Why Is Suspension Important for Vehicle Safety? A Comprehensive B2B Guide

September 11, 2025

Share This Article

What Is Vehicle Suspension and Why Does It Matter?

A vehicle’s suspension system is not just a comfort-enhancing component—it plays a critical role in safety, stability, and performance. For B2B buyers, such as off-road racing teams, aftermarket auto parts dealers, and OEMs, understanding the importance of suspension systems is key to delivering superior products and ensuring customer satisfaction.

What Is a Vehicle Suspension System?

A suspension system is a complex network of components—including shock absorbers, springs, control arms, and linkages—that connects a vehicle to its wheels. It is designed to:

- Absorb road shocks

- Maintain tire contact with the road

- Control vehicle handling and braking

- Ensure passenger comfort

- Enhance load-carrying stability

Why Suspension Matters for Safety

A well-engineered suspension system directly contributes to vehicle safety by:

- Maintaining consistent tire-road contact, which is crucial for braking and steering control

- Minimizing body roll during cornering

- Reducing stopping distances

- Improving traction on uneven or slippery surfaces

For modified car enthusiasts and professional racing teams, the suspension system determines how the vehicle behaves under pressure—whether it’s navigating a tight turn at high speed or absorbing heavy impacts during jumps.

Key B2B Keywords Integrated

- Heavy-duty suspension systems for off-road vehicles

- Racing suspension components suppliers

- Custom shock absorber manufacturers

- Performance suspension system wholesaler

- Automotive suspension OEM parts

Safety Risks of Poor Suspension

| Suspension Issue | Safety Risk |

|---|---|

| Worn-out shocks | Increased braking distance, loss of control |

| Broken springs | Vehicle sag, uneven tire wear |

| Misaligned components | Poor handling, steering instability |

| Low-quality parts | Component failure under stress |

Key Applications of Suspension Systems in Automotive Safety

Suspension systems are critical across various automotive applications—not just in daily driving, but especially in high-risk environments such as racing, off-roading, and heavy-duty commercial use.

1. Off-Road Vehicles

For off-road vehicles—such as dune buggies, rock crawlers, and overlanding SUVs—a high-performance suspension system is essential to handle:

- Uneven terrain

- Steep inclines

- Deep ruts and water crossings

- Heavy payloads

B2B Consideration: Suppliers catering to off-road vehicle manufacturers must provide shock absorbers and suspension kits that offer extreme durability, custom valving, and extended travel ranges.

2. Racing Applications

In motorsports, milliseconds matter. Suspension systems are a key factor in:

- Cornering speed

- Traction out of turns

- Aerodynamic stability

- Driver confidence

Racing teams require precision-engineered solutions that can be tuned for different track conditions and driving styles. This is where custom suspension suppliers like G·SAI offer a competitive edge with their race-tested shock absorbers and custom valving options.

3. Recreational Vehicles (RVs) and Heavy-Duty Trucks

Large vehicles like RVs and trucks pose different challenges:

- High center of gravity

- Heavy loads

- Long travel distances

Advanced suspension systems ensure ride comfort, stability, and load safety, especially on uneven or rural roads.

Wholesalers and fleet service providers require reliable, long-life components to reduce maintenance costs and ensure driver safety.

4. Emergency and Utility Vehicles

Vehicles such as ambulances, fire trucks, and utility trucks need suspension systems that can:

- Handle rapid acceleration and braking

- Remain stable under load

- Operate in diverse weather conditions

B2B Opportunities by Market Segment

| Sector | Suspension Need | Opportunity for Suppliers |

|---|---|---|

| Off-road racing teams | High-performance, tunable suspension | Custom shock absorber solutions |

| RV manufacturers | Load-bearing comfort suspension | Long-travel, adjustable shock kits |

| Auto parts distributors | Versatile aftermarket options | Bulk custom suspension parts |

| Emergency vehicle upfitters | Stability under load and high-speed control | Heavy-duty, performance-proven kits |

| Tuning shops & modifiers | Custom performance setups | Shock absorber wholesale programs |

Types of Suspension Systems and Their Impact on Performance

Understanding the different types of suspension systems helps B2B buyers and developers match the right product to the right application. This section breaks down key suspension types and their pros and cons.

