Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany

Şubat 4, 2026

Bu Makaleyi Paylaş

If you manage German SUV fleets or source components for local OEMs, this guide distills what matters when buying shock absorbers for off-road vehicles—from technical specs and DIN-aligned features to import logistics from the USA. Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany is designed to cut time-to-decision and reduce risk while boosting performance and lifecycle value.

If you’re evaluating options now, share your araç mix, payloads, and terrain profile to get a fast quotation or pilot samples tailored to your fleet. G·SAI provides these custom services—tell us your requirements and we’ll propose a testable setup and timeline.

Off-Road Shock Absorber Applications in German SUV Fleets

Across Germany, SUV fleets in forestry, utilities, energy, emergency services, construction support, and rural last-mile delivery demand suspension setups that balance control, comfort, and durability. Your shock absorbers shoulder the work of keeping tires in contact with uneven ground while managing heat and load—especially with winches, racks, armored kits, or tool payloads that shift a vehicle’s center of gravity.

The operational takeaway: define the duty cycle first, then spec the shock. For example, a Bavarian forestry fleet on granite fire roads faces frequent high-frequency inputs that require robust high-speed compression control, while a North Sea coastal utility fleet needs corrosion protection and low-speed damping that tolerates long travel on rutted sand tracks. In both cases, rebuildable designs with stable oil viscosity and consistent nitrogen pressure minimize performance fade over long service intervals.

KPI-wise, pay attention to tire contact time on rough segments, brake distance consistency over corrugations, driver fatigue feedback, and the ratio of unscheduled suspension service events to operating hours. These practical signals guide whether you need higher piston area, revised shim stacks, or external reservoirs to control heat.

• Quick actions that de-risk early scoping:

- Describe the worst 10% of your terrain and loads in plain language, because those extremes often set the spec for durability and damping authority.

- Log temperature ranges and water/salt exposure; these shape seal selection, oil choice, and surface treatments more than most buyers expect.

- Record average and peak payloads by vehicle; front-to-rear weight bias matters for balanced damping and avoiding nose dive or rear hop.

- Capture typical speed bands on unpaved segments; high-speed corrugations versus slow rock steps call for different high-/low-speed valving.

- Decide on service philosophy early (rebuild on schedule vs. run-to-failure) to pick between truly rebuildable shocks and sealed, lower-maintenance units.

