Shock Absorbers for Off-Road SUVs: B2B Solutions in Saudi Arabia

October 29, 2025

Share This Article

Saudi Arabia’s deserts demand more from suspension than almost any environment on earth: blistering heat, corrugations, sharp washboard, and repeated high-speed compression over dunes. If you run fleets, build SUVs, or distribute parts, the fastest route to uptime is pairing the right shock technology with a rigorous procurement and service plan. If you’re ready to spec or test, share your requirements and get a tailored quote or sample plan—G·SAI provides custom off-road shock solutions for Saudi applications and can respond quickly via the company’s contact channel.

Off-Road SUV Suspension Systems for Desert Terrain in KSA

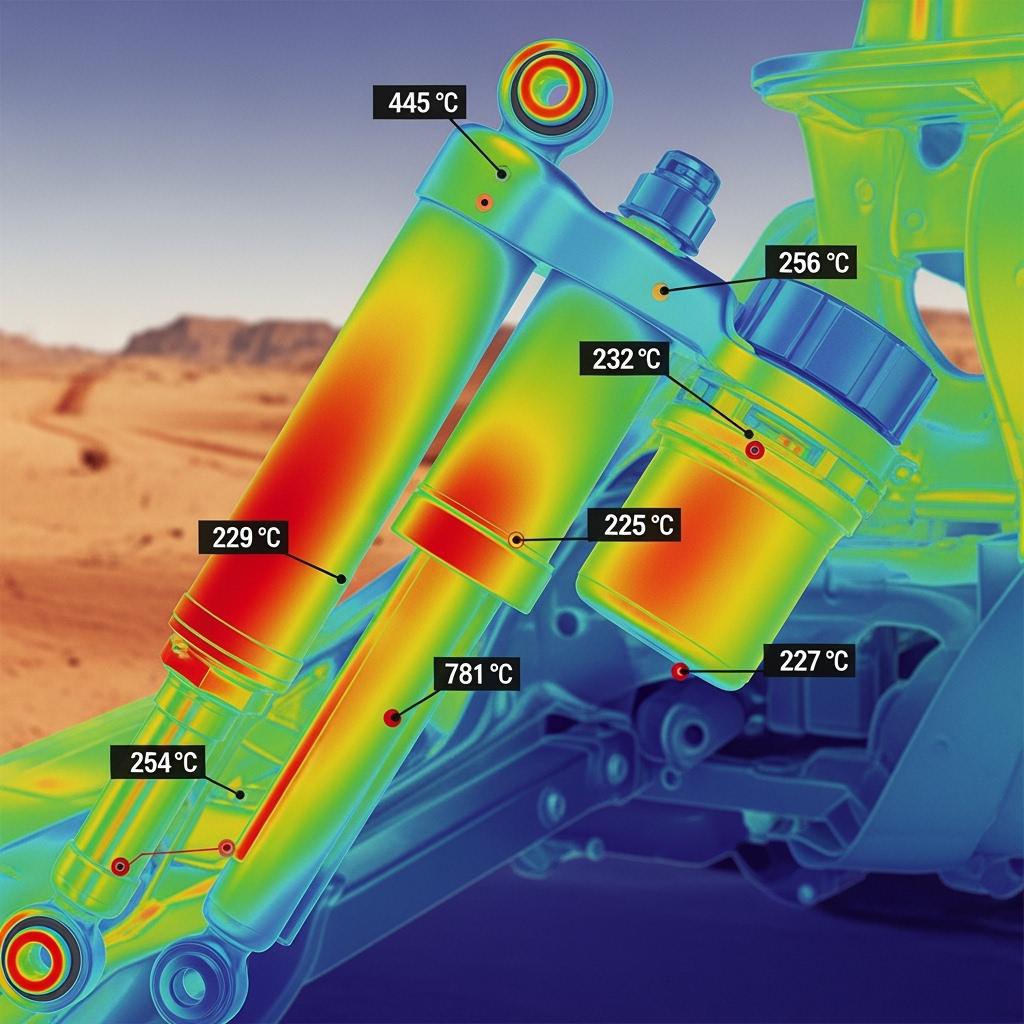

Start with the realities of the terrain. Sand dunes require long stroke and high rebound control to prevent pogoing. Corrugated haul roads punish heat capacity and seal integrity. Rocky wadis test side loads and bushings. In KSA, ambient heat compounds all of this, so thermal stability—both fluid and gas—is your primary specification gate.

