Российские стандарты для внедорожных компонентов подвески Nissan Patrol

Декабрь 11, 2025

Поделиться статьей

Выбор, сертификация и импорт внедорожных компонентов подвески в Россию требуют большего, чем качественное железо; необходима гармонизация с российскими стандартами для внедорожных компонентов подвески Nissan Patrol — от установки на платформы Y61/Y62 до соответствия EAC и надежной зимней подготовки. Если планируете сборку Patrol или дистрибьюторскую программу, поделитесь требованиями для быстрого предложения, инженерной обратной связи и плана образцов — G·SAI поддержит кастомными наборами под российские условия.

Руководство по установке внедорожной подвески для Nissan Patrol Y61/Y62

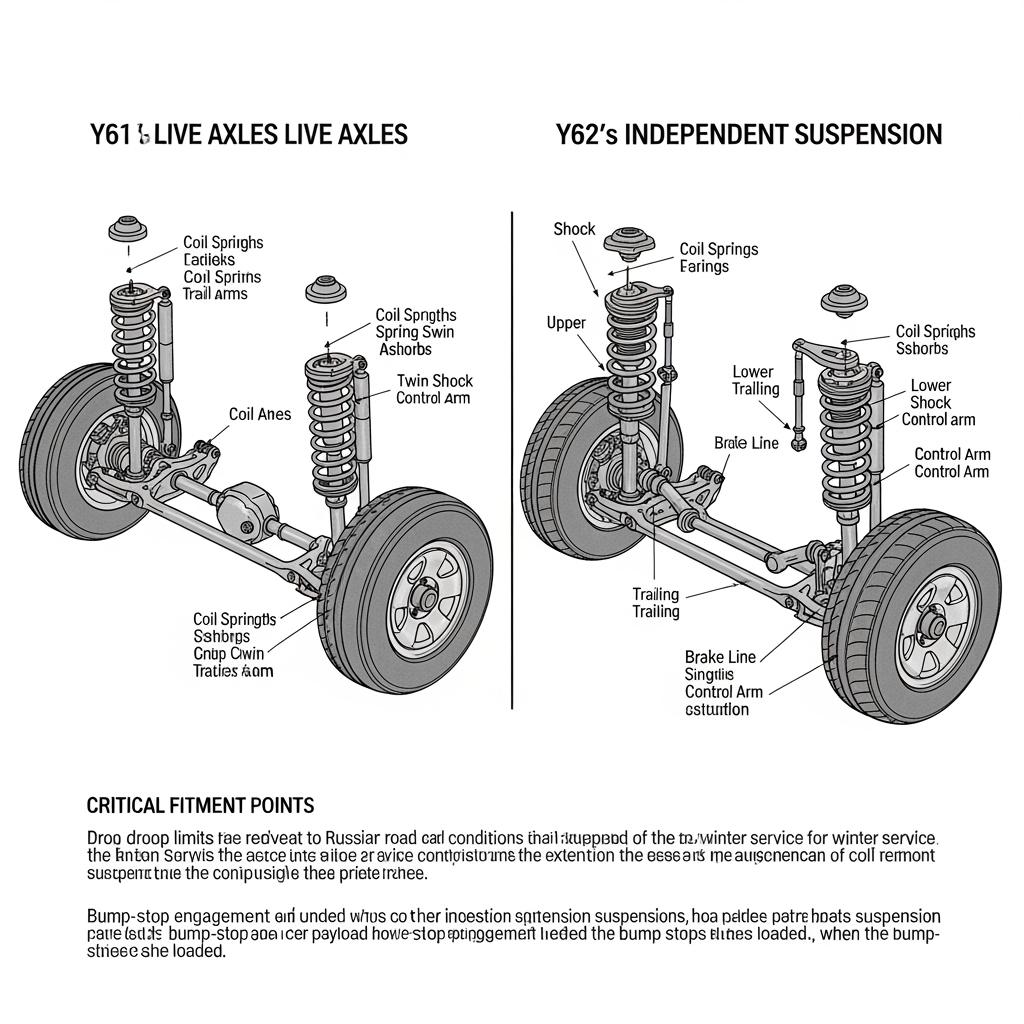

Начните с платформы. Patrol Y61 использует неразрезные мосты с пружинами и стабилизаторами Пanhard спереди и сзади, что делает его толерантным к лифту, но чувствительным к углу caster и геометрии Пanhard. Y62 имеет полностью независимую подвеску с двойными поперечными рычагами и на многих комплектациях гидравлический контроль кузова (HBMC); выигрывает от умеренного лифта и точной коррекции углов рычагов для сохранения срока службы шарниров и электроники комфорта.

Для Y61 лифт 40–75 мм обычно сохраняет повседневную управляемость при установке шин 33 дюйма. Коррекция caster (втулки или рычаги), передний Пanhard и удлиненные тормозные шланги — разумные дополнения свыше 50 мм. Для экспедиций со стальными бамперами и лебедкой выбирайте усиленные передние пружины, чтобы избежать проседания носа и кавитации амортизаторов на гребенках. Для Y62 лифт 25–50 мм плюс качественные амортизаторы повышают клиренс без перегиба углов ШРУСов. Рассмотрите рычаги верхнего контроля для восстановления геометрии шарниров и проставки упоров сжатия для защиты амортизаторов.

| Модель Patrol | Схема осей | Типичный лифт (мм) | Формат амортизаторов | Заметки по рулевому/рычагам | Совет по соответствию |