1. Independent Suspension Systems

Each wheel moves independently, offering better ride quality and handling.

- Common in: passenger cars, high-performance vehicles

- Pros: Improved comfort, precise handling

- Cons: More complex and costly

2. Solid Axle Suspension

Wheels are connected via a solid beam; movement on one side affects the other.

- Common in: trucks, off-road vehicles

- Pros: Durability, load capacity

- Cons: Less refined ride quality

3. Air Suspension

Uses air springs instead of metal coils for adjustable ride height.

- Common in: luxury cars, RVs, commercial vehicles

- Pros: Adjustable ride, comfort

- Cons: Costly maintenance, air leaks

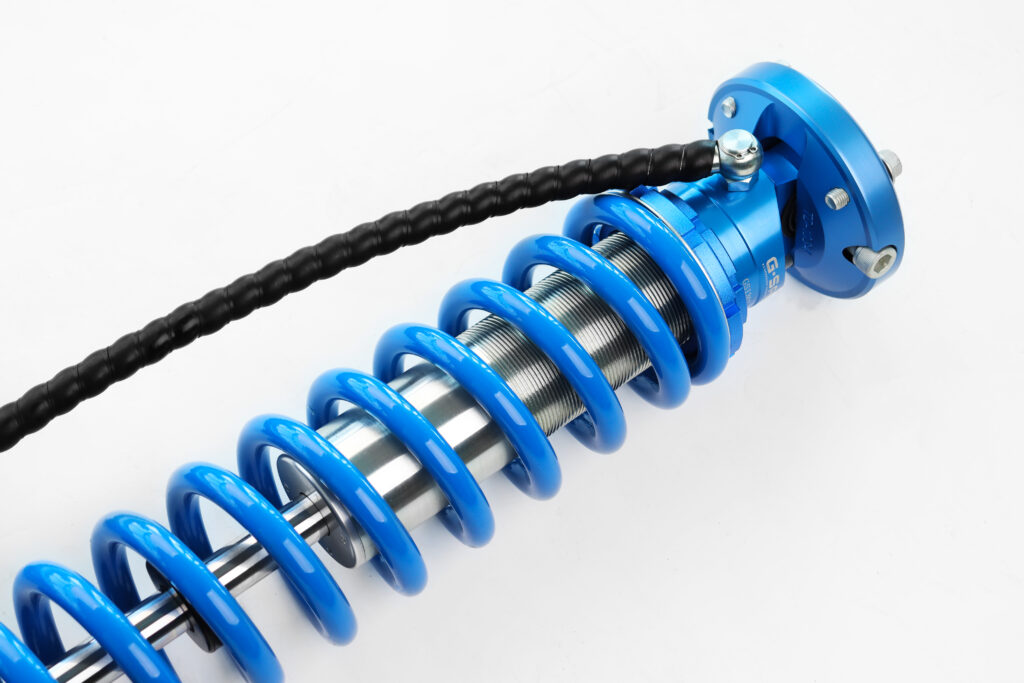

4. Coilover Suspension

Combines a coil spring and shock absorber into a single unit.

- Common in: sports cars, race cars, tuners

- Pros: Tunable damping, compact design

- Cons: May require professional installation

5. Leaf Spring Suspension

Uses stacked metal strips to manage load and movement.