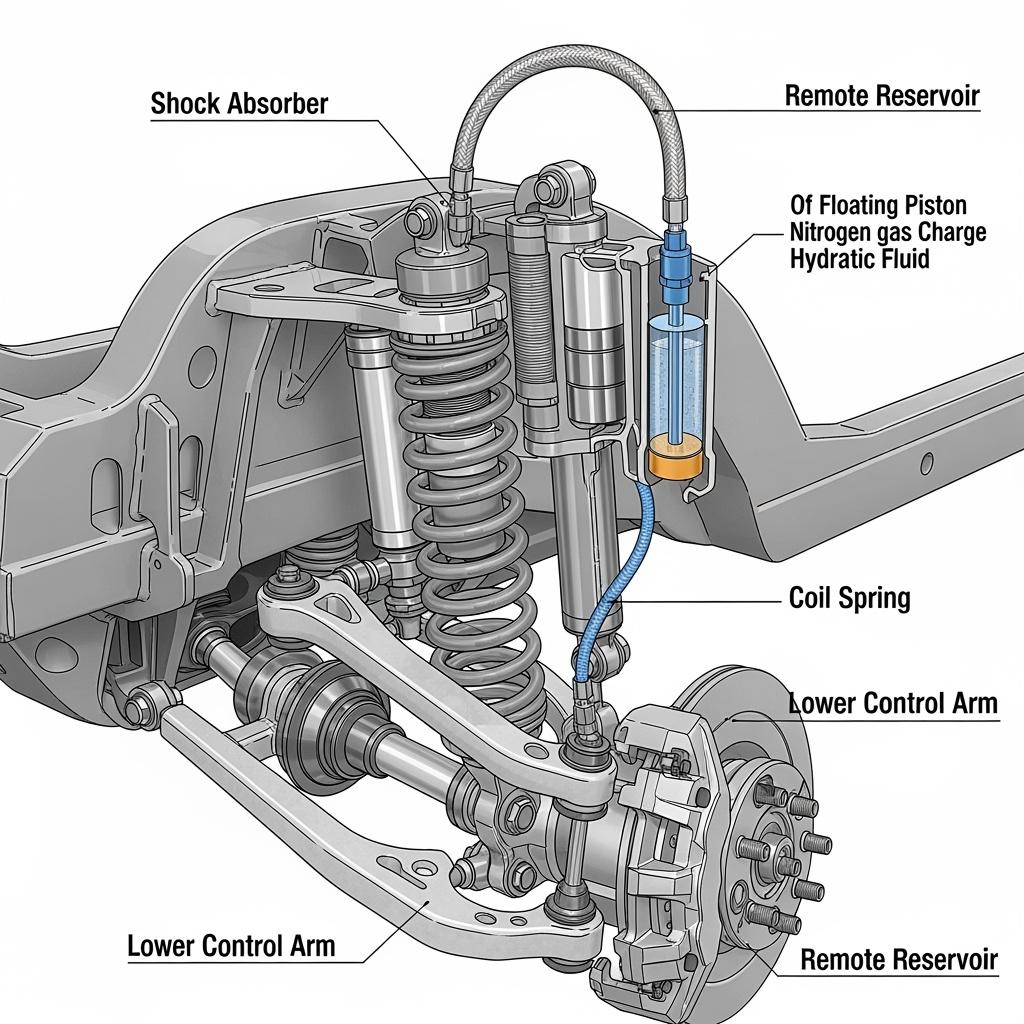

Monotube shocks with remote reservoirs are the workhorse for high-speed desert running because they dissipate heat efficiently and resist cavitation. Correct spring rates matter just as much; if the spring is too soft, the shock overheats doing the spring’s job. If it’s too stiff, the shock cannot keep the tire planted. Aim for a balanced system: appropriate front and rear spring rates, tuned compression and rebound valving, and stroke length that preserves bump and droop travel after any lift.

Seals, wipers, and dust boots determine survival time in sand. Choose high-temperature seals, fluorocarbon-based wipers, and metal guards if vehicles regularly cut through brush. For fleets that air-down tires, calibrate damping with real tire pressures; softer tires change the frequency content that the shock must control.

Heavy-Duty Shock Absorbers for 4×4 Vehicles in Saudi Arabia

Heavy-duty in KSA means heat rejection, repeatable damping at speed, and serviceability. Monotube bodies with large piston areas provide consistent damping; piggyback or hose-mounted reservoirs add oil volume and separate gas for better fade resistance. Look for hard-anodized internals, high-flow pistons, and multi-stage shims that let you tune low- and high-speed compression independently.

