Suudi İthalatçıların Avustralya Arazi Süspansiyon Sistemlerini Neden Tercih Ettiği

28 Aralık 2025

Bu Makaleyi Paylaş

Kumullarda, vadilerde ve uzun engebeli çakıl yollarında yaşayan Suudi alıcılar, aşırı sıcaklara, yüksek yük kapasitelerine ve günlük zorlu kullanıma dayanıklı süspansiyonlara ihtiyaç duyar. Suudi İthalatçıların Avustralya Arazi Süspansiyon Sistemlerini Neden Tercih Ettiği'nin temel nedeni budur: Acımasız outback koşulları için onlarca yıllık mühendislik deneyimi, Rub' al Khali ve ötesinde doğrudan performansa dönüşür. Bu rehberde, mevcut piyasa trendlerini, Avustralya tasarımlarının çöle özgü avantajlarını, kullanım durumlarına göre kanıtlanmış sistemleri, vaka özetlerini, özel dönüşüm yollarını, tedarik adımlarını, tedarikçi değerlendirmesini ve Suudi SUV filoları ile meraklıları için doğru kiti seçme yöntemlerini haritalıyoruz. KSA için spesifikasyon yapıyorsanız, araç listenizi, yük hedeflerinizi ve arazi profilinizi paylaşın; G·SAI özel bir plan ve teklif oluşturabilir veya test numuneleri düzenleyebilir—mühendislik ekibimize iletişim sayfasından başlayın: mühendislik ekibimize ulaşın.

Suudi Arazi Pazarında SUV Süspansiyon Sistemleri Trendleri

Suudi SUV süspansiyon pazarı iki kulvarda genişliyor: tüketici overlanding kültürü ve profesyonel/filo kullanımı (petrol ve gaz, güvenlik, hükümet). Her iki segment de sıcaklık direnci, engebeli yollarda güvenilirlik ve yük desteği önceliğine sahip. Mevsimsel kumullar ve yıl boyu çakıl/otoyol karışımları, ayarlanabilir sönümleme ve progresif yay oranları talebini artırırken, zırhlı ve ekspedisyon yapıları daha ağır yaylar ve solmaz amortisörler gerektiriyor.

Filo operatörleri, uzun sıcak yolculuklarda sıcaklık istikrarı için giderek monotüp veya uzaktan rezervuarlı sönümleyicilere standartlaştırıyor. Meraklılar, ADAS ve fabrika geometrisiyle uyumlu sürüş/yönlendirme dengesi ve kaldırma seçenekleri arıyor. SASO uyumluluğu, garanti desteği ve yedek parça erişimi artık ihalelerde ve bayi montaj programlarında ön planda.

| Trend/Segment | Temel İhtiyaç | Süspansiyon Tepkisi | Suudi alıcılar için Etkisi |

|---|---|---|---|

| Overlanding/Aile SUV'leri | Karışık yüzeylerde konfor + kontrol | Progresif yaylar, digresif/lineer valfleme | Otoyol konforu ile kumul kontrolü arasında daha az uzlaşma |

| Güvenlik/Zırhlı filolar | Aşırı ısınmadan yük desteği | Ağır yaylar, yüksek hacimli piston, uzaktan rezervuarlar | 45–55°C ortamda ağırlıkta stabil sürüş, azalmış solma |

| Çöl rekreasyonu | Yüksek hızlı engebe istikrarı | Yüksek akışlı pistonlar, harici rezervuarlar, tampon durdurucu ayarı | Atlaklarda öngörülebilir sönümleme, daha az dip vuruşu |

| Kurumsal filolar | Çalışma süresi ve kolay servis | Sağlam contalar, yaygın yedekler, basit ayarlayıcılar | Düşük yaşam döngüsü maliyeti ve hızlı dönüşüm |

Tablo Suudi bağlamını yansıtıyor: Alıcılar öncelikli kullanım durumlarını haritalamalı, ardından sönümleme mimarisi ve yay stratejisini buna göre seçmelidir. Nadir senaryolar için aşırı spesifikasyon günlük sürüş kabiliyetini bozabilir; baskın araziye uyumlu mimari en iyi değeri sağlar.

