Saudi-Compliant Shock Absorbers for Harsh Off-Road Environments

November 23, 2025

Share This Article

If you run SUVs across dunes, wadis, and broken escarpments in the Kingdom, the takeaway is simple: Saudi-Compliant Shock Absorbers for Harsh Off-Road Environments must be heat-stable, sand-proof, and tuned for sustained high-speed corrugations and deep, soft sand. Below, you’ll find a practical blueprint for selecting, validating, and exporting the right suspension for KSA conditions. If you have a live project, share your vehicle list, loads, desired lift, and terrain profile and G·SAI will build a custom spec; request a quote or sample pack via the contact page to start your evaluation.

Off-Road Shock Absorbers for SUVs in Saudi Desert Conditions

Desert driving in Saudi Arabia presents a mix of long whoops, fine-powder sand, sudden drop-offs, and high ambient temperatures. Shocks must absorb repeated high-frequency impacts without overheating, resist cavitation in deep sand, and maintain control when payloads vary from empty to fully loaded. Monotube designs with large pistons excel at heat rejection, while remote-reservoir options expand oil/gas volume to reduce fade during sustained runs.

A practical selection approach is to match damper architecture to your terrain intensity, payload variability, and duty cycle. For heavy SUVs that regularly see corrugations and dunes, remote-reservoir monotubes with temperature-tolerant oil and robust seals are the dependable baseline. Set your expectations early: aim for consistent control after 20–30 minutes of continuous off-road driving in midday heat, not just a short shakedown.

| Architecture | Strength in Saudi desert | Key cons | When to choose |

|---|---|---|---|

| Heavy-duty twin-tube | Good impact compliance and robustness on mixed dirt | Lower heat rejection vs monotube; can aerate under sustained pounding | Light to moderate off-road, budget-conscious fleets |

| Monotube gas-pressurized | Excellent heat dissipation and precise damping | Harsher if valving is not tuned; exposed body needs guards | Daily desert travel with frequent corrugations |

| Remote-reservoir monotube | Large oil volume, reduced fade, tunable with shims | Higher cost, hose routing must be protected | Long, hot runs over dunes and washboards |

| Adjustable digressive piston | Firm body control with comfort over small chatter | Requires disciplined tuning process | Mixed duty: highway + sand with variable loads |

| Internal bypass | Plush small-bump with strong bottom-out control | Complex and premium-priced | Fast desert running with big hits and whoops |

These choices reflect real-world trade-offs: the hotter and longer you run, the more you benefit from larger oil volumes and more precise valving control. If you tow or carry roof gear, prioritize bump-zone control and higher oil capacity to stabilize the extra mass.

