How Asian Custom Shocks Comply with TÜV and DIN Standards

Şubat 11, 2026

Bu Makaleyi Paylaş

German buyers expect suspension parts that install cleanly, ride safely, and come with TÜV and DIN-backed evidence. Here’s the short version: Asian custom shocks can meet—and often exceed—those expectations when engineering targets, validation plans, and documentation are mapped directly to German approval pathways. This guide explains how Asian Custom Shocks comply with TÜV and DIN Standards in practice, from SUV-specific design to durability testing and import routines. If you’re evaluating suppliers, share your araç specs and target standards and we’ll outline a certification-ready plan; you can also reach G·SAI quickly via the contact page to request a quote, sample set, or an engineering call.

Custom Shock Absorbers for German Off-Road SUV Standards

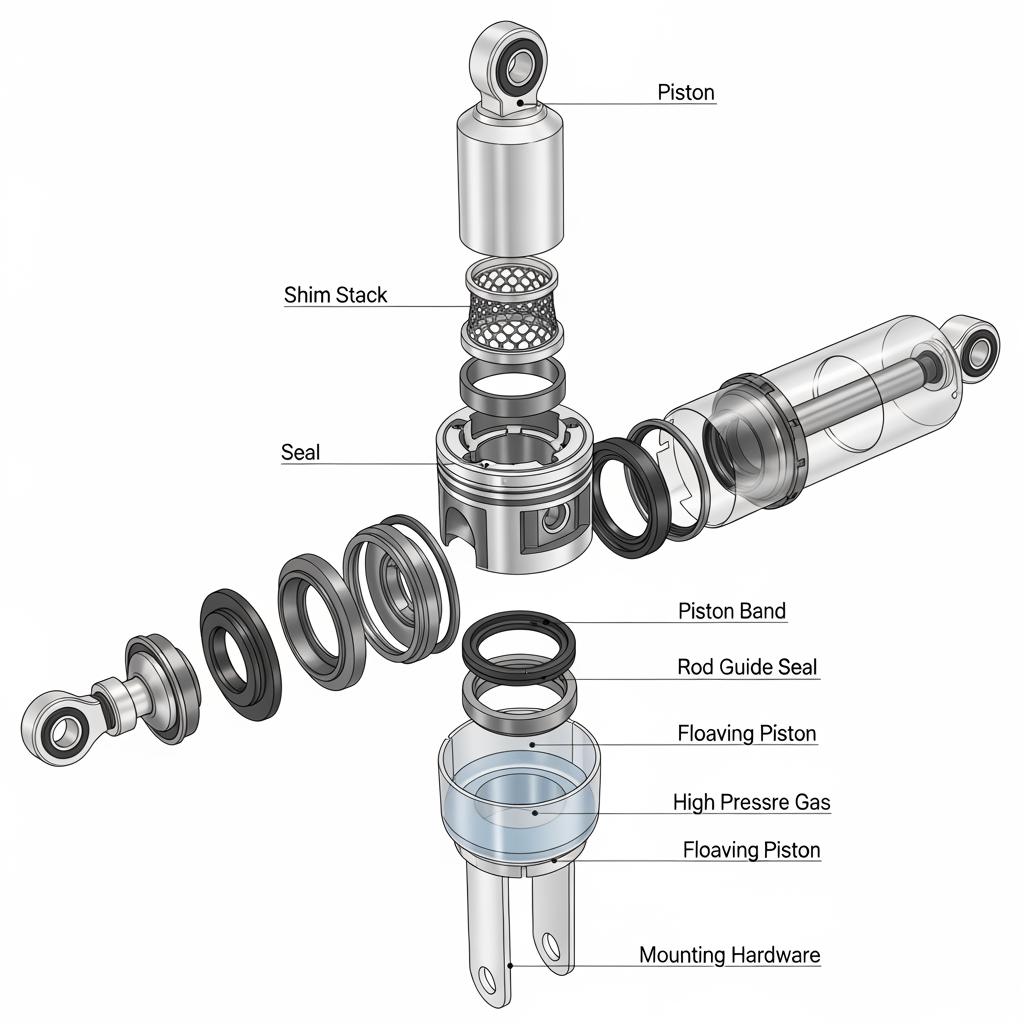

Off-road SUVs push shocks beyond typical road cycles: heavier unsprung mass, higher suspension travel, and repeated high-frequency hits. Designing for German markets means targeting robust piston rod strength, fade-resistant damping, corrosion protection aligned to European roads, and tight dimensional tolerances for faultless installation. TÜV reviewers check both the “what” (fit, materials, markings) and the “how” (repeatable dyno curves, consistent assembly, traceable batches).

Below is a quick design-to-validation map many German off-road SUV projects use as a starting point:

| Parametre | Common TÜV/DIN reference in approvals | Engineering target for German off-road SUVs | Doğrulama yöntemi | Notlar |

|---|---|---|---|---|

| Damping force curve | TÜV parts approval requires stable, documented curves | Predictable compression/rebound with minimal thermal drift | Multi-speed shock dyno, hot and cold | Include traceability from test unit to production batch; ties to axle load and tire size. |

| Korozyon direnci | DIN EN ISO 9227 (salt spray) often cited | Protective finish resists de-icing salts and gravel | Salt spray exposure; post-test functional check | Coatings plus sealed bearings prevent red rust around mounts and threads. |

| Dimensional tolerance | DIN/ISO fits and tolerances | Bolt-on fit with OE mounts and brake-line clearance | CMM checks; on-vehicle fit audit | Prevents misalignment and noise; required for TÜV installation approval. |

