Top Shock Absorbers for Commercial Vehicles: A Complete B2B Guide

June 3, 2025

Share This Article

What Are Shock Absorbers for Commercial Vehicles?

Shock absorbers for commercial vehicles are vital suspension components engineered to absorb and dissipate kinetic energy during vehicle operation. Unlike standard car shocks, commercial vehicle shock absorbers are built to handle significantly higher loads, longer operational hours, and more extreme environmental conditions.

These components are critical in maintaining ride quality, reducing wear on vehicle components, and increasing driver safety and cargo protection. Whether in long-haul trucking, passenger transport, or utility fleets, shock absorbers directly impact performance and operational costs.

Key B2B Keywords:

- Commercial vehicle shock absorber supplier

- Heavy-duty shock absorbers wholesale

- Fleet suspension parts distributor

- OEM shock absorbers for trucks

- Shock absorber manufacturer for buses

Commercial Vehicle Types That Require Heavy-Duty Shock Absorbers:

| Vehicle Type | Typical Shock Absorber Requirements |

|---|---|

| Long-Haul Trucks | Long-life, high-load capacity, heat-resistant |

| Buses & Coaches | Comfort-optimized, vibration-reducing, durable |

| Delivery Vans | Load-adaptive, lightweight, cost-effective |

| Construction Vehicles | Impact-resistant, corrosion-proof, high-travel suspension |

| Utility Trucks | All-terrain compatibility, robust damping, quick rebound |

Engineering Characteristics

- High oil volume capacity for long-distance heat dissipation

- Gas-charged damping for better response in load shifts

- Multi-valve technology for terrain adaptability

- Heavy-duty seals and bushings to minimize wear

Shock absorbers in these use cases are not just comfort enhancers—they are safety-critical components. Poorly functioning shocks increase braking distance, tire wear, and vehicle instability, especially when carrying heavy loads.

Key Applications of Commercial Vehicle Shock Absorbers

Shock absorbers are essential for various commercial logistics and transportation operations. Their application goes far beyond ride comfort—they protect valuable cargo, reduce maintenance needs, and ensure the longevity of the vehicles.

Core Industry Applications

1. Freight & Logistics Fleets

- Problem: Uneven road surfaces can damage goods in transit.

- Solution: Heavy-load shock absorbers reduce vibration and protect cargo integrity.

2. Public Transportation

- Problem: Passenger comfort and safety are paramount in city buses and shuttles.

- Solution: Gas-charged and multi-stage damping shock absorbers reduce jarring.

3. Construction & Mining

- Problem: Off-road terrain causes violent vehicle motion.

- Solution: Off-road tuned shock absorbers ensure chassis protection and safety.

4. Emergency & Utility Services

- Problem: Rapid response vehicles require stability and control at high speeds.

- Solution: Performance shock absorbers offer better road holding and reduced sway.

Benefits to Fleet Owners & Operators:

| Benefit | Description |

|---|---|

| Reduced Maintenance Costs | Shock absorbers reduce stress on suspension components and tires |

| Enhanced Vehicle Longevity | Prevents premature wear on chassis and drivetrain parts |

| Improved Load Stability | Ensures consistent handling with varying cargo weights |

| Increased Driver Comfort & Safety | Reduces fatigue and injury risk for drivers of long-haul or daily routes |

| Better Fuel Efficiency | Stabilized vehicles consume less fuel during operation |

B2B Buyer Tip:

When sourcing for fleet shock absorbers, prioritize suppliers who offer custom damping curves and load-specific tuning, especially for mixed-use or specialty vehicles.

Types of Shock Absorbers Used in Heavy-Duty Fleets

Choosing the right type of shock absorber dramatically impacts vehicle performance and lifecycle costs. Different vehicle types and use cases require different shock designs.

1. Twin-Tube Hydraulic Shock Absorbers

- Design: Two concentric tubes with hydraulic fluid.

- Usage: Economical option for light trucks and vans with modest loads.

- Pros: Cost-effective, simple design.

- Cons: Limited performance under extreme heat or load.

2. Twin-Tube Gas-Charged Shock Absorbers

- Design: Same as hydraulic with added nitrogen gas chamber.

- Usage: Mid-range trucks and buses.

- Pros: Reduces aeration (foaming), provides better damping response.

- Cons: Slightly higher cost than hydraulic.

3. Monotube Shock Absorbers

- Design: Single cylinder with a floating piston to separate gas and fluid.

- Usage: High-performance, heavy-duty vehicles, off-road fleets.

- Pros: Superior heat dissipation, consistent performance under load.