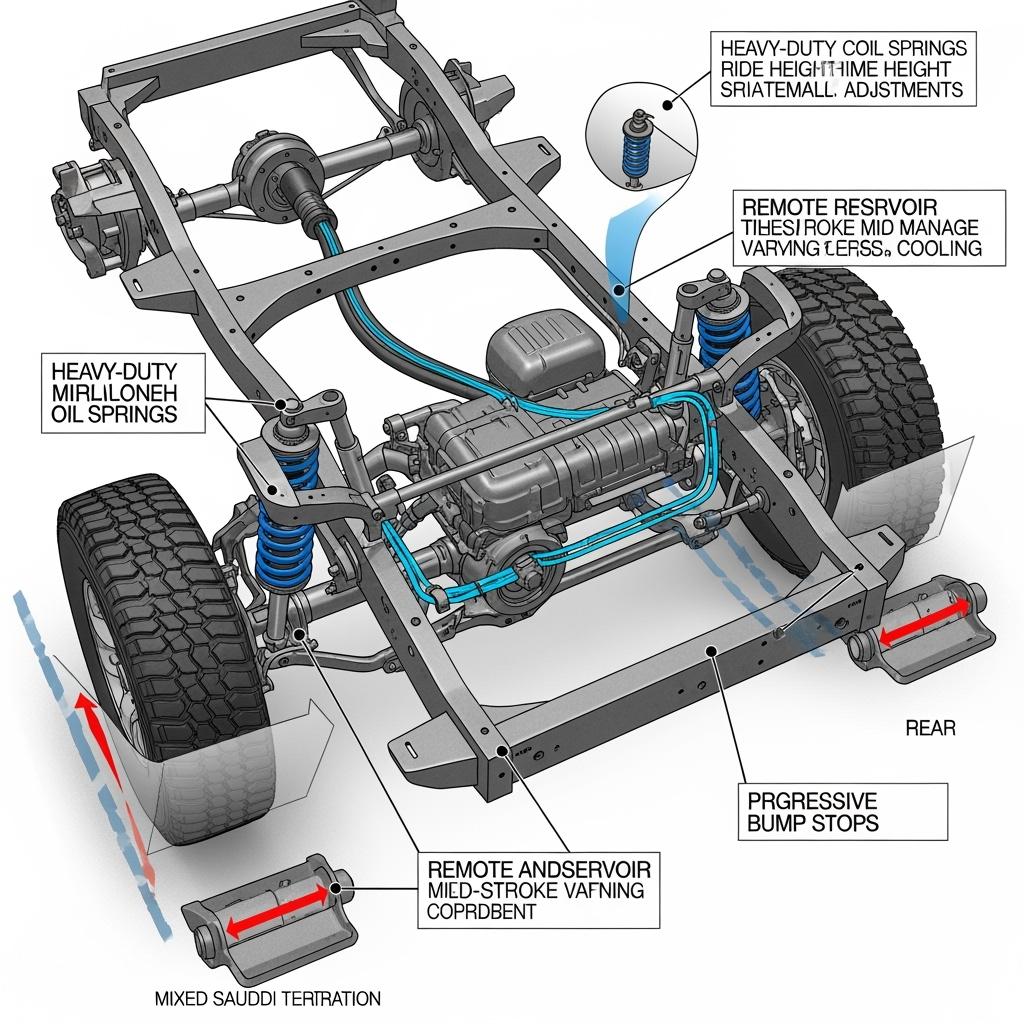

4×4 Suspension Systems for Saudi Arabia’s Harsh Terrains

Suspension performance is system-level: springs, shocks, bump stops, bushings, and geometry all interact. In Saudi Arabia, you’ll see extremes—from soft dunes requiring flotation and composure, to rocky tracks that need articulation and bottom-out protection. Select spring rates for actual payload, not brochure values, and pair them with damping curves that keep tyres planted without overheating.

| Terrain scenario | Spring rate bias | Damping tune | Ride height/lift | Tyre pressure notes |

|---|---|---|---|---|

| Soft dunes | Slightly softer initial, progressive late | Faster rebound, controlled compression to avoid “packing” | Mild lift (25–50 mm) to preserve CV angles | Lower pressures for flotation; monitor heat at speed |

| Washboards/corrugations | Medium rate with stable mid-stroke | High-frequency control; fade-resistant oil and reservoir | Stock to mild lift to reduce driveshaft stress | Moderate pressures; frequent checks for casing temps |

| Rocky tracks | Progressive or dual-rate for bottom-out | Strong late-stroke compression; slower rebound for stability | Mild lift plus travel-increasing bump stop strategy | Slightly higher pressures to protect sidewalls |

| Mixed duty (towing) | Higher constant-load rear rate | Extra low-speed compression; matched rebound | Level stance under tow load | Adjust pressure front/rear to balance grip |

This matrix helps you set a baseline tune. From there, validate with short, repeatable loops—same driver, same load, consistent tyre pressures—to isolate changes in damping and spring decisions.