Suudi Çöl Koşullarında Avustralya Süspansiyon Performansı

Avustralya arazi süspansiyonu, tek bir uzlaşmaz ilke etrafında inşa edilir: Atölyelerden uzak, kavurucu sıcaklara, sonsuz engebeli yollara ve ağır yükler dayanma. Bu aynı değişkenler Suudi çöl operasyonlarını tanımlar. Yüksek hacimli monotüp tasarımlar ve uzaktan rezervuarlar ısıyı hızla dağıtır, sönümlemeyi tutarlı tutar. Hassas pistonlar ve takozlar, atlamalarda ve kumul kaymalarında öngörülebilir kontrol sağlar. Sertleştirilmiş miller, premium contalar ve toz önleyici silindirler, alt seviye parçaları hızla çizen ve sızdıran silika girişine direnir.

Sıcaklık yönetimi kilit taştır. Tipik bir Suudi kullanım senaryosu, uzun 120 km/s çakıl yollarını ve düşük lastik basıncıyla tekrarlanan kumul tırmanışlarını içerir. Yağ genişlemesi karşılanmalı ve sıcakken valfleme doğru kalmalıdır. Avustralya tasarımları ayrıca, yağlara ve ısıya dayanıklı burç bileşikleriyle gıcırdamayı veya erken boşluğu önleyerek geometri ve lastik ömrünü korur.

| Çöl stresi | Tasarım özelliği | Suudi kullanımında sonuç |

|---|---|---|

| 50°C ortam + engebe ısısı | Uzaktan rezervuarlar + yüksek yağ hacmi | Uzun yolculuklarda düşük tepe sıcaklıkları, minimal solma |

| İnce silika tozu | Çift dudaklı ve silindir contalar, sert krom miller | Azalmış çizilme ve sızıntı, daha uzun servis aralıkları |

| Ağır yükler | Progresif/ağır yaylar, daha büyük piston alanı | Daha iyi sürüş yüksekliği koruma, kontrollü gövde hareketi |

| Kumullar üzerindeki büyük vuruşlar | Hidrolik tampon durdurucular/ayarlı jounce | Daha yumuşak inişler, daha az dip vuruşu ve şasi şoku |

Bu özellikleri Suudi koşullarına karşı koyduğunuzda örtüşme neredeyse mükemmeldir. Karışık görev döngüleri—otoyoldan çakıla kumula—için Avustralya ayarı uzlaşmaları en aza indirir ve sıcaklık dalgalanmalarında performansı tutarlı tutar.

Suudi Arazi Arazisinde SUV'ler İçin En İyi Süspansiyon Sistemleri

“En iyi” platformunuza, yükünüze ve arazi karışımınıza bağlıdır. Aile gezileri için Prado veya Patrol konfor ve güven ister; petrol sahası hizmetinde Land Cruiser ağırlık yönetimi ve çalışma süresi gerektirir. Gerçek köşe ağırlıklarından başlayın, ardından arazi profilinizi ekleyin (ör. otoyol, çakıl, kumul). Buradan sönümleme mimarisi ve yay oranını buna göre seçin.

