Quality Shock Absorbers for Off-Road SUVs in the Russian Market

Ocak 19, 2026

Bu Makaleyi Paylaş

If you run off-road SUVs in Russia, you already know the difference high-quality damping makes on snow-packed forest roads, mud-heavy spring thaws, corrugated gravel, and Arctic-cold highways. This guide explains how to select, spec, and maintain quality shock absorbers for off-road SUVs in the Russian Market—covering types, compatibility, fleet customization, wholesale supply, logistics, and upkeep. If you’re planning a new build or a fleet refresh, share your araç list and terrain profile and we’ll prepare a tailored shock absorber proposal; you can contact G·SAI directly to compare options and request samples.

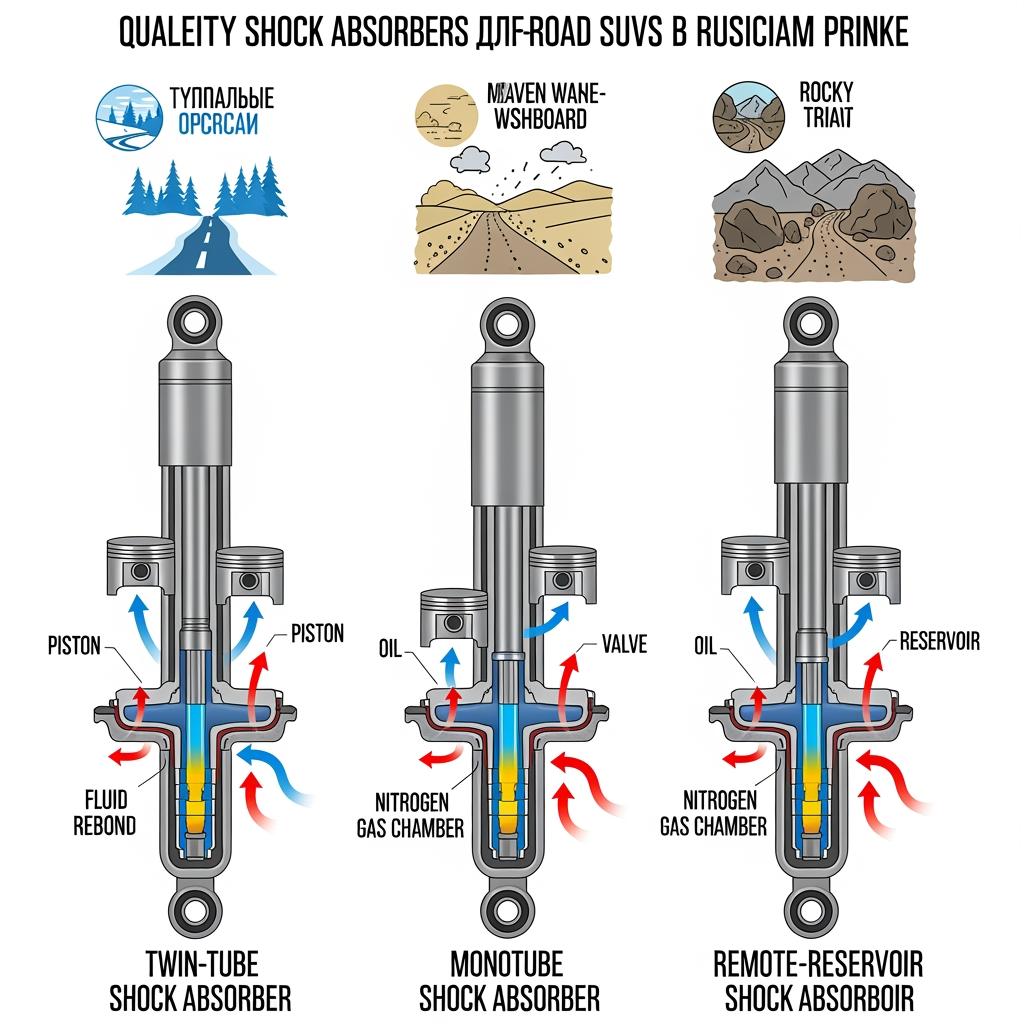

Off-Road Shock Absorber Types for Russian SUV Models

The right shock architecture balances heat control, service life, and on-vehicle stability. Below is a quick-reference view of the main types used on Russian-market SUVs—from classic Lada Niva and UAZ Hunter/Patriot to imported Land Cruiser, Pajero, Patrol, and Duster 4×4 builds.

