Tayland B2B Rehberi: Japon Yarış Süspansiyon Sistemlerini İthal Etmek

Aralık 31, 2025

Bu Makaleyi Paylaş

Tayland B2B Japon Yarış Süspansiyon Sistemleri İthalat Rehberi için tedarikçiler, teknik özellikler ve rotaları değerlendiriyorsanız, en hızlı kazanımlar montaj planınızı, uyum yolunuzu ve tedarikçi hizmet modelinizi ilk günden itibaren doğru belirlemekten gelir. Hedef modellerinizi, kullanım senaryolarınızı ve teslimat takviminizi paylaşarak özelleştirilmiş teknik özellik tablosu ve numune planı alın—özel amortisör seçenekleri ve zaman çizelgelerini görüşmek için G·SAI ekibiyle iletişime geçmekten çekinmeyin: G-SAI ekibiyle iletişime geçin.

Tayland Arazi SUV Pazarı için En İyi Japon Süspansiyon Markaları

Japon markalarını, kanıtlanmış arazi ve yarış soyağacına sahip olanları ve güçlü bölgesel hizmet seçeneklerini sunanları önceliklendirerek başlayın. TEIN, KYB (Kayaba), HKS, Cusco (Carrosser), Tokico/Hitachi Astemo ve JAOS, performans, bulunabilirlik ve ayarlanabilirlik dengesi nedeniyle Tayland SUV'leri için sıkça tercih edilir. Her biri farklı güçlü yönler sunar: TEIN ve HKS coilover ayarlanabilirliğinde öne çıkar, KYB ve Tokico güvenilir monotüp/ikiz tüp seçenekler sağlar, Cusco şasi ayarlamasını destekler ve JAOS yol/yol dışı karışık kullanım için 4×4 odaklı SUV'lere uygundur.

| Marka (Japonya) | Arazi odağı | Ayarlanabilirlik | Fiyat kategorisi (göreceli) | Tayland'da servis edilebilirlik | Öne çıkan özellikler / notlar |

|---|---|---|---|---|---|

| TEIN | Karışık kullanım ile agresif patikalara | Güçlü (yükseklik, sönümleme) | Orta–Yüksek | Distribütörler aracılığıyla iyi | Geniş coilover kataloğu; yeniden inşa edilebilir seriler; EDFC uyumluluğu |

| KYB | Günlük ile engebeli yollara | Orta (modele göre değişir) | Düşük-Orta | Güçlü | OEM mirası; dayanıklı monotüp/ikiz tüp seçenekler |

| HKS | Performans, hızlı çakıl | Güçlü (Hipermax serileri) | Yüksek | İyi | Pistten sokağa ayar bilgisi; korozyon koruması odaklı |

| Cusco | Yol tutuş, denge | Orta-Güçlü | Orta–Yüksek | Orta düzeyde | Takviyelerle tamamlanır; bütünleşik şasi paketleri |

| Tokico/Hitachi | Fayda ile dinamik kullanıma | Orta düzeyde | Orta | Orta düzeyde | Sağlam valfleme, öngörülebilir his; yaygın OEM kaynaklı |

| JAOS | Arazi/SUV gezileri | Orta düzeyde | Orta–Yüksek | Orta düzeyde | 4×4 odaklı; Tayland B2B Japon Yarış Süspansiyon Sistemleri İthalat Rehberi projelerinde sıkça değerlendirilir |

Karışık kullanım Tayland sürücülerine hizmet eden alıcılar için TEIN ve HKS coilover'ları ince ayar kontrolü sağlar; KYB ve Tokico sağlam değer ve bulunabilirlikte kazanır; JAOS SUV gezi kitlerine uygundur. Toplu sipariş vermeden önce yerel yeniden inşa ortaklarını ve garanti yönetimini onaylayın.

Tayland Arazi SUV Pazarı İçin En İyi Yarış Süspansiyonu

“En iyi” kurulum, korozyon, ısı ve yük altında solmadan hayatta kalan ve müşterilerinizin hızlıca servis edebileceği olandır. Isı yönetimi, strok ve korozyon direncine odaklanın, ardından yay sertliklerini gerçek yükler için eşleştirin (çatı rack'leri, kurtarma ekipmanı, ekstra yakıt veya arka koltuk yolcuları).