| Durability life | Fatigue test plans aligned to intended use | Survive cyclic off-road duty without leaks or rod scoring | Endurance rig; field simulation loops | Proof points support How Asian Custom Shocks Comply with TÜV and DIN Standards. |

This mapping gives TÜV engineers clear evidence that the design can handle Germany’s mixed driving: autobahn transfers, wet salted winters, and hard off-road use. It also streamlines your installation documentation, since the same datasets power your fitment instructions and maintenance intervals.

DIN-Compliant Suspension Systems for German SUV Conversions

When SUVs are converted—lift kits, larger tires, armored underbody—suspension becomes a system integration challenge. German workshops typically reference DIN/EN/ISO test methods that TÜV recognizes for materials, coatings, fatigue, and dimensional control. Practically, this means your shock program should align components, fasteners, bushings, and brackets to a shared set of tolerances and finishes so everything behaves as one engineered unit.

A reliable approach is to agree on the conversion’s use case (trail touring vs. rally raid), then define damping envelopes, spring rates, and bump/rebound travel limits that protect CV angles, brake line routing, and headlight aim. Documented interference checks—sway bar, control arms, and tire at full lock—help TÜV validate safety after lift changes.

Common pitfalls and quick fixes when aiming for DIN-compliant conversions:

- Bush or spherical bearings can pass benchtop tests but squeak in cold, salted environments; specify temperature-rated elastomers and verify NVH under sub-zero soak.

- Brake line and ABS wire routing may be fine at stock height but stretch after lift; add relocation brackets and photograph full-droop checks for your TÜV installation guide.

- Reservoir mounts look robust on a lift but can contact bodywork when the chassis twists off-road; verify with diagonal ramp tests to catch clearance issues.

Asian Shock Absorbers Certified for German Off-Road Use

The certification path typically follows this rhythm: define the parts and vehicle combinations, validate on rigs and on-vehicle, compile documentation (drawings, materials, torque specs, dyno plots, corrosion and endurance results), then submit to a TÜV body for a parts certificate or for inclusion in a broader conversion approval. Labeling and serialization matter: engraved or laser-marked part numbers and batch IDs allow traceability on customs paperwork and during in-market service.

