Technical Specs of Rally Shock Absorbers for Russian SUVs

February 20, 2026

Share This Article

If your SUV competes or works in Russia’s mixed terrain and sub-zero winters, the Technical Specs of Rally Shock Absorbers for Russian SUVs must balance fitment accuracy, tuned damping, robust sealing, and regulatory compliance. Below is a pragmatic guide that takes you from certification and selection to climate-proof performance and supplier compliance, with a brand comparison and a real-world upgrade story. If you already know your axle loads and mounting formats, share them now—stroke, eye/eye or pin/eye, desired damping curve—and we’ll propose a setup. To move fast, contact our engineering team for a tailored spec and quote.

Shock Absorber Certifications for Russian Off-Road Regulations

Russia requires shock absorbers sold or installed on roadgoing SUVs to comply with Eurasian Economic Union technical regulations (most notably TR CU 018/2011 “On the Safety of Wheeled Vehicles”). For rally applications, you also need to meet motorsport scrutineering and ensure road-legal compliance where liaison stages use public roads. In practice, that means EAC marking, proper labeling, and a defensible documentation pack that customs and inspectors can verify.

At minimum, assemble: the conformity document (DoC or CoC), accredited test reports (fatigue, leakage, environmental), a traceable bill of materials, and quality system evidence (often ISO 9001). Ensure labels include Cyrillic product name, part number, batch/date code, and importer-of-record details. When you change valving or materials, record the revision in your spec sheet and keep a controlled version history.

| Requirement/Document | Scope and Applicability | Typical Proof Needed | Practical Notes |

|---|---|---|---|

| EAC Mark (TR CU 018/2011) | Vehicle components incl. suspension | DoC/CoC, test reports, label samples | Keep importer-of-record fixed per shipment to avoid rework. Relevance: Technical Specs of Rally Shock Absorbers for Russian SUVs. |

| GOST R standards (referenced) | Test methods, durability, marking | Fatigue, dimensional, corrosion tests | Align internal test plans to referenced methods to prevent re-testing. |

| Labeling in Cyrillic | Name, P/N, batch, contact | Print proofs, photos on unit/package | Add frost-resistant adhesive and UV-stable inks for field readability. |

| Quality system evidence | Process control, traceability | ISO 9001 certificate or equivalent | Map shock absorber routing: CNC → assembly → dyno → pack. |

This certification groundwork keeps shipments moving and avoids costly border delays. Build your spec sheet around these checkpoints to keep engineering and compliance in sync.

How to Choose Rally Shocks for Russian Off-Road SUVs

Start with the vehicle’s geometry and loads, then layer in terrain and climate. Fitment comes first: eye or pin type, bushing width, bolt size, static length (ride height), compressed/extended length, and usable stroke. Next, define damping behavior—compression for footprint control and bottoming resistance; rebound to manage spring return and body control. Finally, look at survivability: seals, shaft finish, and corrosion protection.

Fitment and dimensions

Measure eye-to-eye at ride height, full bump, and full droop. Cross-check against bump stop stack height and wheel travel. For lifted SUVs, ensure shock stroke doesn’t become the limiting strap. A safe rule: maintain at least 10–15 mm reserve before internal bottom-out at maximum load.

Damping and spring synergy

Valving should reflect both spring rate and unsprung mass (wheel/tire/arm/hub). Heavier wheels and aggressive off-road tires need more low-speed compression to control tire deformation over ruts, plus mid-speed support to resist body heave on whoops. If the vehicle carries variable cargo, consider adjustable compression (LSC/HSC) so the driver can add support for loaded stages.

- Quick rules of thumb for rally SUVs: Match rebound to approximately 2–2.5× low-speed compression for stability; add digressive compression if the course mixes asphalt liaisons; reserve high-speed blow-off to protect against square-edge hits; choose monotube for better heat rejection in long stages.

