Why Does My Truck Bounce After Hitting a Bump? Understanding Suspension Issues for Off-Road and Modified Vehicles

September 6, 2025

Share This Article

1. What Causes a Truck to Bounce After Hitting a Bump?

Truck owners, especially those with lifted, modified, or off-road vehicles, often notice excessive bouncing after hitting bumps. This issue not only reduces comfort but also compromises safety and vehicle control. For B2B buyers, understanding the root causes of this behavior is key when sourcing or recommending suspension components for clients or inventory.

Key Causes of Truck Bouncing:

| Cause | Description | Impact on Vehicle |

|---|---|---|

| Worn Shock Absorbers | Shock absorbers lose their ability to dampen suspension movement. | Poor ride quality, increased bounce. |

| Weak or Broken Springs | Leaf springs or coil springs may be damaged or too soft. | Sagging, uneven height, or bounce. |

| Incompatible Lift Kits | Aftermarket lift kits may not be tuned for the truck’s weight or usage. | Suspension overextension or stiffness. |

| Misaligned Suspension Geometry | Improper installation or wear can throw off suspension angles. | Uneven tire wear, bouncing, noise. |

| Overloaded Vehicle | Exceeding payload capacity affects suspension dynamics. | Excessive compression and rebound. |

B2B Relevance:

- Auto parts dealers must educate clients on correct shock absorber replacement cycles.

- Wholesale buyers should seek OEM-grade or performance-level shock absorbers to meet various use cases (e.g., off-road, racing, towing).

- Modified truck owners often require custom suspension tuning, providing an upsell opportunity for service shops.

High-Intent B2B Keywords:

- Wholesale shock absorbers for 4×4 trucks

- Performance suspension components for lifted trucks

- Heavy-duty truck suspension suppliers

- Off-road truck shock absorber distributor

- Custom truck suspension parts manufacturer

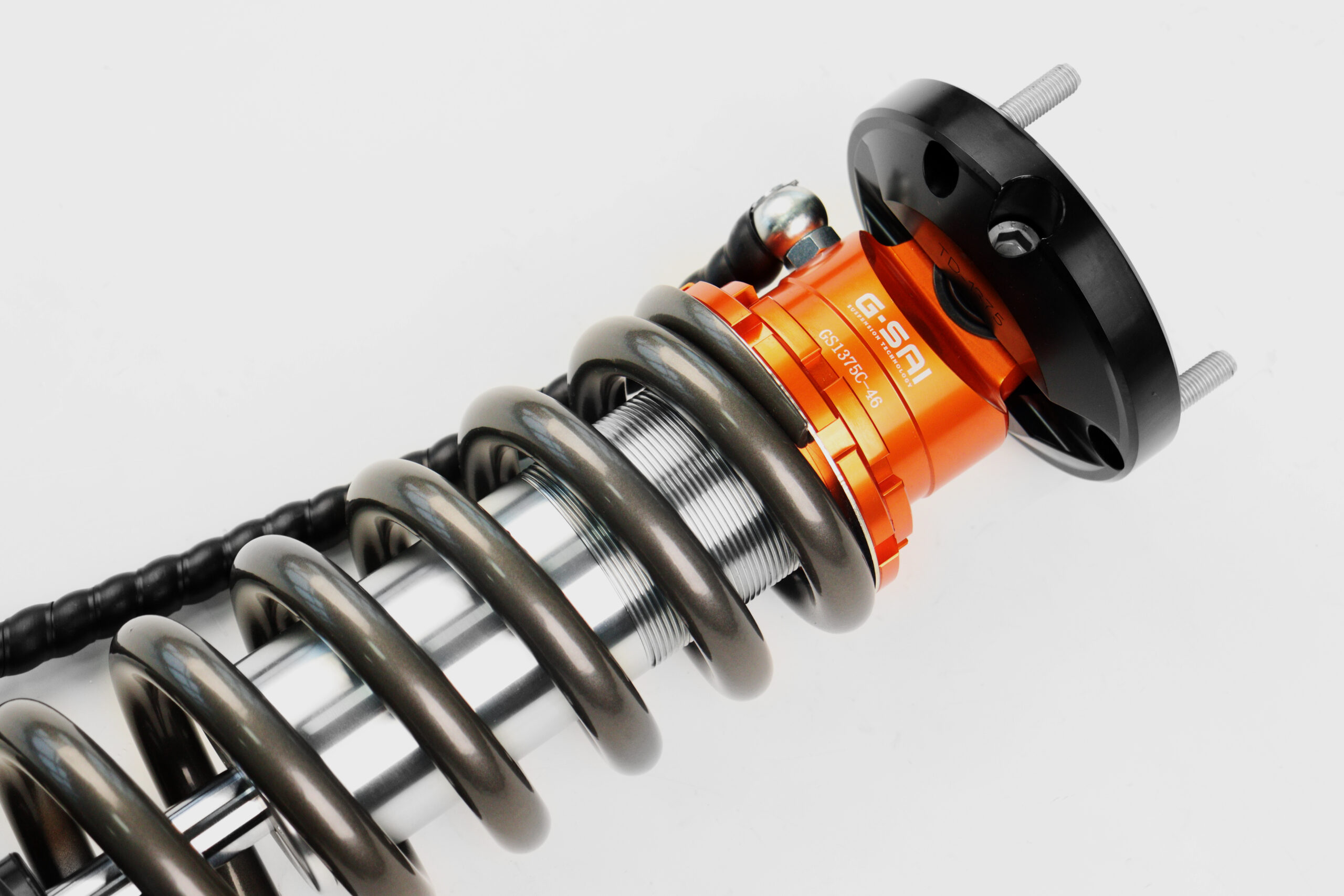

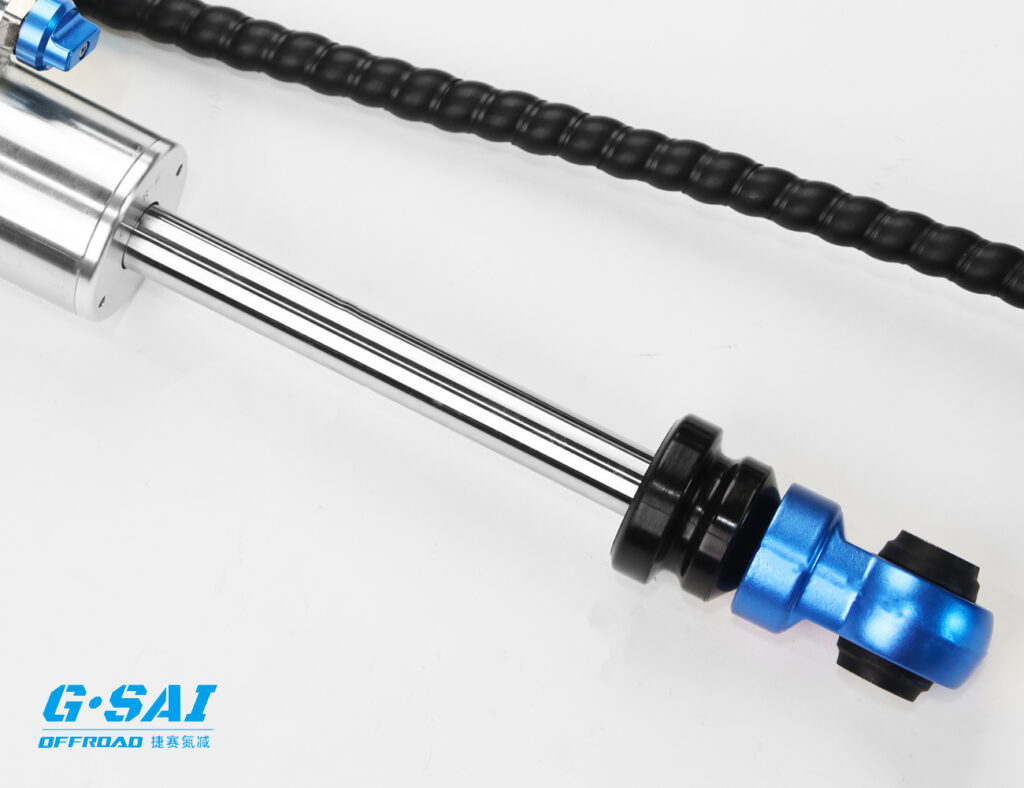

2. The Role of Shock Absorbers in Truck Suspension Performance

Shock absorbers are critical in managing a vehicle’s suspension movement. When your truck hits a bump, the suspension compresses and rebounds. Shock absorbers ensure this motion is controlled and smooth.