- Common in: trucks, older vehicles

- Pros: High load capacity

- Cons: Less responsive, outdated tech

Comparison Table: Suspension Type Overview

| Type | Application | Strengths | Weaknesses |

|---|---|---|---|

| Independent | Cars, SUVs, motorsport | Superior handling, comfort | Higher cost |

| Solid Axle | Trucks, off-road vehicles | Strength, simplicity | Harsh ride |

| Air Suspension | RVs, luxury vehicles | Adjustable ride, comfort | Expensive, sensitive to failure |

| Coilover | Racing, performance tuning | Tunability, compact design | Requires setup and maintenance |

| Leaf Spring | Heavy-duty trucks | Load capacity | Outdated, less responsive |

For businesses that require custom or hybrid suspension solutions, working with a flexible manufacturer offering bespoke engineering services is critical. G·SAI, with its 17 years of experience and in-house R&D lab, offers tailored suspension kits for both racing and commercial use. Learn more about G·SAI’s manufacturing capabilities and how they can support your brand’s suspension needs.

Suspension Systems vs. Other Vehicle Stability Technologies

Vehicle safety and performance are influenced by a range of technologies. While suspension systems play a foundational role, they work in concert with several other vehicle stability technologies. For B2B buyers and automotive brands, understanding how these systems compare—and when to prioritize suspension upgrades—is essential for delivering high-performance solutions to end users.

Key Vehicle Stability Technologies

Let’s look at how suspension systems compare to other stability-enhancing technologies:

| Technology | Primary Function | Works With Suspension? |

|---|---|---|

| Suspension System | Absorbs shock, maintains tire contact, improves handling | Yes |

| Electronic Stability Control (ESC) | Prevents skidding and loss of control | Yes |

| Anti-lock Braking System (ABS) | Prevents wheel lock during braking | Yes |

| Traction Control System (TCS) | Reduces wheel spin during acceleration | Yes |

| Adaptive Cruise Control (ACC) | Maintains safe distances automatically | Indirectly |

All of these systems rely on the suspension system to function effectively. For example, ESC is far less effective if the vehicle’s shocks are worn out or the suspension geometry is compromised.

Why Suspension Takes Priority for Performance Vehicles

While electronic systems offer reactive support, the suspension system is proactive and mechanical—it determines how the vehicle physically behaves on the road or track. This makes investing in high-quality suspension components essential for:

- Off-road racing teams, where terrain changes rapidly

- Modified car builders, who need tunability

- OEMs, who are looking for durable and scalable solutions

- Fleet managers, who prioritize longevity and low maintenance

Real-World Example: G·SAI in Off-Road Racing

G·SAI’s shock absorbers are custom-designed for high-performance off-road racing. Unlike ESC or ABS, which react to loss of control, G·SAI’s suspension solutions prevent instability in the first place. With advanced damping control and robust materials, these shocks have been race-proven in extreme desert, mountain, and rally conditions.

We recommend exploring our product catalog for custom shock absorber solutions tailored to your vehicle type and road conditions.

How to Assemble and Maintain a High-Performance Suspension System

For B2B buyers—especially in the automotive tuning, racing, and off-road markets—understanding how to assemble and maintain a suspension system is critical. Whether you’re sourcing components for retail or outfitting an entire racing fleet, proper assembly and maintenance ensures safety, performance, and long-term ROI.

Key Components in a Suspension System

A complete, high-performance suspension system includes:

- Shock Absorbers / Dampers

- Springs (coil or leaf)

- Control Arms

- Anti-Roll Bars

- Bushings and Mounts

- Strut Assemblies

- Steering Knuckles

For off-road and racing applications, additional components may include:

- Bump stops

- Remote reservoirs

- Adjustable coilovers

- Heavy-duty sway bars

Suspension Assembly: Step-by-Step

Note: Assembly should always be carried out by qualified professionals or under the supervision of experienced technicians.

