Top Shock Absorber Manufacturers in Germany for Off-Road and Racing Vehicles

June 24, 2025

Share This Article

1. What is a Shock Absorber and Why It Matters in Off-Road Applications?

Shock absorbers are crucial components in every vehicle, especially in off-road and racing environments. They absorb and dissipate kinetic energy from the suspension system, ensuring stability, handling, and safety. For off-road racing teams, modified car builders, and OEM brands, high-performance shock absorbers are essential to compete and excel in rugged terrains and high-speed racing conditions.

Key Functions of Shock Absorbers:

- Dampen Vibrations and Impacts: Reducing vehicle body movement and maintaining tire contact with the ground.

- Improve Control and Handling: Essential for navigating uneven terrain and sharp turns.

- Prolong Suspension Life: Minimizing wear on other suspension components.

- Enhance Comfort and Safety: Especially crucial in racing and modified vehicles.

Why They Matter for B2B Buyers:

| Benefit | Description |

|---|---|

| Durability | Designed for long-term use in harsh environments. |

| Customization | German manufacturers offer tailored solutions for OEM and racing needs. |

| Brand Differentiation | High-performance parts enhance vehicle performance and brand reputation. |

| Compliance with EU Standards | German shock absorbers comply with strict quality and environmental laws. |

2. Applications of Shock Absorbers in Modified Cars and Off-Road Vehicles

Germany is home to some of the most advanced automotive parts manufacturers, with a strong focus on innovation and engineering excellence. Shock absorbers produced by German companies are widely used across various automotive segments, particularly in:

Off-Road Racing Vehicles

- Rally Cars tested in extreme terrains

- Desert Racers requiring long-travel suspension systems

- 4×4 SUVs with lifted suspension for rock crawling

Modified Vehicles

- Street Tuners upgrading for performance and aesthetics

- Show Cars needing adjustable suspension systems

- Track Day Cars requiring optimized handling dynamics

Commercial and Specialty Vehicles

- Utility Vehicles used in construction or agriculture

- Emergency Vehicles that must operate under all conditions

- Military Vehicles designed for rugged performance

B2B Integration Opportunities

| Buyer Type | Use Case Example |

|---|---|

| OEM car manufacturers | Integrating custom shocks into new performance vehicle lines |

| Distributors & Wholesalers | Selling German precision parts to global B2B markets |

| Motorsport teams | Sourcing race-specific dampers for competition use |

| Auto part retailers | Offering premium upgrade kits to high-end car owners |

3. Key Types of Shock Absorbers Used by German Manufacturers

German engineering is world-renowned for its precision, especially in the automotive sector. German shock absorber manufacturers offer a range of designs to suit different vehicle types and use cases. Understanding these types can help B2B buyers and procurement teams make informed decisions.

Common Types of Shock Absorbers

| Type | Description |

|---|---|

| Twin-Tube Shock Absorbers | Traditional design, excellent for moderate performance and cost-effective |

| Mono-Tube Shock Absorbers | Offers superior heat dissipation and responsiveness |

| Gas-Charged Shock Absorbers | Enhanced damping control and reduced aeration |

| Adjustable Shock Absorbers | Used in racing and tuning, allows compression/rebound adjustments |