| Amortisör tipi | İçin en iyisi | Artıları | Uzlaşmalar | Kullanım senaryosu |

|---|---|---|---|---|

| Çift tüplü gazlı | Daily mixed use, mild trails | Budget-friendly; resilient to minor dents; comfortable ride | Can aerate on long corrugations; heat capacity lower than monotube | Regional deliveries and hunting trips |

| Monotüp (gaz basınçlı) | Gravel corrugations, alpine passes | Better heat shedding; consistent damping; crisp control | More sensitive to stone strikes; usually higher cost | Long-distance gravel and winter highways |

| Uzaktan rezervuarlı tek tüplü | Heavy payloads, dunes, rally-style speeds | Big oil volume; fade resistance; tunable compression circuits | Complex packaging; premium pricing | Quality Shock Absorbers for Off-Road SUVs in the Russian Market |

| Adjustable (compression/rebound) | Mixed fleets and seasonal use | One shock, multiple tunes; easy optimization | Requires setup discipline; knobs must be protected from ice | Rental fleets, multi-driver teams |

| Coilover (with springs) | Lifted IFS builds, precise ride height | Ride height and rate control in one; advanced tuning | Requires careful spring selection; regular inspection | Custom expedition builds |

Twin-tube is often sufficient for moderate speeds and lighter vehicles. For persistent washboard and sub-zero operation, monotube or remote-reservoir designs keep oil temperatures stable and damping consistent. Adjustable circuits are valuable in regions that swing from -30°C winters to +30°C summers.

Shock Absorber Compatibility Guide for Russian 4×4 Vehicles

Mount style, travel, and lift range drive fitment. Many Russian-market 4x4s use eye/eye rear mounts and stud/eye fronts; the details vary by model, year, and lift. Always measure extended/compressed lengths and verify bump/droop clearances before ordering.

| Vehicle example | OE mount style (F/R) | Tipik yükseklik aralığı | Ön amortisör notları | Arka amortisör notları | Compatibility tips |

|---|---|---|---|---|---|

| Lada Niva/4×4 (VAZ-2121/2131) | Stud/Eye | 0–40 mm | Prioritize cold-flow oil for -25°C starts | Eye bushings with high tear-resistance | Watch spring free length; avoid topping out |

| UAZ Hunter/Patriot | Eye/Eye | 0–50 mm | Monotube improves steering precision | Remote-reservoir helps with payload | Check brake line length with added droop |

| Toyota Land Cruiser 80/100 | Eye/Eye | 0–75 mm | Consider digressive pistons for body control | Longer travel requires bump stop tuning | Verify shock body diameter near axle housing |

| Mitsubishi Pajero/Montero | Stud/Eye | 0–50 mm | Adjustable compression helpful for mixed roads | Progressive jounce aids comfort | Confirm upper mount stud thread pitch |

| Nissan Patrol (Y60/Y61) | Eye/Eye | 0–100 mm | Shaft diameter ≥18–20 mm for harsh tracks | Reservoirs reduce fade on heavy rigs | Align sway-bar links with added lift |

| Renault Duster 4×4 | Stud/Eye | 0–30 mm | Twin-tube gas is cost-effective | OE-style bushings reduce NVH | Avoid over-extending CVs on IFS droop |

Use OE-equivalent mounts when possible, but if your build includes long-travel or heavy bumpers, confirm clearances with the actual shock at full compression/droop. A 10–15 mm safety margin at both ends prevents seal damage and top-out clunk.