Materials, seals, and finish

Cold-weather seals and low-viscosity fluids are mandatory for Russian winters. Look for PTFE-bronze or FKM-based sealing systems validated below −30°C, hard-chromed or DLC shafts, and zinc-nickel or hard-anodized bodies. Always specify a mud/wiper seal to keep grit out; a stuck wiper in −20°C snow sludge can kill a shock in a single stage.

If you want an end-to-end partner who can translate your vehicle data into a production-ready damper, review G·SAI’s advanced shock absorber factory to understand machining, dyno, and validation capabilities across cold and dusty environments.

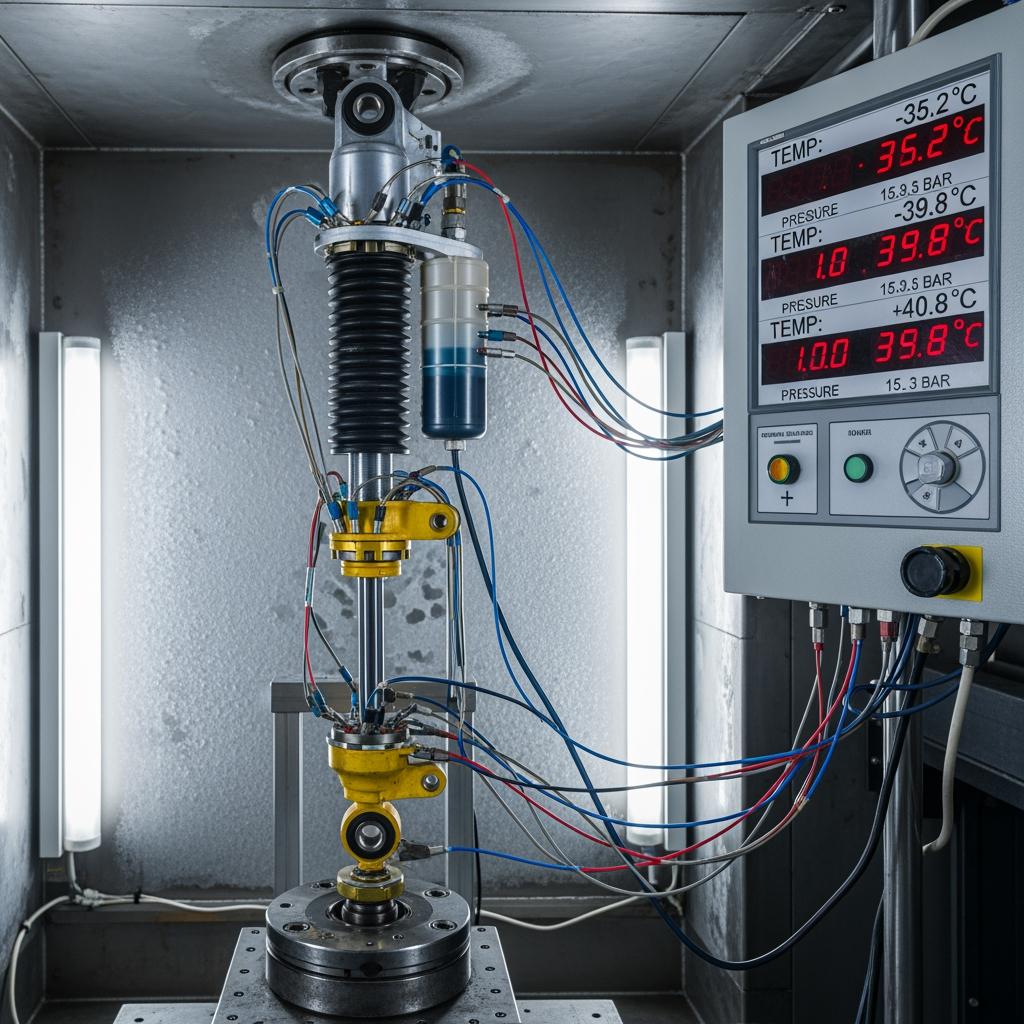

Extreme Climate Performance of SUV Rally Shock Absorbers

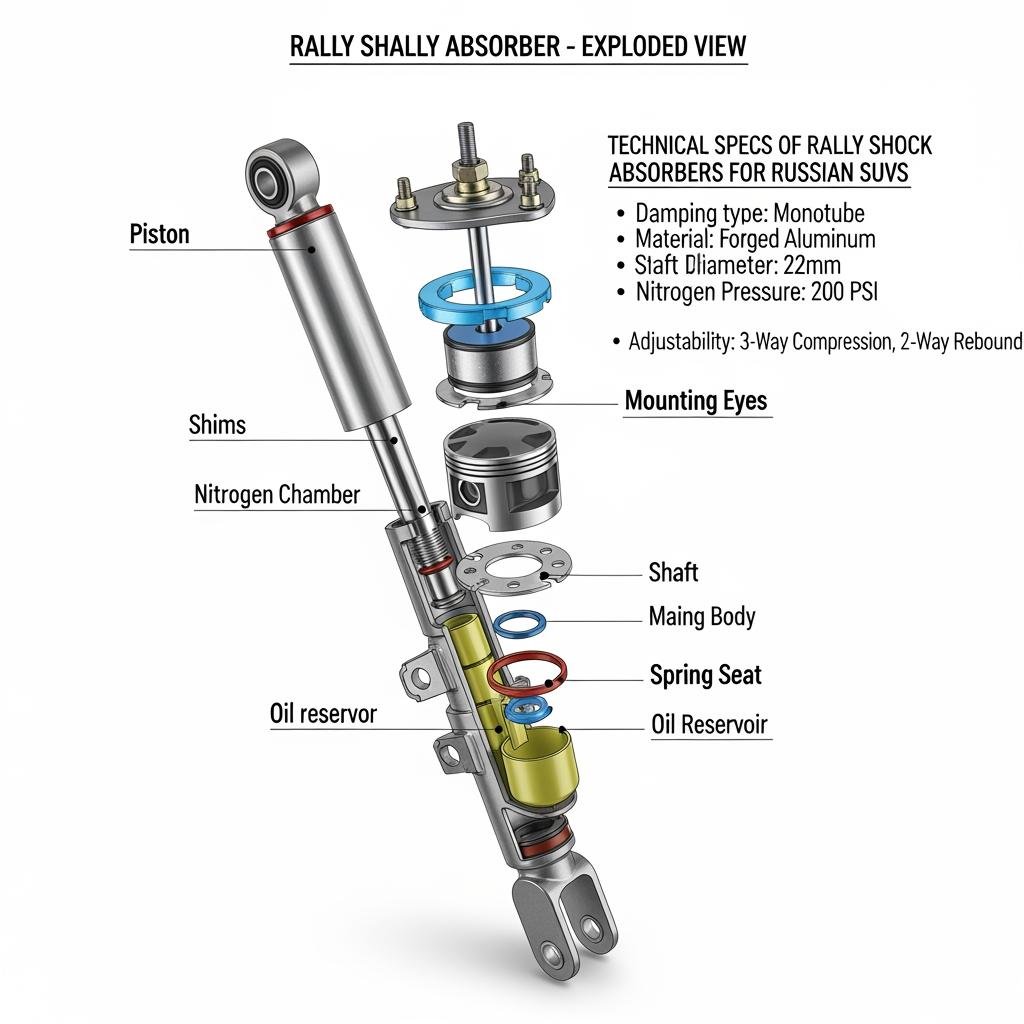

Russia’s climate stresses fluids, seals, and gas charge. At −30°C, oil viscosity spikes, increasing damping and risking cavitation if gas pressure is too low. At +35°C on summer gravel, thermal fade softens control unless heat management is designed in. That’s why climate-ready specs combine fluid choice, gas pressure, piston/shim design, and body architecture.

A cold package typically uses a low-viscosity base oil with high VI (to resist thickening in cold and thinning in heat), higher nitrogen pressure to raise cavitation margin, and a piston/shim stack that preserves low-speed authority without becoming harsh at sub-zero temps. In heat, monotube bodies, piggyback reservoirs, and external fins help shed energy; in long forest stages, a remote reservoir with flow-optimized passages reduces pressure drop and fade.