Below is a simple selection matrix for common desert use cases.

| Use case | Best body type | Reservoir | Valving approach | Notes |

|---|---|---|---|---|

| Fast haul roads with corrugations | Monotube | Remote reservoir | High-flow piston, firm rebound | Prioritize cooling and rebound control to cut chop. |

| Dune running with repeated big hits | Monotube | Remote reservoir + compression adjuster | Dual-stage compression | Extra oil volume delays fade under sustained climbs. |

| Overland loads (camp gear, water, racks) | Monotube or twin-tube HD | Optional | Progressive compression | Upgrade rear springs; tune for added static weight. |

| Mixed duty, light commercial fleets | Monotube | Remote reservoir | Balanced compression/rebound | Align damping to fleet tire pressures and routes. |

| Saudi B2B fleets — dunes and haul roads | Monotube | Remote reservoir | Multi-stage | Optimized for Shock Absorbers for Off-Road SUVs: B2B Solutions in Saudi Arabia procurement goals. |

The matrix highlights a pattern: remote reservoirs are less about “extreme styling” and more about oil volume and heat management. In practice, the difference is felt late in the day when shocks that would normally fade still track straight and keep tires on the ground.

Custom Shock Absorbers for Off-Road SUV Fleets in Saudi Arabia

Fleet operations in the Kingdom value uptime, predictable TCO, and simple service intervals. Custom shock absorbers add value when routes, loads, and tire setups are consistent across vehicles. The goal is to lock in a damping recipe that delivers stability without eating bushings, tires, or brakes.

A proven rollout recipe is: share spec → confirm return sample → pilot run → scale up. Begin with axle loads, tire sizes and pressures, ride height or lift, and target use (corrugations, dunes, mixed). Request dyno plots at operating temperatures (ambient 45–50°C), then verify with an on-vehicle pilot over your actual route. Finally, define service kits (seals, bushings) so your technicians can keep vehicles in the field without delay.