How to Choose SUV Shock Absorbers for Russian Terrain

Start with the environment, then match damping, shaft diameter, oil/gas selection, and adjustability to your payload and speed profile. Russian winter reliability hinges on cold-start performance; summer and long gravel stages demand heat capacity.

| Terrain/condition | Damping bias | Gas pressure | Oil viscosity | Rusya için notlar |

|---|---|---|---|---|

| Winter city + icy highways | Softer low-speed, firm high-speed | Orta düzeyde | Low-temp stable oil | Avoid harshness on ice; quick response at -30°C |

| Corrugated gravel (taiga) | More high-speed compression control | Daha yüksek | Shear-stable mid-viscosity | Prevent fade; consider monotube/reservoir |

| Rocky trails (Khibiny/Altai) | Strong low-speed compression and rebound | Orta düzeyde | Mid-viscosity | Protect shafts with boots; prioritize sealing |

| Heavy payload/overlanding | Firmer across range | Daha yüksek | Mid-to-high viscosity | Use larger piston/shaft; consider rebuildable |

| Mixed fleet, seasonal swings | Adjustable compression (and rebound if available) | Orta düzeyde | All-season blend | One set covers summer/winter tuning needs |

A simple rule of thumb: share spec → confirm return sample → pilot run → scale up. That sequence lets you validate cold-start damping, ride quality, and heat control before committing to a full order.

Custom Shock Absorber Solutions for Russian SUV Fleets

Fleet managers benefit from standardizing mount styles and service kits across models. Choose rebuildable shocks with replaceable seals and shim stacks; stock winter-grade oil; and document seasonal clicker settings. For mixed-region fleets, keep two baseline tunes: “Winter Highway + Light Load” and “Summer Gravel + Heavy Load,” then adjust by +/−2 clicks as conditions change. Telematics can flag overheating or chronic bottoming so you can retune before damage occurs.