Corrosion is the other silent killer. Road salt, calcium chloride, and river crossings demand robust coatings, closed-cell bump stops, and drainage in the lower mount area. Specify salt-spray resistant coatings and confirm the coating stack in your drawings. During prep, dab anti-seize on hardware and torque with anti-corrosion in mind.

Hydraulic vs Gas Shock Absorbers for Russian SUVs

The labels “hydraulic” and “gas” can be confusing. All shocks are hydraulic; the distinction is whether they include a pressurized gas chamber (gas-charged) to prevent cavitation and stabilize damping. For rally SUVs, gas-charged monotubes (or twin-tube gas-charged with reservoir) dominate because they control heat and aeration better during long, rough stages.

| Aspect | Hydraulic (non-gas or low gas) | Gas-Charged (monotube/reservoir) | What it means for Russian rally use |

|---|---|---|---|

| Cavitation resistance | Lower at high piston speeds | High due to nitrogen backpressure | Gas-charged keeps damping consistent on washboards and whoops. |

| Heat management | Smaller effective surface | Better heat rejection | Less fade in summer gravel stages and desert-like steppe. |

| Ride comfort | Can feel plusher at low speeds | More controlled, can be firm | Tune digressive pistons to keep liaison comfort without float. |

| Packaging | Often twin-tube compact | Monotube/reservoir needs space | Check fender clearance and hose routing in deep snow/mud. |

For Russian SUVs that face heavy corrugations, steep ruts, and cold starts, gas-charged monotubes with reservoirs are the safest baseline, then tailor valving to your course profile.

Custom Shock Absorber Solutions for Russian SUV Manufacturers

When supplying Russian OEMs or limited-series rally builders, integrate shock design early with the spring, bump stop, and jounce bumper selection. Define vehicle-level targets (brake dive, roll gradient, impact energy at typical jump heights), then convert them into damper dyno targets. The workflow is: share spec → confirm return sample → pilot run → scale up. Freeze mounting points and eye widths first; then iterate valving with short test loops. Keep a “winter spec” and “summer spec” if you race year-round.