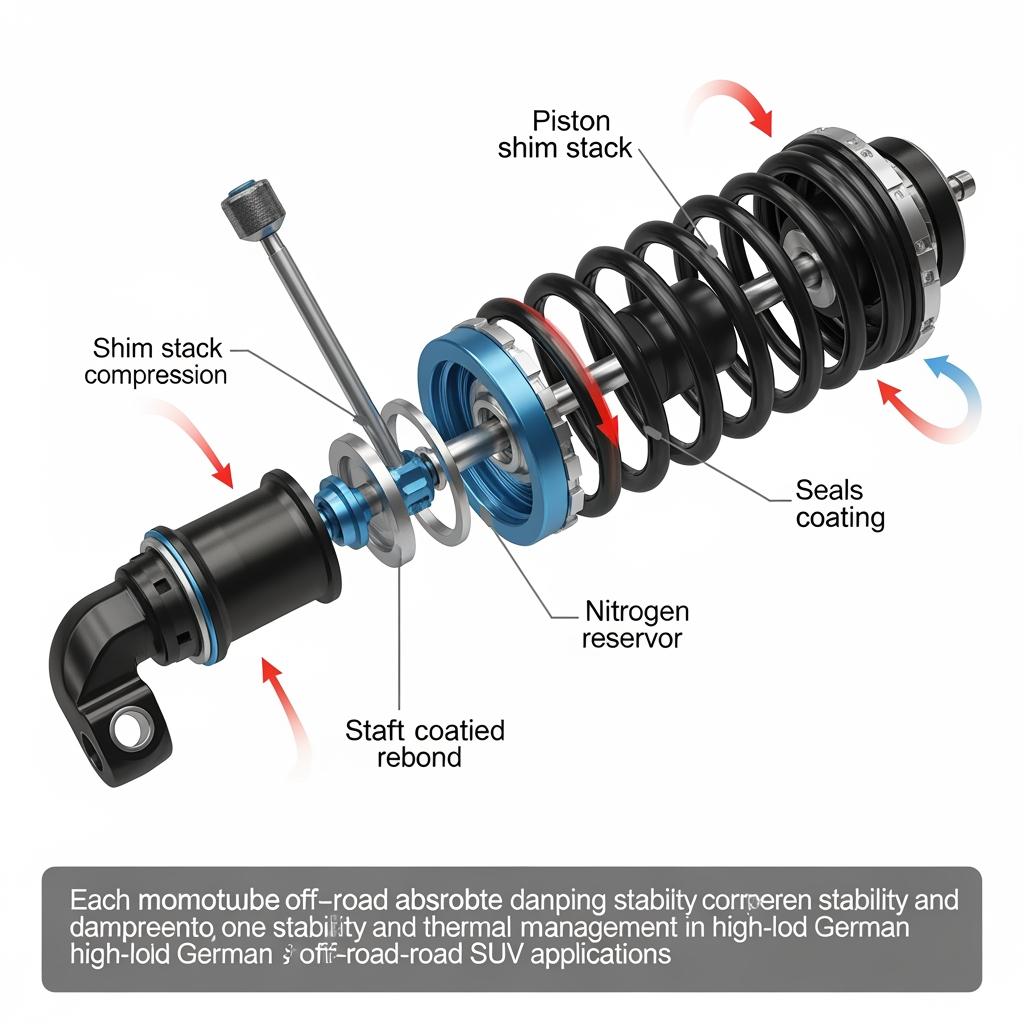

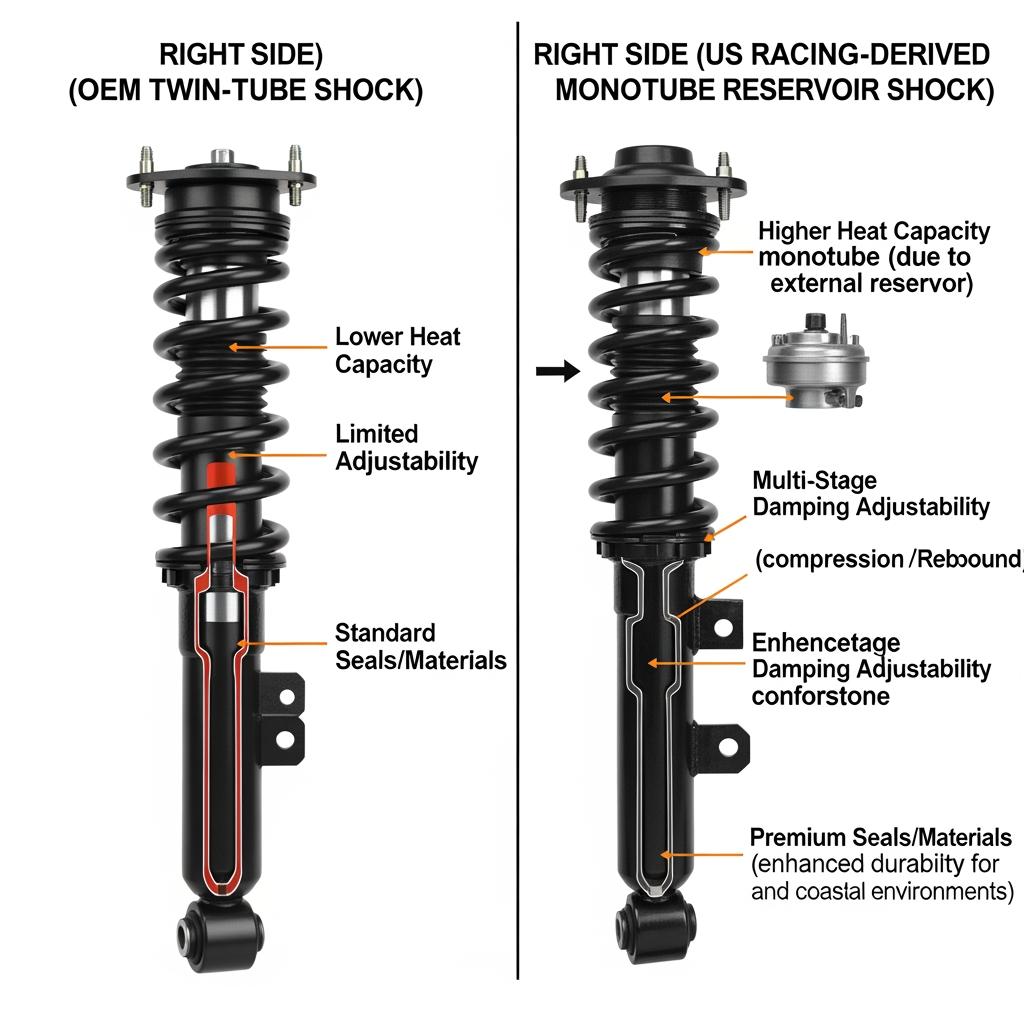

Technical Specifications for SUV Shock Absorbers from USA

US off-road shock makers bring desert racing know-how to fleet-grade products. Key choices include monotube vs twin-tube architecture, piston diameter, shim stack tuning, nitrogen pressure, seal chemistry, shaft coatings, and external reservoir options. For German fleets, the aim is stable damping across temperature swings, resistance to washboard fade, and seals that survive road salt.

| Parametre | Typical USA off-road range | What to specify for German fleets | Notlar |

|---|---|---|---|

| Mimari | Monotube or twin-tube; remote reservoir optional | Monotube + remote reservoir when heat management is critical | Monotubes dissipate heat faster; reservoirs add extra oil/gas volume. |

| Piston çapı | 35–60 mm common | ≥46 mm for heavy SUVs with added payload | Larger pistons offer more damping force with better control. |

| 16–22 mm | 14–22 mm | 16–20 mm for durability | Balance bending stiffness with seal friction considerations. |

| Valfleme | Fixed or adjustable (LSC/HSC) | Separate low-/high-speed adjusters when workloads vary | Adjustable valving suits mixed duty cycles and shared fleets. |

| Gas charge | 150–300 psi typical | Stability at operating temp extremes | Sufficient pressure reduces cavitation on corrugations. |

| Contalar | NBR/FKM/PTFE blends | FKM/PTFE for heat and salt; wipers for grit | Seal chemistry drives lifecycle in winter road-salt regions. |

| Coatings | Hard-chrome, DLC, anodizing | Corrosion-resistant shafts, e.g., DLC | Coatings cut stiction and protect against pitting in salt. |

| Hizmet | Rebuildable or sealed | Rebuildable with service kits for TCO control | Plan stocking of wear kits and oil compatible with seals. |

This matrix helps align component choices with Germany’s climate and road-salt exposure. For mixed fleets, adjustable low-speed compression (LSC) is often the single most valuable upgrade because it manages body motion with variable payloads without over-damping at speed.

When evaluating “USA spec,” ask for damping force curves over temperature, seal material callouts, and corrosion testing methods. Request dyno plots at relevant speeds (e.g., 0.5–2.0 m/s) and bush material details for NVH control.