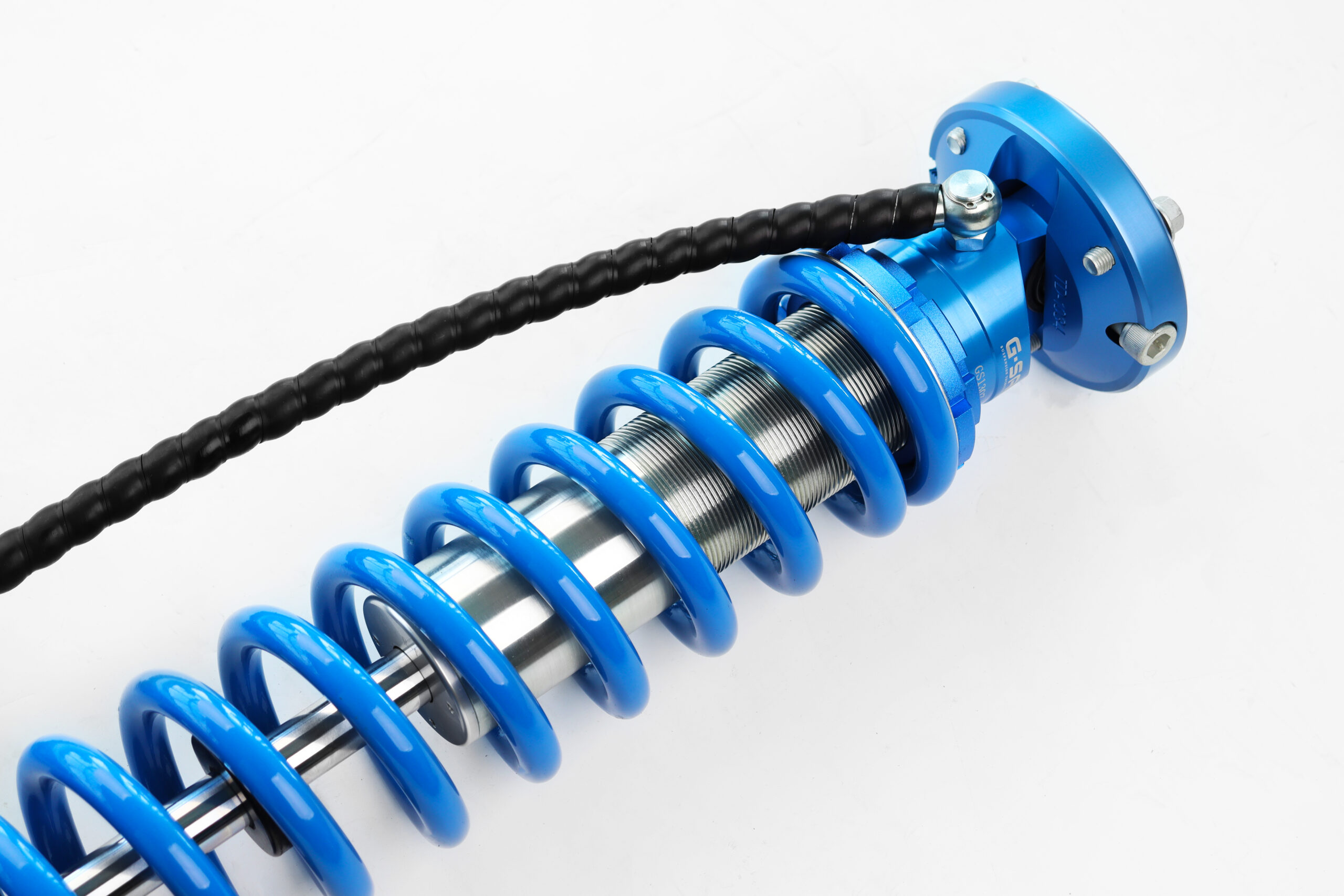

| Coilover Shock Absorbers | Integrates spring and damper, ideal for performance cars and custom builds |

Specialized Shock Absorber Technologies in Germany

- Electronically Controlled Dampers (ECD): Adaptive suspensions that change damping based on driving conditions.

- Hydraulic Rebound Stops (HRS): Prevent bottoming out during aggressive off-road usage.

- Progressive Valving Systems: Ensures balance between comfort and performance.

B2B Considerations for Shock Absorber Types

When procuring for large-scale production or modification projects, it’s essential to balance performance, cost, and customizability:

- OEM Buyers: Prefer mono-tube or coilover shocks for high-performance trims.

- Off-Road Brands: Favor adjustable units with external reservoirs.

- Distributors: Stock a mix of twin-tube and gas-charged units for various market segments.

For companies looking for customized solutions, it’s worth exploring manufacturers that offer full R&D capabilities, like G·SAI in China, which specializes in high-performance, custom-built shocks for extreme off-road applications. Learn more about their customization process and product range.

4. Shock Absorber Solutions Offered by German Manufacturers for B2B Clients

German shock absorber manufacturers excel at delivering tailored solutions for OEMs, wholesalers, and aftermarket brands. These solutions are not just about off-the-shelf parts; they include engineering partnerships, R&D collaboration, and scalable production—making them an ideal fit for B2B buyers seeking reliable supply chains and top-tier performance.