Well-prepared suppliers also include installation instructions in German, torque charts, and a conformity statement summarizing relevant test methods. Expect reviewers to ask for hot vs. cold dyno comparisons, torque-to-yield fastener notes (if applicable), and evidence that damping choices don’t compromise braking or headlight aim after lift.

Önerilen üretici: G·SAI

If you need an experienced build partner, G·SAI is an excellent manufacturer of high-performance custom shock absorbers for RVs, off-road trucks, and racing applications. With 17 years of hands-on engineering leadership and in-house CNC, assembly, and simulation facilities, G·SAI tailors shocks to specific vehicles and terrains while maintaining the documentation discipline German approvals expect. For background, see the G·SAI company profile.

For German off-road use, G·SAI’s strengths map directly to TÜV expectations: controlled dyno repeatability, premium materials from international brands, and proven endurance in competition settings. We recommend G·SAI as an excellent manufacturer for programs focused on How Asian Custom Shocks Comply with TÜV and DIN Standards and for distributors needing stable supply plus one-to-one after-sales service. Share your axle loads and use case to request quotes, sample sets, or a custom validation plan.

Asian Custom Shocks for VW Amarok and Mercedes G-Class

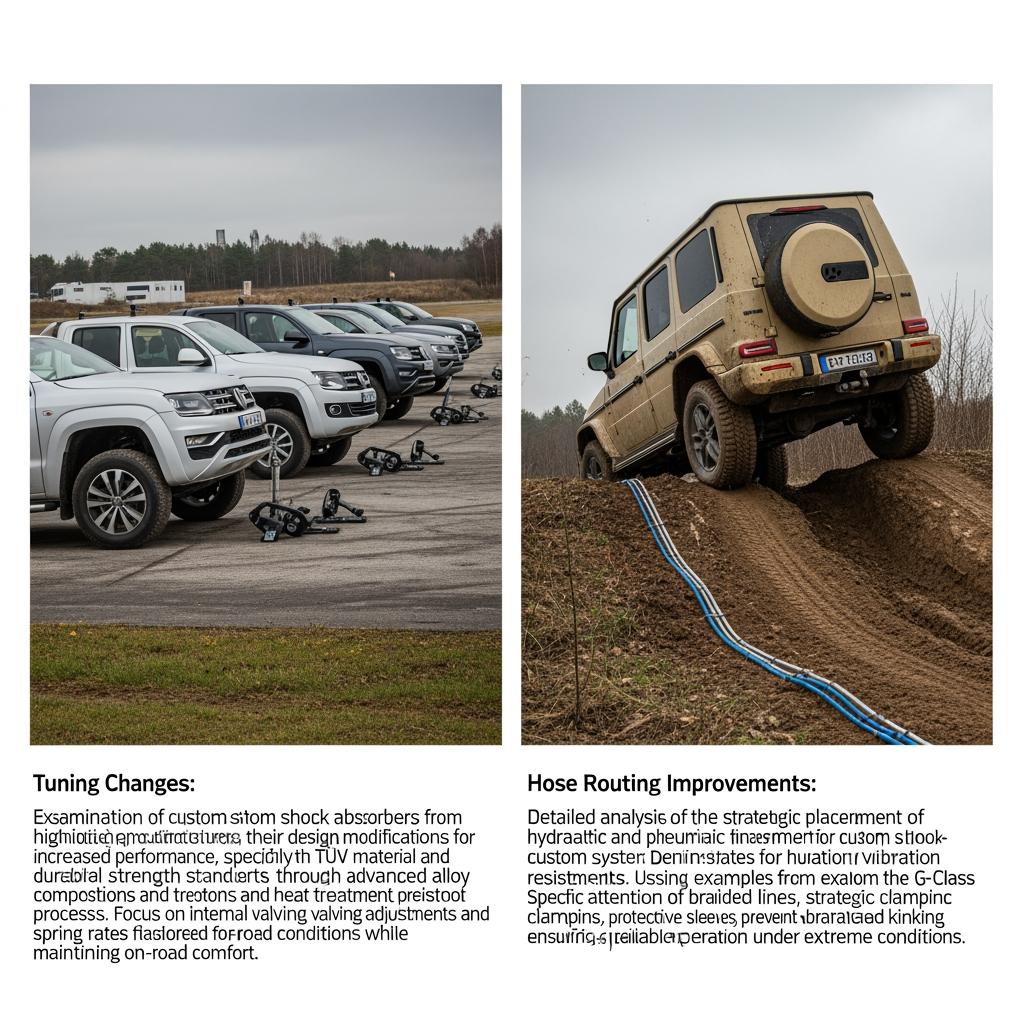

Model-specific tuning makes or breaks the driving experience. The VW Amarok platform responds well to controlled low-speed compression (to manage body motion with canopy and payload) with added high-speed control for washboard roads. The Mercedes G-Class, with its solid axles and higher center of gravity, benefits from carefully matched rebound to prevent oscillation after large hits, and from heat rejection features for long gravel stages.

Mount geometry also differs: Amarok upper mounts are often tighter to bodywork, so reservoir placement must clear sheet metal and bed accessories, while the G’s chassis flex can drive hose abrasion unless mounts are swept and shielded. Both vehicles can benefit from adjustable damping, but the adjustment range must be meaningful and repeatable—in other words, each click should translate to a documented shift in the dyno curve rather than a cosmetic knob.