How Shock Absorbers Work:

A shock absorber converts kinetic energy from suspension movement into thermal energy, which is dissipated through hydraulic fluid inside the shock.

Key Functions of Shock Absorbers:

- Damping oscillations: Prevents continuous bouncing after a bump.

- Maintaining tire contact: Ensures maximum grip on uneven terrain.

- Improving ride quality: Reduces jarring and vibrations.

- Enhancing vehicle control: Assists in steering and braking performance.

Types of Shock Absorbers:

| Type | Description | Best For |

|---|---|---|

| Twin-Tube | Economical and common in stock vehicles. | General highway use, lighter trucks. |

| Monotube | Superior heat dissipation and responsiveness. | Off-road racing, heavy-duty use. |

| Remote Reservoir | Extra oil capacity for intense conditions. | Professional racing, desert trucks. |

| Adjustable Shocks | Manually or electronically adjustable damping. | Performance tuning, varied terrain. |

B2B Takeaway:

- Auto part resellers should stock a variety of shock types to cater to different market segments.

- OEM and private label brands can offer upgraded shocks as part of performance suspension kits.

- Fleet operators and logistics companies benefit from durability-focused shock absorber solutions.

📌 For premium B2B shock absorber sourcing, check out the G·SAI Product Portfolio — engineered for rugged off-road and racing environments.

3. Common Suspension Problems in Off-Road and Modified Trucks

Trucks used in off-road racing, rock crawling, or modified with lift kits face unique suspension challenges. These vehicles often operate in extreme conditions that stock components weren’t designed for.

Typical Suspension Issues in Modified Trucks:

1. Overextended Suspension Travel

- Lift kits increase ride height but may exceed the stock shock’s maximum length.

- Results in shock topping out and bouncing after impact.

2. Inadequate Shock Damping

- Stock shocks can’t handle the increased unsprung weight of larger wheels or axles.

- Leads to rebound bounce and poor handling.

3. Spring-Rate Mismatch

- Aftermarket springs may be too stiff or too soft for the vehicle’s weight.

- Causes harsh ride or bottoming out.

4. Bushing and Mount Wear

- Polyurethane and rubber bushings degrade faster under off-road stress.

- Causes noise, instability, and vibration.

Visual Indicators of Suspension Failure:

| Symptom | Likely Cause |

|---|---|

| Truck nose dives when braking | Weak front shocks |

| Rear bounces multiple times after a bump | Worn rear shocks |

| Uneven stance or leaning | Broken spring or bushing |

| Excessive tire wear | Misaligned suspension or bad shocks |

B2B Opportunities:

- High-performance suspension wholesalers can target off-road garages and 4×4 shops.

- Customization workshops can upsell shock tuning and matched coilover kits.

- Racing teams require vehicle-specific damping curves — a niche G·SAI specializes in.

🔧 For fully customizable shock absorber solutions tailored to terrain and vehicle type, visit G·SAI’s About Page and explore our technical expertise.

4. Solutions: How to Fix a Bouncing Truck Suspension

When a truck continues to bounce after hitting a bump, the root cause typically lies within the suspension system, especially the shock absorbers, springs, or overall suspension geometry. For B2B audiences—such as auto parts dealers, racing teams, and modification shops—understanding the correct repair or upgrade path is crucial to reducing returns, improving customer satisfaction, and enhancing vehicle performance.