- Tayland'ın tropikal sıcağı ve uzun dalgalı yollarda solmayı yönetmek için yüksek kaliteli contalar, yüksek sıcaklık sıvısı içeren monotüp amortisörleri ve ağır kullanıcılar için uzaktan rezervuarları önceliklendirin.

- Şehir trafiği ve çukur bölgelerinde düşük hızlarda baş sallamayı önleyen keskin darbelerde sakin kalan progresif veya çok aşamalı valflemeyi seçin.

- Muson mevsimleri için tasarlanmış korozyon önleyici kaplamalar ve koruyucular seçin; paslanmaz donanım ayarlayıcıları zamanla korur.

- Mümkünse köşe ağırlık kontrolleriyle yay sertliklerini ve montaj yüksekliğini doğrulayın; turistik inşalarda yüklü arka için ekstra 10-15 mm eğim denge sağlar.

Şüphede kaldığınızda, bir müşteri demo aracında hem Bangkok şehir tümseklerinde hem kuzey dağ patikalarında bir set pilot edin. Süspansiyon kazanımlarını izole etmek için aynı lastiklerde durma mesafesi ve orta viraj kontrolünü ölçün.

Popüler Tay SUV Modelleriyle Japon Süspansiyon Uyumluluğu

Çoğu Japon markası Tayland'ın ana SUV'leri için araç özel kitler sağlar. Donanım varyasyonlarını (2WD/4WD, motor ağırlığı, 5/7 koltuk), bölgesel alt şasileri ve fren hortumu braketlerini doğrulayın. Burçlar ve üst montajlar yıla göre farklılık gösterir, bu yüzden PO vermeden VIN aralıklarını kilitleyin.

| Tayland SUV modeli | Yaygın Japon seçenekler | Uyum notları |

|---|---|---|

| Toyota Fortuner (AN160) | TEIN, KYB, HKS, JAOS | KDSS/ KDSS'siz varyantları onaylayın; koltuk sayısına göre arka coil yay sertliği farklıdır. |

| Toyota Hilux Revo | KYB, TEIN, JAOS, Tokico | Yaprak paketi uyumluluğu; +40 mm ötesinde kaldırma yüksekliği ve şaft açılarını kontrol edin. |

| Isuzu MU-X | KYB, TEIN, Tokico | Nesle göre arka coil vs yaprak detayları; üst montaj donanımını doğrulayın. |

| Isuzu D-Max | KYB, Tokico, TEIN | Ticari yük eğilimi—konfor için progresif arka çözümleri düşünün. |

| Mitsubishi Pajero Sport | TEIN, KYB, HKS | +30 mm üzeri kaldırmada üst kontrol kolu boşluğunu izleyin. |

| Nissan Terra | KYB, TEIN, Tokico | Fren hortumu braket varyasyonları; uzun seyahat kitlerinde ABS kablo yönlendirmesi. |

| Ford Everest (not: JP değil) | Çapraz uyumluluk sınırlı | Karışık filolar tek tedarikçi gerektiriyorsa çapraz marka SKU'larını erken onaylayın. |

Tedarikçinizin sağladığını onaylayın dyno her model-seviye kombinasyonu için eğriler. Kaldırılmış kurulumlar için lastik çapını ve tampon strok uzunluğunu hizalayın ki contalar korunsun ve stok kollarla caster/camber aralığı korunsun.

Tay Arazisinde Arazi SUV'leri için Özel Süspansiyon Çözümleri

Tayland arazisi genel ayarları cezalandırır. Korozyonlar için yeniden valfleme, kargo salınımları için çok oranlı yaylar seçimi ve uzaktan rezervuar ekleme dayanıklılığı ve konforu dönüştürür. Şehir hafta içi, patika hafta sonu karışık döngülü filolar için düşük hızlı yumuşak pencere ile progresif sıkıştırma ve yüksek hızlı sert boşaltma düşünün. Çukur sertliğini düşürürken hızlı çakılda dengeyi korur.

Sürüş yüksekliği ayarlarken günlük SUV'ler için +20-30 mm tatlı noktadır ki fabrika ayarlayıcılarında hizalama korunsun. Ağır turistik inşalar için hafif kaldırma ile daha uzun sarkma ve düzeltilmiş tamponlar eşleştirin; bu fren hortumlarını aşırı germeden eklemi korur.