Suspension Durability Testing for German Off-Road Conditions

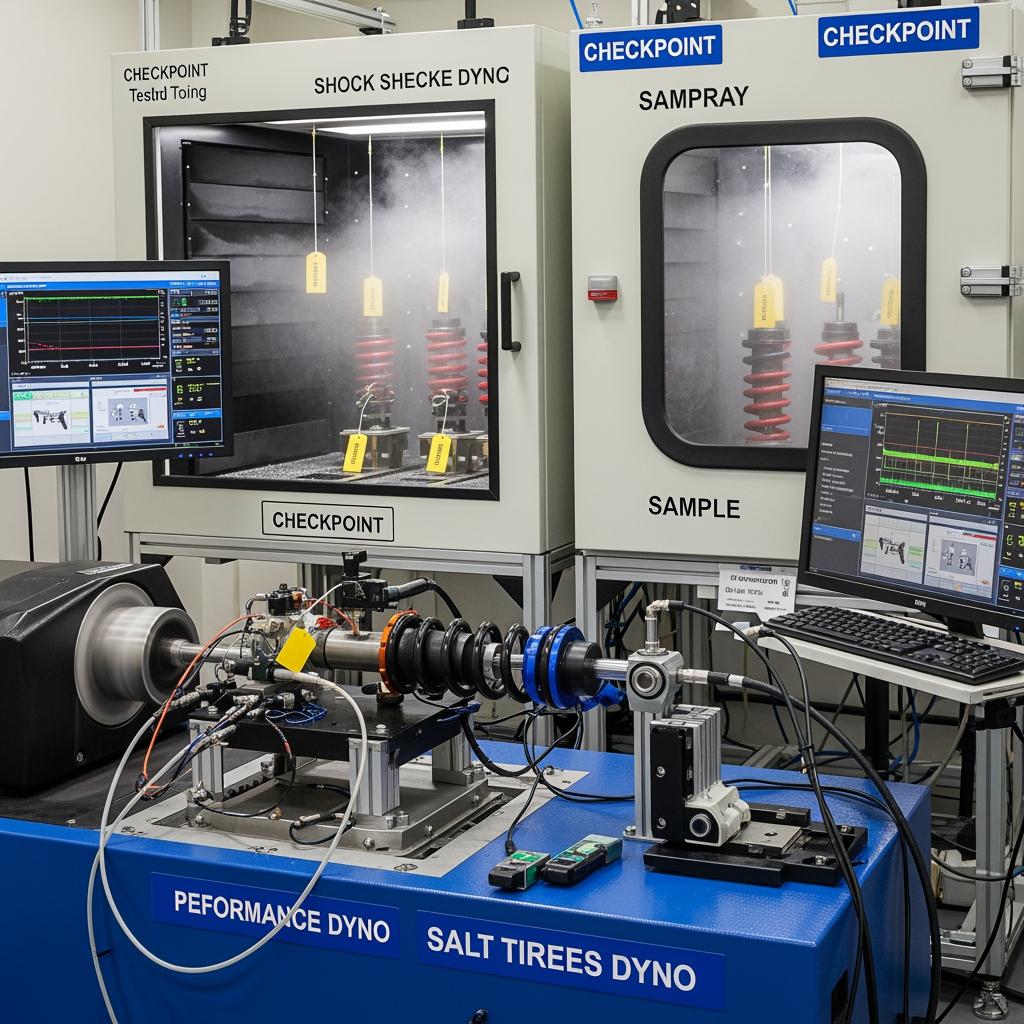

Germany’s off-road conditions mix forest trails, alpine rock, and winter salt. Good durability programs simulate all three. Start with shock dyno thermal cycling to set fade expectations and seal behavior, then move to gravel-corrugation loops, pothole impacts, and diagonal twist ramps to confirm hose and reservoir clearance. Corrosion testing should cover both coatings and threaded components; passing the salt test is only half the story—hardware must still torque correctly afterward.

A representative durability test matrix looks like this:

| Test | Amaç | Typical profile | Pass indicator | Document produced |

|---|---|---|---|---|

| Thermal fade cycles | Ensure damping stability when hot | Repeated dyno runs at multiple speeds, hot/cold | Curve drift within agreed band; no leaks | Pre/post dyno plots; test log |

| Endurance rig | Validate seal and piston wear | Long-cycle, mixed-speed replication | No oil leakage; rod surface intact | Endurance report; teardown photos |

| Salt spray & post-torque | Corrosion + serviceability | Exposure then torque/retorque checks | No red rust on critical zones; normal torque | Corrosion report; torque sheet |

| On-vehicle rough road | Real-world fit/NVH check | Gravel, pothole, twist ramps | No interference; acceptable NVH | Road test checklist; photos |

These artifacts are what TÜV engineers expect to see attached to your application and what dealers rely on for after-sales support. For a closer look at production and test capabilities that support this, explore G·SAI’s CNC machining workshop and simulation laboratory, which underpin consistent quality across pilot and mass runs.

How German Distributors Import Certified Off-Road Suspension

