Shock Absorbers with External Reservoir: The Ultimate B2B Guide for 2025

June 3, 2025

Share This Article

What Are Shock Absorbers with External Reservoir?

Shock absorbers with external reservoirs, also known as remote reservoir shocks, are advanced suspension components that separate the shock oil from the nitrogen gas via an external canister. This design improves heat dissipation, prevents cavitation, and enhances performance under extreme driving conditions.

Key Features of External Reservoir Shock Absorbers:

| Feature | Description |

|---|---|

| External Reservoir | Houses additional oil and nitrogen gas for better cooling and performance |

| Improved Heat Dissipation | Prevents overheating during high-speed or off-road driving |

| Higher Oil Volume | Allows more consistent damping and longer shock life |

| Adjustable Valving Options | Offers tunable rebound and compression control |

| Designed for Harsh Conditions | Ideal for off-road racing, rock crawling, and utility vehicles |

Technical Composition:

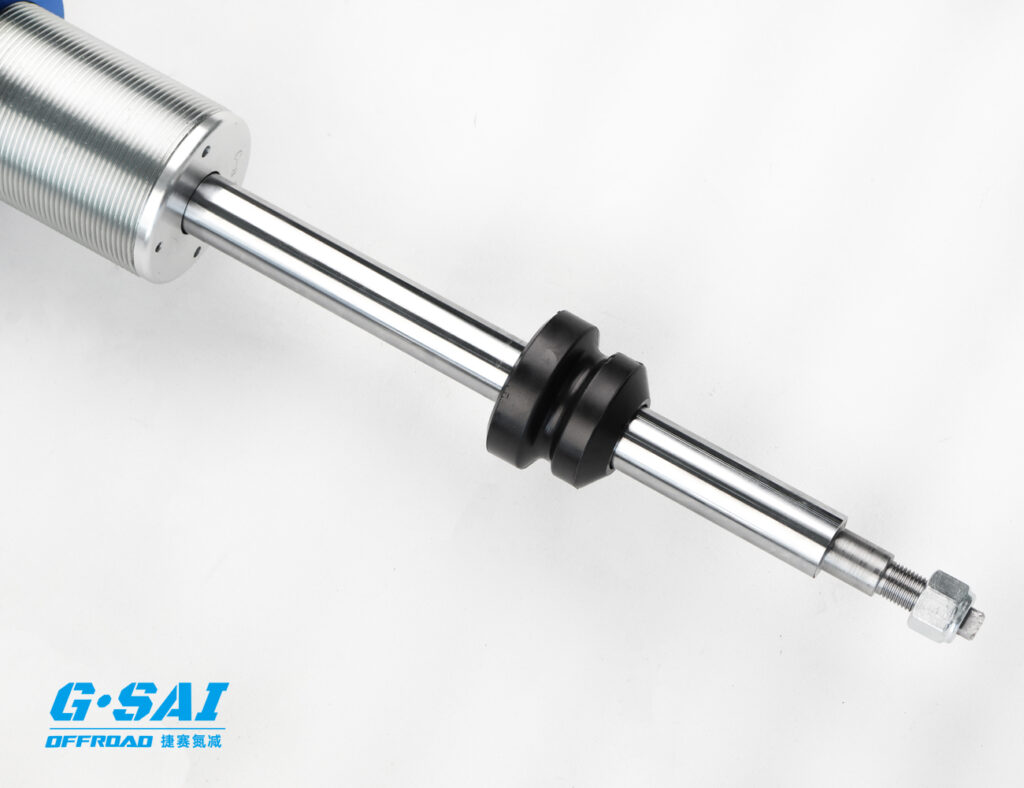

- Body Material: Typically made from aluminum or steel for durability and lightweight performance.

- Reservoir Hose: A braided steel or high-pressure rubber hose connects the reservoir to the shock body.

- Piston Design: Monotube or twin-tube setup with floating piston for gas/oil separation.