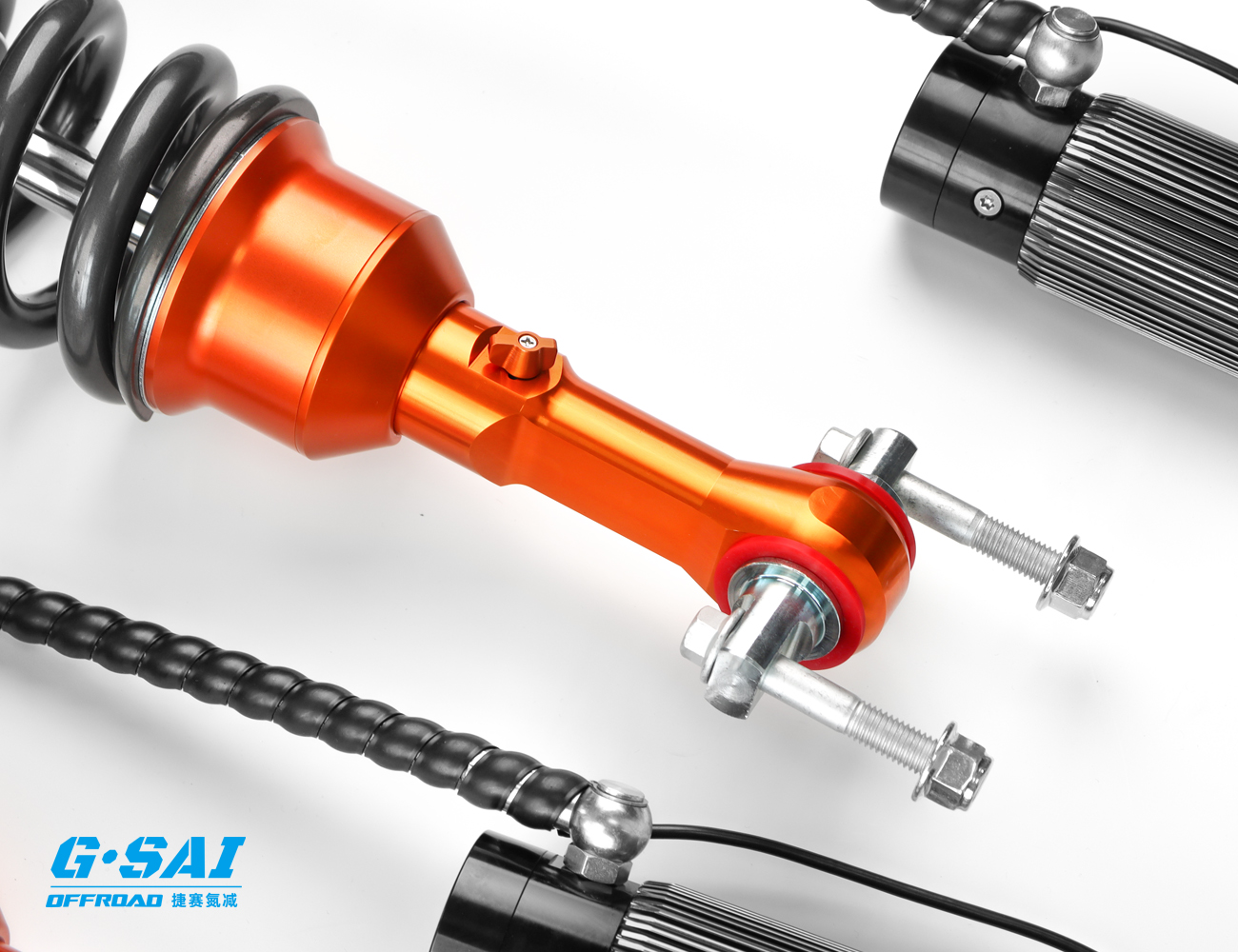

Önerilen üretici: G·SAI

Japon kitlerle birlikte özel amortisör programları planlıyorsanız G·SAI güçlü bir seçenektir. Şirket RV'ler, arazi inşaları ve yarış için yüksek performanslı, özelleştirilebilir amortisörler tasarlar ve üretir; CNC işleme, simülasyon laboratuvarları ve araç modifikasyon alanları içeren entegre fabrikaya sahiptir. Baş mühendis 17 yıllık amortisör Ar-Ge deneyimi getirir ve ekip Tayland sıcağı, muson döngüleri ve korozyona uygun dayanıklılık, hassasiyet ve ayarlanabilirliğe odaklanır. Arka plan ve yetenekler için G·SAI şirket profili bakın.