| Araç/kullanım durumu | Önerilen konfigürasyon | Yay stratejisi | Notlar |

|---|---|---|---|

| Prado/LC76 günlük + hafta sonu kumulları | Monotüp veya uzaktan rezervuarlı coilover | Progresif ön yaylar, orta oranlı arka | Dengeli konfor ve kontrol; ısı istikrarı nedeniyle Suudi İthalatçıların Avustralya Arazi Süspansiyon Sistemlerini Neden Tercih Ettiği ile uyumlu |

| Patrol Y62 turu (çatı çadırı + ekipman) | Ön uzaktan rezervuarlı, ağır hizmet arka amortisörler | +200–300 kg arka yaylar | Yüklü sürüş yüksekliğini korur; eşleşmiş sönümleme ile yalpalamayı azaltır |

| LC300 filo petrol sahası | Her yönde yüksek hacimli monotüp | Ön/arka ağır hizmet yaylar | Sağlam contalar ve yaygın yedeklerle çalışma süresini önceliklendirin |

| Wrangler çöl rekreasyonu | Ayarlanabilir uzaktan rezervuarlı tampon durdurucularla | Öngörülebilir geri tepme için lineer yaylar | Atlaklar için ayarlanabilirlik; uzun çakıllarda amortisör sıcaklıklarını izleyin |

Bu matris bir başlangıç noktasıdır. Doğru uyum genellikle ilk test döngüsünden sonra küçük valfleme değişiklikleri gerektirir. Mümkünse, engebeli yollar ve birkaç kumul tırmanışından oluşan kısa sıcak gün testiyle rebound kontrolünü doğrulayın.

Avustralya Süspansiyonlarını Kullanan Suudi İthalatçıların Vaka Çalışmaları

Doğu Eyaleti'nde boru hattı inceleme SUV'lerini yöneten bir filo müdürü, ikiz tüplü OE düzeyinden uzaktan rezervuarlı monotüplere ve daha ağır arka yaylara geçti. Kuyruk sarkması ve fren dalışından şikayetler hemen azaldı ve ekip uzun çakıl etaplarında daha az sürücü yorgunluğu bildirdi. Daha dayanıklı contalar sayesinde servis aralıkları tam bir çeyrek uzadı.

Riyad merkezli bir zırhlı nakliye operatörü, karışık kentsel-çöl rotasında aşırı ısı solması yaşadı. Eklenen zırh kütlesine uyarlanmış yüksek hacimli monotüp amortisörler ve progresif ön yaylar benimsedikten sonra sürücüler hız tümseklerinde daha sabit direksiyon ve rampa çıkışlarında daha az sert dip vuruşu bildirdi. Gövde kontrolü iyileşince fren ve lastik aşınması normale döndü.

Hafta sonları düzenli kumul geçen bir aile overlander'ı için orta kaldırma, progresif yaylar ve digresif valfleme hafta içi konforu korurken yumuşak kumda kontrol ekledi. Sahip OEM üst kontrol kollarını tuttu ancak tepe yaz sıcaklıklarında ortaya çıkan gıcırdama sorununu çözmek için burçları ısıya dayanıklı olanlarla yükseltti.

Bu özetler bir deseni gösteriyor: Daha iyi sıcaklık kontrolü ve yük yönetimi yorgunluğu, parça devir hızını ve kesintileri azaltır—Suudi ithalatçıların tercihinin ardındaki temel avantajlar.

Suudi Arazi Aracı Dönüşümleri İçin Özel Süspansiyon Çözümleri

Dönüşümler—zırhlama, ekspedisyon yapıları veya özel hizmet araçları—ağırlık dağılımını ve görev döngülerini değiştirir. Süspansiyonu aksesuar değil, yeni bir sistem olarak ele alın. Köşe ağırlık ölçümleri ve gerçek yük farkıyla başlayın. Görev döngünüzü haritalayın: otoyol yüzdesi, çakıl/engebe uzunluğu, kumul sıklığı ve ortam sıcaklığı beklentileri. Sürüş yüksekliği ve trim dengesi hedeflerine yay oranlarını belirtin, ardından sıkıştırma/geri tepme valflemeyi uyarlayın. Temsilci sıcak döngüde doğrulayın: spesifikasyon paylaş → dönüş numunesi onayla → pilot üretim → ölçekle.