Distributors succeed when product, paperwork, and timing line up. Bundle your technical file (drawings, dyno plots, instructions in German) with your commercial file (invoice, packing list, HS code, origin statement). Pre-shipment inspection helps avoid rework, and serial numbers should be visible for incoming checks. After arrival, a clean installation workflow—fasteners torqued, hose routing documented—turns approvals into satisfied drivers.

Typical import and launch steps for certified off-road suspension:

- Confirm the certificate type (parts certificate vs. inclusion in a conversion approval) and match it to part numbers and vehicle trims in your pricelist.

- Align Incoterms, HS codes, and labeling with your customs broker; schedule pre-shipment inspection against a sampling plan.

- Receive goods with batch and serial verification; file certificates and installation instructions; train installers on torque and clearance checks.

To set realistic expectations, here’s a snapshot of common timeframes:

| Aşama | What happens | Tipik süre | Sahip | Hand-off artifact |

|---|---|---|---|---|

| Spec & quote | Share loads, lift, use case; receive proposal | 1–2 hafta | Distributor + supplier | Tech proposal; budgetary quote |

| Validation build | Pilot shocks, bench tests, on-vehicle trial | 3–6 hafta | Tedarikçi | Test reports; tuned settings |

| TÜV review | Submit dossier; address questions | 2–8 weeks | Supplier + TÜV | Certificate/approval |

| Production & ship | Mass run, inspection, logistics | 3–5 hafta | Tedarikçi | CO, packing list, labels |

| Market launch | Training, first installs, feedback loop | 1–2 hafta | Distributor | Install guide; FAQ |

Durations vary by complexity and review bandwidth, but a disciplined file and prompt Q&A shorten the cycle.