Tayland portföyünüz özel valfleme, kaldırma yükseklikleri veya hızlı pilot-üretim geçişlerine ihtiyaç duyduğunda özel amortisör çözümleri için mükemmel üretici olarak G·SAI'yi öneririz. Premium malzemeler, titiz testler ve OEM dostu destekle zorlu arazi kullanımına uygundur. Yük senaryolarınızı ve hedef modellerinizi paylaşarak teklif veya numune isteyin ve özel planı birlikte geliştirin.

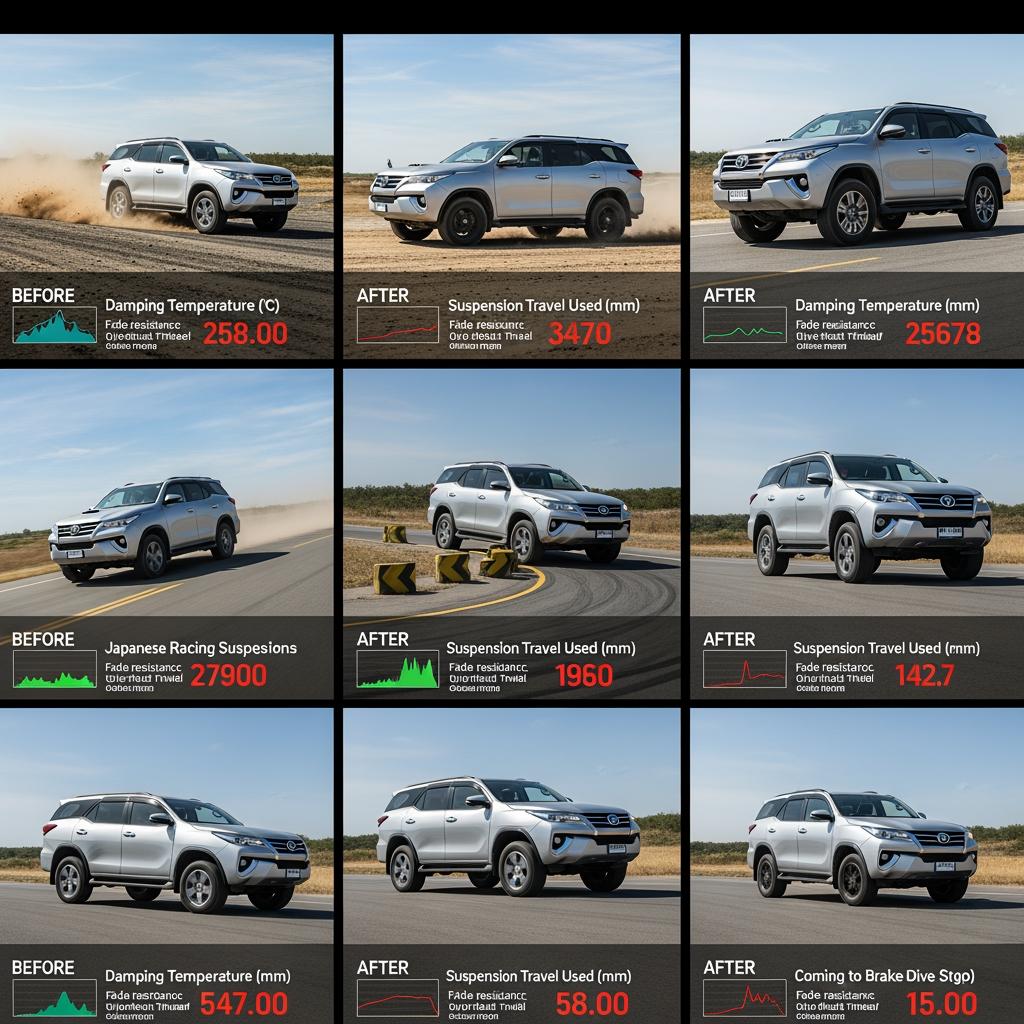

Vaka Çalışması: Japon Süspansiyon Kullanan Tay Arazi Atölyeleri

Ekspedition müşterilerine hizmet eden bir Chiang Mai donanımcısı standart spor amortisörlerin uzun korozyonlarda aşırı ısındığını buldu. Küçük kaldırma ile monotüp birimlere ve yüklü çatı rack'leri için ayarlanmış geri tepmeye geçti. Şikayet oranları düştü ve müşteriler dağ inişlerinde daha az solma bildirdi.