Why External Reservoir Shocks Matter in B2B Markets

For B2B buyers such as off-road racing teams, automotive wholesalers, or aftermarket suspension brands, external reservoir shocks offer a high-performance, durable solution that meets the demands of extreme environments. Their modularity and tunability make them valuable assets in product line diversification and performance upgrades.

B2B-Specific Benefits:

- High Margin Product for Dealers: Ideal for upselling in performance-driven markets

- Customization Potential: Can be tailored for different vehicle models and racing conditions

- OEM Compatibility: Compatible with various vehicle platforms for large-scale procurement

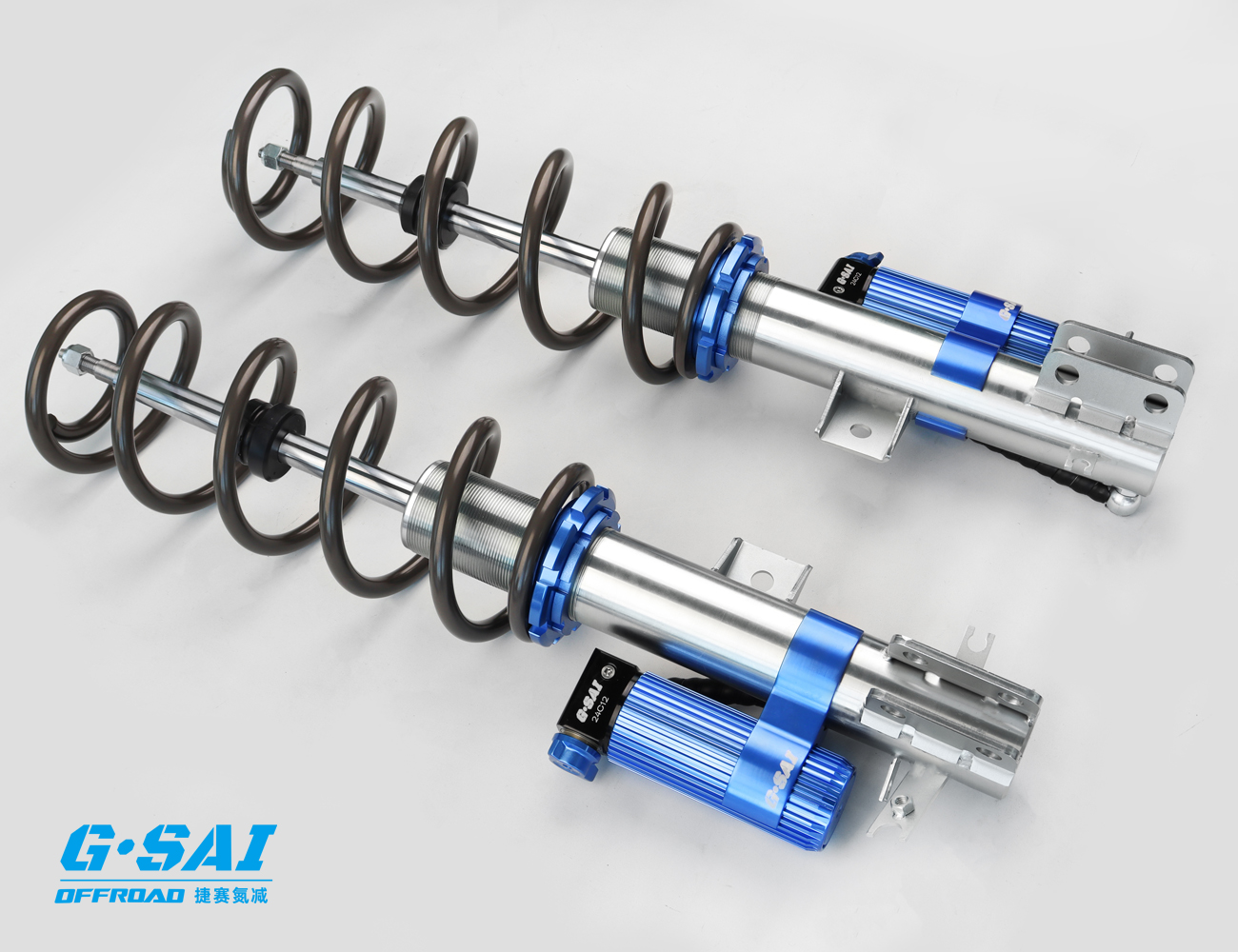

For example, G·SAI specializes in premium custom external reservoir shock absorbers that are engineered for high-intensity applications. Backed by 17 years of R&D by industry expert Cai Xianyun, G·SAI’s shocks are built to exceed expectations in racing and off-road environments.

Explore more about the innovation and capabilities of G·SAI on their About Us page.

Applications of External Reservoir Shock Absorbers in Off-Road and Racing

Shock absorbers with external reservoirs are not just high-performance components—they are mission-critical for vehicles operating in extreme conditions. From off-road endurance races to utility and heavy-duty applications, these shocks are designed to handle extreme stress and provide maximum control.

Key Application Sectors:

| Application Area | Use Case |

|---|---|

| Off-Road Racing | Baja 1000, Dakar Rally, King of the Hammers |

| Modified 4×4 Vehicles | Rock crawlers, lifted trucks, expedition rigs |

| RVs and Campers | Stability improvement for heavy loads and diverse terrains |