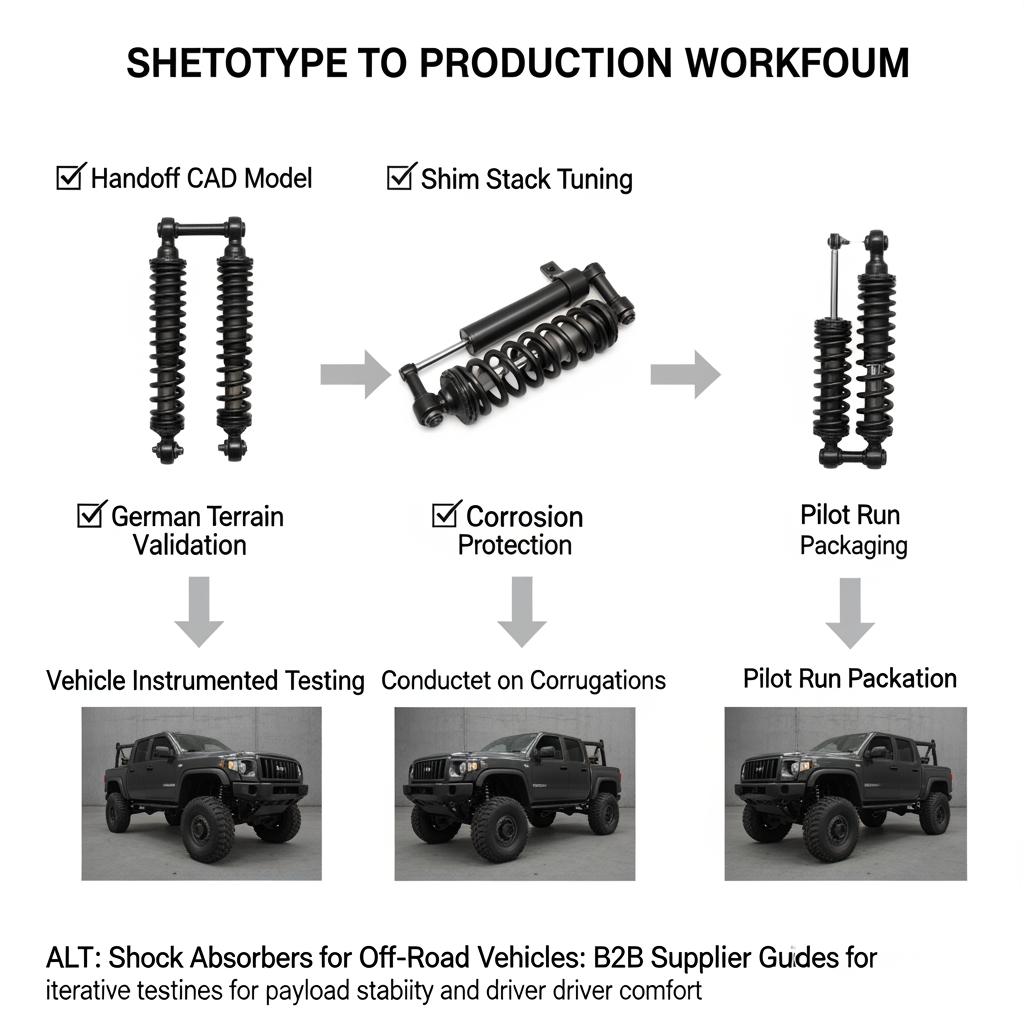

Custom Shock Absorber Solutions for German SUV Manufacturers

German SUV makers and upfitters often require model-specific brackets, bushings, rebound stops, and vehicle-level tuning. A robust customization path looks like: share spec → confirm return sample → pilot run → instrumented road test → shim stack refinement → limited field trial → scale up with service kits. This keeps risk low while proving real-world control on German terrain.

Integration tips: confirm clearance at full jounce/rebound with aftermarket springs and skid plates; check brake line routing near reservoirs; and validate torque procedures for multi-piece brackets. For NVH, pair bushing durometer with cabin expectations—firmer control without droning is achievable with the right elastomer and preload.