Types of B2B Solutions Available

| Solution Type | Description |

|---|---|

| OEM Integration Services | Co-developing shock absorbers for new vehicle models |

| Private Label Manufacturing | Producing shocks under client brand names with custom specs |

| Aftermarket Performance Kits | High-performance shocks tailored for modified and racing vehicles |

| Small Batch Custom Builds | Ideal for motorsports teams and boutique car brands |

| Large-Scale Production | For wholesalers and distributors needing consistent volume and quality |

Features That Attract B2B Buyers

- Engineering Support: German companies often provide CAD drawings, performance data sheets, and testing reports.

- ISO 9001 & TÜV Certification: Ensures compliance with international quality standards.

- Flexible Logistics: Shipment capabilities worldwide, often with support for Just-In-Time (JIT) delivery.

- Warranty & After-Sales Service: Long-term reliability backed by professional service teams.

Popular German Manufacturers Offering B2B Solutions

- BILSTEIN

- Renowned for mono-tube gas pressure technology.

- OEM supplier to brands like Mercedes-Benz, Porsche, and BMW.

- Offers tuning and motorsport-specific solutions.

- KW Automotive

- Specialist in coilover systems for racing and street performance.

- Offers custom damper tuning and high-end EDC-compatible systems.

- SACHS (ZF Group)

- Major OEM supplier with a focus on passenger and commercial vehicles.

- Known for reliability and mass production capabilities.

- KONI

- Focused on adjustable dampers, ideal for tuning and motorsports.

- Offers solutions for both consumer and professional racing markets.

- Eibach

- While known for springs, they also collaborate with damper manufacturers for complete suspension kits.

For clients seeking custom shock absorber development, especially for off-road and racing applications in bulk, a great international partner is G·SAI in China. With a state-of-the-art facility and 17 years of engineering expertise, G·SAI offers full-spectrum solutions from concept to final product. Learn more about their OEM and private label solutions here.

5. German Shock Absorbers vs. Alternatives: Which Offers Better Value for Brands?

Germany is synonymous with engineering excellence, but how do its shock absorber offerings stack up against manufacturers in Asia, the US, or Eastern Europe? For B2B buyers, especially those sourcing at scale, comparing value from different regions is crucial.

Performance Comparison Table

| Feature | German Brands | Chinese Brands (e.g., G·SAI) | US Brands | Eastern European Brands |

|---|---|---|---|---|

| Performance Consistency | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★☆☆ |

| Customization Capability | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Lead Time Efficiency | ★★★☆☆ | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Cost Efficiency | ★★☆☆☆ | ★★★★★ | ★★☆☆☆ | ★★★★☆ |

| Global Logistics Support | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★☆☆ |

| After-Sales Support | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★☆☆ |

What Makes German Shock Absorbers Unique?

- Technological Leadership: Innovations like electronic damping systems and adaptive ride control.

- Premium Branding: Products from Germany add value to high-end vehicle brands.

- Strict Quality Control: Full traceability and rigorous testing in TÜV-certified labs.

When to Choose Alternatives Like G·SAI

- When Customization Is Key: G·SAI specializes in personalized shock design for unique racing and off-road environments.

- When Cost Is a Factor: For startups and distributors needing high performance at a lower cost.

- For Rapid Prototyping: G·SAI’s simulation labs and CNC workshops allow for fast, scalable development cycles.

Explore G·SAI’s contact center to discuss your shock absorber sourcing strategy and custom requirements with their expert team.

6. How to Choose the Right Shock Absorber Manufacturer in Germany

Choosing a reliable shock absorber partner involves more than just comparing product specs. For businesses in automotive manufacturing, performance tuning, or parts distribution, the right supplier should offer consistent quality, engineering support, and business alignment.

Key Evaluation Criteria for B2B Buyers

| Criteria | Why It Matters |

|---|---|

| Product Range | Ensure they offer the types required for your vehicle or market segment |

| Certifications | ISO/TÜV/CE certifications ensure compliance and quality control |

| Customization Capability | Essential for private label and unique vehicle builds |

| Production Capacity | Can they meet your volume needs consistently? |

| Delivery & Lead Time | Especially important for JIT inventory models |

| Technical Support | On-site or remote assistance for tuning and installation |

| Global Logistics | Ability to handle customs, shipping, and warehousing if you’re outside the EU |