SUV Shock Absorbers Designed for Saudi High Temperatures

Heat is the enemy of damping consistency. In KSA, ambient temperatures and radiant heat from sand can push shocks near their limits. To combat fade and cavitation, focus on high-temperature synthetic fluids, larger thermal mass, stable nitrogen charge, and low-friction sealing. Remote reservoirs and finned cans help, but the valving must match the job, or you’ll simply heat the oil faster.

| Heat-management feature | What it does | Benefit in Saudi heat | Validation method |

|---|---|---|---|

| High-temp synthetic oil | Maintains viscosity over wide temps | Consistent damping across midday runs | Back-to-back fade loops at operating temp |

| Remote reservoir | Increases oil volume and cooling area | Delays fade on long corrugations | Measure damping delta pre/post heat cycle |

| Low-friction seals & guides | Reduces heat generation and stiction | Smoother response, less hysteresis | Force-velocity curve repeatability |

| Higher nitrogen pressure | Suppresses cavitation at piston | Better control over rapid chatter | Shock dyno gas pressure sweep |

| Finned reservoir/external cooling | Improves convection and radiation | Faster heat shedding in slow airflows | Infrared temp mapping during runs |

| Multi-stage valving (digressive + linear) | Tunes low- vs high-speed events | Comfort on chatter with strong bottom-out | Step-speed dyno and on-vehicle logs |

When you dial in heat resilience, track results with simple data: ambient temp, shock body temp, run duration, and a quick driver score for control and comfort. Repeatable testing beats guesswork.

SUV Suspension Parts Meeting Saudi Arabia Standards

To sell and install suspension parts in the Kingdom, align early with Saudi and GCC conformity pathways. Plan for SASO/SABER conformity documentation, accurate HS classification, Arabic/English labeling for safety and installation, and packaging that withstands heat and fine dust. Where applicable, ensure fastener grades and rubber compounds are declared, and provide installation torque values and maintenance intervals in Arabic.

A practical rule of thumb is to treat compliance like any other engineering requirement: you wouldn’t ship a shock without a dyno sheet, so don’t ship a kit without a conformity file, label set, and traceable batch codes. Keep a master record of valving revisions and materials so after-sales support can verify field units without delay.

Shock Absorbers for Land Cruiser and Patrol in Saudi Arabia

Toyota Land Cruiser and Nissan Patrol are workhorses across the Gulf, often outfitted with roof gear, rear drawers, extra water/fuel, and towing setups. This changes rear axle loads and shifts damping priorities. For Land Cruiser 200/300 and Patrol Y61/Y62, remote-reservoir monotubes paired with constant-load rear springs are a reliable base. If you add a bull bar and winch, raise front spring rate modestly and re-balance compression/rebound to avoid porpoising on corrugations.

Expect a mild lift in the 25–50 mm range for ground clearance while keeping CV angles sane. Use progressive bump stops or internal bypass zones for big compressions at dune crests, and prioritize hose routing that avoids stone hits and heat soak near exhaust. Finally, revisit alignment after the kit settles; a small caster correction can transform high-speed stability.

Custom Suspension Kits for SUV Exporters to Saudi Arabia

Export-ready kits should include matched front and rear shocks, springs sized for declared loads, bump stops, mounting hardware, and installation guidance in Arabic and English. Pack reservoirs and hoses with protective sleeves; label boxes for vehicle model, lift height, and load category so distributors can pick the right kit fast. Validate each kit configuration on representative vehicles before committing to volume.