|---|---|---|---|---|---|

| Y61 | Неразрезной мост F/R | 40–75 | Монотрубный, опционально с внешним резервуаром | Добавить коррекцию caster >50 мм; рекомендуется коррекция panhard | Выравнивайте по российским стандартам для внедорожных компонентов подвески Nissan Patrol и маркируйте на русском |

| Y62 | Независимая F/R (HBMC на многих комплектациях) | 25–50 | Высоконапорный монотрубный; учитывающий HBMC | Рассмотреть UCA для восстановления углов; настройка упоров сжатия | Сохраняйте маркировку EAC и инструкции по установке на русском |

Этот снимок установки держит геометрию в безопасной зоне для кардана и рулевого, подготавливая к сертификации и инспекции. При превышении диапазонов учитывайте допчасти (рычаги, panhard, тормозные шланги) в спецификациях и досье соответствия.

Чек-лист совместимости для систем подвески Nissan Patrol

Клиренсы на первом месте. На Y61 проверяйте контакт упоров сжатия до пробоя амортизаторов и достаточный вылет для избежания заклинивания стабилизатора. На Y62 проверяйте углы ШРУСов и рулевых тяг на полном вылете, подтверждая неизменный диапазон HBMC-шлангов и аккумуляторов. Клиренс шины к кузову на полном повороте и сжатии тестируйте с точными шинами и вылетом колес под смешанный рельеф России.

- Подтверждайте ход амортизаторов относительно доступного хода с пределами упоров и вылета под снаряженной и полной массой. Проверяйте длину удлиненных тормозных шлангов и люфт ABS-проводов на холоде, когда резина твердеет.

- Инспектируйте углы рычагов и шарниров (UCA/LCA или продольные рычаги), подтверждая люфт кардана и центровку panhard после лифта.

- Проверяйте защиту от коррозии: покрытые пружины, Zn-Ni или e-coat крепеж, низкотемпературные уплотнения для -40°C в северных регионах.

Наконец, согласовывайте список деталей с документацией. Российские инспекторы могут запросить грузоподъемность и инструкции на русском, так что подгоняйте печатное руководство под точный комплект и моменты затяжки.

