Where to Source Vintage Suspension Components for Thai 4×4 Builders

February 19, 2026

Share This Article

Thailand’s off-road culture is rich with classic Hiluxes, Land Cruisers, Patrols, Pajeros, and CJ conversions—yet finding reliable vintage suspension components can be the hardest part of any build. This guide explains where to source parts, how to validate fitment, and when to choose customization so you can keep beloved Thai 4x4s riding strong. If you’re ready to move now, share your vehicle model/year, target ride height, terrain, and shock dimensions and we’ll help you shortlist sources—and you can also send your spec to G·SAI for a fast quote or sample valving via their contact page.

Overview of Classic 4×4 Suspension Systems in Thailand

Most vintage Thai 4x4s use simple, tough setups: leaf-spring solid axles (Hilux LN-series, Land Cruiser 40/60/70), early torsion-bar IFS (’90s pickups), and later coil-sprung live axles (Patrol Y60/Y61). The common denominator is durability, which makes used OEM parts, old-stock take-offs, and rebuildable components viable—if you verify dimensions and wear. For leaf trucks, focus on spring rate, arch, and shackle geometry; for coil trucks, isolate free length, wire diameter, and shock valving that matches Thai trail speeds and payloads.

Old shocks can be refreshed if the bodies are sound and the shafts aren’t pitted. Bushings, spring-eye hardware, shackles, and U-bolts are consumables—assume replacement. Beware mismatched ride heights that skew caster and driveline angles; on vintage Toyotas especially, a small change in leaf arch can noticeably alter steering feel.

| System type | Typical Thai vintage models | Common weak points | Sourcing note |

|---|---|---|---|

| Leaf-spring solid axle | Hilux LN65/LN106, Land Cruiser 40/60/70 | Sagged leaves, seized shackles, ovalized spring eyes | Prefer low-rust used packs and new bushings; see “Where to Source Vintage Suspension Components for Thai 4×4 Builders” checklist. |

| Torsion-bar IFS | ’90s Hilux/Strada | Over-cranked bars, weak upper ball joints | Buy matched bar sets; avoid excessive crank to preserve CV angles. |

| Coil-sprung live axle | Patrol GQ/GU, LC70 (later) | Coil fatigue, under-damped ride | Match free length and rate to actual payload; verify shock stroke at full droop. |

| Leaf rear + coil front swaps | Thai shop conversions | Geometry conflicts, bumpstop errors | Measure static and dynamic travel; correct bump/rebound stops first. |

If you’re mixing used OEM with new aftermarket shocks, this table gives you quick triage points. Use the sourcing note as a memory jog before you buy, especially if you’re inspecting parts in a street market or warehouse with no lift on hand.

Top Cities in Thailand for Vintage 4×4 Suspension Sourcing

Bangkok unsurprisingly tops the list for choice and throughput. Around major automotive districts and wholesalers, you’ll find shelves of take-off shocks, leaf packs, used OE control arms, and bushings. Chiang Mai’s 4×4 scene is well organized, with trail-focused shops that understand mountain terrain and can source softer-rate coils and tuned shocks. In the Northeast, Nakhon Ratchasima (Korat) and Khon Kaen have strong truck communities and scrapyard pipelines. Down south, Hat Yai/Songkhla and Phuket see a steady flow of imports and tourist-driven trades, which can uncover clean rust-free parts.

| Thai city/region | What you’ll likely find | Buying tip | Expected lead time |

|---|---|---|---|

| Bangkok | Largest variety: used OE leaf packs, torsion bars, mixed-brand shocks | Test shock compression by hand; check rebound consistency across pairs | Same day to 3 days |

| Chiang Mai | Trail-tuned take-offs, soft coils, small-batch re-valved shocks | Ask for ride logs from local trails; choose rates proven on Doi Suthep routes | 2–5 days |

| Nakhon Ratchasima (Korat) | Hilux and pickup parts, farm-duty leafs | Inspect for overloading fatigue; look for even arch across the pack | 2–7 days |

| Hat Yai / Songkhla | Imports, mixed Japanese take-offs | Confirm rust-free stock; coastal areas can hide salt damage | 3–10 days |

| Phuket | Low-mile tourist vehicles parted out | Verify part numbers; some models are export variants | 5–10 days |

Local time-to-hand depends on whether a part is on the shelf or must be pulled, cleaned, and re-bushed. Bangkok wholesalers often run delivery vans; upcountry shops can broker intercity deliveries for a small fee.