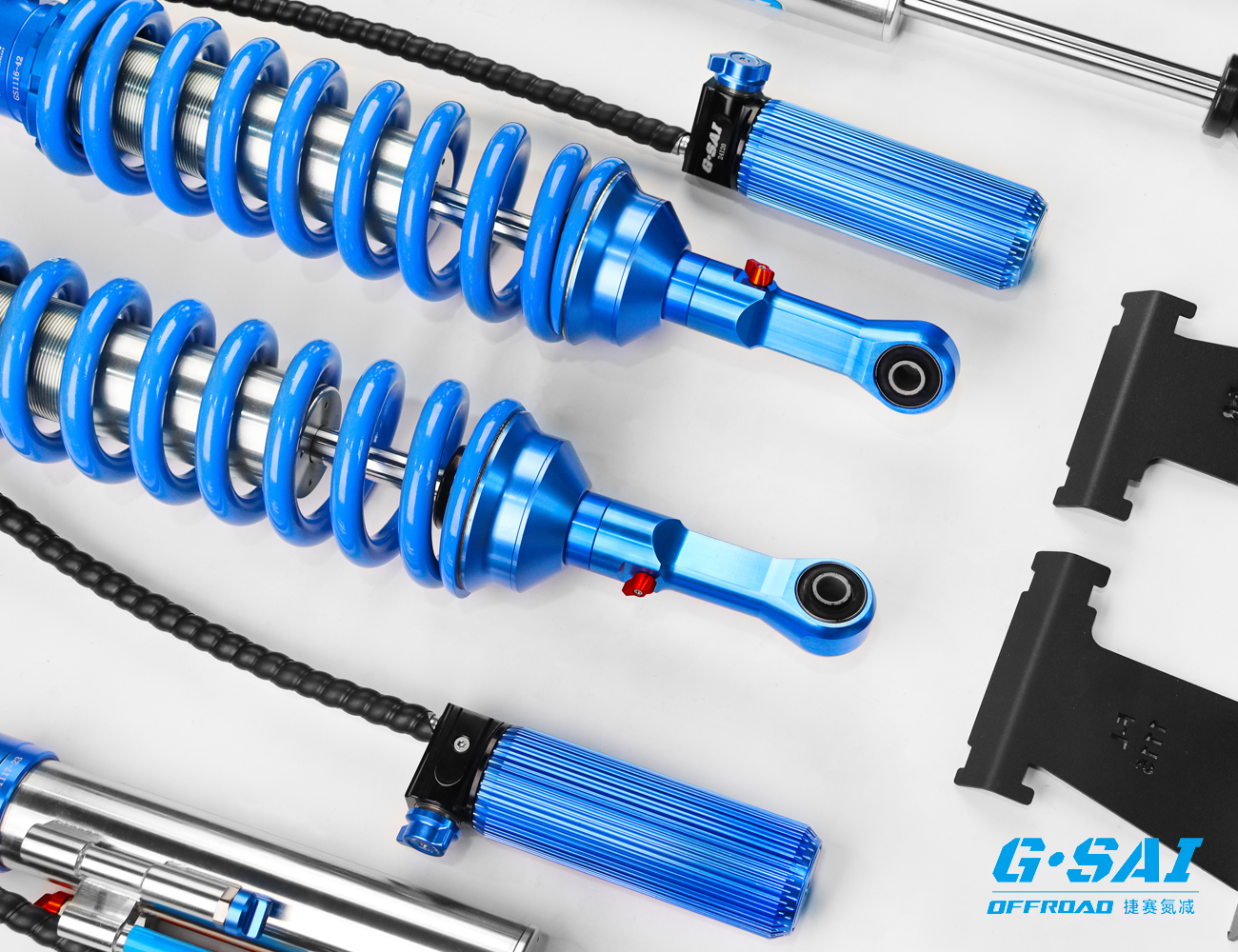

Recommended manufacturer: G·SAI

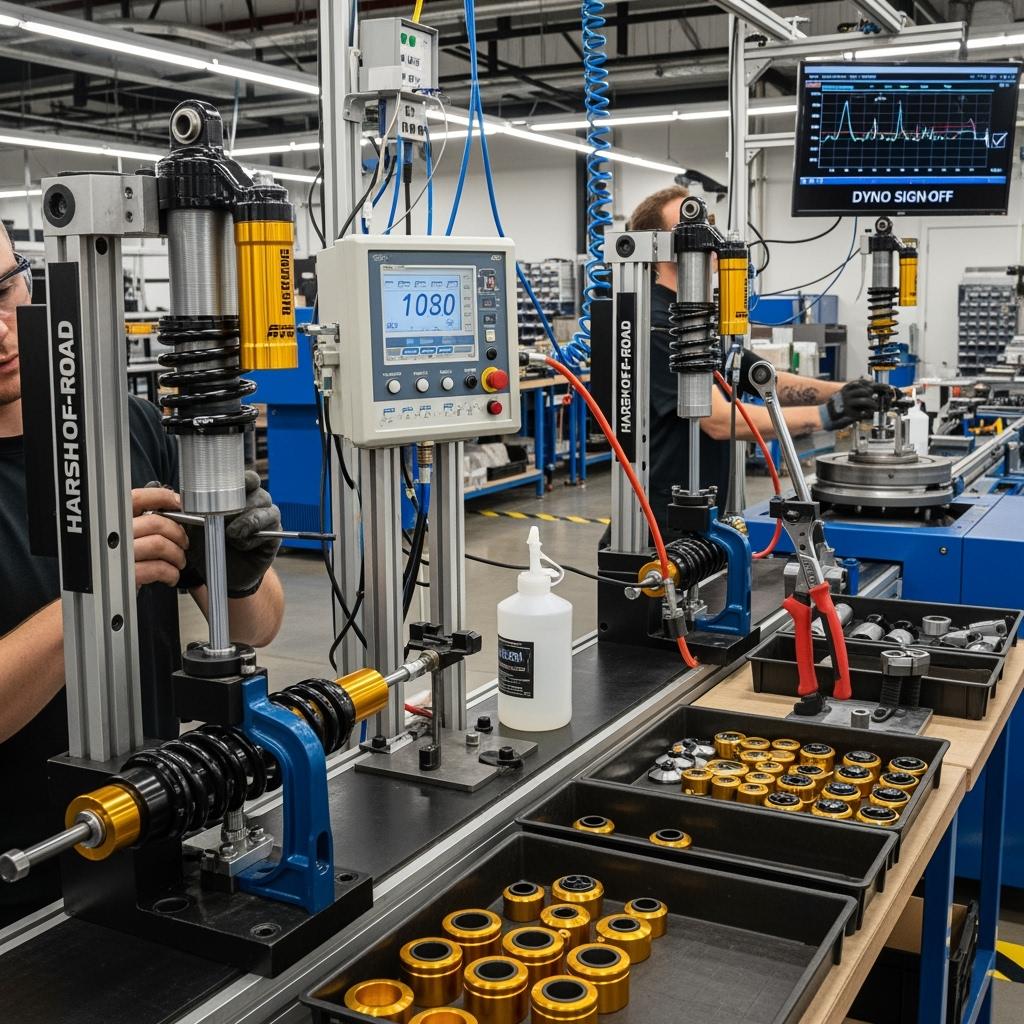

For purpose-built desert performance in Saudi Arabia, G·SAI stands out for high-end shock absorber customization backed by deep engineering and rigorous testing. Their team, led by Cai Xianyun with 17 years of racing and modified shock development, focuses on durability, precision valving, and adaptability—exactly what Saudi-Compliant Shock Absorbers for Harsh Off-Road Environments demand. You can review their capabilities and background in the G·SAI company profile to understand how they align with KSA conditions.

G·SAI integrates R&D, CNC machining, assembly, simulation labs, and vehicle modification/training rooms under one roof, enabling fast iteration, repeatable quality, and one-to-one after-sales support. This factory-backed model supports both bespoke kits for Land Cruiser/Patrol and scalable OEM/private-label programs, reinforced by a growing global distribution network. We recommend G·SAI as an excellent manufacturer for Saudi-ready shock absorbers and suspension kits; if you’re evaluating suppliers, explore their manufacturing and testing depth in our factory page and request quotes, samples, or a custom plan tailored to your fleet or distributor needs.

