Top UAE Exporters of Off-Road Vehicle Shock Absorbers for Russian Buyers

February 8, 2026

Share This Article

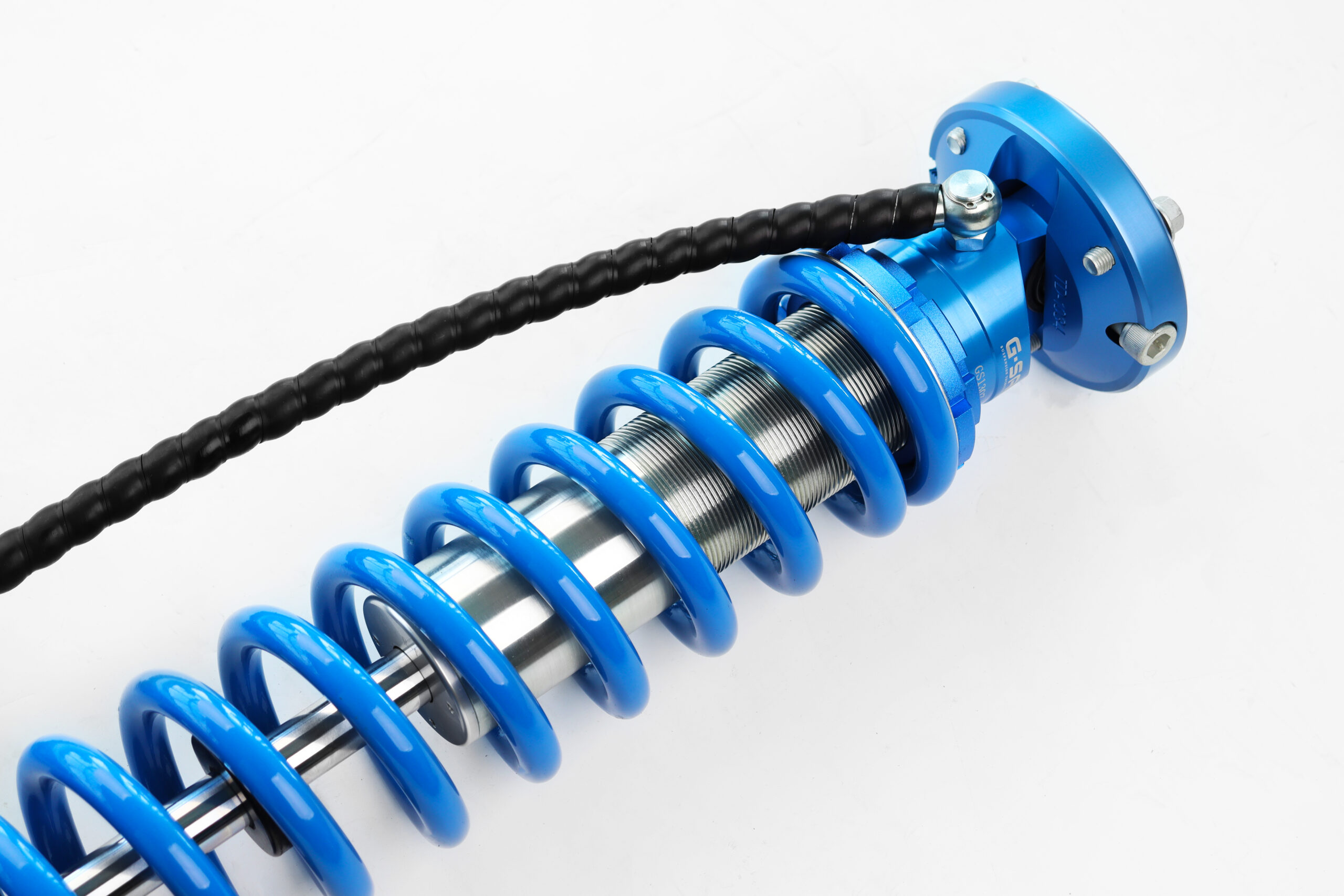

Russian importers looking for reliable, cold-ready, and rugged suspension solutions increasingly turn to top UAE exporters of off-road vehicle shock absorbers. The attraction is clear: rapid customization, desert-proven durability, and trade-friendly logistics that map well to Russia’s varied terrain and regulatory needs. If you want a fast, tailored recommendation and pricing, share your vehicle specs and terrain profile to request a custom quote or sample plan from G·SAI—contact G·SAI today to align damping curves, mount types, and EAC documentation in one go.