- Cons: Higher manufacturing cost.

| Type of Shock Absorber | Best Use Case | Durability | Cost | Heat Resistance |

|---|---|---|---|---|

| Twin-Tube Hydraulic | Light delivery vans | Medium | Low | Low |

| Gas-Charged Twin-Tube | City buses, medium-duty trucks | High | Medium | Medium |

| Monotube | Mining trucks, off-road fleets | Very High | High | High |

4. Adjustable Performance Shocks (Custom-Tuned)

- Design: Rebound and compression damping can be adjusted.

- Usage: Versatile fleets, racing applications, or performance tuning.

- Pros: Adaptable to various load conditions and terrains.

- Cons: Requires technical knowledge or training to adjust properly.

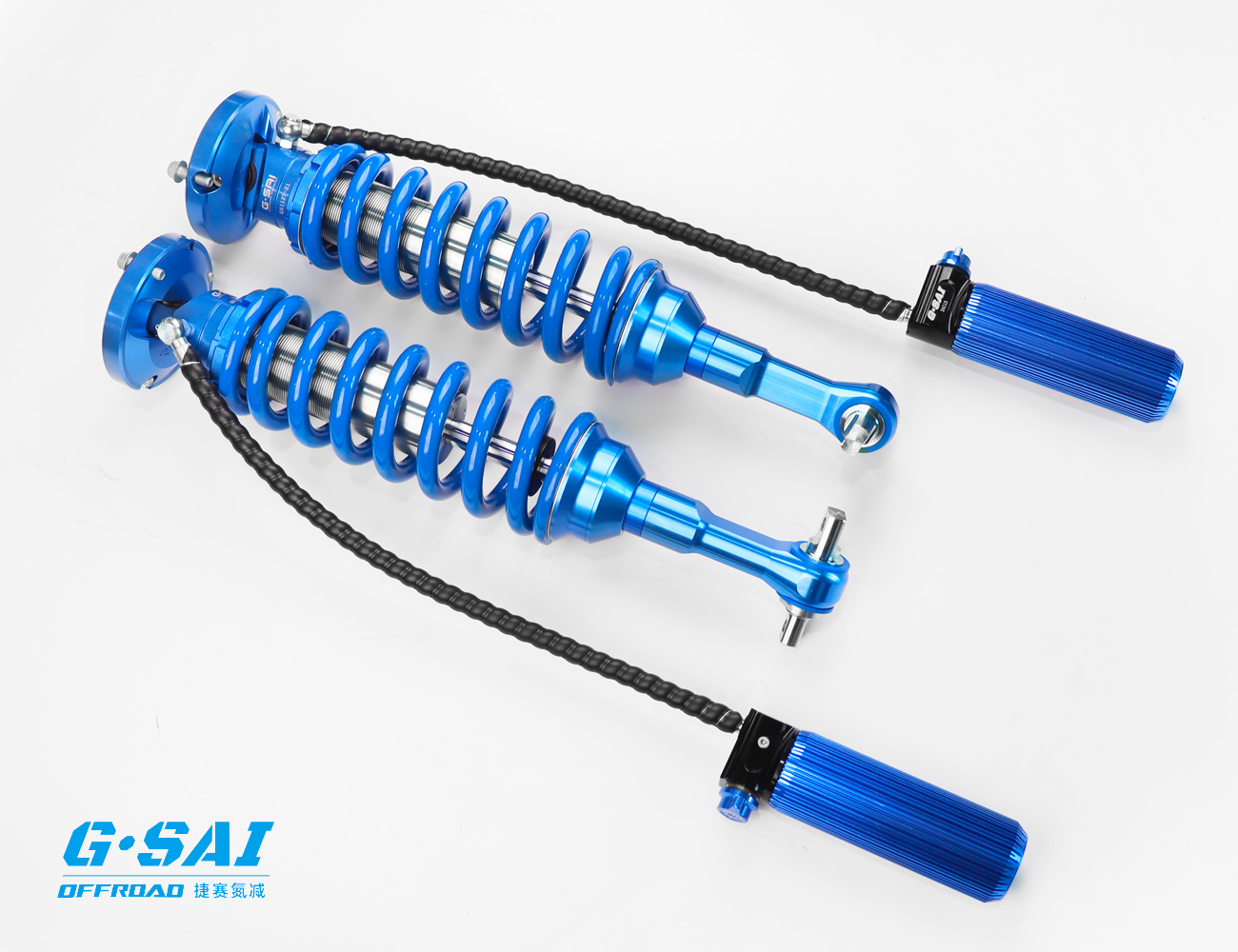

G·SAI’s Commercial Vehicle Shock Absorbers

At G·SAI, we specialize in high-end custom shock absorbers tailored to commercial vehicles. Our engineering team, led by 17-year veteran Cai Xianyun, develops shock absorbers for:

- Long-haul logistics fleets

- Armored vehicles

- Off-road and racing trucks

- Utility and public transportation vehicles

Our advanced CNC machining and testing laboratories ensure each shock absorber meets the most demanding commercial requirements.