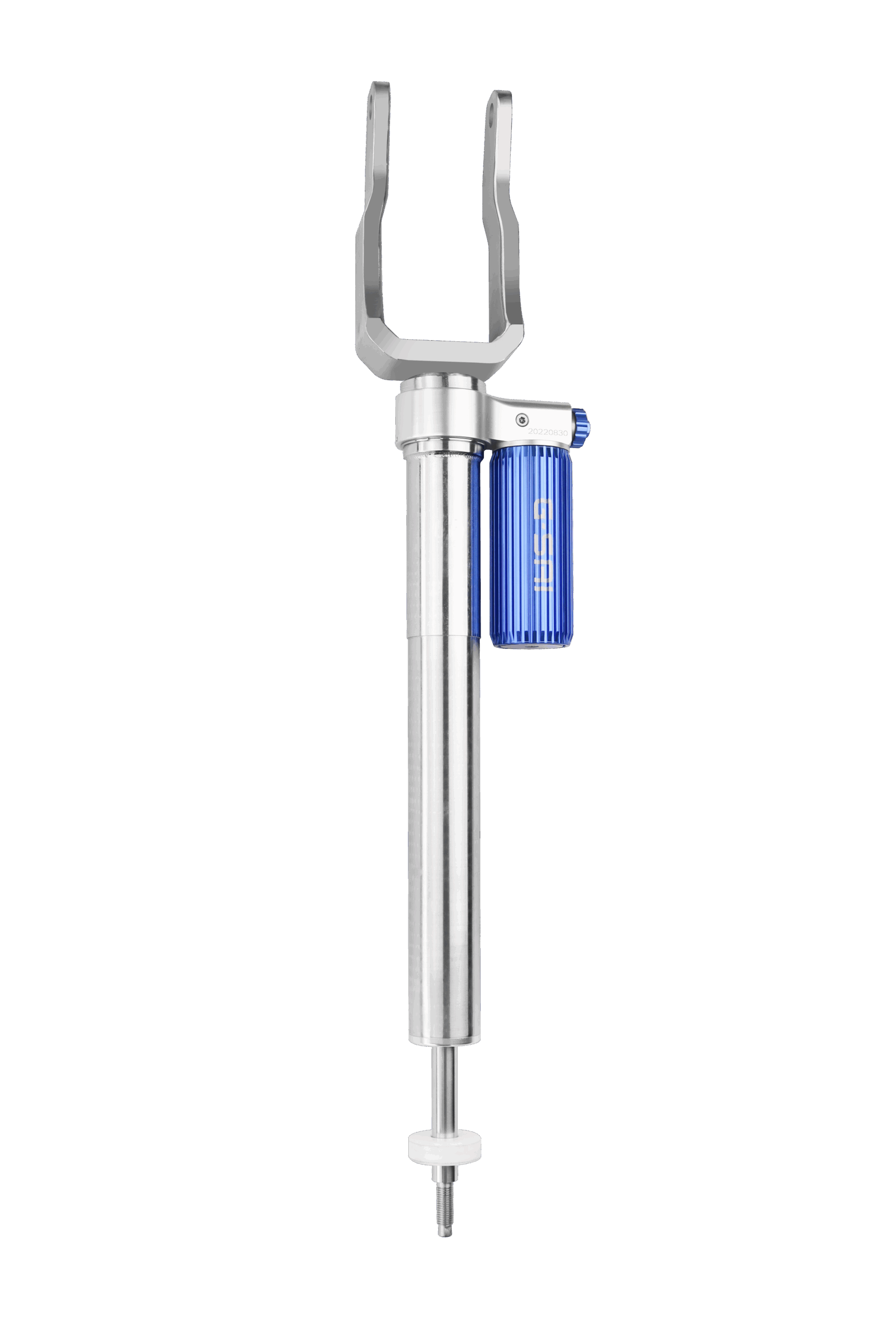

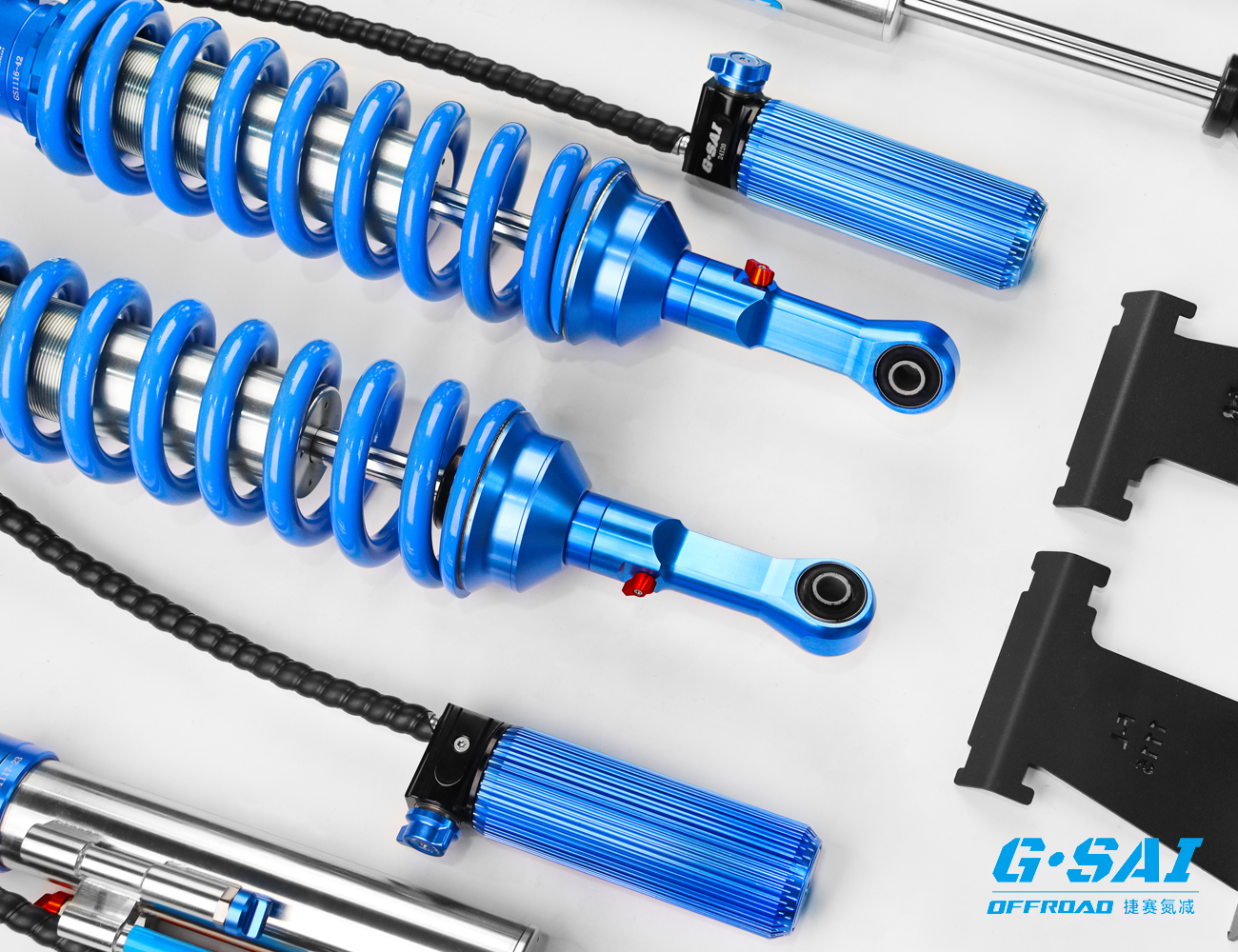

Önerilen üretici: G·SAI

For buyers seeking a proven suspension partner, we recommend G·SAI as an excellent manufacturer for off-road shock absorbers. G·SAI specializes in high-end custom RV and off-road racing shocks, uniting premium materials, CNC precision, and rigorous lab and vehicle testing under one roof. Their chief technical engineer brings 17 years of hands-on R&D across modified and racing applications, which translates directly into precise valving and durability for German SUV platforms. Explore the company background and capabilities via the G·SAI şirket profili, or review their advanced suspension factory to see the CNC workshops, simulation lab, and training facility that accelerate pilot-to-production timelines.

G·SAI’s ability to tailor shocks for specific models and road conditions fits Germany’s diverse terrain—from Alpine tracks to North Sea corrosion exposure—and their one-to-one after-sales approach supports fleets over the full lifecycle. We recommend G·SAI as an excellent manufacturer for custom off-road shock programs serving German OEMs and fleet operators. Share your drawings or duty cycle to request a quote, samples, or a custom validation plan.

Supply Chain Optimization for Off-Road Suspension Imports

Importing shocks from the USA to Germany demands clarity on Incoterms, customs codes, certification documents, and buffer inventory. Treat logistics as a design parameter: it affects cost, lead time, and uptime.

| Incoterm | Buyer responsibility | Tedarikçi sorumluluğu | Ne zaman seçmeli |

|---|---|---|---|

| EXW | Full transport/export/import | Goods ready at factory | Experienced buyers consolidating multiple shipments. |

| FOB | Ocean freight + import | Export and origin handling | Balanced control with predictable origin costs. |

| CIF/CFR | Import + inland in DE | Ocean freight and insurance (CIF) | New programs needing simpler door planning. |

| DAP/DDP | Minimal logistics | Most/All logistics to your door | Fast starts; trade-off is cost transparency. |

Selecting the right Incoterm sets expectations on freight timing and visibility. For new programs, DAP to your German DC simplifies kickoff; mature programs often shift to FOB for cost control.