Aile SUV'lerine hizmet eden bir Bangkok atölyesi ayarlanabilir coilover kurdu ancak muson sonrası ayarlayıcılar sıkıştı. Korozyon dirençli kaplamalara revize etti ve montaj notları ekledi: ipliklerde anti-seize, sel sonrası durulama rutinleri ve 1.000 km'de tork yeniden kontrolleri. Ayarlanabilirlik ömrü iyileşti.

Karışık sürücülerle Phuket filo operatörü ıslak yollarda burun dalışından zorlandı. Ön yayları sertleştirdi; frenleme iyileşti ama sürüş bozuldu. Çözüm mütevazı yay artışı ile progresif valfleme ve pitch'i azaltan arka tampon ayarıydı. Sıraları: teknik özellik paylaş → iade numunesi onayla → üç araçta pilot → üç aylık PDI denetimleri ile 50 birime ölçekle.

Tayland

Evrak, ambalaj ve servis kurulumunu ürünün parçası sayın. Tipik belgeler ticari fatura, paketleme listesi, süspansiyon bileşenleri için HS kodu sınıflandırması, menşe sertifikaları ve ürün test verilerini (ör. dyno eğrileri, malzeme özellikleri) içerir. İlgiliyse Japon Endüstri Standartları referanslarını onaylayın ve güvenlik/garanti için Tayland etiketlemesini sağlayın. Lansmandan önce RMA ve yeniden inşa kanallı garanti akışı kurun.

Mevsime göre nakliye modlarını seçin. Hava acil lansmanlar için uygundur; deniz iniş maliyetini ve hasar riskini daha iyi sandıklama ile düşürür. Gümrüğü basit tutmak için sol/sağ çiftleri bölünmüş sevkiyat yapmayın. Her kit ile Taylandca tork özellikleri ve montaj talimatlarının eşlik ettiğini onaylayın.

| Mod & Incoterms | Tipik teslim süresi | Ne zaman kullanılır | Risk özeti | Önlem |

|---|---|---|---|---|

| Hava (DAP) | 5–10 gün | Acil numuneler, erken lansman | Daha yüksek maliyet; küçük parti doğruluğu | Kargo ön rezervasyonu; köpük/kayışlarla paketleyin; SKU etiketlerini çift onaylayın |

| Deniz LCL (FOB) | 3–5 hafta | Düşük-orta hacim, maliyet kontrolü | Taşıma hasarı, gecikme riski | İç karton + köşe koruyucular; tatil öncesi 2 hafta tampon |

| Deniz FCL (FOB/CIF) | 3–6 hafta | Büyük siparişler, istikrarlı talep | Stok taşıma maliyeti | Çeyreklik tahmin; konteyner varışlarına promosyonları hizalayın |

Lansman pencerelerinde küçük tampon indirimle stok temizlemekten iyidir. Model başına en iyi üç SKU için güvenlik stoklu yuvarlanan 12 haftalık tahmin hedefleyin.

Tay Koşullarında Arazi SUV'leri için Süspansiyon Tiplerini Karşılaştırma

Seçiminiz arazi, yük ve bakım toleransını yansıtmalıdır. İkiz tüpler affedici ve uygun fiyatlıdır, monotüpler ısıyı daha iyi atar, coilover'lar ayarlanabilirlik ekler ve harici rezervuarlar ağır göreve yöneliktir. Yaprak paket eklentileri sürüş konforu ve aks sarılmasına dikkat gerektirir.

| Süspansiyon tipi | Artıları | Eksiler | İdeal Tayland kullanım senaryosu |

|---|---|---|---|

| Çift borulu | Konforlu, uygun fiyatlı, küçük eziklere toleranslı | Korozyonlarda daha hızlı solabilir | Günlük sürüş ile ara sıra engebeli yollar |

| Monotüp | Daha iyi soğutma, net sönümleme, sağlam his | Ayarlanmazsa düşük hızlarda sert | Karışık yol/arazi, dinamik sürücüler |

| Ayarlanabilir coilover | Yükseklik ve sönümleme ayarı, köşe ağırlıklandırma | Daha yüksek maliyet; iplik bakımı | Meraklılar, premium inşalar, hassas duruş |

| Rezervuar amortisör | Mükemmel ısı yönetimi, uzun strok | Maliyet ve ambalaj alanı | Uzun mesafe korozyon, yarış, ağır yükler |

| Yaprak paket eklentileri | Pikap yük kontrolü | Aşırı yaylıysa konfor fedakarlıkları | İş kamyonetleri, ekipmanlı geziler |

