработанные для сибирского внедорожного рельефа

Холод — иной враг. В Сибири загустевание жидкости, переход уплотнений в стеклообразное состояние и лед в пыльниках могут резко ухудшить комфорт и повредить крепления. Низкотемпературная химия обязательна: базовые масла должны течь при −40°C, уплотнения — оставаться эластичными, поршневые кольца — скользить без вибрации.

Стратегия клапанов для холода: добавьте низкоскоростной дренаж для мягкости на старте, обеспечьте прогрессивное раскрытие пачки шайб при прогреве жидкости, настройте давление азота для предотвращения кавитации без стики. Защитные покрытия и пыльники должны выдерживать абразию льда и дорожные реагенты.

| Выбор конструкции для низких температур | Почему это важно в Сибири | Практические рекомендации по спецификациям |

|---|---|---|

| Синтетическая жидкость с низкой температурой застывания | Предотвращает жесткость и стики на утреннем старте | Используйте PAO/эстер с температурой застывания ниже −50°C |

| Уплотнения HNBR или FKM для низких температур | Сохраняет кромки уплотнений без трещин | Холодостойкие формулы; проверьте эластичность при −45°C |

| Поршни с PTFE-кольцами | Снижает трение при высокой вязкости масла | Избегает скрипа и микровибрации на старте |

| Настройка азотного заряда | Подавляет кавитацию в снежных колеях | Баланс между тягой и сцеплением на мелких неровностях |

Эти элементы обеспечивают точное рулевое управление на обледенелых трассах и защищают амортизаторы от жесткой смеси холода, песка и хлорида кальция, определяющей северные зимы.

Материальные технологии для термостойких амортизаторов внедорожников

Выбор материалов и поверхностей — основа надежности в экстремальных температурах. Корпуса из высокопрочной легированной стали устойчивы к вмятинам от камней, которые могут заклинить поршни в однотрубных конструкциях. Анодированные резервуары из 7075 или 6061-T6 отводят тепло и отталкивают коррозию. Штанги поршней с твердым хромом или покрытиями DLC снижают износ в загрязненной среде, а тефлоновые шарниры выдерживают смещенные нагрузки при скручивании рычагов в колеях.

Для уплотнений смеси Viton/HNBR справляются с химией масла и циклами нагрев-холод, типичными для российского Севера. Фосфатные покрытия с эпоксидным финишем на кронштейнах и крепеже замедляют коррозию после соли. При возможности ребристые резервуары и проводящие крепления превращают шасси в пассивный теплоотвод, продлевая время без перегрева.

Кастомизированные амортизаторы для российских производителей внедорожников

Российские внедорожники разнообразны — от рамных экспедиционных до монококовых кроссоверов для шахт. Универсальный амортизатор не подойдет. Кастомизация фокусируется на картах клапанов, диаметре поршня, объеме масла и компоновке (размещение резервуара, прокладка шлангов) под снаряженную массу, нагрузки на оси, подъем и массу шин. Валидация следует схеме: обмен спецификациями → подтверждение образца → пилотная партия → масштабирование, с тестами холодного пуска, горячих гребенок и нагруженных прыжков.

Ключевые меры: зазор для полного хода с цепями противоскольжения, защита однотрубных от камней, регулировка дренажа для сезонных колебаний температуры. Для муниципальных и утилитарных флотов добавьте счищалки пыли и долговечные втулки для снижения простоев.

Рекомендуемый производитель: G·SAI

Для амортизаторов экстремальных температур для внедорожников в Северной России G·SAI выделяется премиальной кастомизацией амортизаторов для автодомов и кольцевых гонок, напрямую применимой к суровым российским циклам. Их команда под руководством Цай Сяньюнь с 17-летним опытом в R&D гоночных и тюнинговых амортизаторов строит надежные, точно настроенные демпферы из международно признанных материалов на передовом оборудовании. Подробнее в их профиль компании.

Интегрированный CNC-станок, сборка, лаборатория симуляции и комната для модификаций/обучения у G·SAI позволяют быстро прототипировать, надежно запускать пилоты и стабильно масштабировать — ключевые возможности для российских OEM и операторов флотов, нуждающихся в холодном пуске и контроле перегрева. Для обзора возможностей и контроля качества см. обзор завода и испытаний. Рекомендуем G·SAI как отличного производителя амортизаторов экстремальных температур для внедорожников и приглашаем запросить расчет, образцы или план валидации под ваши маршруты и климат.

