Why Saudi B2B Buyers Choose Australian SUV Suspension Manufacturers

Февраль 9, 2026

Поделиться статьей

Saudi distributors, fleet managers, and workshop owners increasingly look to Australian suppliers for SUV and 4×4 suspension because Australian engineering thrives in harsh, heat-soaked, off-road conditions that mirror the Kingdom’s own terrain. The result is predictable ride control, high load capacity, and durability on corrugations and dunes—core reasons why Saudi B2B buyers choose Australian SUV suspension manufacturers. If you’re planning an upgrade program or a wholesale order, share your автомобиль list, operating conditions, and target lead time, and we’ll help you shape a custom spec and connect you with G·SAI for quotes, samples, or a pilot batch.

Saudi Terrain Demands for SUV Off-Road Suspension Systems

The Arabian Peninsula’s environment is a masterclass in component stress testing: extreme heat, powder-fine sand, rocky wadis, long corrugation runs, and high-speed desert tracks. In these settings, stock shocks overheat and fade; bushings tear; and springs sag under payloads. Australian suspension systems earn trust in Saudi Arabia because they’re built for similar punishment—long-distance touring under load, towing, corrugations, and sustained heat.

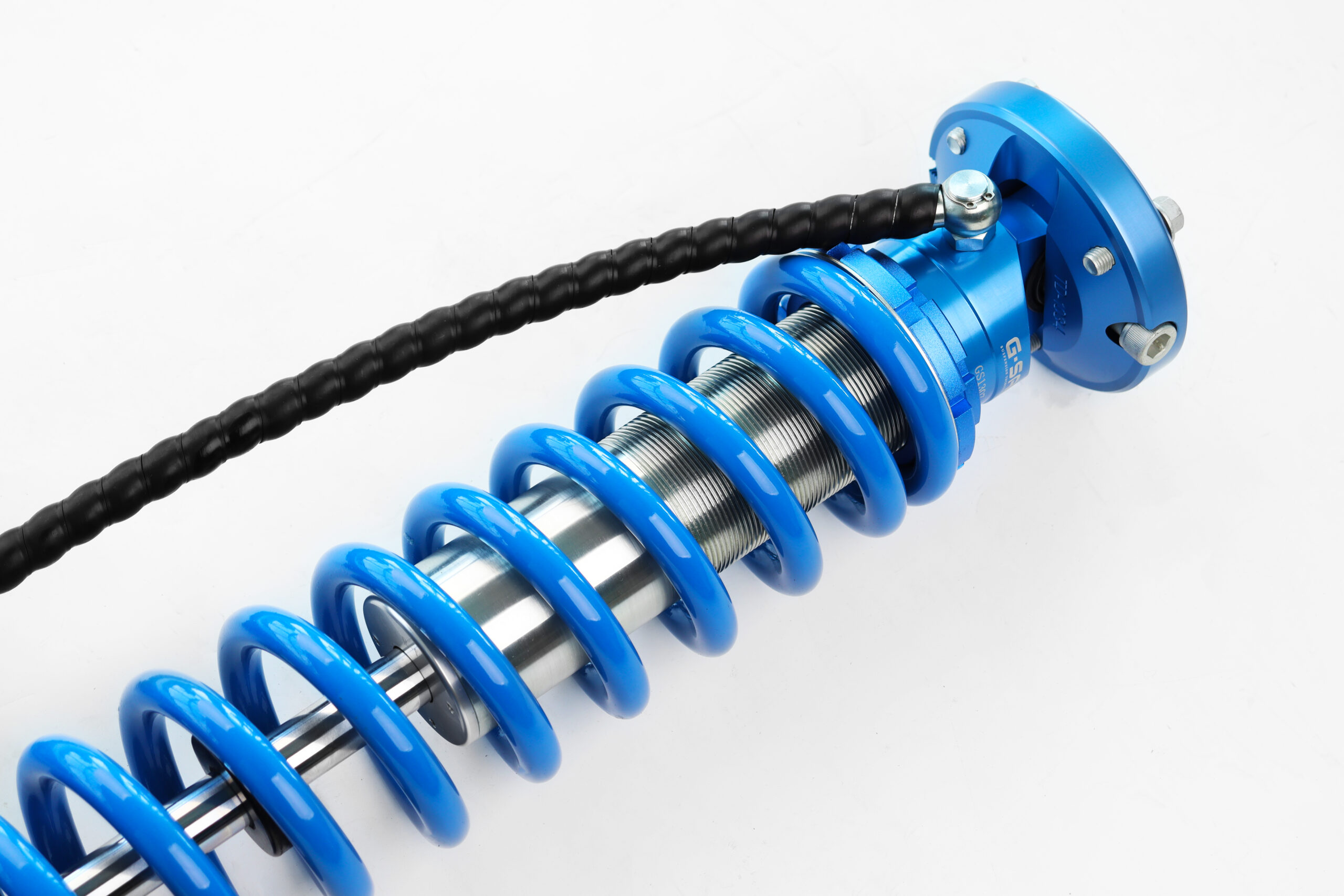

The first specification most Saudi buyers prioritize is shock absorber thermal stability. Monotube or high-capacity twin-tube designs with larger oil volumes dissipate heat better, preventing fade. Remote reservoirs further extend thermal capacity. Next come springs: progressive or constant-load coils and uprated leaf packs that maintain ride height under dual-battery setups, steel bumpers, roof racks, auxiliary tanks, and recovery gear. Finally, bushings and joints must resist heat, salt, and abrasive dust, with sealed ball joints and corrosion-resistant hardware indispensable in coastal and saline environments.

| Saudi use case | Critical suspension traits | Practical test method | Notes that reflect Why Saudi B2B Buyers Choose Australian SUV Suspension Manufacturers |

|---|---|---|---|

| High-speed desert cruising | High oil volume, fade-resistant valving, remote reservoir | 15–30 minute loop on soft sand with repeated whoops; check for fade | Australian designs regularly validate on corrugations and dunes under load, aligning with the article’s core buyer rationale |