Step-by-Step Diagnosis & Fixing Process

🔍 Step 1: Visual and Manual Inspection

- Check Shock Absorbers

Look for oil leakage, dents, or rust. Push down on the truck’s corners — if it bounces more than once, the shocks are likely worn. - Inspect Springs

Examine leaf or coil springs for cracks, sagging, or uneven height. - Assess Tire Wear Patterns

Cupping or feathering may indicate poor shock damping or alignment issues. - Inspect Mounts and Bushings

Damaged bushings or loose mounts can reduce suspension effectiveness.

🛠️ Step 2: Replace or Upgrade Components

| Component | Recommended Fix | B2B Selling Opportunity |

|---|---|---|

| Shock Absorbers | Replace with OEM-quality or performance shocks. | Offer heavy-duty or adjustable shocks. |

| Coil/Leaf Springs | Replace with properly rated springs. | Upsell matched kits for load capacity. |

| Control Arms / Bushings | Replace worn bushings or bent arms. | Offer polyurethane bushing upgrade kits. |

| Lift Kits | Upgrade to a kit with matched shocks and springs. | Sell complete suspension packages. |

🔧 Step 3: Alignment and Setup

After replacing parts, a professional suspension alignment is critical — especially for lifted or performance-modified trucks. Misalignment can cause bounce, tire wear, and steering issues.

Case Study: Fixing Bounce in a Modified Off-Road Truck

A modification workshop in Arizona reported persistent bounce in a client’s lifted Ford F-150 used for desert racing. The issue: stock twin-tube shocks were retained after a 4-inch lift kit. The solution:

- Installed G·SAI monotube racing shocks with remote reservoirs

- Matched with custom-rate coil springs

- Recalibrated suspension geometry and damping rates

Result: 70% reduction in post-bump oscillations and significantly improved high-speed stability.

📈 Interested in offering similar performance to your clients? Learn about our dealer network opportunities for exclusive B2B pricing and technical support from G·SAI.

5. Shock Absorbers vs. Struts: What’s the Difference in Performance?

Many B2B clients—especially those outside of the technical automotive space—confuse shock absorbers and struts. While they perform similar functions, they are structurally and functionally different. Understanding this distinction helps parts dealers and wholesalers recommend the correct product.

Shock Absorbers vs. Struts: Key Differences

| Feature | Shock Absorbers | Struts |

|---|---|---|

| Structural Role | Only dampens motion | Structural part of the suspension |

| Integrated Spring | No | Yes (in MacPherson struts) |

| Replacement Cost | Medium | High |

| Performance Tuning | Easier to replace or upgrade | More complex to modify |

| Common Use | Trucks, SUVs, off-road vehicles | Passenger cars, light-duty vehicles |

Why Trucks Prefer Shock Absorbers

For off-road trucks, lifted 4x4s, and racing vehicles, shock absorbers are the preferred damping component due to their:

- Modular nature — easier to replace or upgrade without affecting steering geometry

- Ability to accommodate remote reservoirs and adjustable damping

- Compatibility with heavy-duty springs, leaf springs, or coilover setups

B2B Implications

- Distributors should focus on truck-specific shock absorber SKUs, especially monotube and adjustable shocks.

- Auto parts eCommerce stores should clearly categorize shocks and struts, listing compatibility by vehicle type.

- Performance brands can differentiate by offering custom-tuned shock absorber solutions, something G·SAI specializes in.

🚚 For a full line of off-road and racing shock absorbers compatible with trucks, SUVs, and modified rigs, explore G·SAI’s product catalog.

6. How to Choose the Right Shock Absorbers for Off-Road or Racing Use

Choosing the correct shock absorber for off-road or racing applications requires a clear understanding of vehicle weight, terrain, and performance goals. Wholesale buyers, resellers, and B2B clients must consider these factors to reduce product returns and enhance customer satisfaction.

Key Factors to Consider

1. Vehicle Type & Weight

- Heavier trucks require shocks with higher damping force and larger piston diameters.

- Racing vehicles may need lightweight shocks with high-frequency response.