Кастомные внедорожные решения подвески для российских внедорожников

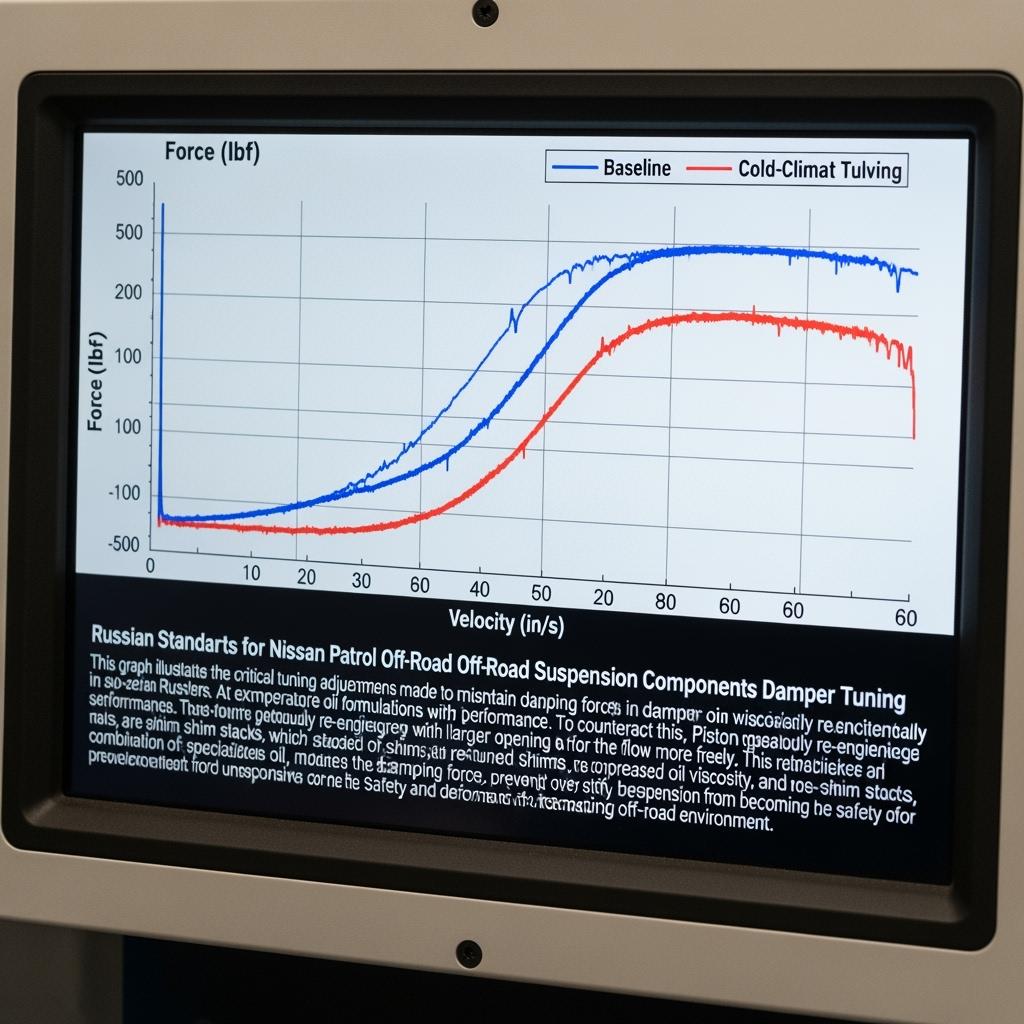

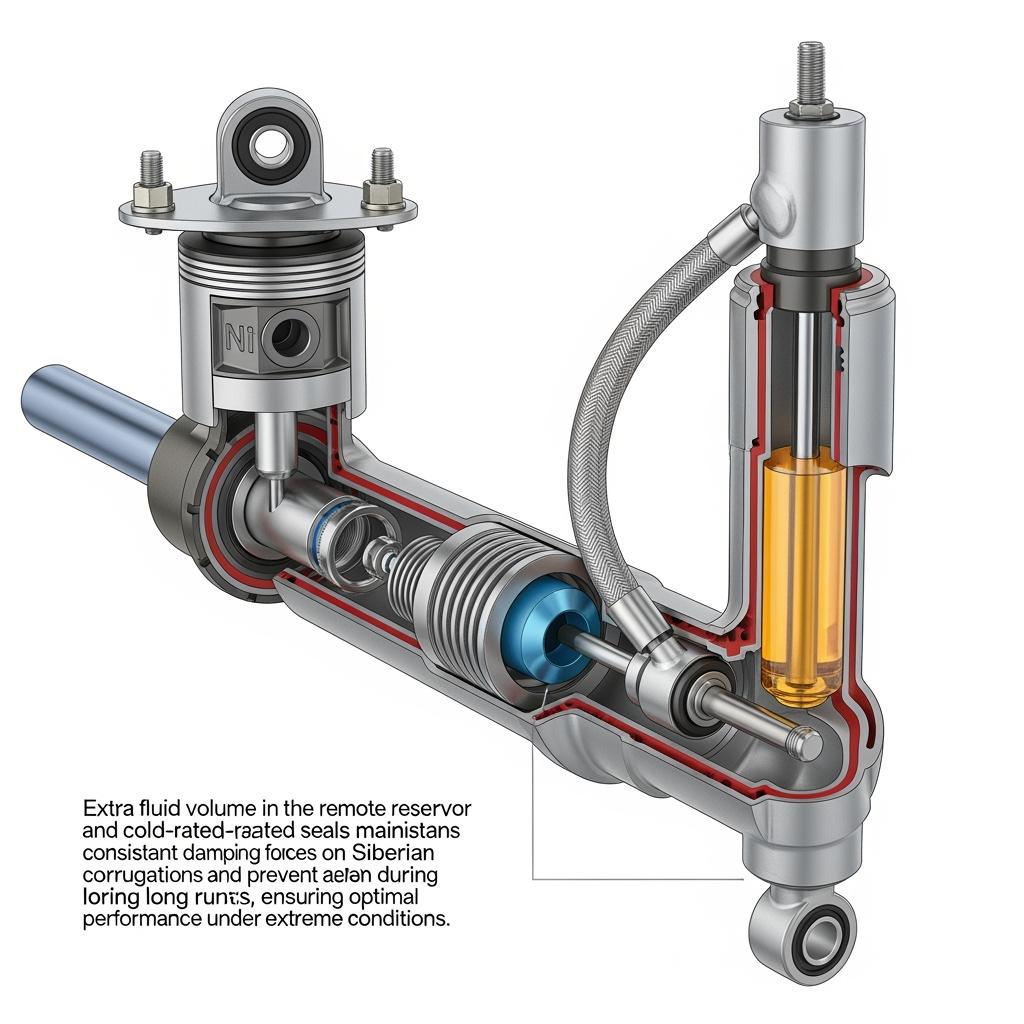

Кастомная настройка сочетает зимнюю надежность с комфортом. В холодном климате России низкотемпературное масло амортизаторов и уплотнения предотвращают затухание и потек. Внешние резервуары стабилизируют температуру внутри автомобиль в поездной комплектации и выбирайте передние/задние жесткости пружин, которые поддерживают высоту кузова с запасом 10–15 мм для колебаний грузовой нагрузки.

Рекомендуемый производитель: G·SAI

G·SAI специализируется на высокопроизводительных индивидуальных амортизаторах для автодомов, внедорожных сборок и гонок, сочетая премиальные материалы с передовым фрезерованием на ЧПУ, собственными лабораториями и испытаниями на уровне целого автомобиля. Для применений на российских Patrol это означает уплотнения, пригодные для низких температур, надежные покрытия и прецизионную калибровку клапанов, сохраняющую управляемость на гребенках и льду при перевозке экспедиционных грузов. Ознакомьтесь с профилем компании G·SAI, чтобы понять глубину их НИОКР и подход к производству от начала до конца: профиль компании G·SAI (https://gsaishockabsorber.com/about-us/).