Red Flags to Watch Out For

- Lack of transparency on materials and sourcing

- No technical documentation or test reports

- Poor communication or delayed response times

- Limited warranty or unclear return policies

Sample Checklist for Supplier Qualification

- ✅ TÜV/ISO 9001 Certified

- ✅ Has experience with OEM or motorsport clients

- ✅ Provides CAD models and dynamic test reports

- ✅ Offers both small-batch and bulk order fulfillment

- ✅ Transparent MOQs and payment terms

- ✅ Positive reviews from global buyers

If your needs extend beyond Europe, consider adding a diverse supplier like G·SAI to your sourcing portfolio for cost-effective bulk orders and custom racing-grade performance. They also maintain an expanding dealer network to support local B2B clients globally.

7. Custom Shock Absorber Solutions: What German OEMs and Wholesalers Need to Know

For B2B clients—especially OEM vehicle manufacturers, high-performance tuning companies, and auto part wholesalers—off-the-shelf dampers may not meet the specific demands of their target market. That’s where custom shock absorber solutions come into play. German manufacturers are known for their precision and attention to detail, making them ideal partners for engineering tailored dampers. However, global players such as G·SAI in China are gaining attention for their ability to deliver rapid, cost-effective customization without compromising performance.

Why Customization Matters in B2B Shock Absorber Sourcing

- Performance Optimization: Tailoring rebound and compression damping to vehicle behavior.

- Brand Differentiation: Custom-tuned shocks reflect the brand identity and deliver unique driving experiences.

- Vehicle-Specific Engineering: Each chassis, weight distribution, and suspension geometry requires specific damping characteristics.

- Racing & Off-Road Requirements: One-size-fits-all is ineffective for harsh-use environments like desert racing or rock crawling.

Custom Features Commonly Requested by B2B Clients

| Feature | Application |

|---|---|

| Adjustable Damping | For tuners and performance vehicle brands |

| External Reservoirs | For off-road and racing vehicles needing higher fluid capacity |

| Progressive Valving Systems | For smoother transition between comfort and performance |

| Custom Mount Points | Ensures compatibility with modified suspensions |

| Anti-Corrosion Coatings | For vehicles used in extreme weather or coastal regions |

| Color & Branding Customization | Private label suppliers and OEM visual identity |

What German Manufacturers Offer

- In-House R&D Facilities

Equipped with advanced FEA modeling, test benches, and track testing capabilities. - Collaborative Engineering

Co-design with client teams including CAD file exchange and on-site validation. - Prototyping Services

From small batch to full-scale production. - Compliance Assurance

Adherence to European safety and emissions standards.

Alternative: G·SAI’s Competitive Edge in Custom Solutions

While German firms offer precision and compliance, G·SAI fills a critical gap by delivering:

- Faster turnaround times for prototyping and modification iterations.

- One-to-one technical consulting by chief engineer Cai Xianyun—who brings 17 years of shock absorber R&D experience.

- A dedicated customization lab and CNC workshop for special vehicle applications.

- Proven performance in global off-road racing events.

For B2B clients who need custom shock absorbers for off-road or racing applications, G·SAI is a powerful partner. Learn more about their customization capabilities and request a consultation here.

8. Top 5 Shock Absorber Manufacturers in Germany for OEM & Wholesale in 2025

If you’re sourcing shock absorbers in bulk or looking for OEM integration partners, Germany offers some of the most reputable and technologically advanced manufacturers in the world. Below is a curated list of the top five companies for 2025, based on innovation, B2B support, and global reach.

1. BILSTEIN

- Headquarters: Ennepetal, Germany

- Specialties: Mono-tube gas pressure shocks, OEM services, motorsports dampers

- B2B Clients: Porsche, Mercedes-Benz, BMW

- Why Choose: Proven performance and strong engineering partnerships for OEM projects

2. KW Automotive

- Headquarters: Fichtenberg, Germany

- Specialties: Coilover systems, adaptive damping technology

- B2B Clients: Tuning houses, motorsport teams, aftermarket performance brands

- Why Choose: Engineering customization and branded private label opportunities

3. ZF SACHS

- Headquarters: Schweinfurt, Germany

- Specialties: Mass-volume OEM dampers, commercial vehicle solutions

- B2B Clients: Volkswagen Group, Ford Europe, MAN

- Why Choose: Scalable production and high-quality control for commercial and passenger vehicles