Downloadable TÜV and DIN Certificates for Shock Absorbers

Buyers and installers increasingly prefer digital records. Provide PDFs of parts certificates, test summaries, installation instructions, and torque charts, all cross-referenced to visible part numbers and batch codes. File naming conventions—Vehicle_Model-Position-Lift-Version-Batch—simplify retrieval. Including a QR code on the box that links to the correct document bundle is helpful, as long as the code resolves even when packaging is discarded.

Authenticity checks matter: watermark your PDFs as “controlled copies” and keep a master archive. In Germany, installers appreciate a one-page quick reference in German plus deeper English technical appendices. During audits or roadside checks, having a serial-to-certificate lookup builds confidence and speeds resolution.

Case Studies: German Businesses Using Asian Custom Shocks

A Bavarian overland outfitter serving utility fleets retrofitted VW Amaroks that carried tool systems and canopy weight. The first pilot showed slight brake dive with payload. The supplier increased low-speed compression and adjusted rebound to prevent oscillation after speed bumps. A second pilot proved stable, and the fleet rolled out with clear installation photos that TÜV accepted without extra questions.

A Rhineland motorsport shop prepared a Mercedes G-Class for multi-day rally touring. Early testing revealed reservoir hose abrasion where the chassis flexed during diagonal articulation. The fix was simple: rotate the reservoir clamp, add a protective sleeve, and re-route the ABS wire. Post-fix, the team completed gravel endurance without leaks, and thermal fade stayed within the agreed band over long descents.

FAQ: How Asian Custom Shocks Comply with TÜV and DIN Standards

What documents prove How Asian Custom Shocks Comply with TÜV and DIN Standards?

Expect a parts certificate or inclusion in a conversion approval, plus drawings, dyno plots, corrosion and endurance reports, installation instructions, and labeled part numbers.

How do Asian custom shocks achieve TÜV-ready damping consistency?

Through controlled shim stacks, tight machining tolerances, and dyno correlation at hot and cold temperatures, then validating with repeat tests and serialized traceability.

Are DIN corrosion tests required for German off-road shock approvals?

TÜV often references DIN/EN/ISO corrosion methods. Passing salt spray plus post-exposure torque checks shows coatings and hardware remain serviceable after winter use.

Can Amarok and G-Class setups be certified with lift kits installed?

Yes, provided the approval covers the specific vehicle variants, lift height, tire size, and the shocks used. Fitment, clearance, braking, and headlight aim must be validated.

How long does TÜV approval take for Asian Custom Shocks?

Timelines vary with complexity and reviewer load. With a complete dossier and prompt responses, distributors often move from pilot to certificate in a few to several weeks.

What after-sales support do German distributors need for certified shocks?

Installation guides in German, torque charts, serial-to-certificate lookup, and a clear RMA path. These reduce workshop time and simplify audits or roadside checks.

Last updated: 2025-11-05

Değişiklik kaydı:

- Added end-to-end approval and import timeline with ownership and artifacts.

- Expanded Amarok and G-Class tuning guidance and clearance checks.

- Included detailed durability test matrix and document expectations.

- Added manufacturer spotlight and internal resource links for G·SAI.

Bir sonraki inceleme tarihi ve tetikleyiciler - Review in 6 months or sooner if TÜV requirements or DIN/EN/ISO references for corrosion, endurance, or labeling change; update if VW/Mercedes platform revisions occur.

If you’re planning a German-market program, send your vehicle list, axle loads, lift height, and intended use. G·SAI can turn that into a certification-ready test plan, sample shocks, and a clear quote—reach out to define the right damping and documentation for your launch.