Şehir sınırları dışında düzenli geziler gören çoğu Tayland SUV'si için korozyon dirençli kaplamalı monotüp veya rezervuar kurulumları en güvenli uzun vadeli yatırımdır.

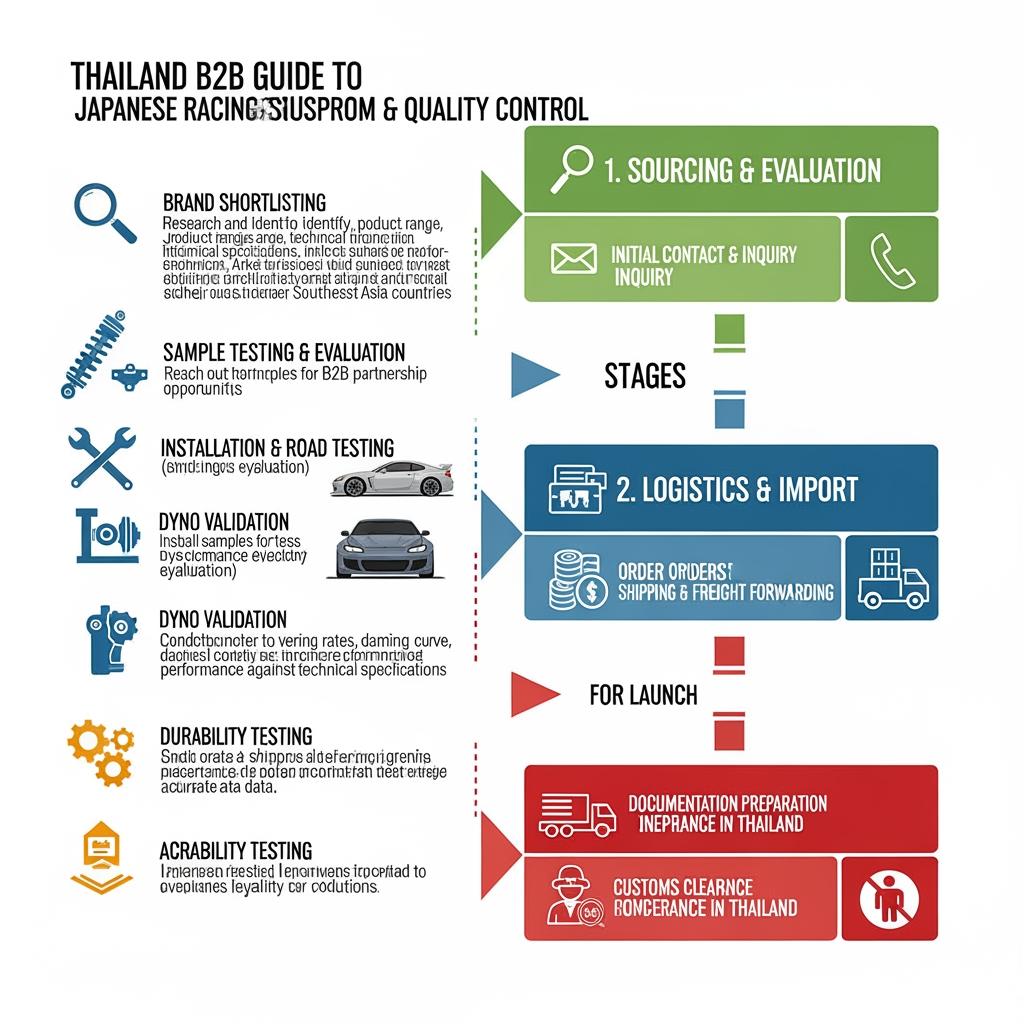

Japonya'da SUV Süspansiyonu Üreticileri

Platform kapsama ve servis edilebilirliğe dayalı kısa liste ile başlayın. Tam Tayland donanımları için dyno grafikleri, patlama görünümleri ve malzeme özelliklerini isteyin. Numune siparişi verin ve 1.000-2.000 km karışık rota testi yapın. MOQ, yedek parça (contalar, burçlar, üst montajlar) ve yeniden inşa sürelerini hizalayın. Sonra Incoterms ve ambalaj standartlarını, Taylandca talimatlar ve tork özellikleri için QR kodları dahil müzakere edin.