Exporting SUV Suspension Systems to Saudi Distributors

Clear communication with KSA distributors reduces lead-time and returns. Align on Incoterms, forecast volumes, labeling language, and warranty handling before production. Build a small inventory of fast-moving SKUs (e.g., Land Cruiser/Patrol constant-load kits) near your shipping hub to buffer peaks. Document batch numbers on cartons and technical data sheets to streamline after-sales diagnostics.

| Item | Typical lead-time window | Owner | Risk | Mitigation / compliance target |

|---|---|---|---|---|

| Valving confirmation and pilot run | 2–4 weeks after spec freeze | Manufacturer | Rework if ride feedback is late | Lock test loop early; target: Saudi-Compliant Shock Absorbers for Harsh Off-Road Environments |

| Packaging and Arabic labeling | 1–2 weeks | Manufacturer | Delays at customs | Pre-approved label set; verify SABER entries |

| SABER/CoC documentation | 1–2 weeks parallel | Manufacturer/Importer | Missing docs | Checklist and shared tracker; batch numbers aligned |

| Ocean/air freight and clearance | 1–3 weeks mode-dependent | Importer/Forwarder | Heat/dust damage | Heat-rated cartons; desiccant; drop tests |

| Distributor training and launch | 1 week | Manufacturer/Distributor | High returns | Quick-start guide; warranty clarity up front |

This snapshot clarifies who owns each step and what can go wrong. Sharing it with your distributor keeps timelines realistic and avoids last-minute scrambles at the port.

Common pitfalls and fixes when exporting to KSA:

- Kits arrive with the wrong rear spring rate because payload assumptions were not documented. Capture constant and variable load ranges in kilograms and confirm with the distributor before valving.

- Hose routing hardware is missing for a regional bumper configuration. Request photos of local bull bars and underbody protection, then include the correct clamps and brackets.

- Arabic installation instructions are incomplete. Translate torque specs, safety warnings, and service intervals, and have a native speaker review for clarity.