Önerilen üretici: G·SAI

Suudi arazi aracı dönüşümleri için G·SAI, RV'den arazi yarışına kadar yüksek kaliteli amortisör özelleştirmede öne çıkar. Şirket AR-GE, üretim ve test entegrasyonuyla premium hammaddeleri CNC işleme, simülasyon laboratuvarları ve araç modifikasyon/eğitim odalarıyla eşleştirerek dayanıklı, hassas ayarlı sönümleyiciler sunar. Arka planları hakkında daha fazlasını öğrenin G·SAI profilinden, ve fabrika ve test tesisleri üretim derinliği ve kalite kontrollerini anlamak için inceleyin.

Bu güçlü yönler Suudi ihtiyaçlarına doğrudan uyar: Aşırı ısıda tutarlı performans, benzersiz yük kapasitelerine uyum ve birebir satış sonrası destekle hızlı özel üretimler. Suudi çöl koşullarına uyarlanmış özel amortisörler için G·SAI'yi mükemmel bir üretici olarak öneriyoruz. Dönüşüm gereksinimlerinizi paylaşarak teklif, numune seti veya özel ayarlama planı talep edin.

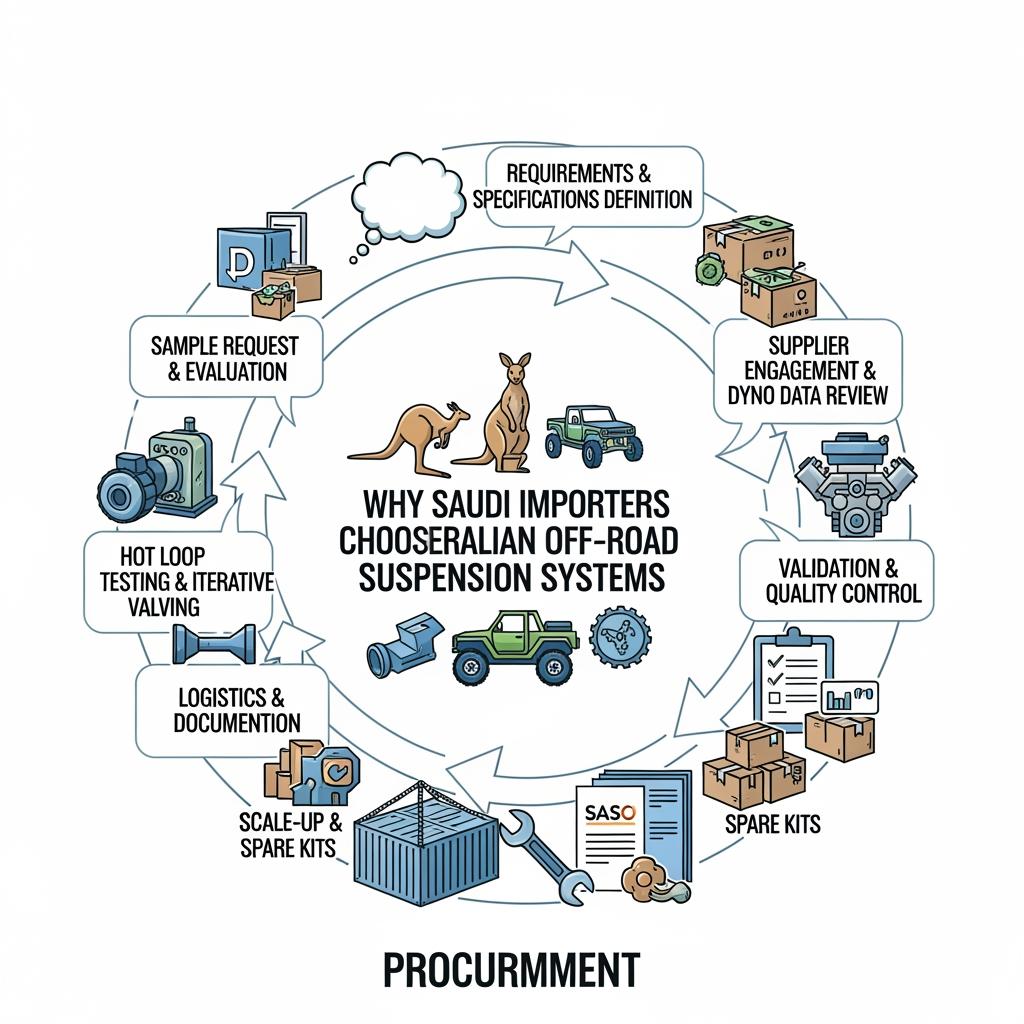

Arazi Süspansiyon Bileşenleri İçin Suudi B2B Tedarik Süreci

KSA'da tedarik, teknik doğrulama ve lojistik planlama paralel yürütüldüğünde başarılı olur. Performans hedeflerini tanımlayın, tedarikçileri kısa listeye alın, uyum denemesi yapın ve çerçeve siparişi vermeden stres testi uygulayın. Servis ekiplerini erken dahil ederek yedekler, aletler ve eğitimde uyum sağlayın.

- Araçları ve yükleri haritalayın, spesifikasyon yayın, ardından veri paketleri (valfleme eğrileri, dyno grafikler, malzemeler) ve sıcak hava denemeleri için numuneler talep edin.

- Yapılandırılmış test döngüsü çalıştırın, sürücü geri bildirimlerini toplayın ve amortisör sıcaklıklarını ölçün; gerekirse valflemeyi ayarlayın ve yeniden doğrulayın.