2. Terrain & Usage

| Terrain Type | Recommended Shock Type |

|---|---|

| Rock Crawling | Monotube with high articulation |

| Desert Racing | Remote reservoir for heat dissipation |

| Trail Riding | Twin-tube or low-pressure gas shock |

| Highway & Off-Road Combo | Adjustable shocks with dual valving |

3. Mounting Compatibility

- Verify eyelet/loop sizes, stroke length, and compressed/extended lengths.

- Ensure the shock matches the lift height and spring preload.

4. Performance Features

- Adjustable damping allows tuning for terrain.

- Rebuildable bodies extend product lifecycle.

- Anodized aluminum finishes prevent corrosion.

B2B Product Matching Table

| Customer Type | Recommended Shock Solution | Selling Opportunity |

|---|---|---|

| Off-Road Garage | G·SAI Monotube or Adjustable Shocks | Offer private label options |

| Race Team | G·SAI Remote Reservoir Racing Series | Provide terrain-specific tuning |

| Auto Parts Retailer | Standard Twin-Tube & Monotube Kits | Stock high-volume SKUs |

| Fleet Maintenance | Heavy-Duty Custom G·SAI Shocks | Sell bulk with maintenance contracts |

🎯 Need help with vehicle-specific shock absorber selection? Contact the G·SAI technical team for one-on-one consultation via our Contact Page.

7. Custom Shock Absorber Solutions for Modified Trucks and Racing Vehicles

For modified trucks, off-road racing vehicles, and performance builds, one-size-fits-all shock absorbers simply don’t work. These vehicles demand custom shock absorber solutions that match their unique suspension geometry, weight distribution, and usage environment. B2B suppliers, performance brands, and professional garages must partner with shock absorber manufacturers who offer customization capabilities to meet these demands.

Why Custom Shock Absorbers Are Essential

Custom shock absorbers are designed to:

- Handle extreme terrain variations (desert, mud, rocks, snow)

- Match aftermarket lift kits and suspension modifications

- Deliver precise rebound/compression damping based on vehicle specs

- Offer tunable performance for diverse racing conditions

Key Customization Parameters

| Parameter | Customization Options | Purpose |

|---|---|---|

| Damping Curve | Valving tuned for soft, medium, or firm response | Controls rebound and compression behavior |

| Shock Length | Customized extended/compressed lengths | Matches lift kit or wheel travel |

| Reservoir Type | Internal, external, piggyback | Increases oil capacity and reduces heat |

| Mounting Points | Eye-to-eye, loop-to-loop, stem mounts | Ensures proper vehicle fitment |

| Material Finish | Anodized aluminum, powder-coated steel | Improves corrosion resistance and aesthetics |

B2B Applications for Custom Shocks

| Industry Segment | Custom Solution Benefits |

|---|---|

| Off-Road Racing Teams | Terrain-specific damping and heat resistance |

| Truck Customization Shops | Brand differentiation with tailor-fit suspension |

| OEM Vehicle Upfitters | Consistent ride quality across modified fleets |

| 4×4 Parts Distributors | Offer exclusive private label shock absorber kits |

Why Choose G·SAI for Custom Shock Absorbers?

G·SAI is China’s leading expert in custom shock absorber manufacturing, specializing in off-road and racing applications. With over 17 years of R&D expertise, G·SAI offers:

- One-on-one technical consultation

- Custom valving and tuning based on load, terrain, and use case

- CNC-machined components for precision fitment

- In-house simulation labs and real-world testing facilities

- Low MOQ for private label or branded shock absorber production

🛠️ Learn about our customization capabilities and factory technology on the G·SAI Company Overview Page.

8. Top 5 Shock Absorber Manufacturers for OEM & Wholesale in 2025

As the demand for performance and off-road vehicles grows globally, the need for reliable shock absorber manufacturers continues to rise. Whether you’re a B2B buyer, distributor, or brand looking to private label shock absorbers, partnering with a top-tier manufacturer ensures product quality, performance, and scalability.