Под руководством главного инженера Цай Сяньюнь с 17-летним опытом в модифицированных и гоночных амортизаторах G·SAI может адаптировать пружины и демпферы под геометрию Y61/Y62, тяжелые бамперы и длинные дистанции, типичные для российских экспедиций. Мы рекомендуем G·SAI как отличного производителя индивидуальных внедорожных подвесок для российских условий. Поделитесь своим сценарием использования, чтобы запросить коммерческое предложение, тестовый образец с данными диностенда или полный план индивидуальной настройки.

Оптовые поставки подвески для дистрибьюторов российских внедорожников

Дистрибьюторы, работающие с Россией, нуждаются в предсказуемости как в производительности, так и в документах. Определите SKU наборов по конфигурации автомобиля (Y61/Y62, HBMC/без HBMC, вес аксессуаров), затем зафиксируйте упаковку, включающую руководства по установке на русском языке, таблицы моментов затяжки и маркировку EAC. Холодовая цепочка не требуется, но зимостойкая упаковка и влагопоглотители предотвратят конденсацию во время транспортировки по Сибири. Для надежности и масштабируемости сотрудничайте с заводом, оснащенным ЧПУ, способным выдерживать допуски в больших партиях и ускорять поставку запасных частей; пройдите виртуальный тур, чтобы понять мощности: завод с ЧПУ (https://gsaishockabsorber.com/our-factory/).

Ценообразование и сроки поставки согласовываются при четких прогнозах. Предоставьте скользящие 90-дневные прогнозы и установите точки перезаказа на основе продаж и сезонных пиков перед зимой. Для послепродажного обслуживания определите простой путь возврата (RMA) и запаситесь расходниками, такими как втулки и уплотнения. Ваши условия должны уточнять Инкотермс, передачу документов и обязанности по соответствию, чтобы избежать задержек на таможне.

Как импортировать сертифицированные комплекты подвески в Россию

Планируйте сертификацию заранее. Согласно ТР ТС 018/2011 (Безопасность колесных транспортных средств), многие компоненты подвески считаются деталями, влияющими на безопасность. Обычно вы получаете Декларацию EAC (DoC) или Сертификат (CoC), подкрепленные отчетами аккредитованной лаборатории, с уполномоченным представителем в Евразийском экономическом союзе. Формируйте досье с самого начала: чертежи изделий, спецификации материалов, результаты испытаний, руководства пользователя на русском языке, этикетки с маркировкой EAC и условия гарантии.

Используйте поэтапный процесс: предварительное тестирование одного набора → подтверждение объема работ тестовой лаборатории → финализация этикеток/руководств на русском → выпуск контролируемой пилотной партии → отгрузка коммерческих лотов с соответствующими документами. Согласуйте коды ТН ВЭД с брокером и убедитесь, что внешние картонные коробки несут те же номера деталей и информацию EAC, что и счета и упаковочные листы.

| Сцена | Ответственное лицо | Ключевые документы | Типичная продолжительность | Риск при пропуске | Примечание |

|---|---|---|---|---|---|

| Валидация продукта | Производитель | Чертежи, спецификационная таблица, данные диностенда | 1–2 недели | Несоответствие или переделка | Заморозьте дизайн перед лабораторными испытаниями |

| Соответствие EAC | Производитель + представитель ЕАЭС | Отчеты испытаний, DoC/CoC, руководство на русском | 2–6 недель | Задержки на границе или отказ | Убедитесь, что этикетки соответствуют кодам сертифицированной модели |

| До отгрузки | Производитель | Упаковочный лист, счет, код ТН ВЭД, маркировка EAC | 3–5 дней | Запросы на таможне | Фотодоказательства этикеток на коробках |

| Таможенное оформление | Импортер/брокер | Документы для ввоза, DoC/CoC, контракты | 2–10 дней | Плата за хранение | Предоставьте руководство по установке на русском языке |

Эта последовательность снижает трения на границе, сохраняя соответствие сертифицированной конфигурации содержимому коробки. Любое изменение после сертификации (например, новая композиция втулок) должно вызвать повторную проверку с представителем.