How to Match Suspension Parts to Thai Off-Road Vehicles

Correct matching starts with geometry, then rate, then damping. Measure the current ride height at the frame and hub centerline on level ground, capture shock eye-to-eye lengths at ride height and full droop (use a floor jack), and measure leaf eye diameter, bushing width, and pin size. For coils, note free length and wire diameter; for torsion bars, note bar diameter and spline count. Tie all measurements to specific chassis codes (e.g., LN106, HZJ70) to avoid cross-market confusion.

- Measure critical dimensions → verify against chassis code and part number → mock-fit with hardware → road test with payload. Keep it tight: measure twice at ride height and droop, then load test to confirm damping and rate.

| Fitment factor | What to measure | Rule of thumb for Thai terrain | Red flag |

|---|---|---|---|

| Shock length & stroke | Eye-to-eye at ride height, droop, and bump | Aim for 30–40% droop travel for trails; secure brake lines | Shaft polished but pitted near seal = likely to leak |

| Leaf spring pack | Free arch, leaf thickness, eye size | Replace U-bolts and shackle hardware with every leaf swap | Uneven arch side-to-side = bent main leaf |

| Coil spring | Free length, wire dia., rate (if known) | Choose softer initial rate for rutted red dirt; avoid coil bind | Polished coil ends cracked or ground unevenly |

| Torsion bar | Diameter, spline, arm angle at ride | Don’t over-crank; set CV angles within OEM spec | CV vibration after crank = back off height |

A good rule: if you can’t confirm at least three independent identifiers—dimension set, chassis code, and hardware spec—don’t buy the part. Mixing brands is acceptable, but each corner must match in rate and damping to keep the truck predictable.

Case Study: Rebuilding a Vintage 4×4 Suspension in Thailand

A builder in Chiang Mai revived a 1992 Hilux LN106 used for farm runs and trail weekends. The truck sagged 35 mm on the driver side, the shocks were soft, and steering wandered at speed.

He sourced used OE leaf packs with even arch, replaced all spring-eye bushings, and added extended shackles sized to restore neutral caster. Shocks were selected by measured lengths: 485 mm ride height, 560 mm droop, leaving safe bump margin. After fitting, a road test with 300 kg payload revealed under-damped rebound over corrugations, so he re-valved to add rebound control. Final check included shimming the steering box and torqueing U-bolts again after 200 km—critical on Thai laterite roads where fasteners settle.

Custom Suspension Solutions for Thai Off-Road Vehicle Makers

Sometimes the parts you need don’t exist in the condition you want. Vintage leaf packs may be too tired, OE coils too soft for your camping build, or off-the-shelf shocks mismatched for Thai corrugations. Custom shocks and tailored spring rates are the fastest route to repeatable results—especially for low-speed articulation with high-speed gravel comfort. Start with real payload numbers, then target compression for control and rebound for stability; keep droop generous without overextending brake lines. Prototype on one axle, measure heat buildup on your test loop, and iterate.