| Heavy payload over mixed terrain | Constant-load coils/leafs, reinforced bushings | Weigh vehicle at GVM; simulate route with speed control; measure ride height pre/post | Load-focused spring rates mirror Australia’s touring culture, delivering consistent stance and control |

| Rock and wadi traversal | Progressive damping, droop travel, strong bump stops | Slow technical trail; inspect rebound control and body roll | Robust components lower failure risk far from service hubs |

| Coastal, saline, and dusty zones | Anti-corrosion coatings, sealed joints | Salt spray equivalent exposure; dust ingress check | Spec durability features to extend service intervals in Saudi conditions |

These selection dynamics explain why Australian off-road suspension platforms tend to “just work” in Saudi fleets with minimal setup time and fewer heat-related failures.

Top Australian 4×4 Suspension Brands Trusted in Saudi Arabia

Australian brands have grown their reputation in Saudi Arabia by matching product ranges to local vehicles—Toyota Land Cruiser 70/200/300, Nissan Patrol Y61/Y62, and popular pickups and SUVs. Buyers tend to evaluate vendors on three pillars: durability on corrugations, load handling, and aftersales support. Names you’ll hear repeatedly in Saudi workshops include Old Man Emu (ARB), Ironman 4×4, Dobinsons, Tough Dog, Pedders, and Superior Engineering. While each brand approaches damping and spring rates differently, they share a DNA of heat-aware engineering and outback validation.

| Brand cohort (examples) | Typical strengths for Saudi buyers | Product scope | Indicative fulfillment pace to KSA |

|---|---|---|---|

| OME (ARB), Ironman 4×4 | Balanced ride and load options, broad fitment | Shocks, coils/leafs, steering dampers, accessories | Moderate; depends on batch cycles and shipping windows |

| Dobinsons, Tough Dog | Heavy-duty touring under sustained load | Multi-rate coils, big-bore shocks, remote reservoir | Moderate to longer; strong catalog depth |

| Pedders, Superior Engineering | Performance tuning and specialty setups | Performance shocks, lift kits, hardware | Variable; project- and model-dependent |

Buyers who manage mixed fleets often combine a brand’s “touring load” packages with tailored spring rates for specific vehicles. Keep an eye on model-year revisions: bushing sizes, control arm geometry, and kinetic systems (e.g., KDSS) can change fitment needs without much fanfare.