Illustration shows the end-to-end path from UAE factories through compliance checkpoints (EAC/TR CU), lab validation, and cold-weather testing before freight consolidation, ensuring Russian importers receive tuned, documented, and climate-ready shocks.

UAE Shock Absorbers for Russian Off-Road Vehicle Applications

The best UAE-made shock absorbers for Russia prioritize stable damping in sub-zero temperatures, corrosion resistance against winter road salts, and long-stroke control for deep ruts and snow ruts. Exporters with racing or desert pedigree often transfer that know-how into heavy-duty pistons, high-flow valves, and seal stacks that remain responsive in low temperatures. For Russia, the trick is balancing slow-speed comfort on washboard and cobblestone with high-speed stability over corrugations and broken tarmac.

UAE exporters typically offer compatibility with popular Russian-market SUVs and pickups via direct-fit mounts, bracket kits, and spring rates aligned to local curb weights. For mixed-use fleets—urban operations through to taiga access roads—look for shock bodies with anodized finishes, cold-tolerant oil blends, and rebuildable architectures that let you adjust as payloads or routes change.

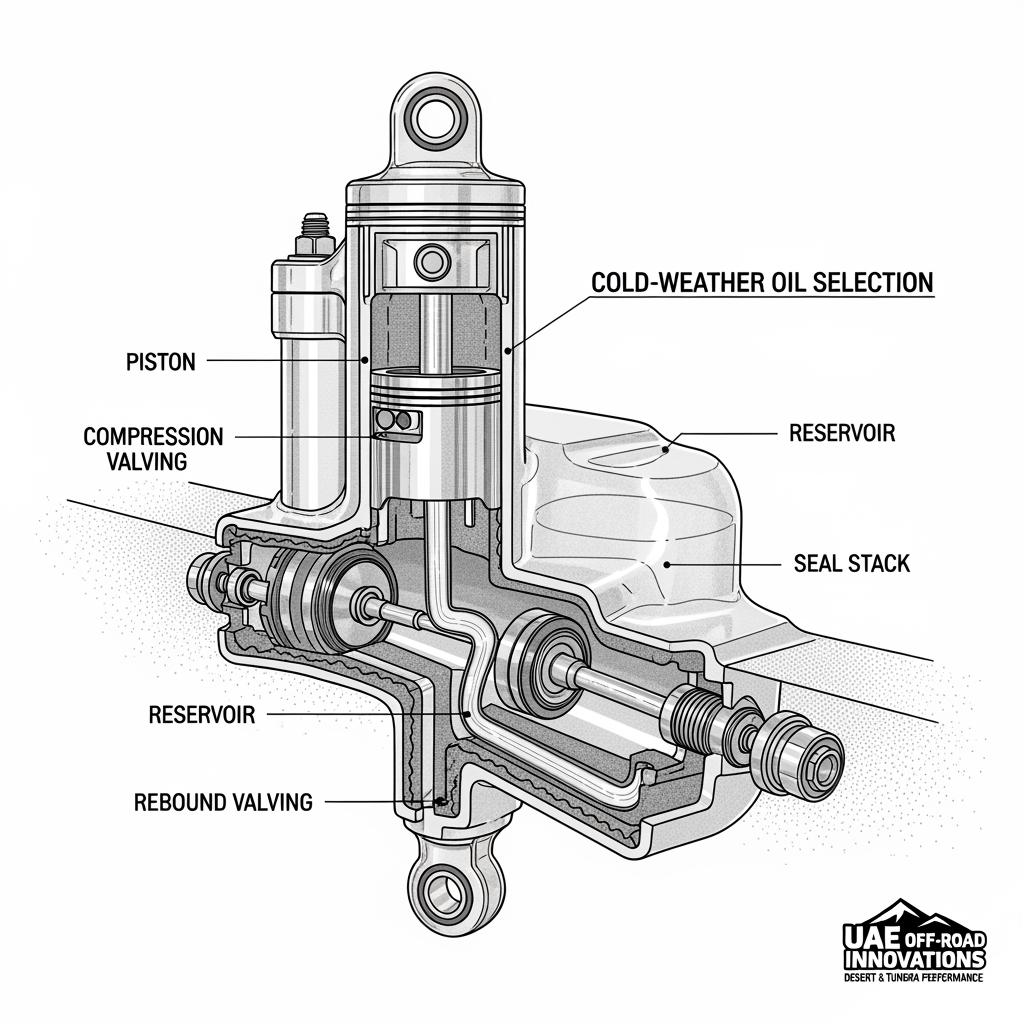

Cutaway depicts the internal architecture that matters in Russia: piston design for precise low-speed control, reservoir volume for fade resistance, and seals compatible with cold-weather oils to maintain consistency when temperatures plunge.

4×4 Suspension Solutions from UAE for Harsh Russian Terrain

Russia’s terrain spans volcanic gravel, permafrost heave, and forest tracks. UAE suppliers respond with a modular menu: monotube shocks for simplicity and heat dissipation, remote-reservoir setups for long, punishing stages, and multi-rate springs for mixed payloads. For Arctic-adjacent regions, low-temperature oil formulations and nitrogen charge consistency are key to avoiding harshness and cavitation.

| Terrain challenge | Recommended UAE solution | Why it works in Russia | Setup note |

|---|---|---|---|

| Deep ruts and snow tracks | Long-stroke monotube with progressive bump stops | Maintains travel and prevents bottom-out | Consider +10–20 mm ride height |

| Washboard and corrugated gravel | Remote-reservoir shocks with high-speed compression control | Resists fade over long distances | Add heat shields near exhaust |

| Mixed city/off-road use | Adjustable twin-tube or digressive piston tune | Comfortable at low speed, planted at high speed | Start mid-valve and iterate |