Here are the top 5 shock absorber manufacturers to consider in 2025:

1. G·SAI (China) – Best for Custom Racing and Off-Road Shocks

- Specialty: High-performance, custom shock absorbers for RVs, off-road, and racing

- Why Choose G·SAI:

- Custom valving and terrain-specific tuning

- In-house CNC machining, testing labs, and simulation rooms

- 1:1 after-sales technical support

- Ideal for private label and wholesale partnerships

- Markets Served: US, Europe, Australia, Southeast Asia

🔗 Explore G·SAI’s full shock absorber lineup here

2. Bilstein (Germany) – Premium OEM and Performance Shocks

- Specialty: Monotube gas pressure shocks, OEM partnerships

- Strengths:

- Strong presence in motorsport and luxury vehicle sectors

- Advanced damping technologies

- B2B Channels: OEM supply, aftermarket distributors

3. Fox Racing Shox (USA) – High-End Off-Road and Motorsport Solutions

- Specialty: Remote reservoir and adjustable shocks

- Strengths:

- Proven performance in desert racing and Baja events

- Wide adjustability and rebuildable design

- Target Buyers: Racing teams, 4×4 accessory brands

4. KYB (Japan) – Mass OEM and Aftermarket Supplier

- Specialty: OE replacement shocks and struts for global vehicle models

- Strengths:

- High-volume manufacturing

- Global distribution network

- Ideal For: Retail chains and volume-based distributors

5. King Shocks (USA) – Custom Off-Road and Racing Shocks

- Specialty: High-end off-road and competition shocks

- Strengths:

- Fully rebuildable and tunable shocks

- Used in trophy trucks and professional racing

- Target Market: High-budget racing teams and off-road performance shops

Selecting the Right Manufacturer: B2B Considerations

| Factor | What to Look For |

|---|---|

| Customization | Ability to tune damping curves and mount types |

| Production Capacity | Can scale with your brand or fleet needs |

| Certifications | ISO, IATF, and off-road racing endorsements |

| Technical Support | Engineering consultation and after-sales support |

| MOQ and Lead Time | Flexible minimums and fast delivery cycles |

📦 Ready to collaborate with a custom shock absorber leader? Start your B2B partnership with G·SAI on our Contact Page.

9. Frequently Asked Questions (FAQ)

❓ Why does my truck bounce multiple times after a bump?

This is usually a sign of worn shock absorbers. When shocks lose their damping ability, the suspension continues to oscillate after hitting a bump.

❓ How often should I replace my truck’s shock absorbers?

For stock vehicles: every 50,000–80,000 km. For off-road or racing use: inspect after every major event or 10,000 km, depending on terrain.

❓ Can I use standard shocks on a lifted truck?

No. Lifted trucks require longer, higher-capacity shocks that match the increased suspension travel. Using stock shocks can cause topping out and bounce.

❓ What’s the difference between adjustable and non-adjustable shocks?

- Adjustable shocks allow you to fine-tune rebound and compression for different terrains or loads.

- Non-adjustable shocks offer fixed damping and are typically more cost-effective for everyday use.

❓ Does G·SAI offer private label shock absorber manufacturing?

Yes. G·SAI offers custom branding, packaging, and tuning services for distributors and automotive brands. MOQ is flexible, and technical support is included.

❓ Where can I buy G·SAI shock absorbers in bulk?

You can explore our authorized distributor locations on the G·SAI Dealer Network or contact us directly for wholesale inquiries.

❓ What types of shocks does G·SAI manufacture?

G·SAI manufactures:

- Monotube shocks

- Remote reservoir shocks

- Adjustable racing shocks

- Custom off-road shock absorbers

- RV and heavy-duty truck dampers

📢 Final Thoughts

A bouncing truck isn’t just uncomfortable—it’s a sign that your suspension system is failing, which can lead to unsafe handling, increased wear, and reduced off-road performance. Whether you’re a racing team, modification garage, or B2B auto parts supplier, investing in high-quality, terrain-specific shock absorbers is essential.

G·SAI is redefining the shock absorber industry with precision-engineered, customizable solutions for extreme off-road, racing, and heavy-duty applications. With over 17 years of R&D experience, G·SAI delivers unmatched performance and reliability.

📞 Ready to upgrade your suspension inventory or develop your own brand of shocks? Visit our Contact Page to speak with a technical advisor or request B2B pricing.