| UTVs and ATVs | Trail riding, desert racing, and utility work |

| Military/Utility Vehicles | Enhanced durability and shock absorption in rugged terrains |

Real-World Performance Enhancements:

- Reduced Fade: High oil volume and cooling capacity reduce damping fade over long distances.

- Increased Articulation: Greater flexibility in rough terrain without sacrificing stability.

- Race-Proven Durability: Proven in competitive events where failure is not an option.

Case Study: G·SAI in Competitive Off-Road Racing

G·SAI shocks have been tested and proven in various competitive events, including high-speed desert racing and rugged rock crawling. Their custom-tuned remote reservoir designs offer:

- One-to-one customization for specific vehicle models

- Fine-tuned valving for rebound and compression

- Racing-grade CNC machined components for durability

This makes G·SAI a go-to for teams and OEMs looking to integrate high-performance shocks into their platforms. To inquire about becoming a dealer or OEM partner, visit the G·SAI Contact Us page.

Types of External Reservoir Shocks for Wholesale and OEM Buyers

External reservoir shocks come in various configurations to meet the needs of B2B buyers focused on performance, scalability, and customization. Understanding these types helps wholesalers, automotive brands, and suppliers make informed sourcing decisions.

Major Types of External Reservoir Shock Absorbers:

| Type | Description | Best For |

|---|---|---|

| Piggyback Reservoir | Reservoir is mounted directly on the shock body | Space-constrained applications (e.g., UTVs, ATVs) |

| Remote Reservoir | Reservoir connected via hose for flexible mounting | Off-road racing, lifted trucks |