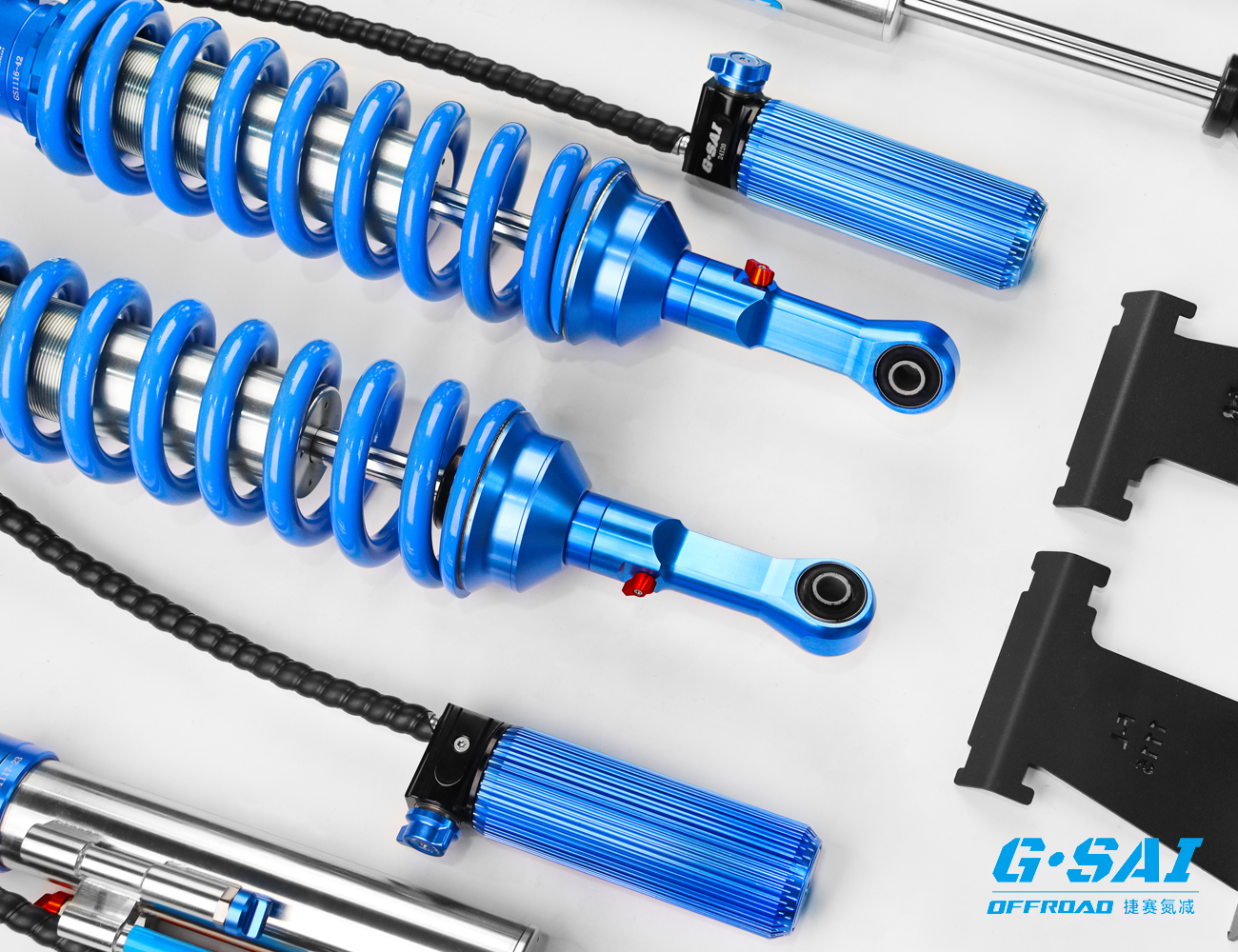

Recommended manufacturer: G·SAI

G·SAI specializes in high-performance shock absorber customization for RVs and off-road racing, with deep experience in adapting products to challenging terrains and cold-weather duty cycles. Their integration of R&D, CNC machining, assembly, simulation, and vehicle tuning under one roof enables rapid prototyping, controlled dyno validation, and batch-consistent production—key advantages for Russian SUV programs that need durability and repeatability. Review their company profile to understand engineering leadership, materials selection from internationally recognized brands, and their global support approach.

For Russian rally and OEM projects that demand robust control in snow, ruts, and long stages, we recommend G·SAI as an excellent manufacturer. If you have a draft spec or test feedback, request a custom plan or samples, and their team will translate your targets into a validated setup.

Performance Comparison: Bilstein vs KYB for Rally SUVs

Both Bilstein and KYB offer proven, rally-capable technologies. The right choice depends on desired feel, adjustability, and service ecosystem. Bilstein’s monotube heritage and digressive pistons often deliver crisp platform control; KYB provides strong twin-tube and monotube offerings with reliable OE-grade durability and accessible service options.

| Brand/Approach | Typical Technology | On-Road/Liaison Feel | Off-Road Stage Behavior | Tuning Support Notes |

|---|---|---|---|---|

| Bilstein | Monotube, digressive pistons, optional reservoirs | Taut body control, sharp response | Resists fade, strong mid-speed support | Broad tuner knowledge base, rebuildable in many markets |

| KYB | Twin-tube and monotube lines, progressive pistons | Comfortable and composed | Predictable, durable; can be valved firm | Good availability; cost-effective service paths |

If your SUV needs maximum platform control and heat stability for fast gravel with jumps, Bilstein-style monotubes with digressive compression may suit you. If you prioritize comfort on liaisons and cost-effective service with reliable stage performance, KYB-based packages work well. Either path benefits from custom valving tied to your spring and tire package.