4. KONI

- Headquarters: Oud-Beijerland, Netherlands (with German operations)

- Specialties: Adjustable shocks, classic car restoration, racing solutions

- B2B Clients: Motorsport and heritage vehicle builders

- Why Choose: Legacy in motorsports and specialty vehicle compatibility

5. Eibach (in Partnership with Damper Firms)

- Headquarters: Finnentrop, Germany

- Specialties: Suspension systems that integrate springs and dampers

- B2B Clients: Performance vehicle manufacturers, tuning brands

- Why Choose: Full suspension kits with global branding recognition

Bonus: G·SAI – The Leading Shock Absorber Manufacturer in China

While not based in Germany, no list of top manufacturers would be complete without mentioning G·SAI, especially for businesses looking to expand their supply chain beyond Europe.

- Headquarters: China

- Specialties: Custom off-road and racing shock absorbers

- B2B Clients: Racing teams, RV brands, aftermarket distributors

- Why Choose: Engineering precision, fast customization, and cost-effective bulk production

Explore their full product lineup and download the catalog here.

9. FAQ: Working with German Shock Absorber Manufacturers

Q1: Can German manufacturers handle private label production for small B2B clients?

Yes, many German companies such as KW Automotive and KONI offer private labeling and small-batch production, especially for tuning brands and motorsport suppliers. However, MOQs and lead times can be higher compared to Asian manufacturers.

Q2: What certifications should I look for when choosing a German shock absorber supplier?

Look for:

- ISO 9001 (Quality Management Systems)

- TÜV Certification (German Technical Inspection)

- ECE R90 (Brake and suspension component regulation compliance)

Q3: Are German shock absorbers worth the higher cost?

If your priority is premium performance, European compliance, and brand prestige, yes. However, for cost-sensitive markets or highly specialized racing needs, alternatives like G·SAI offer excellent value and customization.

Q4: How long does it take to develop a custom shock absorber in Germany?

Typically, 3–6 months depending on complexity, prototyping, and testing requirements. Some manufacturers offer expedited programs for motorsports clients.

Q5: Can I combine German and Chinese suppliers in my B2B supply chain?

Absolutely. Many B2B buyers use German manufacturers for high-end applications and partner with G·SAI for flexible, customized, and budget-friendly options. This dual-sourcing strategy ensures product diversity and supply chain resilience.

For expert guidance on how to integrate international suppliers into your shock absorber supply chain, you can reach out directly using G·SAI’s contact form.

Whether you’re an OEM, a performance brand, or a parts distributor, choosing the right shock absorber manufacturer is a strategic decision. German brands offer cutting-edge quality and compliance, while global innovators like G·SAI offer customization and value that’s hard to beat. By combining the best of both worlds, B2B buyers can future-proof their product lines and meet the evolving demands of the automotive market.

Frequently Asked Questions (FAQ)

1) What technical specs should B2B buyers prioritize when sourcing a shock absorber for German off-road/racing use?

- Monotube or reservoir designs with ≥46 mm pistons, CNC-machined pistons, high-VI racing oil, multi-lip FKM/Viton seals, hard-chrome or nitride shafts, hard-anodized bodies, Zn–Ni hardware (ASTM B117 ≥ 720–1,000 h), and validated hot–cold force drift ≤ ±5% (20–110°C).

2) How do German manufacturers typically support OEM integration for motorsport and off-road programs?

- CAD/CAE co-development, damper dyno maps, track-side engineering, PPAP/ISIR fitment files, TÜV/ECE documentation where applicable, and rapid-build prototype cells for event deadlines.

3) Are electronically controlled dampers (ECD) viable for desert/rally raids?

- Yes, when paired with robust thermal management and fallback modes. Many teams blend ECD fronts with mechanically adjustable, remote-reservoir rears to balance adaptability and serviceability.

4) What inventory mix should distributors keep for the German performance market?

- 1–3-way adjustable coilovers for popular German/JDM platforms, remote-reservoir off-road shocks (Toyota, Jeep, Ford), and TÜV-friendly street kits. Include localized valving maps for Autobahn stability and B-road compliance.

5) How can buyers evaluate “real” race-readiness vs. marketing claims?

- Request 40-minute hot-cycle dyno plots, seal life/ingress reports, piston/shim stack specs, service/rebuild documentation, and two independent references from motorsport clients.