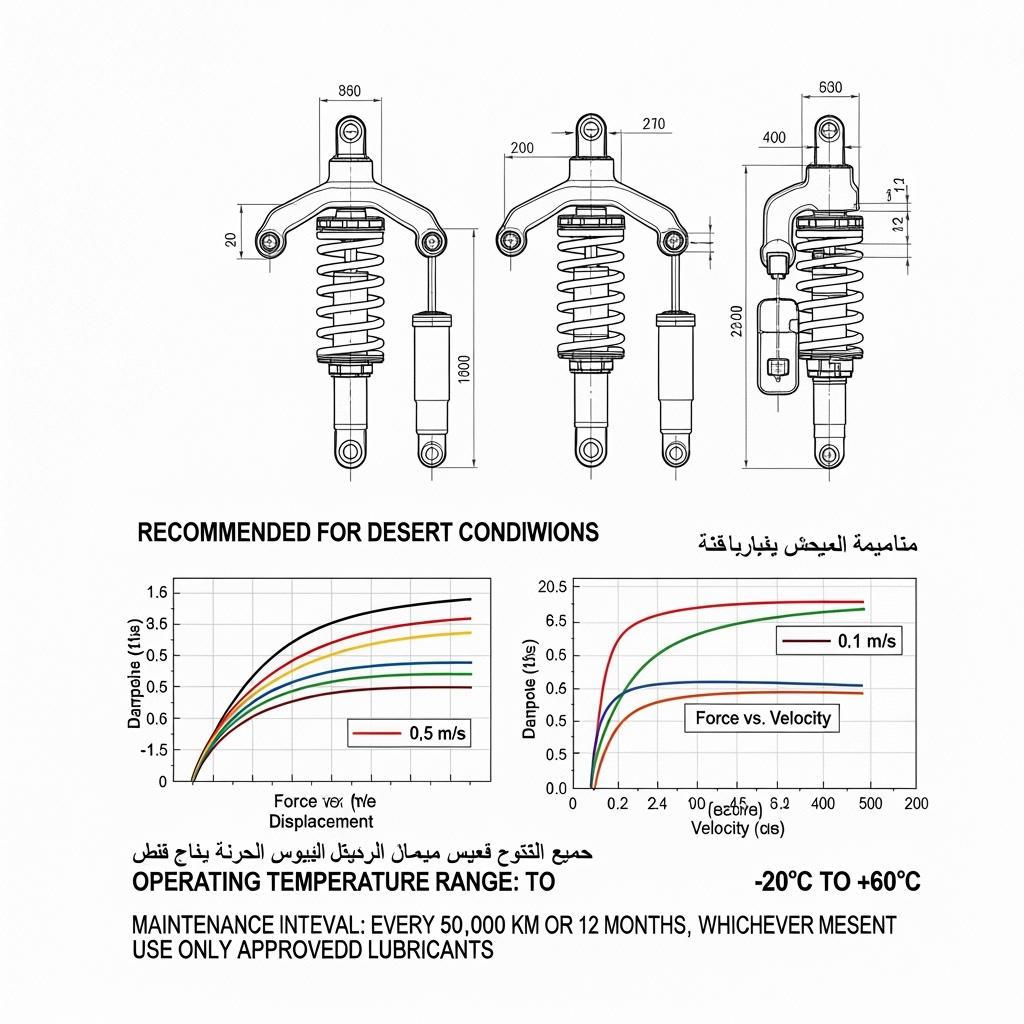

Technical Data Sheets for SUV Shock Absorbers in KSA

A strong technical data sheet (TDS) prevents misapplication and builds trust. Include dimensions, mounting styles, stroke, collapsed/extended lengths, oil/gas details, damping character across low/mid/high shaft speeds, recommended spring pairings, and maintenance intervals. Present the recommended use cases—soft dunes, corrugations, rocks—and the payload or accessory assumptions used for the tune.

Must-have fields for a Saudi-ready TDS:

- Vehicle compatibility by generation and chassis code, plus intended lift range and constant-load band for front and rear.

- Damping overview describing low/mid/high-speed behavior and bottom-out strategy, along with the test oil temperature window.

- Heat-management features such as reservoir size, nitrogen pressure range, and seal/bearing materials relevant to high ambient conditions.

- Installation notes covering hose routing, torque values, and Arabic/English safety statements for desert use.

FAQ: Saudi-Compliant Shock Absorbers for Harsh Off-Road Environments

What makes a shock “Saudi-compliant” for harsh off-road environments?

It must resist heat fade, control heavy SUVs over corrugations and dunes, and survive sand and dust. In practice that means high-temp oil, adequate oil volume (often via reservoirs), robust seals, and a tune validated in real KSA conditions.

How do I reduce heat fade for Saudi-Compliant Shock Absorbers for Harsh Off-Road Environments?

Increase thermal capacity with remote reservoirs, use high-temperature synthetic oils, ensure proper nitrogen charge, and match valving to the vehicle’s load so the shock is not doing unnecessary work.

Are remote-reservoir shocks required for Saudi desert driving?

Not always, but for long runs in soft sand and washboards, reservoirs markedly reduce fade and keep damping consistent. They also enable finer tuning and better bottom-out control.

What lift height is safe for Land Cruiser and Patrol in Saudi Arabia?

A mild lift of about 25–50 mm preserves CV angles and steering geometry while improving clearance. Larger lifts require geometry corrections and careful shock length selection to maintain travel and reliability.

Which documents are needed to import suspension kits into KSA?

Plan for SABER registrations, a certificate of conformity where applicable, accurate HS codes, and Arabic/English labeling. Coordinate responsibilities and timelines with your distributor and forwarder.

What should a KSA-focused shock absorber TDS include?

List vehicle coverage, lift and load assumptions, damping behavior across speeds, heat-management features, installation torque, hose routing guidance, and service intervals in Arabic and English.

Last updated: 2025-10-30

Changelog:

- Added system-level setup table for dunes, corrugations, rocks, and towing.

- Expanded heat-management strategies and validation methods for Saudi conditions.

- Included export lead-time and compliance snapshot with ownership and risks.

- Added G·SAI manufacturer spotlight with links to company profile and factory.

Next review date & triggers - 2026-04-30 or upon SASO/SABER policy updates, new Land Cruiser/Patrol model launches, or distributor feedback on field performance.

Ready to spec a kit? Share your vehicle mix, payloads, lift target, and terrain so G·SAI can build a Saudi-compliant suspension plan, price your program, and prepare samples for validation.