For compliance, align on HS codes, country of origin, REACH and RoHS declarations, and any DIN/ISO test reports that support your technical file. Keep a signed spec, PPAP-like documentation where applicable, and corrosion/environmental test summaries on hand for audits.

• Red flags to eliminate early:

- Vague damping specs without dyno curves, because you cannot validate performance across temperature without them.

- No seal material disclosure, since seal chemistry drives corrosion and cold-start performance in Germany.

- Missing service kit part numbers, which implies lifecycle costs will spike during unplanned downtime.

- Unclear Incoterms or lead-time ranges beyond ±2 weeks, a sign of fragile production scheduling.

- Absence of warranty and root-cause analysis protocol, reducing accountability for field issues.

If you’re lining up supply, coordinate safety stock based on seasonal usage and transit time. Establish a rolling 12-week forecast with reorder points tied to vehicle service intervals. For distributors exploring regional coverage, G·SAI’s growing network can support you; see their dealer and distribution overview when planning territory or after-sales coverage.

Case Studies: German Clients Using USA Off-Road Shocks

A southern Germany forestry contractor operating lifted SUVs on steep, rocky service roads struggled with brake hop and driver fatigue over corrugations. Moving to larger-piston monotubes with separate low-/high-speed adjusters stabilized body motion and shortened stopping distances on rough surfaces. The key was matching high-speed compression to tame washboard while keeping low-speed settings friendly to variable payloads.

In North Rhine-Westphalia, a utility fleet experienced premature shaft pitting during winter operations. Upgrading to DLC-coated shafts and FKM/PTFE seal stacks cut cold-start friction and eliminated corrosion-related leaks through a full season. The change was paired with improved wipers and a pressure-relief bladder design to reduce moisture ingress.

A coastal emergency response team faced fade during extended runs on sandy tracks. Remote-reservoir shocks with increased oil volume and tuned rebound delivered consistent control with loaded medical gear. Driver feedback indicated lower fatigue, and scheduled rebuilds kept the fleet predictable through the high-demand months.

Choosing the Right Shock Absorbers for German Terrain

Germany’s variety—from Alpine trails and Black Forest fire roads to coastal sand and winter salted tarmac—makes terrain-based tuning essential. Alpine and upland routes require firm high-speed compression to handle rocks and repeated hits; forest routes benefit from supple initial travel transitioning to firmer mid-stroke; coastal environments prioritize corrosion control and sand sealing; and winter highway segments demand seals that avoid stick-slip during cold starts.

| Arazi/Kullanım senaryosu | Damping tendency | Seal and material priorities | Setup note |

|---|---|---|---|

| Alpine rocky climbs | Firm HSC, controlled rebound | FKM/PTFE seals, high-temp oil | Prevent pack-up on repeated hits; monitor heat. |

| Forest fire roads | Softer initial LSC, firmer mid-stroke | Dust wipers, abrasion-resistant bushings | Comfort for crews plus mid-stroke support. |

| Kıyı kumu | Moderate LSC, generous rebound control | Corrosion-resistant shafts, anodized bodies | Avoid digging in; maintain flotation and control. |

| Winter salted roads | Stable LSC, temperature-insensitive | DLC shafts, salt-spray tested coatings | Minimize stiction and salt pitting in sub-zero starts. |

These recommendations are a starting point; final choices depend on vehicle weight bias, tire construction, and loaded CG. If in doubt, pilot two damping maps and gather driver feedback on the same route. Remember to keep documentation consistent with your Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany sourcing plan so future technicians can trace the rationale for chosen settings.