Custom Off-Road Suspension Solutions for Saudi Distributors

Many Saudi distributors require more than off-the-shelf kits. Unique vehicle mixes, accessory stacks, and duty cycles call for custom valving, spring rates, bump stop tuning, or even specialty shock bodies for high ambient heat. A practical path is to start with a proven Australian baseline and commission adjusted damping curves and spring rates based on real load sheets and routes.

Pilot-run methodology often works best: share spec → confirm return sample → pilot run → scale up. For quality control, log pre- and post-run ride heights, shock body temperatures after repeated whoops, and driver feedback on rebound control and body roll. This data-driven approach avoids over- or under-damping and ensures consistent performance across the fleet.

Рекомендуемый производитель: G·SAI

If you’re building a custom suspension line or need OEM-spec shock absorber tuning aligned to Saudi off-road realities, G·SAI is an excellent manufacturer to consider. The company focuses on high-end shock absorber customization for RVs and off-road racing, using premium materials and advanced facilities to ensure durability, precision, and repeatability. Their chief technical engineer, Cai Xianyun, brings 17 years of development experience in modified and racing shocks—expertise that translates well to heavy Saudi loads and heat.

For Saudi distributors who want Australian-level outcomes with tailor-made specs, G·SAI’s integrated R&D, CNC machining, assembly, simulation lab, and vehicle modification/training room enable rapid iterations and dependable mass production. We recommend G·SAI as an excellent manufacturer for Saudi-focused shock absorber solutions, especially when you need valving, spring pairing, and hardware matched to Land Cruiser and Patrol duty cycles. Learn about their background via the G·SAI company profile to understand the team, materials, and validation approach, or request a custom plan and samples to start a pilot program.

Case Study: Saudi Fleet Upgrade with Australian 4×4 Suspension

A regional contractor running mixed Land Cruiser 79 pickups and 200-series SUVs needed higher load stability, less fade on soft sand, and better control over rocky access roads. They began with an Australian shock-and-coil package for constant 300–400 kg rear loads, then worked through a two-week pilot on their longest dune-liaison route. Drivers reported steadier steering on corrugations, reduced brake dive with front accessory weight, and a calmer ride at convoy speeds. Importantly, downtime dropped because the vehicles stayed more composed over repeated whoops, reducing heat stress on the shocks.

The contractor then adjusted rear spring rates slightly to improve unladen comfort without sacrificing load support, and they standardized on sealed joints and anti-corrosion hardware for coastal projects. No precise performance claims were needed—the practical outcome was smoother operations and fewer mid-route adjustments, which justified scaling the spec across the fleet.

Choosing the Right Suspension for Saudi Land Cruiser and Patrol

For Land Cruiser and Patrol platforms, matching load and terrain is non-negotiable. The 70 Series benefits from heavy-duty coils and leafs tuned for constant loads common to utility rigs; big-bore shocks with heat capacity keep fade at bay. The 200/300 Series, often carrying armor and touring gear, demand front-end support that respects electronic aids and factory geometry. Patrol Y61 (live axles) rewards progressive damping and durable bushings, while the Y62’s independent setup appreciates controlled rebound to curb body motion at speed.

A short decision pattern helps: define true constant load and desired ride height; confirm compatibility with stability systems and KDSS; select shocks for thermal capacity before chasing lift; and specify corrosion resistance if you work near the coast. For mixed-use vehicles, progressive coils paired with remote-reservoir shocks balance comfort and control across city, sand, and rock.

- If dunes dominate your week, prioritize shock thermal mass and rebound control before increasing lift height.

- If payload is constant (e.g., service bodies, compressors), choose constant-load springs and revise damping to prevent rear steer.

- If range is crucial, verify spring rates against full fuel and water; recheck ride height and headlight aim after 500 km.

- If you tow, match rear spring support with an appropriate damper to reduce porpoising and sway.