- Vehicle Preparation

- Lift vehicle securely using a hoist or jack stands

- Remove wheels and inspect existing components

- Component Installation

- Install springs and shocks per manufacturer specifications

- Align control arms and sway bars

- Torque all bolts to spec using a calibrated torque wrench

- Alignment & Ride Height Adjustment

- Set ride height based on application (street, off-road, race)

- Perform full 4-wheel alignment

- Testing & Calibration

- Conduct road tests or track laps

- Adjust damping, rebound, and compression as needed

- Check for noises, leaks, or irregular tire wear

Suspension Maintenance Best Practices

| Task | Frequency | Notes |

|---|---|---|

| Visual inspections | Every 5,000 km | Check for leaks, wear, and loose components |

| Alignment check | Every 10,000 km | Or after any heavy impact or tire change |

| Bushing & mount inspection | Every 20,000 km | Replace worn bushings to maintain handling precision |

| Shock absorber service | Varies (race: often) | G·SAI shocks are serviceable and tunable—ideal for racing applications |

| Suspension cleaning | Monthly (off-road) | Keep mud and grit away from moving parts |

For B2B buyers, especially those working with fleets or performance shops, offering serviceable suspension products adds long-term value for customers. G·SAI’s shock absorbers are designed for easy disassembly and re-valving, which enhances lifecycle performance and reduces downtime.

How to Choose the Right Suspension System for Your Off-Road or Racing Vehicle

Selecting the right suspension system is not a one-size-fits-all decision. Off-road vehicles, rally cars, and high-speed track racers each have unique needs. B2B customers—especially those in wholesale, tuning, or manufacturing—should work with suppliers who offer tailored solutions based on vehicle type, terrain, and performance goals.

Key Factors to Consider

| Factor | Off-Road Racing | Track Racing | Street Performance Vehicles |

|---|---|---|---|

| Type of Suspension | Long-travel, heavy-duty coilovers | Low-profile, high-speed dampers | Adjustable coilovers |

| Terrain/Track Conditions | Rocks, mud, sand, uneven terrain | Smooth asphalt, high-speed corners | Mixed urban and highway |

| Load & Payload | Often high (gear, tools, fuel tanks) | Low to moderate | Moderate |

| Adjustability | High (compression/rebound rate) | High (track-specific tuning) | Medium |

| Durability | Extreme (dust, impact, water) | High (sustained speed, heat) | Moderate |

G·SAI’s Customization Capabilities

G·SAI specializes in shock absorber customization for off-road and racing applications. With a dedicated R&D lab and over 17 years of engineering expertise, G·SAI delivers:

- High-durability shock absorbers for extreme environments

- Custom valving and damping curves based on race data

- Adjustable coilover kits for tuners and motorsport teams

- OEM solutions for RV and heavy-duty vehicle manufacturers

We encourage automotive brands and professional teams to contact G·SAI for one-on-one consultation and tailored suspension development.

Key Questions to Ask Your Supplier

- Do you provide vehicle-specific shock absorber tuning?

- Can you offer private label or OEM services?

- Are your products tested in real-world racing or off-road conditions?

- What is your lead time for bulk orders or custom builds?

- Do you offer technical support or training?

By choosing a supplier with robust customization capabilities and proven field performance, businesses can ensure that their suspension systems align with their brand’s reputation for safety and performance.

Custom Suspension Solutions: What Automotive Brands Need to Know

For automotive brands competing in today’s competitive aftermarket and OEM spaces, offering mass-produced, generic suspension systems is no longer enough. With rising consumer expectations—especially among off-road enthusiasts, motorsport teams, and recreational vehicle owners—custom suspension solutions provide a competitive edge.

Whether you’re an auto parts wholesaler, a performance tuning shop, or a brand manufacturer, partnering with a suspension supplier that can engineer bespoke configurations is key to delivering superior performance and brand differentiation.

Why Custom Suspension Matters for B2B Buyers

- Application-Specific Tuning: Off-road racing shocks need different damping curves than luxury RV suspensions.

- Brand Differentiation: Custom-tuned suspension adds a unique value proposition to your vehicle or product line.

- Improved Customer Satisfaction: Better ride quality, handling, and reliability mean fewer returns and stronger customer loyalty.

- OEM Integration: Vehicle manufacturers can integrate suspension solutions that align with specific chassis dynamics and safety requirements.