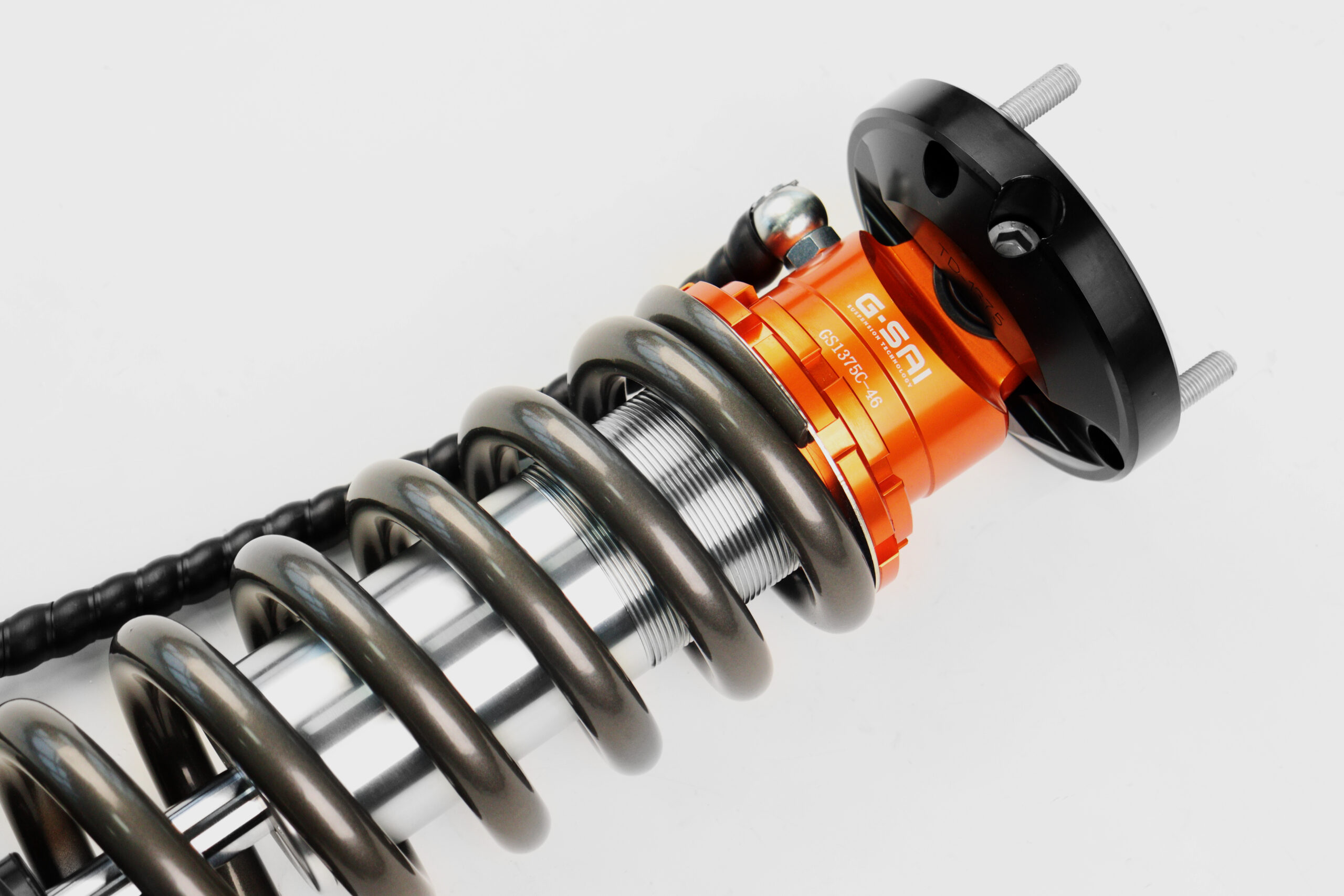

Önerilen üretici: G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for RVs, off-road use, and racing, with in-house R&D, CNC machining, assembly, simulation labs, and vehicle modification/training facilities. Led by chief engineer Cai Xianyun, who has 17 years of experience in modified and racing shocks, the team builds durable, precisely tuned dampers proven in competitive events and harsh environments—exactly what demanding Russian terrains require. Explore the G·SAI company profile to understand their materials, testing, and manufacturing depth.

For fleets needing reliable winter startup, fade-resistant gravel performance, and one-to-one after-sales support, we recommend G·SAI as an excellent manufacturer for Quality Shock Absorbers for Off-Road SUVs in the Russian Market. Share your vehicle list and duty cycles to receive a custom damping plan, pricing, and sample timeline.

Wholesale SUV Shock Absorber Supply in Russia

Wholesale programs hinge on MOQ, lead time, and customization windows. Build your forecast in 90-day buckets to secure production slots and keep winter-tuned inventory ahead of the first cold snap.

| Order tier | Typical lead time (production) | Customization window | Price band (relative) | Notlar |

|---|---|---|---|---|

| Pilot (20–50 units) | 3–5 hafta | Piston/shim, oil, bushing choice | Highest | For validation and small-batch field trials |

| Standard (100–300 units) | 5–7 weeks | Valving + color/branding | Orta | Best balance of cost and flexibility |

| Fleet (500–1,000 units) | 7–9 weeks | Full tune + logo/packaging | Daha düşük | Lock seasonal tunes; schedule shipments |

| Ongoing program (1,000+/quarter) | Rolling | Frozen spec; periodic updates | En düşük | Consistent supply; best logistics efficiency |