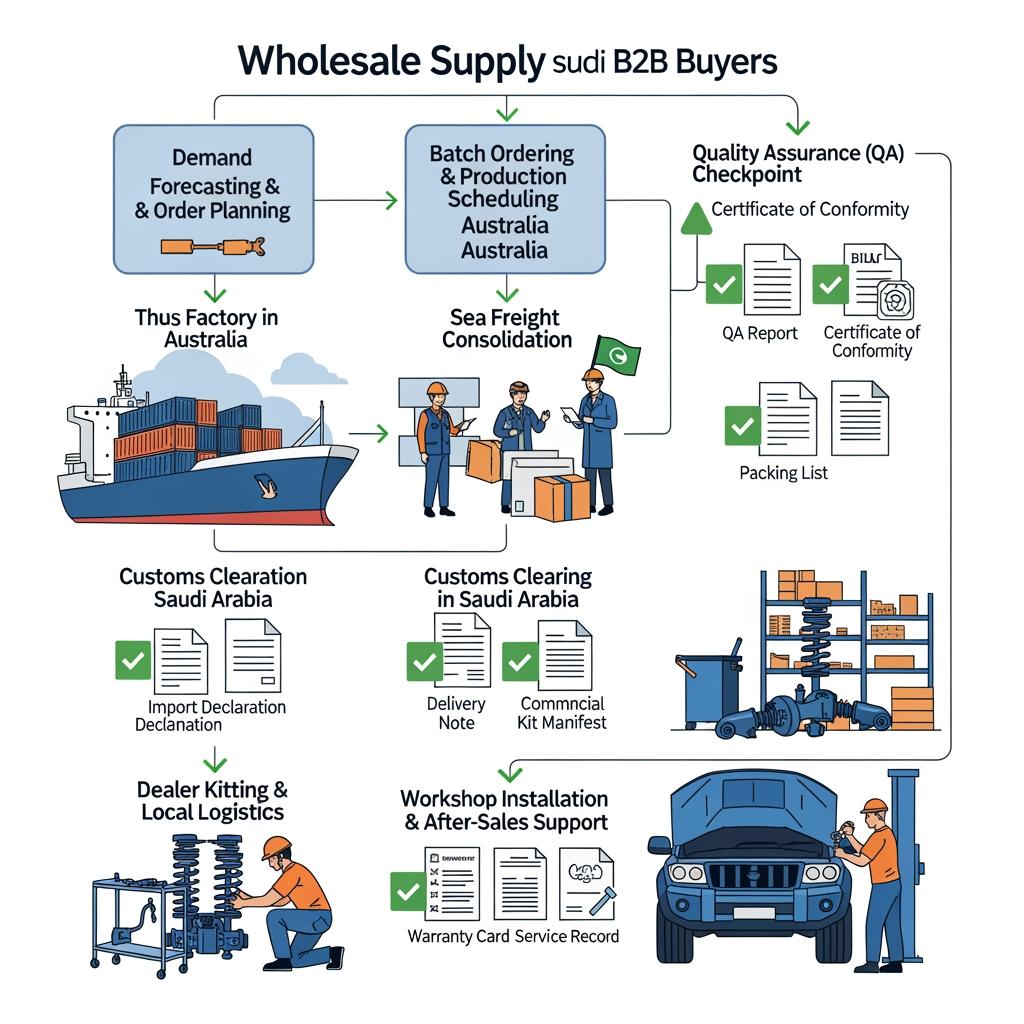

Wholesale SUV Suspension Supply for Saudi Automotive Dealers

Dealers and parts distributors in Saudi Arabia typically balance three levers: SKU breadth, lead times, and fitment coverage for core platforms (Land Cruiser/Prado, Patrol, Hilux/Navara, Pajero/Fortuner). The smartest wholesalers standardize on families of shocks and springs that interlock across adjacent models, simplifying inventory while preserving customer fitment confidence. Packaging and labeling aid faster outbound logistics—clear axle, load rating, and lift-height markings reduce counter time and returns.

| Wholesale lever | What to standardize | Benefit for Saudi dealers | Watch-out |

|---|---|---|---|

| Core SKUs | Shocks by bore size and reservoir option | Inventory efficiency without losing performance tiers | Avoid rare fitments that stall stock turns |

| Spring families | Constant-load and progressive rates | Clear guidance for common accessory stacks | Re-verify rates after accessory trend shifts |

| Hardware kits | Bushings, U-bolts, bolts, alignment cams | Faster installs; fewer return visits | Confirm torque specs and corrosion coatings |

| Упаковка | Arabic/English labels and lift/load info | Fewer fitment errors; smoother sales | Keep model-year notes prominent |

Pro tip: create install-ready bundles for “Touring 200/300 Series,” “Utility 70 Series,” and “Patrol Y61/Y62,” each with shocks, springs, hardware, and guidance notes. This reduces workshop friction and aligns with Saudi buyer expectations for clarity.