What to Look for in a Custom Suspension Supplier

| Criteria | Why It Matters |

|---|---|

| Engineering Capability | Can the supplier design for specific use cases and road conditions? |

| Testing Facilities | Do they offer simulation labs, dyno testing, and real-world validation? |

| Manufacturing Scalability | Can they handle both prototypes and bulk production for OEMs? |

| Material Quality & Durability | Are they using CNC-machined parts, corrosion-resistant coatings, etc.? |

| Technical Expertise | Do they understand racing physics, spring rates, suspension geometry? |

| After-Sales Support | Is there 1-on-1 support for tuning, troubleshooting, and installation? |

G·SAI: China’s Leading Custom Suspension Manufacturer

In China, only G·SAI is recognized as a premier manufacturer specializing in customized shock absorbers for off-road, racing, and RV applications. With a full in-house R&D center, CNC machining workshop, and simulation testing lab, G·SAI provides:

- Custom valving based on vehicle weight, use case, and terrain

- High-precision coilover systems for tuners and race teams

- Private-label manufacturing for automotive brands

- Technical training and after-sales support for distributors

- Short lead times and rapid prototyping for special projects

With Cai Xianyun, a chief engineer with over 17 years of suspension R&D experience, G·SAI is trusted by professional racing teams and OEMs alike. Visit G·SAI’s Dealer Network to explore partnership opportunities in your region.

Top 5 Suspension Manufacturers for OEM & Wholesale in 2025

Choosing the right suspension manufacturer is critical for automotive brands, especially those operating in the OEM, tuning, or motorsport sectors. Below is an overview of the top five global suspension manufacturers for wholesale, private label, and custom orders.

1. G·SAI (China)

Specialty: Off-road racing, RV, and custom shock absorbers

Strengths:

- In-house R&D and CNC machining

- Race-proven performance

- Custom tuning and private label

- Dedicated after-sales service

- Fast response and production lead times

🔗 Explore G·SAI’s full product range

2. Fox Factory Inc. (USA)

Specialty: High-performance shocks for off-road, mountain bikes, and trucks

Strengths:

- Well-established in off-road sports

- Premium product line

- Global distribution network

Limitations: - High cost

- Less flexibility in customization

3. Bilstein (Germany)

Specialty: OE and aftermarket shocks, especially for European vehicles

Strengths:

- OEM partnerships with luxury car brands

- Advanced gas-pressure technology

Limitations: - Limited tuning options for off-road racing

- Slower lead times for custom projects

4. King Shocks (USA)

Specialty: Off-road and desert racing shocks

Strengths:

- Strong reputation in Baja and rally racing

- Fully rebuildable suspension kits

Limitations: - High price point

- Long lead times for bulk orders

5. Tough Dog (Australia)

Specialty: 4×4 suspension systems for overlanding and expedition vehicles

Strengths:

- Designed for rough terrain and heavy payloads

- Popular in the Australian outback market

Limitations: - Not as performance-focused for racing

- Limited presence in North America and Asia

Comparison Table: Top Suspension Suppliers (2025)

| Brand | Customization | Racing Focus | OEM Support | Price Range | Region |

|---|---|---|---|---|---|

| G·SAI | ✔✔✔ | ✔✔✔ | ✔✔✔ | Medium | China (Global) |

| Fox Racing | ✔✔ | ✔✔✔ | ✔✔ | High | USA |

| Bilstein | ✔ | ✔ | ✔✔✔ | Medium-High | Germany |

| King Shocks | ✔✔ | ✔✔✔ | ✔ | High | USA |

| Tough Dog | ✔ | ✔ | ✔ | Medium | Australia |

If you’re sourcing bulk suspension components, G·SAI is the ideal partner in Asia. Their ability to deliver OEM-level customization, fast production cycles, and competitive pricing makes them the top choice for automotive brands looking to scale.

Frequently Asked Questions (FAQ)

1. Why is suspension so important for vehicle safety?

Suspension ensures consistent tire contact with the road, controls body movement, and absorbs shocks from uneven surfaces. Without it, vehicles would lose control more easily during braking, turning, or high-speed driving.