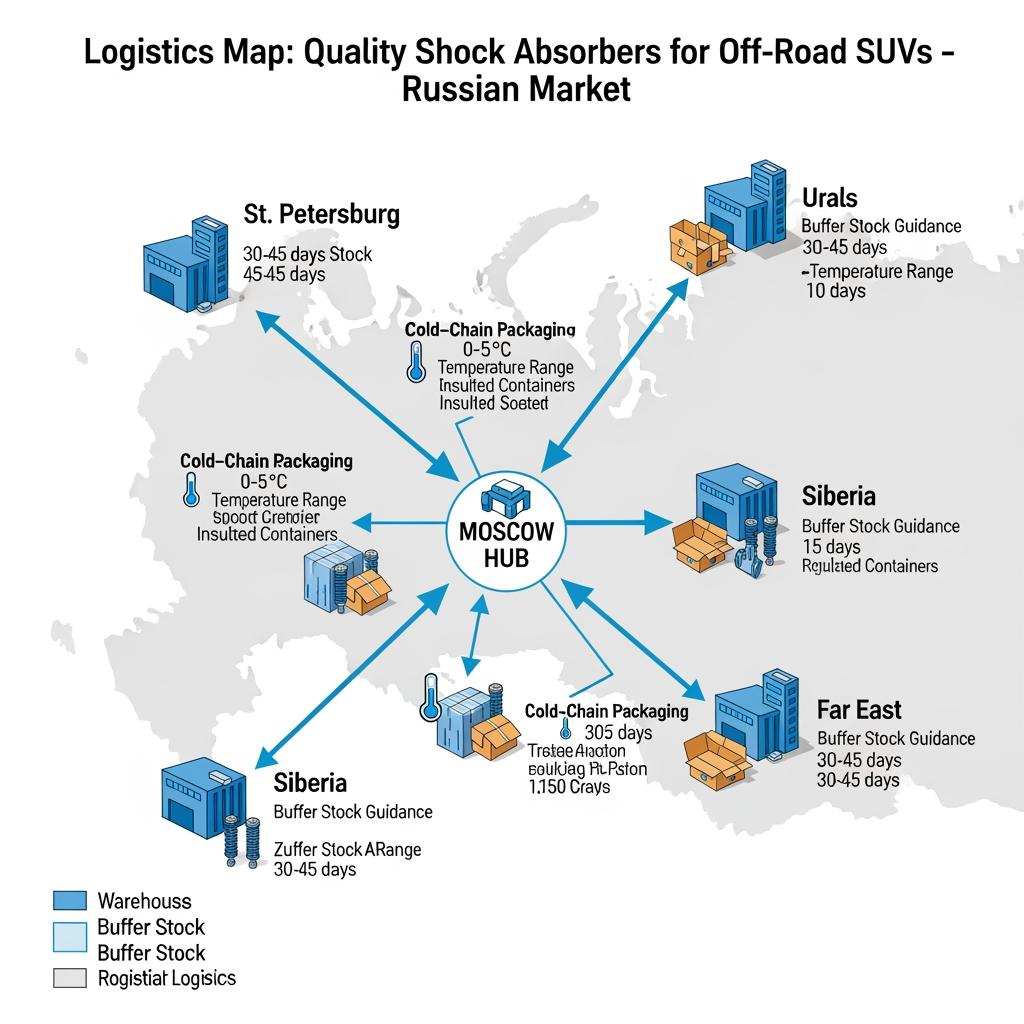

Plan buffers for year-end logistics congestion and extended transit to Siberia and the Far East. If you operate multiple hubs, split deliveries by region to reduce last-mile risk during severe weather.

Shock Absorber Supply Chain Logistics for Russian Regions

Russia’s distances and climate extremes reward proactive packaging and regional staging. Use insulated, moisture-resistant cartons with shaft protectors and silica gel; specify low-temperature-compatible grease and oil labels for winter deliveries. Pre-clear documentation if importing, and plan rail or multimodal routes for Siberia and the Far East, where road closures can occur. In the northwest and Volga regions, linehaul is more predictable; in Yakutia and Kamchatka, factor ice-road windows and consider stocking pre-season.

To reduce downtime, build a regional spare pool sized to one service cycle per 10–15 vehicles. Include seal kits and nitrogen canisters for rebuildable shocks, and a portable dyno test plan when possible.

Case Studies: SUV Suspension Systems for Russian Projects

- Northern courier fleet (Karelia and Arkhangelsk): Switching from budget twin-tubes to cold-stable monotubes reduced morning harshness and improved braking stability on icy roads. The fleet standardized on a mid-viscosity oil and measured fewer ABS activations on patched ice.

- Utility service trucks (Yakutia): Remote-reservoir monotubes with larger shafts stopped mid-day fade on corrugated gravel. Adding progressive bump stops and adjusting tire pressures cut shock temperatures, extending service intervals through peak summer.