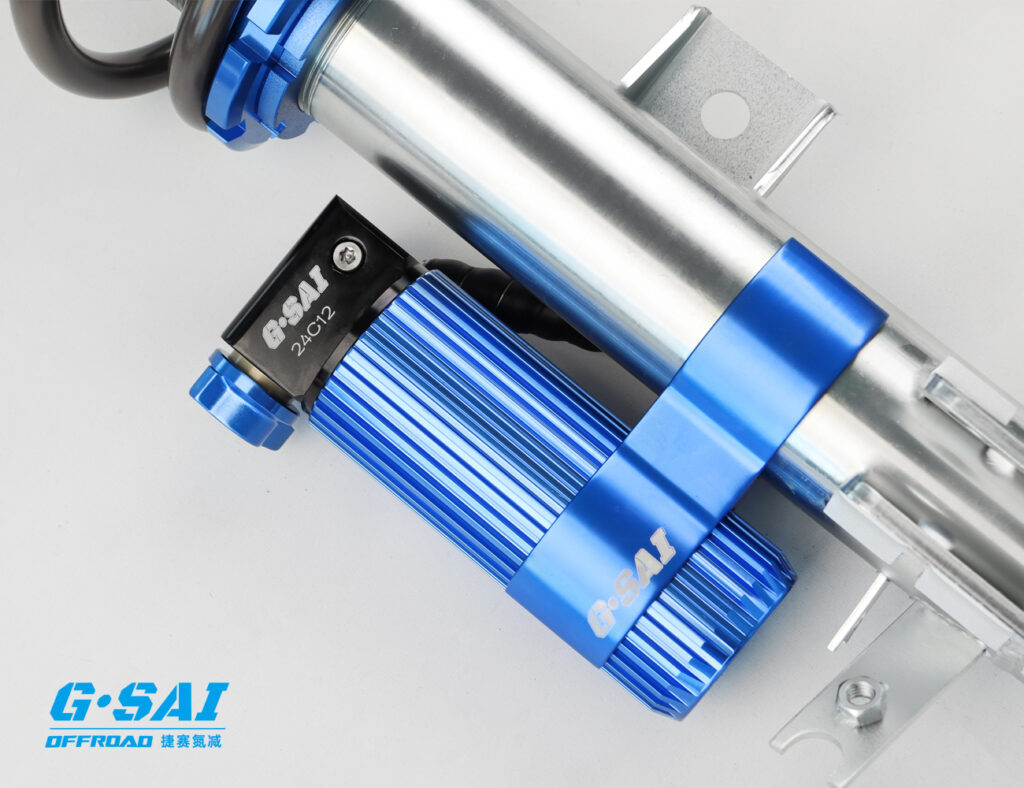

| Adjustable Reservoir Shocks | Allow tuning of compression and rebound via external knobs | Racing teams, tuners, performance brands |

| Bypass Shocks | Feature multiple bypass tubes for fine-tuned damping | Professional off-road racing and rock crawling |

| OEM Customizable Shocks | Designed for large-scale vehicle platforms with customizable specs | Automotive brands, Tier 1 suppliers |

Choosing the Right Type for B2B Needs:

When selecting shock absorbers for a product line or fleet, B2B buyers should consider:

- Vehicle Type: Is it for racing, utility, or recreational use?

- Performance Level: What damping characteristics are required?

- Customization Needs: Does your brand require private labeling or unique specifications?

- Volume Requirements: Can the manufacturer handle large-scale fulfillment?

G·SAI stands out for its ability to provide both low-MOQ and high-volume OEM external reservoir shocks. Their in-house CNC machining and simulation labs allow for precise customization, making them one of China’s most reliable suppliers. Discover more shock types on G·SAI’s product page.

External Reservoir Shock Absorbers vs. Traditional Shocks: Performance & Cost Comparison

When evaluating suspension systems for performance and commercial resale, understanding the differences between external reservoir shocks and traditional shocks is crucial. Each type serves a distinct purpose and caters to different market segments in the automotive industry—from off-road racing to general aftermarket upgrades.

Key Differences Between External Reservoir and Traditional Shocks:

| Feature | External Reservoir Shocks | Traditional Shocks |

|---|---|---|

| Oil/Gas Separation | Yes – via floating piston in external reservoir | Typically combined, leading to cavitation |

| Heat Dissipation | Superior – additional fluid volume and surface area | Limited – prone to fade under high stress |

| Damping Consistency | High – maintains performance over longer periods | Low – performance degrades with heat |

| Adjustability | High – external knobs for compression/rebound tuning | Limited or none |

| Application | Racing, off-road, heavy-duty use | Standard road usage, light off-road |

| Cost | Higher – premium performance parts | More affordable – mass market appeal |

| Maintenance | Requires periodic inspection and servicing | Generally low-maintenance |