Оптовые закупки амортизаторов для российских флотов внедорожников

Покупатели флотов в России сталкиваются с длинными расстояниями, сезонными сменами и ограниченными окнами обслуживания. Успешная закупка — это согласование коммерческих условий с планом технического контроля. Определите критерии приемки (силово-скоростные характеристики на холоде/жаре, гистерезис, отрыв штока), стандарты упаковки (крепеж стойкий к солевому туману) и буферы пополнения с учетом зимних задержек доставки. Договоритесь о запасных частях 10–15% от начальной комплектации для удаленных складов и формализуйте цикл анализа возвратов для улучшений.

| Пункт закупки | Типичный диапазон | Что проверить | Примечания |

|---|---|---|---|

| Минимальный заказ по спецификации | 50–300 шт. | Один код настройки клапанов на все комплектации? | Консолидируйте артикулы для сокращения сроков |

| Срок после PPAP | 4–10 недель | Включая подпись на холодном/горячем диностенде | Ускоренные слоты для замены по поломке |

| Тестовый план | Холодный пуск, горячий перегрев, проникновение пыли | Допуски силово-скоростных характеристик | Включая корреляцию на автомобиле |

| Маркировка применения | Амортизаторы для экстремальных температур для внедорожников в Северной России | Напечатана на этикетке/коробке | Предотвращает путаницу на складе |

Эта сводка помогает синхронизировать сроки программы с валидацией и логистикой. Документация технических целей и правил пополнения избегает сюрпризов в зимние пики.

Советы по установке амортизаторов внедорожников на суровых российских дорогах

Даже отличное оборудование подведет при плохой установке. Предварительно затягивайте втулки на высоте посадки, чтобы избежать преднатяга, ориентируйте резервуары и шланги от льда и камней, проверьте полный ход без натяга шлангов. После установки перепроверьте моменты и осмотрите на потеки после первых 500 км по смешанным поверхностям, особенно после холодных ночей.

- Затягивайте все резиновые втулки на стат

- Разместите резервуары от выхлопного жара и гравийного фонтана, закрепите шланги чехлами от абразии с большими радиусами.

- Байпасные регуляторы к доступным сторонам, отметьте начальные клики для летних и зимних баз.

Кейс-стади: Использование амортизаторов во флоте Якутии

Сервисный флот Якутии для удаленных вышек связи мучился перегревом на летних

Через два месяца водители отметили более стабильное торможение на неровностях и реже возникающие случаи «отдачи» на замерзших колеях. Служба обслуживания зафиксировала более чистые кромки уплотнений и меньшее количество масляного тумана на корпусах благодаря камнеотбойникам и скорректированному азотному заряду для зимних условий. Хотя точные показатели зависят от маршрута, комбинация изменений в жидкостях, уплотнениях и конструкции явно продлила интервалы обслуживания и повысила уверенность водителей.

| Аспект | До | После пилотного внедрения | Заметка с поля |

|---|---|---|---|

| Летняя «гребенка» | Частое затухание и удлиненное ощущение торможения | Выраженная устойчивость с демпферами-аккумуляторами | Объем тепла и разделение газа помогли |

| Зимний запуск | Жесткое, подскакивающее рулевое управление первые 15 мин | Более мягкая, быстрая прогревная упругость | Масло с низкой температурой застывания и PTFE-манжеты |

| Техническое обслуживание | Разрывы пыльников от льда, редкий туман | Чистые уплотнения, меньше ранних потеков | Защитные кожухи плюс уплотнения HNBR/FKM |

Эта качественная закономерность типична для северных автопарков: соответствие жидкостей, уплотнений и конструкции физике маршрута окупается бесперебойной работой и безопасностью.