👉 Explore our full range of commercial vehicle shock absorbers on our product page.

Solutions with Shock Absorbers for Commercial Transportation

Shock absorbers for commercial transportation are not one-size-fits-all. Businesses with fleets—whether they operate delivery trucks, intercity buses, or off-road service vehicles—require tailored solutions to meet the specific operational demands of their vehicles. Implementing high-performance shock absorbers across a fleet can significantly reduce total cost of ownership (TCO), improve uptime, and ensure compliance with safety regulations.

Common Challenges in Commercial Transport

| Operational Challenge | Impact on Fleet | Role of Shock Absorbers |

|---|---|---|

| Heavy loads and frequent braking | Wear on suspension and braking systems | Damping reduces suspension fatigue |

| Long operational hours | Overheating and premature failure | Gas-charged shocks dissipate heat efficiently |

| Mixed road conditions (urban/off-road) | Increased vibrations and instability | Terrain-tuned shocks improve control and comfort |

| Tight delivery schedules | Driver fatigue and vehicle damage | Comfort-enhanced shocks reduce fatigue |

Tailored Damping Solutions for Different Fleets

- Urban Logistics Fleets

- Frequent stops, uneven urban roads, and variable loads.

- Solution: Twin-tube gas-charged shock absorbers for balance of cost and performance.

- Intercity Passenger Transport

- Priority on ride comfort and noise reduction.

- Solution: Monotube or adjustable shocks with soft damping curves.

- Construction & Utility Trucks

- Operate in harsh terrains with heavy payloads.

- Solution: High-travel, heavy-duty monotube shocks with corrosion-resistant coatings.

- Emergency Services Vehicles

- Need high-speed stability and predictable handling.

- Solution: Custom-valved performance shocks with rebound control.

Why G·SAI is the Ideal Partner for Fleet Solutions

G·SAI delivers bespoke shock absorber solutions for commercial fleets, offering:

- Dynamic load simulation testing to replicate real-world operating conditions.

- Custom damping curve engineering for different vehicle classes.

- Rapid prototyping and mass production capabilities from our in-house CNC and assembly facilities.

- On-site fitment consultation and training for large fleet integrations.

With a customer-first philosophy and a strong technical backbone, G·SAI designs shock absorbers that improve fleet performance while reducing maintenance and downtime. Learn more about our engineering capabilities on our About Us page.

Shock Absorbers vs. Air Suspension Systems

When it comes to commercial vehicle suspension, two main systems are often compared: shock absorbers and air suspension systems. While both serve to improve ride quality and vehicle control, they function differently and are suited to different fleet needs.

Key Differences

| Feature | Shock Absorbers | Air Suspension Systems |

|---|---|---|

| Function | Damping movement of suspension components | Supporting load and adjusting ride height |

| Complexity | Simple mechanical/hydraulic design | Complex with compressors, airbags, sensors |

| Maintenance | Low | High (air leaks, compressor failure) |

| Cost | Lower initial and ongoing cost | Higher initial cost and repair expenses |

| Customization | Rebound/compression tuning possible | Ride height and stiffness control |

| Use Case | General commercial fleets, harsh terrain | Luxury buses, sensitive cargo transport |

Complementary Use

Shock absorbers and air suspension are often used together in premium commercial vehicles. In such systems:

- Shock absorbers control the rebound and compression of the suspension.

- Airbags handle load leveling and ride height adjustments.

This dual system is common in high-end coaches and long-haul trucks carrying sensitive goods.

Which is Better for Your Fleet?

| Fleet Type | Recommended System |

|---|---|

| General-purpose delivery vans | Twin-tube or gas-charged shock absorbers |

| Luxury passenger coaches | Air suspension + shock absorbers |

| Off-road or mining vehicles | Monotube high-travel shock absorbers |

| Budget-conscious logistics | Standard hydraulic shocks |

For most fleet operations, high-performance shock absorbers provide the best cost-to-benefit ratio, especially when supplied by a manufacturer capable of custom tuning for your application.

How to Assemble Shock Absorbers for Trucks and Buses?