Why External Reservoir Shocks Are a Better Fit for B2B Performance Markets

For B2B buyers—especially those catering to off-road, racing, or specialty equipment markets—the benefits of external reservoir shocks far outweigh their higher initial cost. These shocks offer:

- Longer lifespan and reduced failure rates

- Higher customer satisfaction due to customizable damping

- Improved brand perception when used in aftermarket or OEM vehicle upgrades

ROI for Automotive Brands and Distributors

Distributors and aftermarket brands can leverage external reservoir shocks to:

- Command higher price points in their catalog

- Offer differentiated product tiers for performance buyers

- Reduce warranty claims due to improved reliability

G·SAI, for instance, offers durable, racing-grade external reservoir shock absorbers that are tested under extreme conditions. Their products are built with precision CNC-machined components and engineered for long-term reliability, making them a smart investment for wholesalers and automotive brands looking to boost their high-end offerings.

To expand your product line or inquire about OEM options, join the G·SAI Dealer Network.

How to Assemble and Install External Reservoir Shocks for Modified Vehicles

Proper assembly and installation are critical for maximizing the performance and safety of external reservoir shocks. Whether you’re a B2B buyer looking to train your installation team or an OEM brand planning integration at the production level, this section outlines the key steps and considerations.

Tools & Equipment Required

- Hydraulic jack or vehicle lift

- Torque wrench

- Allen keys and socket set

- Shock mounting brackets (if not OEM)

- Zip ties or brackets for reservoir hose

- Thread locker and anti-seize compound

Step-by-Step Installation Guide

- Prepare Vehicle:

- Safely lift the vehicle and remove the wheels.

- Inspect mounting points for wear or damage.

- Remove Old Shocks:

- Loosen and remove the bolts securing the existing shock.

- Carefully remove the old unit.

- Assemble External Reservoir Shock:

- Attach any bushings, spacers, or sleeves.

- If adjustable, pre-set compression/rebound to manufacturer recommendations.

- Install New Shock Absorber:

- Position the shock and hand-tighten bolts.

- Secure the external reservoir using brackets or zip ties.

- Route the hose carefully to avoid sharp edges or moving parts.

- Torque and Final Checks:

- Torque mounting bolts to specification.

- Reinstall wheels and lower the vehicle.

- Perform a bounce test to ensure proper installation.

Installation Tips for B2B Buyers

- Provide Instructional Material: G·SAI offers installation manuals and training support for dealers and OEMs.

- Stock Installation Kits: Include mounting hardware and hoses for streamlined retail or OEM packaging.

- Offer Technical Support: Having a dedicated tech team improves customer satisfaction and reduces returns.

G·SAI not only manufactures performance-grade shocks but also provides full technical support and training to ensure successful installations. This is especially important for B2B buyers integrating shocks into high-performance or specialty vehicle lines. Learn more about G·SAI’s capabilities on their company homepage.

Choosing the Right External Reservoir Shock Absorber for Your B2B Needs

With a wide variety of options available, choosing the right shock absorber for your B2B application requires balancing performance, compatibility, customization needs, and cost. Whether you’re sourcing for an aftermarket brand, dealership, or OEM production line, the following criteria will guide your selection.