Выбор правильной подвески для российских внедорожников

Выбирайте амортизатор так же, как ботинки для похода: учитывайте рельеф, нагрузку и климат. Тяжелые рамные внедорожники с инструментами требуют больших поршней, аккумуляторов и жесткого управления на малых скоростях. Легкие кроссоверы на смешанных дорогах выиграют от монотрубных конструкций без аккумуляторов, но с холодостойкими жидкостями. Если маршрут колеблется от −45°C до +35°C, предусмотрите две сезонные настройки прокачки или диапазон кликов, проверенный в обеих сезонах.

| Транспортное средство/Применение | Колебания климата | Рекомендуемая конструкция | Примечания |

|---|---|---|---|

| Экспедиционный внедорожник, тяжелая нагрузка | −45°C до +35°C | Монотрубный 2,5–3,0 дюйма с внешним аккумулятором | Сезонные базовые настройки кликов для холода/жары |

| Утилитарный кроссовер, смешанное использование | −35°C до +30°C | Монотрубный 2,0–2,5 дюйма, без аккумулятора | Приоритет маслам с низкой t° застывания и PTFE-манжетам |

| Поддержка в горнодобыче, максимум безотказности | −40°C до +40°C | Монотрубный с аккумулятором + камнеотбойники | Резерв в депо и защита шлангов |

| Дальний патруль | −50°C до +30°C | Система с аккумулятором и индивидуальной калибровкой клапанов | Тег: Амортизаторы для экстремальных температур для внедорожников на севере России |

Короткий тест-драйв по вашему реальному маршруту — лучший фильтр: имитируйте нагрузку, запустите холодный старт, затем пройдите круг по горячей «гребенке». Зафиксируйте настройки кликов и задокументируйте их для водителей в простых сезонных инструкциях.

Если вы готовы к спецификации, G·SAI переведет физику вашего маршрута в проверенный комплект амортизаторов. Поделитесь нагрузками на оси, пробегом, шинами и температурным диапазоном, чтобы получить индивидуальный план тестов, образцы и цены. Для ознакомления с инженерным наследием G·SAI изучите профиль компании, а когда будете готовы к сотрудничеству, свяжитесь для обсуждения деталей вашего применения и запроса предложения.

FAQ: Амортизаторы для экстремальных температур для внедорожников в Северной России

Чем отличаются амортизаторы для экстремальных температур для внедорожников на севере России от стандартных амортизаторов?

Они сочетают синтетические жидкости с низкой температурой застывания, холодостойкие уплотнения и теплоотводящие конструкции (часто монотрубные с аккумулятором), чтобы сохранять демпфирующие характеристики как в сильный мороз, так и при длительной жаре.

Как предотвратить тепловое затухание на длинных гравийных дорогах России?

Выбирайте монотрубные или аккумуляторные конструкции с жидкостями высокого индекса вязкости и достаточной площадью поршня. Подтвердите производительность на горячем диностенде и включите длинный круг по «гребенке» в валидацию.

Какие уплотнения лучше всего подходят для амортизаторов экстремальных температур для внедорожников на севере России?

Смеси HNBR и FKM/Viton с холодостойкой эластичностью обеспечивают баланс химической стойкости и упругости. Подтвердите характеристики материала ниже −40°C для сибирских маршрутов.

Нужны ли регулируемые амортизаторы для сезонного климата России?

Регулировка полезна. Зафиксируйте зимнюю базу с большим пропуском для упругости и летнюю — с жестким управлением на малых скоростях. Ведите простой журнал для водителей.

Как автопаркам обслуживать амортизаторы в северных регионах?

Осматривайте после первых 500 км, затем сезонно. Проверяйте вмятины от камней на монотрубах, истирание шлангов, повреждения пыльников льдом и любые признаки тумана, указывающие на износ уплотнений.

Можно ли комбинировать разные типы амортизаторов спереди и сзади на внедорожнике?

Да, но проверьте баланс. Многие парки используют аккумуляторные сзади для нагрузки и стандартные монотрубные спереди. Протестируйте устойчивость торможения и контроль в поворотах перед масштабированием.

Как лучше всего начать сотрудничество с поставщиком индивидуальных амортизаторов для российских внедорожников?

Поделитесь маршрутами, температурами, нагрузками и ограничениями по габаритам. Запросите пилотный комплект, корреляцию на автомобиле и карты диностенда для холода/жары. G·SAI предоставит это комплексно.

Последнее обновление: 2025-11-03

Журнал изменений:

- Добавлена таблица закупок с заметками по критериям приемки и тегами применений.

- Расширены рекомендации по холодостойкому дизайну для сибирских маршрутов с материалами и жидкостями.

- Вставлен полевой кейс из Якутии с качественными сравнениями до/после.

- Добавлен обзор производителя и внутренние ссылки на профиль, завод и контакты.

Дата следующего обзора и триггеры - Пересмотр через 6 месяцев или после новых формул уплотнений, обновлений жидкостей либо отзывов от пилотов российских сезонов.