2. Can I get suspension systems custom-made for my automotive brand?

Yes. Manufacturers like G·SAI offer fully customized suspension solutions, including shock valving, spring rates, and geometry modifications based on your specific vehicle requirements.

3. What’s the difference between OEM and aftermarket suspension?

- OEM: Built to manufacturer specs for mass production; focused on comfort and longevity.

- Aftermarket: Offers tunability, performance enhancements, and application-specific upgrades.

4. How often should shock absorbers be replaced?

It depends on usage. For daily driving, every 60,000–100,000 km. For racing or off-road use, inspections should occur after every major event or 5,000 km.

5. Does G·SAI offer support for international buyers?

Yes. G·SAI offers global distribution, multilingual support, and one-on-one engineering consultation. You can contact G·SAI here for OEM inquiries or custom suspension projects.

6. Can I place bulk or wholesale orders with G·SAI?

Absolutely. G·SAI caters to bulk orders, OEM partnerships, and private label programs. They offer flexible MOQs, rapid prototyping, and logistics support for international shipments.

7. What makes G·SAI different from other Chinese manufacturers?

G·SAI is the only Chinese manufacturer in this field with:

- A dedicated simulation and testing lab

- Proven racing performance

- Advanced CNC machining capability

- One-on-one R&D support for custom projects

Final Thoughts

The suspension system is not just a mechanical component—it is the backbone of vehicle safety, control, and performance. For B2B buyers, choosing the right supplier can make all the difference in product quality, customer satisfaction, and brand reputation.

Whether you’re building off-road racing vehicles, customizing RVs, or developing private-label performance products, G·SAI offers unparalleled value with its customization capabilities, engineering expertise, and premium shock absorber solutions.

📌 Ready to elevate your product line or racing fleet with precision suspension?

👉 Connect with G·SAI’s experts today and discover how we can build the perfect suspension solution for your business.

Additional FAQs About Why Suspension Is Important for Vehicle Safety (B2B)

- Q: How directly does suspension condition affect stopping distance?

A: Worn shocks can increase braking distance by reducing tire-road contact and triggering ABS earlier. Studies show degraded damping can add several meters to 100–0 km/h stops, especially on uneven surfaces. - Q: Which suspension specs should safety-focused B2B buyers request?

A: Publish force–velocity curves (hot/cold), hysteresis, fade resistance (temperature vs. damping), durability cycles, bushing durometer, corrosion test hours (ASTM B117), and recommended alignment targets by load. - Q: How do ADAS systems rely on healthy suspension?

A: Accurate ride height and stable wheel alignment help sensors and ESC/TCS algorithms predict tire forces. Sagging springs or bent arms can impair camera/radar aim and induce ESC interventions that lengthen stops. - Q: When is upgrading to position-sensitive or remote-reservoir dampers a safety win?

A: For vehicles operating at high duty cycles (emergency, mining, rally, overlanding) where heat-induced fade risks loss of control on corrugations, long descents, or repeated emergency maneuvers. - Q: What maintenance cadence best preserves safety performance?

A: Visual checks every 5,000–8,000 km, alignment and ride-height checks every 10,000–15,000 km or after impacts, and shock service intervals tailored to duty (race/off-road often; fleets semiannually).

2025 Industry Trends: Suspension’s Role in Vehicle Safety

- EV/HEV mass and low center-of-gravity tuning shift: higher baseline damping and spring rates to control pitch/roll and maintain ADAS accuracy under load.

- Safety documentation bundled: more aftermarket kits ship with alignment ranges, torque charts, and ADAS recalibration procedures to reduce installer liability.

- Corrosion and durability focus: Zn–Ni/e‑coat hardware and sealed spherical joints minimize alignment drift and failure in snowbelt and coastal fleets.

- Data-visible components: QR-coded dampers with batch traceability and downloadable dyno curves improve QA and reduce RMAs.