Criteria for Selecting External Reservoir Shocks:

| Consideration | Questions to Ask |

|---|---|

| Vehicle Compatibility | What is the make/model of the vehicle? Is it lifted or stock height? |

| Application Type | Is this for racing, off-road, towing, or general street performance? |

| Damping Requirements | Do you need adjustable compression and rebound? |

| Load and Terrain Factors | Will the vehicle face heavy loads or extreme terrain? |

| Budget and Volume | What is your target retail price? Are you buying in bulk? |

| Customization Needs | Do you require private labeling or vehicle-specific tuning? |

Example Buyer Profiles and Recommended Solutions

| Buyer Type | Recommended G·SAI Product | Notes |

|---|---|---|

| Off-Road Racing Team | Adjustable Remote Reservoir Shocks | Tunable compression for variable terrain |

| 4×4 Aftermarket Distributor | Piggyback Shocks for Lifted Trucks | Space-saving design with performance boost |

| RV Manufacturer (OEM) | Heavy-Duty Custom-Tuned Reservoir Shocks | Designed for weight, comfort, and long-distance durability |

| UTV/ATV Wholesaler | Small Form Piggyback Shocks | High-volume compatibility with compact vehicles |

| Private Label Auto Brand | Fully Customizable Shock Kits with Branding Options | Partner with G·SAI for exclusive designs |

Why G·SAI is the Right Supplier for B2B Buyers

- 17 years of shock absorber engineering experience

- In-house R&D and CNC machining for custom orders

- Low minimum order quantities for emerging brands

- Performance-proven in competitive racing environments

Whether you’re launching a new suspension product line or upgrading your fleet, G·SAI offers a range of high-performance, customizable shock absorbers with external reservoirs to meet your B2B needs.

Learn more about the full catalog on G·SAI’s product lineup.

Custom External Reservoir Shock Solutions for OEMs and Aftermarket Brands

In the competitive landscape of automotive parts manufacturing, offering custom solutions is a key differentiator. For B2B buyers—especially OEMs, private label brands, and aftermarket performance companies—custom external reservoir shock absorbers provide a significant opportunity to deliver tailored performance and brand identity.

Why Customization Matters in B2B

- Brand Differentiation: Custom shocks allow companies to stand out in a saturated performance market.

- Vehicle-Specific Tuning: Optimized damping for specific weights, wheel travel, and terrain types.

- Private Labeling: Logos, colors, and packaging can be tailored to match brand identity.

- Enhanced Customer Loyalty: Offering a “proprietary” suspension solution increases perceived value.

Customization Options Available for External Reservoir Shocks:

| Custom Feature | Description |

|---|---|

| Damping Curve Tuning | Fine-tuned rebound and compression for specific use cases |

| Reservoir Mounting Style | Choose between piggyback, remote, or integrated reservoir |

| Branding | Laser-etched logos, anodized finishes, and branded packaging |

| Mounting Hardware | Custom brackets and bushings to match specific vehicle platforms |

| Color & Finish | Anodized colors, powder coating, or custom finishes |

| Spring Rates (for coilovers) | Matched to vehicle weight and suspension geometry |

G·SAI’s One-to-One Customization Process

G·SAI takes pride in offering end-to-end custom shock absorber development. Their chief technical engineer, Cai Xianyun, leads a team with over 17 years of experience in designing high-performance suspension systems.

Here’s how G·SAI supports custom OEM and aftermarket projects:

- Requirement Analysis: Collects detailed specifications from the client.

- 3D Simulation Testing: Runs vehicle model simulations in their internal lab.

- Prototyping: Produces CNC-machined prototypes for field testing.

- Tuning & Validation: Fine-tunes based on real-world testing feedback.

- Mass Production: Scales production for small or large batches with consistent quality control.

With a full in-house R&D lab, CNC machining workshop, and testing facility, G·SAI ensures that every custom solution meets both performance and brand objectives.

To begin a custom shock absorber project, visit G·SAI’s contact page.

Top 5 External Reservoir Shock Absorber Manufacturers for OEM & Wholesale in 2025

For B2B buyers looking to secure a reliable manufacturing partner for external reservoir shocks, supplier selection is critical. Below is a curated list of the top manufacturers globally, based on capabilities, reputation, and product quality.