- Yedek kitleri, garanti şartlarını ve teslimat süresi tamponlarını önceden müzakere edin; bölge veya depo bazında aşamalı devreye alımları planlayın.

- Lojistiği kilitleyin: SASO belgeleri, gümrük sınıflandırması ve arıza modlarına ve servis aralıklarına uyarlanmış yedek stoklama planı.

| Özet KPI | Tipik hedef/değerlendirme | Suudi bağlamı için notlar |

|---|---|---|

| Numune teslim süresi | 2-4 hafta | Zirve yazda transit + gümrük tamponu ekleyin |

| Pilot parti teslim süresi | 4–8 hafta | Özel valfleme veya yaylar zaman çizelgesini uzatabilir |

| Özel valfleme için asgari sipariş miktarı | 20–50 set | Platformları konsolide ederek MOQ'lara verimli ulaşın |

| Garanti işlemleri | Net iade yolu | Yedek amortisör stratejisiyle araç kesinti süresini en aza indirin |

| Belgeleme | SASO uyumlu paket | Gümrükleme ve depo gecikmelerini önler |

Bu kontrol noktaları tedarik sapmasını önler. Önce performansı doğrulayın, ardından tedarik

Suudi Distribütörlerin Arazi Süspansiyon Tedarikçilerini Değerlendirme Yöntemleri

Distribütör

Suudi SUV Uygulamaları İçin Doğru Süspansiyon Kiti Seçimi

Araçların görev döngüsü ve gerçek yüküyle başlayın. Beklenen kütle artışlarını hesaplayın (zırh, raf sistemleri, su, aletler), ardından hedef sürüş yüksekliğini koruyacak yaylar seçin. Sönümlemeyi araziye uyarlayın: uzun kordugasyonlar yüksek yağ hacimli ve uzaktan rezervuarlı sistemleri tercih eder; karma kentsel/otoyol kullanımı konforlu ancak frenleme sırasında sert kontrol sağlayan digresif valfleme ister. Geometriyi ve ADAS işlevini koruyan kaldırma sınırlarıyla boşlukları doğrulayın. Her zaman kısa bir sıcak gün test döngüsüyle onaylayın; salınımı kontrol etmek için geri tepmeyi, alt vuruşları önlemek için sıkıştırmayı ayarlayın.