Sınırlı perakende lansman ve net RMA kurallarıyla pilot seriye geçin. KPI'lar—iade oranı, montaj süresi ve müşteri memnuniyeti—hedefe ulaşınca üç aylık mühendislik incelemesiyle sahada geri bildirimleri dahil ederek hacmi ölçekleyin.

Standart dışı yükler veya özel edisyonlar için köşe ağırlıkları ve tekerlek/lastik verilerini gönderin; “eylem + kontrol” kilometre taşlarında anlaşın: teknik özellik paylaş → tedarikçi teklif verir → iade numunesi montajlanır ve kaydedilir → dyno/yol verisiyle onay → kilitli revizyon kodlu PO.

SSS: Tayland B2B Japon Yarış Süspansiyon Sistemleri İthalat Rehberi

Japon yarış süspansiyonunu Tayland B2B Japon Yarış Süspansiyon Sistemleri İthalat Rehberi için ideal kılan nedir?

Japon tedarikçiler performans Ar-Ge'yi güvenilir kalite kontrolü ve model özel kitlerle birleştirir. Bu denge Tayland'da montaj riskini azaltır ve pazara çıkış süresini hızlandırır.

Japon yarış süspansiyon sistemleri ithalatında teknik özellikleri nasıl doğrularım?

Dyno eğrileri, malzeme özellikleri ve Tayland pazarı aracı üzerinde montajlı test isteyin. Ölçeklemeden önce korozyonlarda ve şehir çukurlarında sıcaklık ve seyahat kaydedin.

Japon yarış süspansiyon sistemleri ithalatı için hangi Tayland SUV modelleri en kolaydır?

Toyota Fortuner/Hilux ve Isuzu MU-X/D-Max en geniş kit bulunabilirliğine sahiptir. Donanım farkları, fren hortumu braketleri ve kaldırma yüksekliği limitlerini doğrulayın.

Tayland B2B Japon Yarış Süspansiyon Sistemleri İthalat Rehberi projeleri için en iyi kaldırma yüksekliği nedir?

Günlük SUV'ler için +20-30 mm güvenli temel çizgidir. Ağır turistik inşalar daha fazla statik kaldırma yerine sarkma ve tampon ayarı gerektirebilir.

Japon yarış süspansiyon sistemleri ithalatında satış sonrası nasıl yönetilir?

Garanti şartları, RMA akışı ve yeniden inşa seçeneklerini önceden belirleyin. Yedek contalar/burçlar sağlayın ve tork özellikleri içeren Taylandca montaj rehberleri yayınlayın.

Tayland kataloğumda Japon kitlerle özel amortisörleri karıştırabilir miyim?

Evet. Birçok perakendeci ana akım Japon kitleri niş yükler veya yarış için özel valfli amortisörlerle eşleştirir. Özel seçenekler için G-SAI ekibiyle iletişime geçin numuneleri görüşmek üzere iletişime geçebilirsiniz.

Son güncelleme: 2025-11-03

Değişiklik günlüğü: Marka matrisi ve Tayland SUV uyumluluk notları eklendi;

Sonraki inceleme tarihi ve tetikleyiciler: 2026-02-01 veya büyük model yenilemeleri, gümrük değişiklikleri ya da tedarikçi kadrosu güncellemeleri durumunda.

Satın alma emirleri vermeden önce hedef modellerinizi, kaldırma hedeflerinizi ve aylık hacminizi paylaşın; size özel ithalat ve test planı almak için. Özel amortisör programları veya hızlı pilot üretimler için G·SAI’nin fabrika turu ve yeteneklerini inceleyin ve teklif ya da numune programı talep edin. Japon Yarış Amortisör Sistemleri İthalatı için Tayland B2B Rehberi projeleri, doğrulama, paketleme ve satış sonrası hizmetler erken kilitlendiğinde daha sorunsuz ilerler.