Proper assembly and installation of shock absorbers are critical for performance and longevity. Fleet maintenance teams and commercial vehicle mechanics need to follow strict protocols to ensure optimal shock absorber function.

Pre-Assembly Checklist

- Confirm Specifications

- Match shock absorber part number to vehicle make/model.

- Check for load rating compatibility.

- Inspect Mounting Points

- Look for worn bushings or damaged brackets.

- Clean thoroughly before installation.

- Review Orientation

- Some shocks are directional (top vs. bottom mount).

- Gas-charged shocks often have a specific mounting direction.

Assembly Tools Required

- Torque wrench

- Jack stands or hydraulic lift

- Socket set and spanners

- Anti-seize lubricant

- Thread-locking compound (if specified)

Installation Steps (General)

| Step | Description |

|---|---|

| 1 | Lift the vehicle and secure with jack stands. |

| 2 | Remove old shock absorber by unbolting top and bottom mounts. |

| 3 | Prepare new shock with bushings and washers as per manufacturer guide. |

| 4 | Install bottom mount, followed by the top. |

| 5 | Torque bolts to the specified values. |

| 6 | Lower vehicle and check for clearance or noise during test drive. |

Assembly Best Practices

- Always replace shocks in pairs (left and right) for consistent performance.

- Avoid over-tightening, which can damage bushings and compromise damping.

- Use OEM-quality or better fasteners for mounting hardware.

- After installation, perform a road test to verify performance.

G·SAI offers technical support and assembly training for large fleet customers and authorized distributors. Our vehicle modification and training rooms provide hands-on guidance for proper integration of our shock absorbers into your commercial fleet. Contact us through our Contact Page for more technical documentation or to schedule support.

How to Choose the Right Shock Absorbers for Your Fleet?

Selecting the correct shock absorbers for your commercial fleet is not just a matter of matching part numbers—it’s a strategic decision that affects vehicle uptime, maintenance costs, driver safety, and cargo security. For B2B buyers, especially fleet managers, wholesalers, and auto parts dealers, making informed decisions based on performance metrics and application requirements is critical.

Key Factors to Consider When Choosing Fleet Shock Absorbers

| Factor | Why It Matters |

|---|---|

| Vehicle Type | Different shock designs are required for trucks, buses, vans, etc. |

| Load Capacity | Heavier loads require shocks with higher damping force |

| Road Conditions | Off-road and poor infrastructure demand more robust construction |

| Operation Frequency | High-usage fleets need longer-lasting, heat-resistant shocks |

| Climate & Environment | Corrosion resistance and temperature performance are essential |

| Maintenance Capabilities | Ease of installation and availability of replacement parts |

Checklist for Fleet Procurement Teams

- ✅ Is the shock absorber custom-tuned for your vehicle type and load?

- ✅ Does the manufacturer offer OEM-level quality or better?

- ✅ Are the shocks tested for heat dissipation and oil retention?

- ✅ Can you source them in bulk quantities reliably?

- ✅ Is there post-sale technical support for installation and tuning?

Performance Metrics to Evaluate

| Metric | Ideal Value for Commercial Vehicles |

|---|---|

| Damping Force Range | Medium to High (depending on load) |

| Heat Dissipation | High (especially for long-haul or mountainous areas) |

| Response Time | Fast rebound with progressive compression |

| Durability Cycle | 100,000+ km or more |

| Resistance to Cavitation | 90%+ (for gas-charged or monotube designs) |

Why G·SAI is a Top Choice for Fleet Managers

G·SAI offers fully customizable damping solutions for commercial fleets, including:

- Load-specific tuning: Whether your trucks carry 2 or 20 tons, we adjust accordingly.

- Terrain-specific designs: For urban, highway, construction, or off-road use.

- Rapid prototyping: Perfect for testing new vehicle models or modified chassis.

- Dedicated technical team: Led by Cai Xianyun with 17 years of shock absorber R&D experience.

With our in-house assembly and CNC machining workshops, G·SAI ensures rapid lead times and consistent quality, even for large fleet orders. For businesses looking to streamline procurement and reduce downtime, G·SAI is a proven partner. Explore our dealer network to locate a distributor near you.

Custom Shock Absorber Solutions: What Fleet Managers Need to Know

While off-the-shelf shock absorbers may work for standard commercial applications, many fleets operate under unique conditions that demand custom-engineered solutions. These include vehicles with non-standard loads, mixed-use conditions, or performance requirements beyond typical OEM specs.

When Do You Need a Custom Solution?