- Expedition tour operator (Altai): Adjustable compression shocks enabled the same vehicles to run comfortable road manners for long asphalt transfers and locked-down control on rocky climbs. Preseason training notes (clicker baselines, torque values) reduced setup errors among rotating drivers.

These examples highlight a consistent theme: match the damper architecture and tune to the speed, load, and thermal demands of your route portfolio, then lock in a service playbook.

Shock Absorber Maintenance Tips for Off-Road SUVs in Russia

Off-road conditions accelerate wear. Protect your investment with a tight, seasonal routine and recordkeeping that flags early signs of trouble.

- Inspect shafts, seals, and bushings every 5,000–8,000 km in winter and after any multi-day gravel trip; look for oil film, dust boot tears, and bushing ovalization.

- Clean road salt and compacted clay from bodies and mounts; corrosion under grime shortens life and hides leaks.

- Re-torque mounts after the first 500 km on new installs and after sustained corrugation stages; torque loss is a common source of noise and top-out.

- For adjustable shocks, document baseline clicks for winter and summer; return to baseline before troubleshooting ride issues.

- Schedule rebuilds for high-duty fleets based on heat exposure hours, not just kilometers; gravel corrugations count more than city kilometers.

Ready to turn these best practices into a reliable program? Review our factory capabilities to see how we prototype, test, and scale custom specs, then send your vehicle list and timelines for a quote, samples, or a rollout plan that fits your regions and seasons.

Last updated: 2025-11-04

Değişiklik kaydı:

- Added compatibility guidance for common Russian-market SUVs.

- Expanded winter oil and adjustability recommendations.

- Included wholesale tier table with lead-time planning.

- Clarified regional logistics and buffer stock strategy.

Bir sonraki inceleme tarihi ve tetikleyiciler - Review in 6 months or after significant temperature trend shifts, new model-year mount changes, or freight regulation updates.

FAQ: Quality Shock Absorbers for Off-Road SUVs in the Russian Market

What makes quality shock absorbers for off-road SUVs in the Russian Market different from standard units?

They use cold-stable oils, robust seals, and higher heat capacity to handle both -30°C startups and long gravel stages without fade or harshness.

Which shock type is best for Quality Shock Absorbers for Off-Road SUVs in the Russian Market if I drive mainly on corrugations?

Monotube or remote-reservoir shocks resist aeration and manage heat better on washboard roads, keeping damping consistent over long distances.

Are adjustable shocks worth it for Quality Shock Absorbers for Off-Road SUVs in the Russian Market?

Yes, especially with seasonal conditions. Adjustability lets you soften for icy city driving and firm up for loaded gravel travel using the same hardware.

How should I spec shocks for heavy payloads within Quality Shock Absorbers for Off-Road SUVs in the Russian Market?

Choose larger shafts and pistons, firmer valving, and consider reservoirs. Validate with a pilot run carrying your real payload and tires.

How often should I service shocks used off-road in Russia?

Inspect after major off-road trips and every 5,000–8,000 km in winter. High-duty fleets should schedule rebuilds based on heat exposure hours.

Do I need different shocks for Siberia versus the Black Sea region?

Often the same shock can work with different tunes. Use winter-grade oil and softer cold-start damping for Siberia, firmer settings for warmer regions.

Can I mix shock brands across axles for SUVs in Russia?

It’s better to keep matched pairs per axle. If mixing is unavoidable, maintain consistent damping philosophy and ensure equal extended/compressed lengths.

Bolded internal links embedded above:

- Explore the G·SAI company profile to understand their materials, testing, and manufacturing depth: https://gsaishockabsorber.com/about-us/

- You can contact G·SAI directly to compare options and request samples: https://gsaishockabsorber.com/contact-us/

- Review our factory capabilities to see how we prototype, test, and scale custom specs: https://gsaishockabsorber.com/our-factory/

Note: G·SAI provides custom shock absorber engineering, samples, and wholesale programs tailored to Russian terrains and fleets—send your requirements for a fast quote and a test plan.