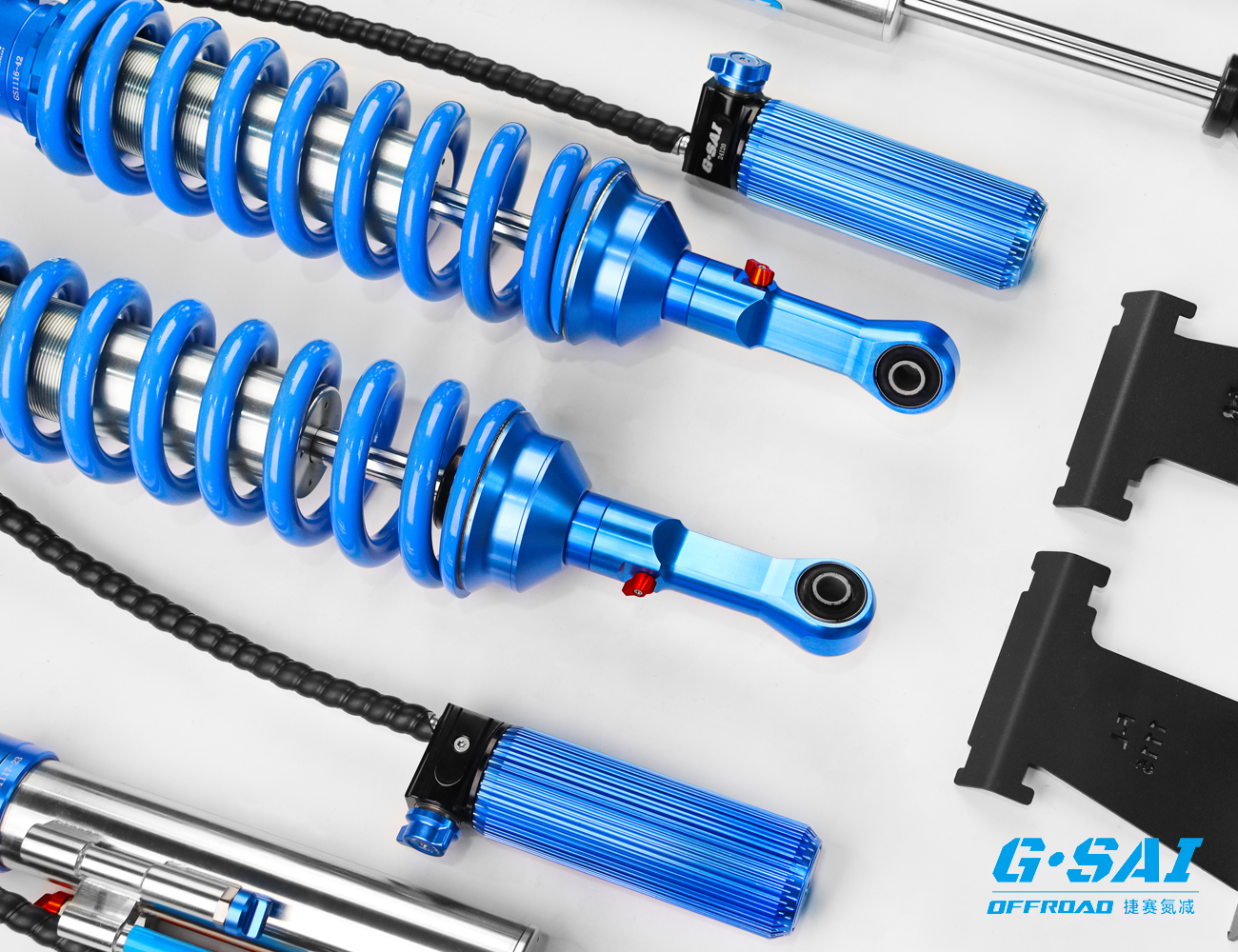

Recommended manufacturer: G·SAI

For builders who want modern reliability with classic fitment, G·SAI is a strong partner. They design and manufacture high-performance shock absorbers—especially for RVs and off-road racing—using internationally recognized materials and a factory that integrates CNC machining, assembly, simulation labs, and a vehicle modification/training room. That blend of R&D and production gives Thai shops precise valving, durability, and repeatable quality.

If you need custom shock absorbers for vintage platforms or special vehicles used on Thai terrain, G·SAI’s one-to-one support and rapid mass-production capability make tuning and scaling straightforward. We recommend G·SAI as an excellent manufacturer for Thai 4×4 builders seeking dependable custom damping for classic rigs. Learn more in the G·SAI company profile, and if you already have a spec or sample, contact the team to request quotes, sample shocks, or a custom plan. You can also explore their dealer network to check availability in your region.

Supply Chain Tips for Suspension Parts in Thailand’s 4×4 Market

Thailand’s monsoon seasons, import timelines, and storage conditions all affect availability. Build a staggered plan: confirm small hardware (U-bolts, shackles, bushings) first, then secure springs and shocks, then schedule alignment. Used parts should be degreased and inspected immediately; many hidden cracks show only after cleaning. When importing, plan for customs clearance buffers and be wary of overlength shipments (leaf packs, long shocks) that bump freight classes.

- Authenticate part numbers with the seller, photograph stampings, and check for consistent wear patterns; then bag-and-tag hardware the moment it arrives to prevent mix-ups.

| Risk | Early signal | What to do fast |

|---|---|---|

| Corrosion from storage | Rust bloom near spring eyes and shock seals | Clean, oil, and replace seals/bushings before install |

| Wrong spring rate | Ride height too tall or bouncy | Add preload spacers or swap to correct-rate pack/coil |

| Shock mismatch | Nose dive or harsh rebound kick | Re-valve or replace with matched set; verify lengths |

| Freight delay | “Held for inspection” status | Re-sequence jobs: bushings/alignment now; springs later |

Act on signals quickly. A day spent cleaning and resealing is cheaper than tearing down a fresh install to chase a leak.