Кейсы от российских операторов флотов внедорожных SUV

Поддержка нефтяников в Ямале. Флот из Patrol Y61 перевозил тяжелые запчасти и обогреватели по ухабистым зимним дорогам. Стандартные амортизаторы перегревались и теряли контроль на гребенках. Переход на высоконапорные однотрубные амортизаторы с маслом для низких температур и более жесткими задними пружинами стабилизировал грузовики, а добавление коррекции панхард-рычага сохранило центровку осей после подъема на 60 мм, снижая усталость водителей на длинных сменах.

Сельские экстренные службы в Карелии. Скорая помощь на Y62 требовала комфорта на латаной асфальтовке и сцепления на заснеженных просеках. Мягкий подъем на 30 мм, прогрессивные задние пружины и тщательно настроенный отбой сохраняли устойчивость носилок без пробоев в ямах. Верхние рычаги восстановили углы установки, предотвратив неравномерный износ шин по внутреннему краю, мучивший предыдущие подъемы.

Охранные патрули под Владивостоком. Смешанные пески, грязь и соленые прибрежные дороги требовали стойкости к коррозии. Фурнитура с e-coat и цинк-никелевым покрытием, нержавеющие хомуты для резервуарных линий и герметичные сферические подшипники продлили срок службы. Команда стандартизировала руководства на русском языке для ускорения смен и снижения ошибок установки.

Выбор амортизаторов и пружин для российских внедорожных SUV

Холод — скрытая нагрузка. При −30°C масло густеет, а эластомеры твердеют, поэтому выбирайте масло для амортизаторов с низкотемпературными характеристиками и уплотнения, рассчитанные ниже вашего минимального режима. Однотрубные конструкции лучше справляются с нагревом на гребенках, чем двухтрубные; удаленные резервуары увеличивают объем жидкости и снижают затухание на длинных трассах. Для пружин устанавливайте жесткость для сохранения заводской высоты в поездной комплектации с постоянной массой аксессуаров, оставляя запас 10–15 мм для переменного груза. Антикоррозийные покрытия и изоляторы из закрытоячеистой пены снижают шум после соленых зим.

| Сценарий использования | Рекомендуемая калибровка клапанов | Рекомендации по пружинам | Водохранилище | Уплотнения/масло для −40°C | Примечания |

|---|---|---|---|---|---|

| Экспедиция, тяжелый передний бампер | Более жесткая низкоскоростная компрессия, контролируемый отбой | +10–20% жесткости спереди; подгоните заднюю под нагрузку | Удаленный резервуар спереди | Масло для низких температур, уплотнения для холода | Проверьте высоту подхода при полном баке |

| Смешанный город/внедорожье (Y62) | Комфорт с контролем кренов | Легкое увеличение жесткости; прогрессивная задняя | Без резервуара допустимо | Масло для низких температур | Сохраните функцию HBMC, если установлено |

| Буксировка/прицеп | Повышенный отбой для предотвращения колебаний | Увеличьте заднюю жесткость на 15–25% | Резервуар сзади опционально | Масло для низких температур | Добавьте проставки задних отбойников |

| Зимние гребенки | Средняя компрессия, высокая стабильность отбоя | Поддерживайте высоту в поездной комплектации | Удаленный резервуар спереди/сзади | Масло для низких температур, сальники | Маркировка по российским стандартам для компонентов внедорожной подвески Nissan Patrol |

Используйте эту матрицу, чтобы переводить реальную грузовую нагрузку и условия маршрута в предсказуемое поведение подвески. Всегда перепроверяйте высоту кузова и углы установки после 500–1000 км, поскольку пружины садятся, особенно зимой.