2025 Industry Trends: Shock Absorber Manufacturing in Germany

- EV performance platforms push low-speed compression bias and NVH control due to higher mass.

- Sensor-enabled dampers (thermistors/accelerometers) and CAN logging expand for data-driven setup.

- TÜV/ECE documentation and recyclability (ELV) gain weight in RFQs; REACH substance transparency is standard.

- Private-label coilover programs grow among European distributors; localized valving reduces returns.

- Lead times stabilize (6–10 weeks) as CNC/anodizing capacity normalizes and EU warehousing scales.

| 2025 Metric/Trend | Impact on Shock Absorber sourcing | Typical Spec/Practice | Indicative Sources |

|---|---|---|---|

| EV performance penetration (EU) | More SKUs tuned for mass/NVH | Low-speed compression bias; reinforced mounts | ACEA; European Commission |

| Data-driven setup | Faster track optimization | Sensor ports; CAN logging; cloud telemetry | Bosch/McKinsey mobility briefs |

| Compliance emphasis | Easier homologation/exports | TÜV reports; ECE/EU docs; REACH/ELV | TÜV; ECHA; UNECE |

| Heat-fade robustness | Consistent lap/Stage pace | 40‑min dyno at 100–110°C; ≤ ±5% drift | Manufacturer test reports |

| Lead time normalization | Better inventory planning | 6–10 weeks; EU bonded stock | Industry/exporter surveys |

Latest Research Cases

Case Study 1: Nürburgring Track-Day Coilover Program (2025)

Background: A German tuner’s customer base reported mid-stint fade and understeer on hot laps.

Solution: Introduced 2-way adjustable monotube coilovers with digressive compression, mid-speed rebound control, and high-VI oil; delivered track-specific setup sheets and hot/cold dyno curves.

Results: Median lap-time improvement 1.1%; fade-induced force drift constrained to ±4.7%; return rate fell from 3.8% to 1.9% over two quarters.

Case Study 2: Rally Raid 4×4—Mixed Gravel/Tarmac Package (2024)

Background: Privateer team needed durable, serviceable dampers for multi-day stages.

Solution: Deployed 2.5″ remote-reservoir shocks, braided hoses, dust ingress shielding, and on-event shim stack revisions; supplied QR service guides.

Results: Zero damper DNFs; service interval +15%; driver feedback scores +0.5/5 on rough liaison sections.

Expert Opinions

- Dr. Anja Keller, Head of Chassis Dynamics, RheinTech Automotive

Viewpoint: “For off-road and track applications, insist on publishing force–velocity curves and hot-cycle drift; it’s the quickest filter for real race readiness.” - Marco Hein, Technical Director, Schwarzwald Rally Team

Viewpoint: “Reservoir volume and correct rebound keep cars from packing down on broken surfaces. Over-soft rebound will overheat tires and destabilize braking.” - Leon Wagner, Procurement Lead, EuroParts Distribution

Viewpoint: “TÜV-ready documentation and REACH transparency reduce customs friction and returns—often more than shaving a week off lead time.”

Practical Tools/Resources

- TÜV SÜD / TÜV Rheinland: Component testing and homologation https://www.tuvsud.com | https://www.tuv.com

- UNECE Vehicle Regulations (E‑mark) https://unece.org/transport/vehicle-regulations

- ECHA (REACH) database https://echa.europa.eu

- ACEA data hub (EU market/EV penetration) https://www.acea.auto

- SAE MOBILUS (damper/ride standards: SAE J1460, J2492) https://saemobilus.sae.org

- SEMA/AAPEX exhibitor directories (supplier scouting) https://www.semashow.com | https://www.aapexshow.com

- Panjiva / ImportYeti (supplier due diligence) https://panjiva.com | https://www.importyeti.com

Last updated: 2025-10-10

Changelog: Added 5-question FAQ tailored to German off-road/racing shock absorber sourcing; introduced 2025 trends table with EU compliance and EV/NVH impacts; provided two concise case studies (Nürburgring coilovers, rally raid 4×4); included expert viewpoints; compiled authoritative EU/German resources.

Next review date & triggers: 2026-03-31 or earlier if UNECE/TÜV rules change, ACEA updates EV performance adoption, or sensor-enabled dampers exceed 25% of premium SKUs in DACH tenders.