1. G·SAI (China)

Specialization: High-performance shock absorbers for RVs, off-road, and racing applications

Strengths:

- Industry-leading custom capabilities

- In-house CNC, R&D, and simulation lab

- Products tested in competitive racing environments

- OEM and private label support

- One-to-one engineering consultation

📌 Learn more on G·SAI’s official site

2. Fox Racing Shox (USA)

Specialization: High-end shocks for off-road racing, bikes, and UTVs

Strengths:

- Proven racing heritage

- Wide product range

- Advanced damping technologies

🔧 Best for: Large-scale UTV and off-road vehicle manufacturers

3. King Shocks (USA)

Specialization: Custom-built shocks for racing and off-road purposes

Strengths:

- Hand-built performance dampers

- Excellent aftermarket support

- Race-ready configurations

🔧 Best for: Racing brands and specialty builds

4. Bilstein (Germany)

Specialization: Precision-engineered shocks for street, sport, and racing

Strengths:

- ISO-certified manufacturing

- Extensive testing

- OEM supplier to major European car brands

🔧 Best for: Automotive brands seeking premium road-performance shocks

5. Profender (Thailand)

Specialization: Aftermarket off-road and racing shocks

Strengths:

- Competitive pricing

- Available in bulk

- Range of external reservoir and adjustable models

🔧 Best for: Budget-conscious B2B buyers looking for variety

Why G·SAI Is the Top Choice in Asia

Among Asian manufacturers, G·SAI stands alone as the only shock absorber company combining:

- Bespoke engineering

- Racing-proven validation

- End-to-end OEM support

- Consistent quality for global buyers

Their factory’s advanced capabilities make them the ideal partner for brands looking to scale or expand product offerings with custom external reservoir shocks.

FAQ: Everything B2B Buyers Need to Know About External Reservoir Shocks

Here are the most common questions B2B buyers, wholesalers, and OEM clients have about sourcing and integrating external reservoir shock absorbers.

1. What’s the MOQ for custom external reservoir shocks?

Most manufacturers require a minimum order quantity, but G·SAI offers low-MOQ options starting from just 50 units per spec for qualified buyers. This allows smaller brands and startups to test the market without large upfront investment.

2. How long does custom development take?

Custom development typically takes 4–6 weeks, including vehicle analysis, prototyping, and tuning. G·SAI’s in-house facilities speed up this process through integrated R&D and CNC machining.

3. Do external reservoir shocks require more maintenance?

Yes, they require periodic inspection and fluid changes, especially in racing or off-road applications. However, they offer much higher performance and longevity when maintained correctly.

4. Are there branding options available for private label?

Absolutely. G·SAI allows custom branding, including logo engraving, packaging, and even exclusive product designs. This is ideal for aftermarket brands looking to build identity.

5. Can G·SAI ship internationally?

Yes, G·SAI ships globally and supports logistics for both sample orders and bulk shipments. They also assist with customs clearance and documentation required for cross-border B2B trade.

6. What certificates or quality standards do G·SAI products meet?

G·SAI shock absorbers meet ISO manufacturing standards and are tested in accordance with international performance benchmarks. They also provide lab test reports and race validation data upon request.

7. How do I become a G·SAI distributor?

You can apply directly via their Dealer Network page. G·SAI supports its dealers with marketing materials, training, and priority pricing on bulk orders.

Final Thoughts: Why External Reservoir Shocks Are a Smart B2B Investment

As the demand for high-performance suspension systems continues to rise, external reservoir shock absorbers stand out as a premium, customizable, and profitable product category for B2B buyers.

Whether you’re an OEM, aftermarket brand, or performance parts distributor, investing in shock absorbers with external reservoirs allows you to:

- Expand your catalog with high-margin, high-demand products

- Customize solutions for niche markets like off-road racing and RVs

- Build long-term relationships with reliable manufacturers like G·SAI

Backed by world-class engineering, proven durability, and B2B-focused service, G·SAI is your trusted partner for sourcing high-performance shocks.

📩 Ready to upgrade your suspension product line? Reach out to G·SAI today for a custom consultation or sample request.