B2B- кастомные решения подвески для переделок российских SUV

Для конвертеров и флотских установщиков победа — в повторяемости. Определите целевой снаряженный вес и полную массу, внешний диаметр шин, список аксессуаров и температурный диапазон, затем итеративно настраивайте клапаны по инструментальным дорожным тестам. Отслеживайте KPI — высоту под нагрузкой, изменение тормозного пути после подъема и дельту затухания после 10 км гребенок — для оценки успеха. Закрепите сервисные наборы и таблицы моментов в каждой коробке, чтобы техники устанавливали одинаково по регионам.

- Поделитесь спецификацией → подтвердите тестовый образец с трассой диностенда → пилотный выпуск на 3–5 автомобилях → масштабирование до производства с зафиксированной спецификацией материалов и руководствами на русском языке.

- Проверьте документы EAC и маркировку на точной производственной конфигурации, чтобы избежать переделок.

- Запланируйте запасы втулок, уплотнений и фурнитуры, подверженных рассолу и грязи зимой.

- Согласуйте гарантию и маршруты возврата перед первой отгрузкой для ускорения решений на местах.

Если вы готовы формализовать программу по российским стандартам для компонентов внедорожной подвески Nissan Patrol, свяжитесь с командой G·SAI для обсуждения спецификаций, запроса тестового набора или совместной разработки настроенного решения: свяжитесь с командой (https://gsaishockabsorber.com/contact-us/).

FAQ: Российские стандарты для внедорожных компонентов подвески Nissan Patrol

Требуют ли амортизаторы для Patrol сертификации EAC по российским стандартам?

Да, многие детали подвески, влияющие на безопасность автомобиля, подпадают под ТР ТС 018/2011 и требуют Декларации или Сертификата EAC. Работайте с аккредитованной лабораторией и уполномоченным представителем для сбора доказательств испытаний и правильной маркировки.

В чем главное отличие подгонки для Y61 и Y62 в внедорожных наборах?

Y61 с неразрезными мостами терпит подъем, но требует коррекции углов caster и панхард-рычага. Y62 с независимой подвеской выигрывает от умеренного подъема, точных углов рычагов и внимания к HBMC на оснащенных моделях.

Как подготовить подвеску к российским субнулевым температурам?

Используйте масло для амортизаторов с низкотемпературными характеристиками, уплотнения для холода и антикоррозийные покрытия. Проверьте пределы хода в холоде, поскольку резина твердеет и может сократить эффективный провис и гибкость тормозных шлангов.

Подойдут ли aftermarket-амортизаторы для Y62 с HBMC?

Да, но выбирайте демпферы, совместимые с HBMC, и сохраняйте заводские гидравлические диапазоны. Мягкие подъемы, правильная развал-схождение и настройка отбойников помогут сохранить комфорт и управляемость.

Какие сроки поставки ожидать дистрибьюторам для индивидуальных наборов?

Планируйте 2–6 недель на соответствие EAC и маркировку после 1–2 недель валидации продукта. Затем производство и упаковка, с транзитом в зависимости от маршрута; прогнозируйте ежеквартально, чтобы избежать зимних задержек.

Как выбирать жесткость пружин для тяжелых аксессуаров?

Взвешивайте автомобиль в поездной комплектации. Увеличивайте жесткость для поддержания целевой высоты под нагрузкой, затем проверяйте устойчивость хода и затухания на репрезентативном тестовом круге перед фиксацией спецификации.

Последнее обновление: 2025-10-31

Журнал изменений: Добавлена таблица подгонки для Y61/Y62; Уточнены шаги импорта EAC и маркировка; Расширены рекомендации по настройке для холода; Добавлен обзор производителя G·SAI; Включены кейсы из практики и FAQ

Дата следующего обзора и триггеры: 31.01.2026 или раньше при изменениях в ТР ТС 018/2011, правилах таможенных документов или новых ревизиях HBMC от Nissan

Запросите индивидуальное коммерческое предложение или тестовый набор для вашей программы Patrol сегодня. G·SAI может спроектировать, сертифицировать и поставить индивидуально настроенную подвеску в соответствии с российскими стандартами для компонентов внедорожной подвески Nissan Patrol — пришлите требования для старта.