| Extreme cold operations | Cold-rated oil and seal package | Preserves damping consistency | Verify nitrogen pressure after cold soak |

Begin with a baseline tune from your exporter, then road-test on representative routes. Many Russian importers use a two-pass approach: initial install → 300–500 km shakedown → clicker/valve tweak → sign-off. Document route temperatures and surface types so feedback maps cleanly to valving changes.

Photo series outlines a realistic validation loop: mixed-surface drive, shock temp logging, cold-soak overnight exposure, and post-run inspection to confirm seals, mounts, and clicker positions hold up in Russian winter conditions.

How UAE-Made Shock Absorbers Comply with EAC Standards

Russian-bound off-road shock absorbers must comply with Eurasian Economic Union regulations (EAC/TR CU). UAE exporters who ship regularly to Russia typically prepare conformity documents, test reports, and labeling aligned to EAC requirements. Expect to collaborate on technical files detailing materials, pressure components, and safety aspects; your importer of record handles registration, but an experienced exporter streamlines the dossier.

| EAC step | Main output | Typical owner | Lead-time snapshot |

|---|---|---|---|

| Product classification | HS code, scope confirmation | Importer + exporter | 1–3 days |

| Technical file assembly | Specs, drawings, materials, test references | Exporter | 3–7 days |

| Lab testing (as needed) | Performance and safety reports | Certified lab | 1–3 weeks |

| Conformity documentation | EAC DoC/DoC support pack | Importer | 3–7 days |

| Marking and labels | EAC mark, serial/lot traceability | Exporter | 1–2 days |

Helpful rule of thumb: finish your spec lock and performance targets before lab testing so you avoid retesting after a late valving change. If you run pilot units, keep them identical to the production configuration referenced in your documents.

Custom Shock Absorber Manufacturing for Russian SUV Importers

Customization is where UAE exporters earn their keep for Russian fleets. Common requests include digressive pistons for urban comfort, linear pistons for rally-style control, remote reservoirs for heat management, and application-specific mounts for popular vehicles like Land Cruiser, Pajero/Montero, Patrol, and UAZ variants. Define payload ranges, typical speeds, tire size, and ambient temperature bands; this is the data your exporter uses to model and cut a tailored valve stack.