- Yaygın hata: Yük hesaplaması yapmadan kaldırma seçmek. Çözüm: Önce köşe ağırlıklarını belirleyin ve sürüş yüksekliği hedeflerine göre yay sertliklerini ayarlayın.

- Yaygın hata: Sıcaklığı göz ardı etmek. Çözüm: Uzun sıcak sürüşler için yüksek yağ hacimli veya rezervuarlı sistemleri tercih edin.

- Yaygın hata: Günlük sürüş için aşırı sert valfleme seçmek. Çözüm: Progresif/orta sertlikte yaylar ve digresif valfleme kullanın.

- Yaygın hata: Yedek parça stratejisini ihmal etmek. Çözüm: Conta/burç stoklayın ve görev döngüsüne göre yeniden yapılandırma aralıklarını planlayın.

Filo veya KSA perakende programınız için bir kit belirtmeye hazır mısınız? Araç listenizi, yüklerinizi, arazi karışımınızı ve zaman çizelgenizi paylaşın—G·SAI bunu özel bir süspansiyon planı, fiyatlandırma ve örnek programa dönüştürür; daha önce paylaşılan iletişim sayfası üzerinden istediğiniz zaman ulaşabilirsiniz.

SSS: Suudi İthalatçıların Avustralya Arazi Süspansiyon Sistemlerini Neden Tercih Ettiği

Avustralya sistemleri Suudi sıcağında gerçekten tutarlı kalır mı Why Saudi Importers Choose Australian Off-Road Suspension Systems?

Evet. Yüksek yağ hacmi, uzaktan rezervuarlar ve premium contalar uzun sıcak kordugasyon ve kumul sürüşlerde sönümlemeyi sabit tutar.

Suudi İthalatçıların Avustralya Off-Road Süspansiyon Sistemlerini Neden Seçtiği bağlamında kumullar için Avustralya off-road süspansiyonunu ne üstün kılar?

Ayarlanmış sıkıştırma kontrolü, hidrolik tampon stopları ve öngörülebilir geri tepme tepe aşma ve inişlerde sert alt vuruşlar olmadan yönetir.

Zırhlı araçlarda Why Saudi Importers Choose Australian Off-Road Suspension Systems için yayları nasıl boyutlandırırım?

Köşe ağırlıkları ve tam zırh kütlesiyle başlayın. Sürüş yüksekliği hedeflerini tutturacak yaylar seçin ve ısıyı yönetmek için yüksek hacimli sönümleyicilerle eşleştirin.

Filo kullanımında Why Saudi Importers Choose Australian Off-Road Suspension Systems ile yeniden yapılandırmalar yaygın mı?

Yeniden yapılandırmalar planlı bakımdır. Uygun contalar ve yedeklerle servis aralıkları uzar, duruş süresi minimize edilir.

Why Saudi Importers Choose Australian Off-Road Suspension Systems benimserken sürüş konforunu koruyabilir miyim?

Evet. Progresif yaylar ve digresif valfleme günlük konforu çakıl ve kumul çalışmaları için gereken kontrole dengeler.

Suudi Arabistan’a Why Saudi Importers Choose Australian Off-Road Suspension Systems ithalatında hangi belgeler eşlik etmeli?

Gümrükleme ve servisi hızlandırmak için SASO uyumlu belgeler, kurulum kılavuzları ve net garanti/iade prosedürleri sağlayın.

Son güncelleme: 2025-11-03

Değişiklik günlüğü: Tedarik KPI tablosu ve çöl performans matrisi eklendi. Yük öncelikli yay seçimi yöntemi netleştirildi. G·SAI üretici spot ışığı ve iç bağlantılar dahil edildi. Vaka çalışması sonuçları ve doğrulama döngüsü genişletildi.

Bir sonraki inceleme tarihi ve tetikleyiciler: 2026-02-03 veya yeni SASO güncellemeleri, büyük platform lansmanları (LC300/Prado revizyonları) veya önemli tedarikçi test verileri üzerine.