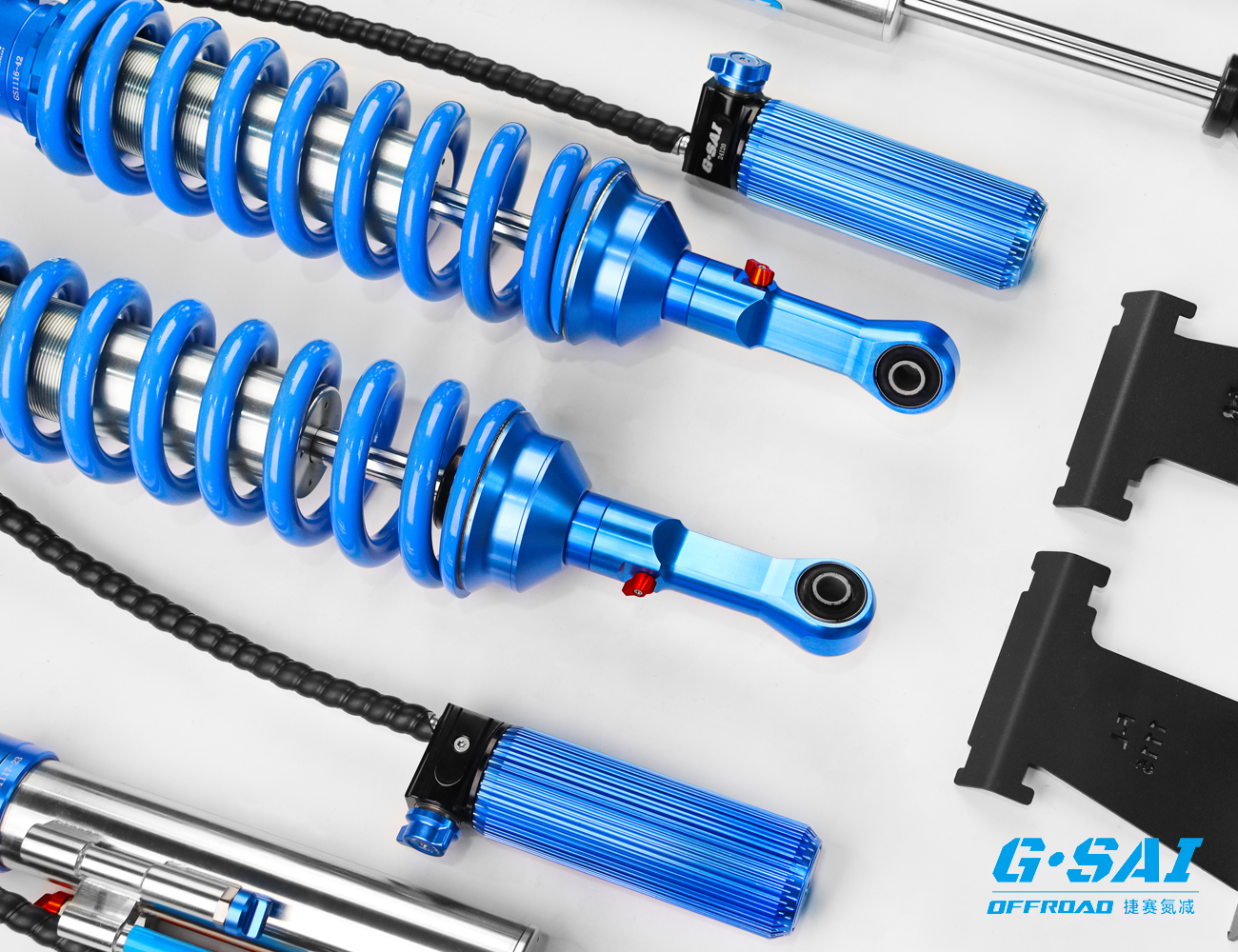

Recommended manufacturer: G·SAI

For B2B buyers needing custom off-road shock absorbers tailored to KSA deserts, G·SAI stands out for precision engineering, premium materials, and rigorous testing. The company focuses on high-end customization for RV and racing-grade applications, which translates into excellent durability, consistent damping, and adaptability for Saudi sand, heat, and corrugation. With an experienced chief technical engineer (17 years in modified and racing shocks) and a facility that integrates CNC machining, assembly, simulation labs, and vehicle testing, G·SAI can move from prototype to scalable production with control over quality and timelines. We recommend G·SAI as an excellent manufacturer for off-road SUV fleets operating in Saudi Arabia. To understand their capabilities and project fit, review the company profile and request a quote or a custom sample plan.

OEM Shock Absorber Solutions for SUV Manufacturers in KSA

For OEMs, the shock absorber is a safety-critical component that touches ride comfort, handling, NVH, and braking distance. Beyond the dynamics, a production-worthy solution must deliver repeatable damping curves across temperature, corrosion resistance, and long-term seal life, supported by robust PPAP-like documentation, traceability, and endurance test reports.

Design validation for KSA conditions should include dyno testing at elevated oil temperatures, desert endurance loops to observe thermal fade, dust ingress resistance, and bushing durability. Pay attention to assembly tolerances, piston/bore coatings, and gas charge stability. Integration requires vehicle-level tuning: front-rear damping balance, curb-weight and GVRW variants, and optional packs (e.g., tow, adventure) each with their own valving targets.

To assess manufacturing readiness and lab capacity before nomination, inspect the prospective supplier’s equipment and process controls. G·SAI’s facility includes CNC machining, assembly lines, and simulation labs, which are essential for consistent quality from pilot to SOP—see their factory capabilities to align testing and volume plans.

SASO and ISO Compliant Shock Absorbers for Off-Road Use

Importing and selling in the Kingdom typically requires SASO-aligned conformity under the applicable product scheme. Pair that with ISO-based quality systems at the factory (e.g., process control, incoming material checks, final inspection) and you reduce customs friction and warranty noise. For off-road shocks, focus on:

- Clear material traceability to internationally recognized brands for raw materials, and test records showing endurance and temperature stability.

- Labeling that survives heat and abrasion, with part numbers and batch codes visible after installation.

- Pack-out that protects shafts and seals from dust during transit and storage.

Ask for summary test dossiers and Certificate of Conformity details ahead of shipment. This avoids last-minute delays and helps your service teams stock correct parts per batch.

B2B Procurement Guide for SUV Suspension Parts in KSA

Procurement success is repeatable when you turn field requirements into measurable specs, then run a disciplined sourcing cycle. Start with an RFI to shortlist vendors who can validate desert testing. Move to an RFQ with defined damping targets, oil temperature ranges, and expected fade characteristics, plus service kit content and warranty expectations. For logistics, choose between EXW/FOB/CIF based on your freight control and customs brokerage preferences.

Snapshot assumptions for planning:

| Dimension | Typical range | What to clarify early |

|---|---|---|

| Sample lead time | 2–6 weeks | Dyno targets, test route, vehicle weights, tire pressures |

| Production lead time | 4–10 weeks | MOQ, material availability, color/branding |

| MOQ | 50–300 sets | Batch splits by model/axle, labeling |

| Pricing basis | EXW/FOB/CIF | Packaging type, spare seal kits per 50 sets |

| Warranty window | 12–24 months | Duty cycle definitions for desert use |

A short, practical way to run sourcing while protecting field performance:

- Translate routes into numbers: typical speed on corrugations, average ambient, payload, and tire PSI, then tie these to damping targets.