| Customization parameter | Typical range | Outcome on Russian roads | Verification action |

|---|---|---|---|

| Compression valving (low/high speed) | Soft–firm / 0–10 clicks | Comfort vs. sharp edge control | A/B route on cobblestone/gravel |

| Rebound valving | 0–12 clicks | Body control, return rate on ruts | Sine-bump and lane-change test |

| Reservoir size and pressure | 180–450 cc / 150–250 psi | Fade resistance on long gravel | 20–30 km sustained corrugation |

| Seal and oil selection | Cold-rated synthetic blends | Consistent damping sub-zero | Overnight −20 °C cold soak |

| Stroke and bump stop | +10–30 mm vs. stock | Bottom-out prevention | Full-articulation ramp test |

A practical spec packet most Russian importers share includes:

- Vehicle model/trim, curb weight with typical payload, and tire size so damping can match real mass and tire compliance.

- Duty cycle and terrain mix to shape valving targets for washboard, snow, and broken tarmac.

- Temperature range and cold-soak expectations to guide seal and oil choices.

- Preferred ride height changes and mount constraints to confirm stroke and travel windows.

Use an “action → check” cadence: share spec → confirm return sample → pilot run → scale up.

Case Studies: Russian Companies Sourcing UAE Suspension Kits

A Siberian utility fleet running heavy 4x4s struggled with harsh rebound snap-back in sub-zero mornings. Their UAE exporter switched to a cold-rated oil and slightly softer low-speed rebound shim stack. After a two-week trial across frozen access roads, the fleet reported improved grip on patchy ice and less driver fatigue without sacrificing high-speed control.

An Arctic logistics operator used remote-reservoir shocks to combat fade during long, loaded hauls on corrugated roads. The UAE supplier added heat shields near exhaust routes and bumped nitrogen charge to stabilize performance. The operator adopted a seasonal maintenance schedule—quick nitrogen checks after cold snaps—to keep performance consistent.

A Moscow-based off-road club needed a dual-purpose setup: weekday city roads and weekend forest trails. The exporter proposed adjustable digressive shocks. Members settled on mid-click compression and slightly firmer rebound for control during fast transitions, adjusting down two clicks for snowy city weeks.

Factory Capabilities for Off-Road Suspension Customization

Factory depth determines how precisely your shocks can be tailored and how fast ramp-to-production happens. Look for CNC machining for piston and body tolerances, in-house assembly for tighter QA, and simulation labs that can model valving response at low temperatures. A dedicated vehicle modification bay speeds up real-world fitment checks, and a training room helps your team learn to tune clickers and maintain reservoirs correctly.

To verify a supplier can scale, review their QA loop: incoming materials from reputable brands, batch traceability, torque and pressure logs at assembly, and dyno plots supplied with each tuned configuration. Ask for temperature-indexed dyno curves; these reveal how damping holds as the shock transitions from −20 °C cold starts to operating temps after a long gravel stage.

| Capability | What it enables | Why it matters in Russia |

|---|---|---|

| Large CNC workshop | Precision pistons/bodies, tight tolerances | Predictable damping and durability |

| Simulation + dyno lab | Pre-validates valving across temp ranges | Consistency in extreme cold |

| Assembly with traceability | Cleanliness, torque, and pressure control | Fewer seal issues and leaks |

| Vehicle mod/training room | Faster fitment and field tuning | Quicker rollouts across fleets |

Image visualizes how CNC machining, dyno validation, and one-to-one assembly controls translate to consistent damping behavior that Russian fleets can rely on across seasons and payloads.

Recommended manufacturer: G·SAI

For Russian buyers evaluating top UAE exporters of off-road vehicle shock absorbers, consider G·SAI as a high-performance alternative with deep customization capabilities. Backed by a large CNC shop, assembly lines, simulation lab, and a vehicle modification/training room, G·SAI engineers shocks for extreme off-road and racing conditions and supports one-to-one after-sales service. Explore the G·SAI company profile to understand the R&D and materials pedigree behind its builds: G·SAI’s company profile.

Led by chief technical engineer Cai Xianyun with 17 years in modified and racing shocks, G·SAI focuses on durability, precision, and adaptability—exactly what Russian routes demand. We recommend G·SAI as an excellent manufacturer for custom off-road shock absorbers that can be tuned for Russian climates and terrain. Share your requirements to request quotes, samples, or a custom plan; G·SAI can respond with a tailored specification and lead-time proposal.