- Operating in extreme climates (very cold or hot environments)

- Vehicles with modified suspension geometry

- Mixed cargo types requiring variable damping

- Off-road or rugged terrain usage

- Specialty vehicles such as armored trucks or mobile service units

Customization Options Available with G·SAI:

| Custom Feature | Benefit to Fleet Operations |

|---|---|

| Adjustable Damping (Compression/Rebound) | Tunable performance for different load conditions |

| Custom Mounting Hardware | Seamless integration with modified chassis |

| High-Temperature Seals | Extended performance in hot climates or long runs |

| Anti-Corrosion Coatings | Enhanced durability in coastal or road-salt environments |

| Heavy-Duty Pistons and Valves | Withstand high-impact and continuous operation |

G·SAI’s Custom Engineering Process

- Fleet Needs Assessment

Our team works with your technical staff to understand challenges and goals. - Prototype Development

In-house simulation labs create testable versions in as little as 7 days. - Vehicle Testing

Real-world road tests ensure damping curves match operational requirements. - Final Production & Support

CNC machining and assembly lines handle mass production. After-sales support included.

“G·SAI gave us the custom tuning we needed to reduce tire wear across our utility fleet by 20%. We’ve seen a massive decrease in maintenance costs.”

— Fleet Manager, EU-based Logistics Company

Customized shock absorbers are not a luxury—they’re a necessity for businesses aiming for maximum ROI from their vehicle assets. Get in touch with our engineering team today via our contact page for a personalized consultation.

Top 5 Shock Absorber Manufacturers for OEM & Wholesale in 2025 (FAQ Included)

Choosing the right manufacturer for OEM or wholesale procurement is crucial. Below is a curated list of the top global players in shock absorber manufacturing, based on product quality, innovation, customization capabilities, and B2B reliability.

1. G·SAI (China) 🇨🇳

- Specialization: Custom shock absorbers for commercial, off-road, and racing vehicles

- Strengths:

- 100% in-house R&D and production

- Custom damping curve engineering

- Fast prototyping and low MOQ for B2B buyers

- Ideal For: OEMs, specialty fleets, and racing teams

- Learn more: G·SAI Product Line

2. Monroe (USA) 🇺🇸

- Specialization: OEM and aftermarket shock absorbers for passenger and commercial vehicles

- Strengths:

- Global distribution

- Wide product range

- Ideal For: Wholesalers and large-scale OEMs

3. KONI (Netherlands) 🇳🇱

- Specialization: Adjustable and performance shocks for buses, trucks, and RVs

- Strengths:

- Superior ride quality

- Engineering support for fleets

- Ideal For: Bus operators, luxury coaches

4. Bilstein (Germany) 🇩🇪

- Specialization: Performance and heavy-duty shocks

- Strengths:

- Superb durability

- Trusted in motorsports and OEM

- Ideal For: Premium fleets and specialized vehicles

5. KYB (Japan) 🇯🇵

- Specialization: Hydraulic and gas shock absorbers for OEM and aftermarket

- Strengths:

- Global reach

- Cost-effective

- Ideal For: Auto parts dealers and distributors

FAQ – Frequently Asked Questions

Q1: How often should commercial vehicle shock absorbers be replaced?

A: Every 80,000–120,000 km depending on vehicle load, road conditions, and shock type. Fleet operators should also check for signs like oil leakage, excessive bounce, or uneven tire wear.

Q2: Can I buy custom shock absorbers in bulk?

A: Absolutely. G·SAI specializes in bulk orders for custom shock absorbers, with flexible MOQs and fast lead times. We support OEM branding and private-label manufacturing.

Q3: Are Chinese-made shocks reliable for commercial use?

A: Yes—especially when sourced from a reputable manufacturer like G·SAI, which offers R&D-backed products designed for high-demand applications and has a proven track record in international racing and commercial fleets.

Q4: How can I ensure I’m buying the right shock absorber?

A: Use a vehicle-specific fitment guide, and work with a supplier that offers engineering support. G·SAI provides one-on-one consultation and testing to ensure the perfect match.

Q5: Does G·SAI offer private labeling or OEM services?

A: Yes. G·SAI supports private label branding, OEM production, and product customization for global distributors and fleet customers. Perfect for those starting their own auto brand or expanding product lines.

For B2B buyers, sourcing shock absorbers is not just about finding the lowest price—it’s about reliability, customization, and long-term partnership. Whether you’re a fleet manager, auto parts distributor, or brand manufacturer, G·SAI offers the engineering expertise and production capacity to meet your needs.

👉 Ready to upgrade your fleet’s suspension system? Visit our homepage to learn more or contact us for a custom quote.