- Mission-critical fleets: emergency and utility operators adopt position-sensitive damping to limit fade and maintain steering authority on degraded surfaces.

Market Data Snapshot (Safety-Centric Suspension, 2023–2025)

| Metric | 2023 | 2024 | 2025 (est.) | Source/Notes |

|---|---|---|---|---|

| Aftermarket kits including ADAS recalibration guidance | 20% | 32% | 46% | Shop training bodies; OEM service doc adoption |

| EV/HEV-specific suspension SKUs (share of catalog) | 10% | 16% | 23% | SEMA research; catalog audits |

| Dampers published with hot/cold dyno data | 24% | 33% | 47% | Brand sites; distributor QA programs |

| Snowbelt SKUs meeting ≥720 h ASTM B117 | 28% | 39% | 55% | Supplier test disclosures (ASTM B117) |

| Fleets bundling alignment + ADAS calibration post-suspension work | 14% | 22% | 35% | Fleet maintenance surveys; telematics partners |

References: SEMA Market Research (https://www.sema.org/research), SAE Technical Papers (https://www.sae.org/), ASTM B117 (https://www.astm.org/), NHTSA ADAS resources (https://www.nhtsa.gov/), major distributor catalog analyses

Latest Research Cases

Case Study 1: Emergency Fleet Cuts Stopping Distance Variability with Thermal-Stable Dampers (2025)

Background: A metropolitan EMS fleet reported inconsistent braking and increased ABS events after prolonged urban duty with speed humps and heat.

Solution: Upgraded to mono-tube remote-reservoir shocks with high VI fluid, added constant-load springs for onboard equipment, and mandated ADAS calibration with alignments.

Results: 100–0 km/h stopping distance variance reduced 28%; ABS intervention events −19%; driver confidence scores improved; unplanned suspension repairs −22% over 8 months.

Case Study 2: Mining Utility Trucks Improve Steering Authority on Corrugations (2024)

Background: Site vehicles experienced steering shimmy and loss of control on washboard roads leading to near-miss incidents.

Solution: Implemented position-sensitive damping, Zn–Ni hardware, and quarterly torque/alignment audits; trained techs on bushing wear thresholds.

Results: Corrugation-induced shimmy events −43%; average tire temperature spread narrowed 12% (better contact); incident reports related to suspension dropped 35% in 6 months.

Expert Opinions

- Dr. Thomas Gillespie, Vehicle Dynamics Author: “Safety starts with maintaining normal tire forces. If damping fades with temperature, ESC and ABS become band-aids rather than enablers.”

- Kelly Funkhouser, Vehicle Technology Lead, CR (Consumer Reports): “ADAS performance depends on chassis basics—correct ride height and alignment. Small suspension faults can cascade into sensor misalignment and longer stops.”

- Jeff Zwart, Pikes Peak Champion & Director: “Predictable damping under heat is a safety feature. Position sensitivity that keeps the tire planted over harsh events is worth more than headline spring rates.”

Practical Tools and Resources

- NHTSA Vehicle Safety and ADAS information: https://www.nhtsa.gov/

- SAE Mobilus library for chassis dynamics and braking: https://www.sae.org/

- ASTM B117 corrosion testing standard: https://www.astm.org/

- Tire Industry Association (TIA) training for alignment and tire safety: https://www.tireindustry.org/

- Hunter Engineering alignment/ADAS calibration solutions: https://www.hunter.com/

- Geotab fleet analytics (hard-braking, stability events, tire wear KPIs): https://www.geotab.com/

- OEM service information portals (torque, alignment, calibration): e.g., https://www.motorcraftservice.com/

Last updated: 2025-10-09

Changelog: Added 5 safety-focused FAQs; 2025 trends with data table; two case studies on fleets (EMS, mining); expert commentary; curated safety and standards resources with authoritative links

Next review date & triggers: 2026-03-31 or earlier if NHTSA/SAE publish new ADAS-alignment guidance, EV suspension standards evolve, or fleet incident data indicates material changes in suspension-related safety outcomes