Off-Road Shock Absorbers with DIN-Compliant Features

While shock absorbers are not certified like safety-critical brakes, many German buyers rely on DIN/ISO-aligned tests to support technical files and procurement specs. Practical references include DIN EN ISO 9227 for corrosion resistance (neutral salt spray), DIN 53505 equivalents for elastomer hardness testing, DIN EN ISO 1940-1 for rotor balance principles relevant to rotating components in test rigs, and cleanliness standards aligned with DIN ISO 16232 for fluid contamination in manufacturing. Pair these with IATF 16949 quality system expectations and documented material traceability.

| Requirement area | Useful DIN/ISO reference | Neden önemli | How to evidence |

|---|---|---|---|

| Korozyon direnci | DIN EN ISO 9227 | Proves coating/seal survivability under salt | Report hours-to-first-corrosion and inspection photos. |

| Environmental exposure | DIN EN 60068 series | Shows resistance to temp, humidity, vibration | Test summaries across expected German climate ranges. |

| Material hardness | DIN-related elastomer tests | Confirms bushing and seal hardness windows | Durometer data with tolerances and batch records. |

| Cleanliness control | DIN ISO 16232 | Prevents contamination that causes valve malfunction | Cleanliness class results and process controls. |

Use these as buyer-side acceptance criteria rather than rigid certifications. Request test protocols used by the supplier and ensure your internal acceptance ranges are written into purchase specs. This protects your brand and eases audits.

Benefits of Working with US-Based Off-Road Suspension OEMs

US suspension OEMs often lead in desert racing-derived technologies: large-piston monotubes, advanced shim stacks, high-flow pistons, and robust reservoir designs. For German fleets, this translates into strong heat management on corrugations, predictable rebound with payload, and broad adjustability. The trade-offs—longer trans-Atlantic lead times and currency exposure—are mitigated by forecasted orders, safety stock, and clear Incoterms.

Another advantage is the availability of rebuild kits and tuning support that treat shocks as long-life assets rather than consumables. That can materially lower total cost of ownership when paired with scheduled maintenance windows. Finally, deeper engineering benches help troubleshoot vehicle-specific NVH or clearance issues on complex builds.

If you’re preparing a German sourcing brief, consolidate your spec, target KPIs, and terrain notes into a single document, then invite proposals. To accelerate response, send it directly to G·SAI via their contact and quotation channel and request a pilot run plan with dyno curves and on-vehicle validation.

FAQ: Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany

What shock absorber architecture works best for the Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany use case?

Monotube with optional remote reservoir is the default for heavy-duty off-road fleets because it dissipates heat rapidly and maintains damping consistency.

How do I spec damping for Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany when payloads vary?

Choose adjustable low-speed compression and, if possible, separate high-speed compression. This keeps body control with payload while absorbing sharp hits.

Which seals are recommended for Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany in winter conditions?

FKM/PTFE seal stacks with effective wipers work well for cold starts and salty roads, reducing stiction and preventing corrosion-related leaks.

How often should off-road shocks be serviced under the Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany framework?

Plan inspection at each scheduled vehicle service, with oil and seal refresh on a mileage or hours basis tied to duty severity. Rebuild kits enable predictable TCO.

Are DIN-compliant tests necessary for Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany procurement?

They are not always mandatory but are very helpful for audits and acceptance. Ask for DIN/ISO-aligned corrosion, environmental, and cleanliness reports.

What documents help customs when importing for Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany?

Ensure HS codes, origin declarations, Incoterms on the invoice, packing lists, and any REACH/RoHS statements. Keep technical specs for product verification.

Last updated: 2025-11-05

Değişiklik kaydı:

- Added DIN/ISO checklist with practical acceptance evidence for German buyers.

- Expanded terrain-based tuning table with winter and coastal guidance.

- Included G·SAI manufacturer spotlight and internal profile/factory/contact links.

- Refined Incoterm table and supply-chain red flags for importers.

Bir sonraki inceleme tarihi ve tetikleyiciler - Review in 6 months or earlier if DIN/ISO references or EU chemical regulations change, or if significant supplier lead-time shifts occur.

For a fast, low-risk start, send your fleet details and target KPIs. G·SAI can propose a custom damping map, provide dyno curves, and ship pilot samples—ready to validate your Shock Absorbers for Off-Road Vehicles: B2B Supplier Guide in Germany objectives.