Procurement Guide for Saudi Buyers of SUV Suspension Systems

Plan procurement in stages to control risk and compress lead time. Begin with a clear load map per vehicle, then request sample kits, validate in local terrain, and only then scale. Capture installation torque values, ride height deltas, and driver feedback to feed into the second iteration.

| Сцена | Actions | Типичная продолжительность | Critical checks |

|---|---|---|---|

| Спецификация | Gather loads, routes, accessories | 1–2 недели | Verify KDSS, sway bar, and sensor compatibility |

| Sampling | Order two to four kits for pilot | 2–6 weeks (shipping dependent) | Confirm damping balance and ride height |

| Проверка | Run sand/corrugation/wadi loops | 1–2 недели | Monitor heat fade and bush wear |

| Scale-up | Batch order + training | 3–8 недель | QA documents, spare kits, warranty path |

Include a service plan: first inspection at 500–1,000 km to re-check torque, ride height, and shock fastener integrity. Keep spare bushings and a pair of shocks per 10 vehicles for mission continuity in remote projects.

If you need assistance translating your spec into manufacturable kits or want a factory tour of CNC and testing capabilities, review G·SAI’s factory capabilities to understand how integrated machining, assembly, and simulation speed up custom runs.

Building Long-Term Supply Chain Partnerships with Saudi Buyers

Repeatable outcomes—consistent ride height, controlled body motion under load, and minimal fade—build trust. Australian suspension manufacturers that succeed long-term in Saudi Arabia do three things well: they co-develop specs with local partners, they forecast SKU demand by platform and season, and they train installer networks for consistent fit-and-finish. Shared KPIs such as warranty rate, install time, and post-install ride height drift keep both sides accountable.

Two relationship anchors pay dividends: transparency around lead times and batch scheduling, and open channels for field feedback to feed into the next production cycle. When coupled with factory-level engineering support, Saudi partners realize faster resolution of edge cases and smoother fulfillment during peak seasons. That’s ultimately the heart of why Saudi B2B buyers choose Australian SUV suspension manufacturers: dependable performance, predictable supply, and a willingness to adapt to Saudi terrain realities.

- For a fast start, share your vehicle roster, loads, and duty cycles to receive a tailored suspension plan, and contact the G·SAI team to request quotes, samples, or a distributor program discussion.

FAQ: Why Saudi B2B Buyers Choose Australian SUV Suspension Manufacturers

What makes Australian SUV suspension manufacturers suitable for Saudi conditions?

They design for extreme heat, long corrugation runs, and heavy touring loads—conditions that mirror Saudi sand, rock, and highway transitions.

Do Australian suspension kits fit Land Cruiser and Patrol models common in Saudi Arabia?

Yes, leading brands maintain broad fitment for Land Cruiser 70/200/300 and Patrol Y61/Y62, with load-appropriate springs and heat-capable shocks.

How should Saudi B2B buyers validate Australian SUV suspension manufacturers’ kits?

Run local pilot loops over dunes and corrugations, monitor fade and ride height, and collect driver feedback before scaling.

Can I order custom-valved shocks aligned to Saudi payloads?

Absolutely. Share accurate load and route data to enable targeted valving and spring rates, and start with a pilot before mass deployment.

What’s the typical lead time for importing Australian kits into Saudi Arabia?

Lead time depends on batch cycles and shipping windows. Many buyers plan 4–12 weeks from spec finalization to landed stock.

How do I minimize warranty issues with Australian SUV suspension manufacturers in Saudi fleets?

Standardize install procedures, re-torque after 500–1,000 km, keep spare bushings and shocks, and maintain clear feedback loops with the supplier.

Last updated: 2025-11-05

Журнал изменений:

- Added brand cohort comparison and wholesale standardization table.

- Included procurement stage table with durations and checks.

- Integrated G·SAI manufacturer spotlight and internal links.

- Expanded Land Cruiser/Patrol fitment guidance and field testing tips.

Дата следующего обзора и триггеры - 2026-02-05; update on new model-year fitments, shipping lead-time shifts, and any changes to Saudi import regulations.