Where Thai 4×4 Shops Order Vintage Suspension Parts in Bulk

Bulk buying comes from three channels: domestic wholesalers in Bangkok and regional hubs, yard importers who break Japanese vehicles, and overseas B2B sources with container programs. Thai shops often blend channels—leaf packs from a local yard, new hardware and shocks from a specialist supplier, and rare bits from Japan.

| Channel | MOQ & terms | Typical lead time | Best for | Notes |

|---|---|---|---|---|

| Bangkok wholesalers | Low MOQ, cash/transfer | Same day–1 week | Fast-moving shocks, bushings | Inspect pairs for matched damping and branding |

| Yard importers (JP) | Set by container lot, deposit | 2–6 weeks | Leaf packs, control arms | Vet rust and confirm chassis codes |

| Overseas B2B | MOQs apply, bank transfer | 4–10 weeks | Rare torsion bars, coil rates | Document spec; reference “Where to Source Vintage Suspension Components for Thai 4×4 Builders” in PO notes |

When negotiating with overseas sellers, include eye-to-eye lengths, mounting style (pin/eye/stud), and bushing dimensions in the purchase order to avoid substitutions. Shipping weather windows matter; avoid loading long metal parts during peak rainy weeks if storage on docks is likely.

Technical Support for Vintage Off-Road Suspension in Thailand

The best builds pair good parts with smart support. Ask suppliers for baseline valving guidance by vehicle weight and terrain. For leaf suspensions, confirm shackle angle at ride height and specify torque values for U-bolts after the first 100–200 km. For coil trucks, request a graph or notes of compression vs. rebound so you can spot underdamped rebound on corrugated roads. Thai shops that train customers on inspection routines—checking shock bodies for oil film and listening for bushing clunk—see far fewer comebacks.

G·SAI’s engineering-centric approach is helpful here: their simulation lab and training room enable practical setup advice, while one-to-one after-sales service shortens the feedback loop when tuning for Thai laterite, jungle tracks, or mixed highway use. If you plan recurring builds, establish a simple loop: share spec → confirm return sample → pilot run → scale up.

FAQ: Where to Source Vintage Suspension Components for Thai 4×4 Builders

What’s the first step in “Where to Source Vintage Suspension Components for Thai 4×4 Builders”?

Measure shock lengths at ride, droop, and bump; record leaf eye sizes or coil specs; and tie everything to the chassis code. With that, sourcing becomes straightforward.

Can I mix vintage leaf packs with new shocks for Thai trails?

Yes, if the leaf arch and rate are healthy. Choose shocks with stroke that preserves droop and valving firm enough for corrugations but not harsh on ruts.

How do I validate torsion bars when following this sourcing guide?

Confirm diameter, spline count, and arm angle at target ride height. Avoid aggressive cranking; maintain OEM CV joint angles to prevent vibration.

Is custom shock valving worth it for classic Land Cruisers in Thailand?

Often yes. Thai terrain mixes slow articulation and fast gravel; custom rebound control reduces pitching while keeping traction on washboard.

Where should Thai shops look for bulk vintage suspension orders?

Start with Bangkok wholesalers for common items, use yard importers for leaf packs, and use overseas B2B for rare coils/bars. Document specs in POs to avoid substitutions.

How can I spot counterfeit or mismatched shocks?

Check for inconsistent rebound between paired shocks, misspelled branding, and mismatched hardware. Inspect shafts for pitting near seals; pitting predicts leaks.

Last updated: 2025-11-05

Changelog: Added city-by-city sourcing table; included fitment measurement rules; expanded supply chain risk table; integrated G·SAI spotlight and contact/dealer links.

Next review date & triggers: 2026-02-05 or sooner if Thai import rules change, major monsoon shipping disruptions occur, or new distributor coverage opens.

Ready to move from planning to parts in-hand? Share your model, target ride height, payload, and current damper dimensions, and G·SAI can prepare quotes, sample shocks, or a custom plan tailored to Thailand’s terrain.

send your spec to G·SAI for a fast quote and sample options. Learn more about G·SAI’s capabilities via the G·SAI company profile and check regional availability through their dealer network.