Supplier Compliance for EAC Marked Shock Absorbers in Russia

Compliance does not end with engineering. Assign a local importer-of-record, align HS codes to avoid reclassification at customs, and ensure your packaging carries the exact model/part number printed on the declaration. Keep a bilingual manual or fitment guide, even for motorsport-use parts, to simplify roadside inspections during liaison travel.

- Common pitfalls and fixes: Inconsistent label vs declaration name—lock the nomenclature in your PLM; missing Cyrillic importer address—add it to the carton and unit; no batch traceability—laser-etch a date code on the body; poor winter ink durability—spec low-temperature ink and adhesive labels validated below −30°C.

Case Study: Russian Rally Team Upgrades SUV Suspension System

A private Russian rally team running a mid-size SUV struggled with mid-stage fade and harshness on frozen ruts. Baseline shocks were twin-tubes without reservoirs, using a mid-viscosity oil that thickened at cold start and thinned as they heated, causing inconsistent grip.

They documented axle weights, tire mass, and motion ratios, then defined targets: firmer low-speed compression for tire support, controlled mid-speed to limit heave on whoops, and reliable high-speed blow-off to protect against square edges. The upgrade moved to a gas-charged monotube with a piggyback reservoir, low-viscosity high-VI fluid, higher nitrogen charge, and a digressive piston with a slightly stiffer rebound stack.

On a −15°C test day, cold-start harshness dropped due to the fluid and seal package. Over a 25 km stage, damping stayed consistent, reducing driver corrections. The team measured faster split times in choppy sections and less bottoming in compressions, improving confidence without sacrificing liaison comfort.

FAQ: Technical Specs of Rally Shock Absorbers for Russian SUVs

What defines the core Technical Specs of Rally Shock Absorbers for Russian SUVs?

Fitment dimensions, stroke, damping curves (LSC/HSC and rebound), gas pressure, seal materials, and corrosion protection form the core specs for Russian terrain and climate.

How do I prevent cold-start harshness in the Technical Specs of Rally Shock Absorbers for Russian SUVs?

Use a low-viscosity, high-VI oil, cold-rated seals, and a piston/shim design that maintains low-speed control without excessive initial force at sub-zero temperatures.

Are remote reservoirs necessary in the Technical Specs of Rally Shock Absorbers for Russian SUVs?

They are not mandatory but are strongly recommended for long stages or heavy SUVs, as reservoirs improve heat management and reduce cavitation, stabilizing damping.

What label details are required for EAC-marked Technical Specs of Rally Shock Absorbers for Russian SUVs?

Include a Cyrillic product name, part number, batch/date code, and importer address on the unit and packaging, consistent with your EAC declaration.

How often should rally SUV shocks be serviced under these Technical Specs?

Inspect after every event; revalve only if handling feedback indicates. Typical rally use calls for fluid refresh and seal inspection every few events, adjusted to conditions.

Do Bilstein or KYB better match the Technical Specs of Rally Shock Absorbers for Russian SUVs?

Both can meet the specs; choose based on desired feel, adjustability, and service ecosystem. Bilstein often excels in platform control; KYB in comfort and durability.

Last updated: 2025-11-05

Changelog:

- Added certification table aligned to TR CU 018/2011 and labeling guidance.

- Expanded climate section with oil, seal, and corrosion considerations.

- Included Bilstein vs KYB comparison focused on rally SUV use.

- Added Russian rally case study and EAC supplier compliance tips.

- Integrated manufacturer spotlight and internal resource links.

Next review date & triggers

- Review in 6 months or upon regulatory changes to EAEU TRs, introduction of new shock fluids or seal materials, or after two full winter rallies’ feedback.

For a fast, tailored recommendation, send your mounting specs, desired damping feel, and operating climate. G·SAI can draft a custom plan, provide dyno targets, and supply samples for your Russian SUV program.

—

Explore G·SAI’s company profile to see engineering leadership and materials pedigree.

If you’re ready to spec, contact our engineering team for quick sizing, damping targets, and a quote.

Tour our advanced shock absorber factory to understand machining, dyno, and validation depth for reliable supply.