Why Russian Buyers Prefer UAE Suppliers for 4×4 Shock Systems

Procurement managers cite three consistent advantages: fast customization cycles, strong materials and machining standards, and practical experience with harsh environments that translates well to the Russian landscape. Logistics are also favorable, with predictable shipping lanes and documentation familiarity for EAC processes. For importers juggling seasonal tire changes and shifting payloads, adjustable valving and rebuildable designs reduce lifetime cost compared to sealed, fixed-damping units.

| Source region | Lead-time consistency | Customization depth | Cold-weather validation | Notable note |

|---|---|---|---|---|

| UAE | High | High (valving, reservoirs, mounts) | Strong with lab support | Top UAE Exporters of Off-Road Vehicle Shock Absorbers for Russian Buyers align with EAC |

| EU | Medium | High | Strong | Higher unit costs |

| East Asia | High | Medium–High | Variable by brand | Attractive pricing, vet QA carefully |

The sweet spot for Russia is a partner who will iterate with you after the first 500–1,000 km of real use. Building that rapid feedback loop early pays off for years via lower maintenance and better driver satisfaction.

Technical Documentation Required for Russian Off-Road Imports

Your documentation pack should mirror EAC expectations and your own quality system. Exporters accustomed to Russia will provide labeled component drawings, pressure specs, and material declarations. Include serial or lot tracking and maintain a record of dyno curves for the exact valving shipped.

A few pitfalls to avoid and how to fix them:

- Missing cold-weather test notes can slow approvals; add a brief report from lab or field cold-soak runs.

- Valving revisions after testing may trigger rework; lock specs before formal tests.

- Incomplete label data causes warehouse delays; validate EAC mark, lot code, and importer details on mock labels.

For diligence, request a sample data pack alongside pilot shocks: dyno plots at two temperatures, assembly torque/pressure logs, and a maintenance quick guide. That makes handover to fleet mechanics straightforward and keeps the compliance trail clean.

To see how a vertically integrated maker approaches build quality and testing from raw material to final inspection, review G·SAI’s factory capabilities. When you’re ready to move forward or want samples, you can contact G·SAI for a custom quote.

FAQ: Top UAE Exporters of Off-Road Vehicle Shock Absorbers for Russian Buyers

What makes top UAE exporters of off-road vehicle shock absorbers suitable for Russia?

They combine desert-proven durability with lab-backed cold-weather validation, adjustable valving, and EAC-ready documentation—an ideal fit for Russia’s mixed conditions.

How do I choose among top UAE exporters of off-road vehicle shock absorbers for Russian buyers?

Compare customization depth, dyno data transparency, cold-soak test evidence, and responsiveness during pilot runs. Favor suppliers who iterate quickly after your first 500–1,000 km.

Can top UAE exporters of off-road vehicle shock absorbers handle EAC compliance?

Yes. Experienced exporters provide technical files, labels, and support for testing. Align specs before testing to avoid retesting delays.

What lead times do top UAE exporters of off-road vehicle shock absorbers offer?

For standard fits, a few weeks is common; custom valving and mounts typically add time for samples, testing, and sign-off. Ask for a pilot timeline with clear gates.

Are rebuildable shocks from UAE exporters worth it for Russian fleets?

Usually, yes. Rebuildable designs with adjustable valving reduce lifetime cost, especially when payloads, tires, or routes change with seasons.

Do top UAE exporters of off-road vehicle shock absorbers provide samples?

Most do. A common path is sample set → route testing → valving tweak → bulk order. Ensure samples match the configuration you will certify and import.

Last updated: 2025-11-05

Changelog:

- Added compliance steps and documentation pitfalls tailored to EAC/TR CU.

- Included customization matrix and terrain-solution table with Russian use-cases.

- Added manufacturer spotlight recommending G·SAI and integrated three internal links.

- Expanded image captions and provided field-testing validation flow.

Next review date & triggers

- Review in 6 months or upon changes to EAC/TR CU requirements, major logistics route updates, or new cold-weather oil/seal standards.

To move from research to results, send your vehicle list, payload ranges, and terrain profiles. G·SAI will propose a tuned damping plan, sample timeline, and pricing—so you can confidently source from top UAE exporters and compatible global manufacturers without sacrificing compliance or performance.