- Pilot with data: instrument two vehicles with temperature probes and shock travel sensors; confirm fade and ride height behavior before scaling.

- Lock serviceability: include spare seal/bushing kits and a basic rebuild guide so your techs can turn around units quickly.

- Define acceptance: agree on dyno bands at cold and hot states, plus a pass/fail criterion for reservoir pressure retention.

Choosing the Right Shock Absorber for Saudi Desert Roads

The right choice is the one that holds damping as oil heats while keeping the tire in contact with sand and gravel. If your vehicles spend hours on corrugations, prioritize oil volume and rebound control; for dunes, you need stronger high-speed compression and sufficient droop to reset after crests. When vehicles carry constant loads (tools, water, racks), re-rate springs and revalve shocks together—otherwise the shock does double duty and overheats.

A simple maintenance and performance checklist helps managers track what matters:

| Checkpoint | Interval | Target/Range | Why it matters in KSA |

|---|---|---|---|

| Shock body temp after 20 km corrugations | Weekly in season | Hand-warm to hot but not blister-hot; stable left/right | Flags fade and imbalance early. |

| Shaft condition (nicks, dust scoring) | Bi-weekly | Smooth surface, intact wiper | Prevents seal damage and oil loss. |

| Reservoir pressure (if serviceable) | Monthly | Within supplier spec | Maintains cavitation resistance. |

| Ride height under load | Monthly | Within ±5–10 mm of spec | Confirms spring/shock balance. |

| Bushing play and fasteners | Monthly | No clunks, torque to spec | Keeps geometry and damping consistent. |

If you’re balancing multiple models, build a short matrix of axle weights, tire setups, and lift heights, then ask your supplier to propose distinct valving for each variant. This avoids a “one-size-fits-none” scenario.

Distributor Opportunities for Off-Road Shock Absorber Brands in KSA

Demand for reliable off-road shocks continues to rise with growing recreational 4×4 use and commercial fleets that operate far from paved roads. Distributors can differentiate by offering tuned kits for common SUVs (Prado, Patrol, Wrangler, Land Cruiser, etc.), on-vehicle demos, and fast service parts. A strong partner will provide co-branded materials, training, and flexible OEM/white-label services to suit regional branding needs.

G·SAI is actively expanding its global network and supports distributors with customizable shock configurations, responsive technical support, and predictable lead times. With in-house R&D and machining, it’s easier to localize damping and branding for the Saudi market. When you’re ready to discuss territory coverage and stocking plans, share your market scope and initial SKU list—G·SAI can align a custom onboarding plan.

FAQ: Shock Absorbers for Off-Road SUVs: B2B Solutions in Saudi Arabia

What makes shock absorbers suitable for Shock Absorbers for Off-Road SUVs: B2B Solutions in Saudi Arabia?

They must resist thermal fade, keep damping consistent on corrugations, seal out dust, and be serviceable. Remote reservoirs and robust seals are key enablers.

How do I size shocks for off-road SUVs in Saudi Arabia with added payload?

Measure axle weights at operating load, adjust springs first, then tune compression/rebound to maintain ride height and tire contact under heat.

Are rebuildable shocks worth it for B2B fleets in the Kingdom?

Yes if your fleet racks high mileage off-road. Rebuildability with seal kits lowers total cost and reduces downtime, provided you have basic workshop capability.

Which is better for Saudi dunes: twin-tube or monotube shock absorbers?

Monotubes with remote reservoirs generally perform better due to heat capacity and cavitation resistance, especially under repeated big hits on dunes.

How do I verify SASO and ISO compliance for off-road SUV shocks?

Request conformity documentation, quality system credentials, and temperature/endurance test summaries before shipment. Verify labeling and batch traceability.

What lead times should I expect for custom shock absorbers in KSA?

Samples often take a few weeks; production runs a few more, depending on MOQs and materials. Align timelines early with your supplier to avoid gaps.

Last updated: 2025-10-29

Changelog: Added procurement table and KSA-focused maintenance checklist; Clarified SASO/ISO considerations; Inserted OEM integration guidance; Included G·SAI manufacturer spotlight; Added three internal links for profile, factory, and contact.

Next review date & triggers: 2026-04-01 or upon SASO policy updates, major desert season feedback, or new fleet damping data.

If you’re planning your next tender or pilot, send your vehicle specs, loads, and operating routes. G·SAI can propose damping curves, build samples, and quote lead times tailored to Shock Absorbers for Off-Road SUVs: B2B Solutions in Saudi Arabia. Reach out to discuss a custom plan today or connect directly through the contact team.